Occupational Environment Monitoring at the 3D Printing Plant

99,000 ₫

Note: The above price is calculated for one sample, and the price may vary depending on the area of the environment to be monitored and market fluctuations. For more accurate pricing support, please refer to the quotation table or contact our consulting staff directly.

Occupational environment monitoring at a 3D printing plant is a process of collecting, analyzing, and evaluating workplace factors that may harm workers’ health.

Table of Contents

Toggle1. Overview of the 3D printing factory

a. What is a 3D printing factory?

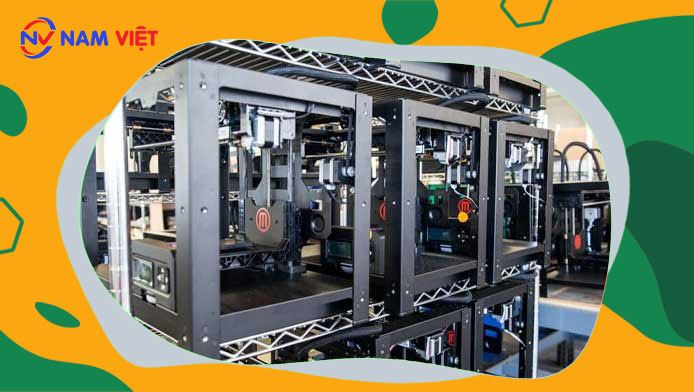

Factory 3D printing is a manufacturing facility where the 3D printing process takes place, also known as additive manufacturing or layered printing. This is the process of creating three-dimensional objects by stacking multiple layers of material sequentially according to a digital model. A 3D printer will read information from the digital model and create the object by printing successive thin layers until completed.

In a 3D printing factory, 3D printers are used to carry out the printing process. There are many different types of 3D printers, including 3D printers based on binding principle, sintering principle, material jetting principle, and various other 3D printing technologies. 3D printers can use materials such as plastic, metal, wood, carbon fiber, glass, and many other materials to create products according to customer requirements and designs.

b. The stages of operating a 3D printer

The stages of operating a 3D printer usually include the following steps:

- Preparing a digital model: Before starting to print, a digital model of the desired object is required. This model can be created using CAD (Computer-Aided Design) software or downloaded from available model sources.

- Preparing the print file: The digital model will be converted into a standard print file format such as STL (Standard Tessellation Language) or OBJ (Object File Format). This print file contains information about the shape and dimensions of the object.

- Preparing the printer: Before starting to print, the 3D printer needs to be prepared. This includes checking the material feed level, ensuring the print surface is clean, checking mechanical and electronic components, and preparing the working surface.

- Setting up the printer: Setting printing parameters such as resolution, print speed, bed temperature, and material temperature. This depends on the type of 3D printer and material used.

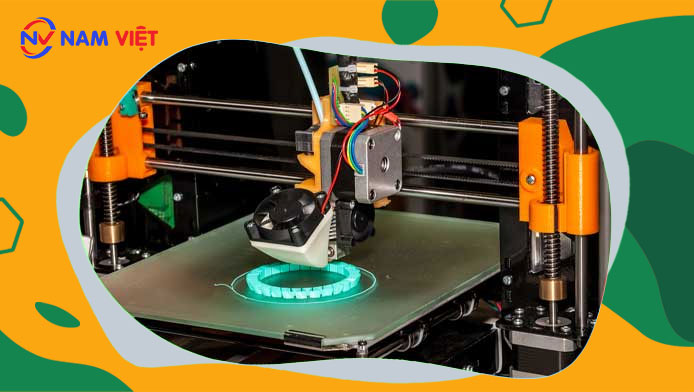

- Starting the print: After setting up the parameters, start the printing process. The printer will accept the print file and begin creating the first layer of the object by stacking subsequent layers of material.

- Monitoring and controlling the printing process: During printing, the operator needs to monitor the process to ensure no issues occur and the print quality is maintained. This may include monitoring temperature, print speed, accuracy, and inspecting the object after each layer is completed.

- Completing and finishing the object: After printing is finished, the object needs to be removed from the 3D printer and finished. The finishing process may include cleaning, smoothing surfaces, painting, or additional treatments to achieve the desired final result.

c. What occupational diseases may occur to workers in a 3D printing factory?

Workers in 3D printing factories may face the following occupational diseases:

- Respiratory diseases: 3D printing activities may generate small particles from printing materials, such as dust and fumes released into the air. When inhaled, these small particles may cause respiratory issues such as bronchitis, asthma, pneumonia, and other problems.

- Skin allergies: Contact with printing materials and cleaning agents may cause skin allergies such as dermatitis, itching, rashes, and other skin irritations.

- Chemical poisoning diseases: 3D printing materials and chemicals used in the printing process may contain toxic compounds such as heavy metals, volatile organic compounds, and other additives. Long-term exposure to these substances may cause health issues such as hepatitis, kidney damage, nerve damage, and other problems.

- Eye diseases: Small particles and fumes from the printing process may irritate and damage the eyes, causing infections, dry eyes, and other eye issues.

- Heat-related diseases: In some cases, 3D printers may require heating or cooling processes to create and process materials. Workers may have to work in hot environments, leading to issues such as heat stress, heat stroke, and discomfort while working in such conditions.

To reduce the risk of these occupational diseases, 3D printing factories need to implement safety and health protection measures, including providing personal protective equipment, improving ventilation and dust extraction systems, providing occupational safety training, and ensuring compliance with occupational safety regulations.

d. Common types of 3D printed products on the market

3D printing technology has developed diversely and allows the creation of many different products. Below are some common 3D printed products on the market:

- Prototypes and models: 3D printing technology allows the creation of accurate prototypes and 3D models, helping industries such as product design, architecture, healthcare, and automotive quickly test and evaluate designs before mass production.

- Jewelry and accessories: 3D printing provides the ability to create unique, personalized, and customized jewelry and accessories. Examples include rings, necklaces, bracelets, and earrings.

- Machine parts and tools: 3D printing enables the production of highly precise and complex machine parts and tools, helping to reduce production time and costs.

- Medical products: 3D printing is used to create customized medical products such as replacement parts, direct implants, and surgical simulation models. Examples include dental products, prosthetic frames, and organ simulators.

- Interior decorations: 3D printing can produce interior decoration products such as lamps, holders, trays, and unique artworks.

- Toys and games: 3D printing allows the creation of customized and unique toys and games. Examples include models, remote-controlled cars, and board games.

2. Overview of occupational environment monitoring services

a. What is occupational environment monitoring at 3D printing factories?

Occupational environment monitoring (or workplace environmental measurement) at 3D printing factories is the activity of collecting, evaluating, and analyzing measured indicators of workplace environmental factors at 3D printing factories, in order to implement timely measures to minimize environmental impacts on workers’ health and prevent occupational diseases. Occupational environment monitoring is a mandatory requirement for 3D printing factories.

Occupational environment monitoring plays the most important role in caring for, protecting, and improving workers’ health because the main resource of enterprises and the direct contributors to profits are the workers. Workers frequently exposed to hazardous factors exceeding permissible standards will suffer health effects and occupational diseases.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICE

b. Occupational environment monitoring program of Nam Viet

The occupational environment monitoring program of Nam Viet is a program researched by monitoring engineers in the field of occupational safety and environmental protection. With the goal of ensuring health and safety for workers, this program uses modern measurement methods to monitor air quality, water, and microclimate, physical, dust, and other workplace environmental factors. This is a very important program in ensuring a safe working environment and protecting workers’ health.

In addition, the occupational environment monitoring program of Nam Viet also plays an important role in researching and developing new solutions to improve workplace environmental quality. With the dedication and professionalism of the monitoring expert team, Nam Viet’s exclusive monitoring program is becoming a breakthrough in occupational safety management and environmental protection in Vietnam.

c. Standardization in workplace environmental measurement procedures

Standardization in workplace environmental measurement procedures of Nam Viet is a very important aspect in ensuring the quality of measurement results. To ensure the accuracy and reliability of the measurement results, this program uses recognized standards and standardized procedures of the Ho Chi Minh City Department of Health. This ensures that the collected data will be used with high reliability in workplace environmental assessment and in making decisions to improve the workplace environment to protect workers’ health.

These standardized procedures also ensure that measurement results are performed by a highly qualified and experienced monitoring specialist team, allowing managers and experts to trust the results from An Toan Nam Viet and make accurate and valuable decisions in protecting workers’ health and the environment.

By applying standardization in workplace environmental measurement procedures, Nam Viet demonstrates its commitment to ensuring a safe working environment and protecting workers’ health, while also contributing positively to the development and enhancement of occupational safety management and environmental protection quality in Vietnam.

d. Monitoring report results of 3D printing factories

Occupational environment monitoring results are prepared according to form No. 04 Appendix III issued together with Decree 44/2016/ND-CP and prepared in 02 copies: 01 copy sent to the workplace contracting to carry out occupational environment monitoring and 01 copy kept at the monitoring organization.

The storage time of occupational environment monitoring results is regulated by law as indefinite record retention.

e. Frequency of occupational environment monitoring according to legal regulations

According to Clause 2 of Article 18 of the Law on Occupational Safety and Hygiene 84/2015/QH13, employers must conduct occupational environment monitoring to assess harmful factors at least once a year.

f. Deadline for submitting occupational environment monitoring reports according to legal regulations

The deadline for submission is before December 31 every year. Enterprises belonging to production facilities are required to submit occupational environment monitoring reports to the Department of Health at the locality where the headquarters and employees are working.

When there are changes in technology processes, production processes, or when renovating or upgrading workplaces that may generate new harmful factors affecting workers’ health, enterprises at production facilities must update occupational hygiene records related to harmful factors requiring occupational environment monitoring.

g. Penalties for violations of occupational environment monitoring by employers

According to Article 27 of Decree No. 12/2022/ND-CP dated January 17, 2022 on administrative penalties in the field of labor, social insurance, and Vietnamese workers working abroad under contracts:

- Clause 2: A fine of 2,000,000 – 5,000,000 VND for employers who fail to publicly announce to workers at the occupational environment monitoring site and the site inspected, evaluated, and managed for hazardous factors immediately after obtaining the monitoring results and inspection results.

- Clause 3: A fine of 20,000,000 – 40,000,000 VND for employers who fail to conduct occupational environment monitoring to control harmful effects on workers’ health as required by law.

- Clause 4: A fine of 40,000,000 – 60,000,000 VND for employers who collude with monitoring organizations to commit fraud in occupational environment monitoring activities but not to the extent of criminal prosecution.

3. Harmful environmental factors for workers working in a 3D printing factory

Workers working in a 3D printing factory may be exposed to several harmful environmental factors. Below are some environmental factors that may be harmful in the working environment of a 3D printing factory:

- Dust and fine particles: The 3D printing process can generate dust and fine particles from 3D printing materials, especially when using materials such as plastic, fiberglass, or metal. Long-term exposure to dust and fine particles may cause respiratory irritation and other health issues.

- Chemical emissions: Some 3D printing processes use materials and compounds that can generate chemical emissions. This can be dangerous if not properly treated or in the case of prolonged exposure. The emissions may include volatile organic compounds (VOCs), metal fumes, and additives.

- Temperature and humidity: 3D printing processes can generate high temperature and humidity, especially in factories operating continuously. Improper temperature and humidity may cause discomfort and affect work performance.

- Noise: Some 3D printers may generate significant noise during operation. Long-term exposure to noise may cause hearing problems and affect overall health.

- Electrical safety: 3D printers operate by using electricity and electronic components. If not properly used or maintained, there may be risks of fire, explosion, or harm to workers.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICE

4. Measures to improve the working environment in a 3D printing factory

The following measures can be applied:

- Safety management system: Establish and comply with regulations on safety and occupational health protection, including identifying and ensuring compliance with procedures, regulations, and safety guidelines during factory operations.

- Vacuum and air filtration system: Use a vacuum system and air filtration system to remove dust and fine particles during the 3D printing process. Ensure the filtration system is maintained and replaced periodically to ensure air filtration efficiency.

- Use safe materials: Select safe 3D printing materials that produce less harmful emissions and fine dust. Use materials with safety certifications and ensure compliance with the manufacturer’s safety instructions.

- Adjust temperature and humidity: Ensure proper adjustment of temperature and humidity in the working space to create comfortable working conditions and reduce the risk of fatigue and dehydration.

- Ventilation system: Ensure effective ventilation in the working space to clean the air and remove potential chemical emissions.

- Training and guidance: Provide training on safety and use of 3D printing machines for workers. Ensure they clearly understand risks and personal protective measures, as well as safety procedures when working with machinery.

- Inspection and maintenance of equipment: Conduct periodic inspections and maintenance of 3D printing machines to ensure safe and efficient operation. Repair and replace damaged or defective components immediately.

- Periodically organize occupational environment monitoring in factories and enterprises, collect and analyze harmful factors for workers, thereby adjusting and reducing the level of danger to prevent occupational diseases for them.

5. Benefits of periodic monitoring of a 3D printing factory

An Toan Nam Viet provides businesses with great benefits when using occupational environment monitoring services in accordance with Decree 44/2016/ND-CP on the management and control of harmful factors in the working environment affecting workers.

- Businesses can proactively control harmful factors at workshops or factories.

- Receive consultation and recommendations for measures to minimize harmful factors, improving the quality of the working environment.

- Indirectly protect human resources, the main factor in the development process of the business.

- Minimize the harmful effects of occupational diseases on human health, thereby reducing future medical treatment costs.

- The health of workers is improved, leading to guaranteed and maintained product quality as well as output.

- Comply with legal regulations on occupational safety, avoiding legal risks.

- Create reputation and professionalism in all aspects, thereby enhancing the brand of the business.

The occupational environment monitoring service of Nam Viet is the solution to minimize the harmful effects of occupational diseases, contributing to creating a healthy and high-quality working environment.

6. National occupational environment monitoring center

Occupational environment monitoring center of Nam Viet is a professional unit in monitoring and measuring the quality of the occupational environment across all provinces and cities in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

In addition to providing monitoring services, the center also supports customers in planning, handling, and monitoring occupational environment issues. With the motto “customers are the center”, the center cares about customer satisfaction, meets all customer needs, and is committed to providing the best solutions for businesses.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICE

With investment in technology, equipment, and human resources, the monitoring center of Nam Viet has been and is becoming one of the prestigious units in the field of occupational environment monitoring in Ho Chi Minh City with the following objectives:

- We always value brand reputation and the quality of our service products.

- We provide customers with the best possible and most suitable solutions.

- Together with a team of experienced and professional Masters and Engineers with the desire to protect the environment and bring benefits to businesses.

- Coming to the Occupational Environment Monitoring team of Nam Viet, companies will receive professional services from experts in the field of monitoring. At the same time, they will receive the best possible cost benefits.

The process of conducting occupational environment monitoring at Nam Viet includes the following basic steps:

- Before conducting occupational environment monitoring, our company always ensures that machinery and equipment used for occupational environment monitoring are adjusted and calibrated in accordance with legal regulations.

- Strictly and fully implement the occupational environment monitoring process committed to the Department of Health.

- Truthfully notify occupational environment monitoring results to employers.

- In case the occupational environment monitoring results do not ensure safety for workers, Nam Viet company will support in providing remedial solutions and the labor facility will implement as follows:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health examinations to detect early occupational diseases and work-related illnesses for workers in unsafe occupational environments.

- Provide material benefits for workers in accordance with labor law regulations.

7. Quotation for occupational environment monitoring

To help businesses carry out occupational environment monitoring professionally and effectively, Nam Viet provides customers with a quotation table for occupational environment monitoring services with quality and reasonable costs.

- Our monitoring quotation table provides detailed information about the prices of monitoring services that we are providing. This includes costs related to transportation, measurement, analysis, and reporting results. Customers can be completely assured of the accuracy and reliability of the monitoring reports that we provide.

- We commit to always offering the most competitive and reasonable prices in the market, and at the same time, we are always ready to provide consultation and quickly answer all inquiries about monitoring services in the most professional way.

- With the monitoring quotation table of Nam Viet, customers can easily choose service packages that suit their needs. We commit to bringing customers the highest satisfaction with professional service quality.

1 review for Occupational Environment Monitoring at the 3D Printing Plant

No comments yet

maituyet.cuong12

Professional labor environment monitoring unit