Personal Protective Equipment (PPE)

Overview, Regulations, and Importance of Occupational Safety Equipment

Occupational safety is a crucial and indispensable aspect of the work environment. This article will help you better understand its regulations and importance for health and safety in the workplace.

I. Explanation of the basic concept and meaning of occupational safety

Occupational safety is an important concept in the field of workplace safety and human resource management. It represents a collection of measures and regulations applied to ensure safety, occupational hygiene, and worker health in the work environment. Occupational safety refers not only to equipping workers with personal protective equipment, but also to identifying and eliminating risks that cause injury or death during the work process.

The essence of occupational safety is to ensure that workers are protected from hazardous elements in the work environment. It includes risk assessment and management, designing safe work processes, providing training on occupational safety, supplying appropriate personal protective equipment, and monitoring worker health. Occupational safety plays a significant role in maintaining labor productivity, reducing losses from workplace accidents and occupational diseases, and enhancing the quality of life for workers.

The main goal of occupational safety is to ensure a safe work environment, protect worker health, and minimize the risk of workplace accidents. This benefits both the workers and the business, as it helps reduce time off due to accidents or illness, increases work efficiency, and improves the company’s image. In summary, occupational safety is an important part of managing the work environment and contributes to the sustainable development of businesses and society.

II. Mentioning regulations and laws related to occupational safety

Regulations and laws on occupational safety play an important role in ensuring occupational protection. They provide the legal framework and specific guidance on how to organize and implement measures to protect workers.

- Labor Law: The Labor Law is the most important document regarding labor management and occupational safety in many countries. It stipulates the rights and obligations of employees and employers, including rules on occupational safety.

- Law on Occupational Safety and Hygiene: An important part of the labor law system, the Law on Occupational Safety and Hygiene focuses on ensuring that employers provide a safe work environment and meet standards for occupational hygiene.

- Decrees and Decisions: In addition to basic laws, many countries also have specific decrees and decisions on occupational safety. These documents provide detailed guidance on implementing occupational safety in specific industries.

- Technical Standards: Regulatory agencies frequently update and issue technical standards to ensure occupational safety. These standards include guidance on the use of protective equipment, safe work procedures, and other technical requirements.

- Training and Monitoring Programs: Legislation often requires employers to provide occupational safety training for employees and to regularly inspect and evaluate the work environment.

III. Presenting common risks and workplace accidents that can occur if safety is not followed

Risks and workplace accidents are closely related to compliance with protective measures and occupational safety training. If workers do not comply or lack understanding of safety rules, they may face the following risks:

- Risks from Machinery and Equipment: Using machinery and equipment without adhering to safety rules can lead to serious accidents. These risks include collisions, being pulled into machinery, or being struck by moving parts.

- Chemical Risks: In work environments where chemicals are used, accidents related to this issue can be harmful to health. Exposure to toxic chemicals or non-compliance with rules on storage and use can cause accidents or poor health.

- Risks at Construction Sites: In the construction industry and working at sites, risks related to working at heights, using lifting equipment, and moving heavy objects can cause accidents if rules are not followed and safety measures are not fully implemented.

- Electrical Risks: Work involving electricity, such as performing repairs or maintenance on electrical systems, carries a risk of electric shock if safety rules are not followed and appropriate protective gear is not used.

- Risks During Commuting: Workers can have accidents when the path to work is unsafe, or when not following traffic rules while commuting from home to the workplace.

IV. Assessing types of protective equipment and tools commonly used to ensure safety

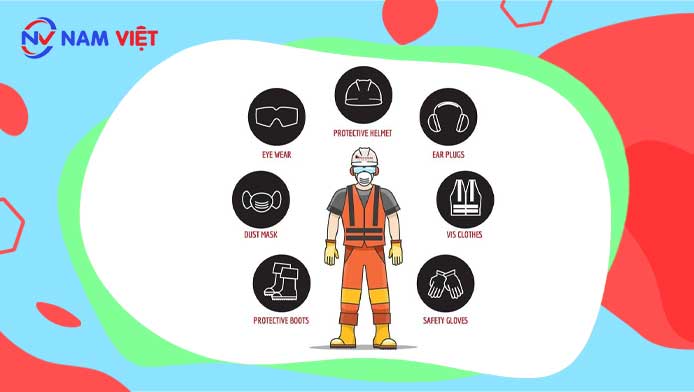

Occupational protection is an important part of the Occupational Safety Certificate and plays a vital role in ensuring the safety and health of workers. There are many types of protective equipment and tools commonly used to minimize the risk of workplace accidents.

-

- Safety Helmets: Safety helmets are designed to protect the head from risks such as impacts, injuries, and collisions. They are commonly used in the construction and industrial sectors.

- Protective Clothing: Protective clothing often includes fire-resistant jackets or vests, raincoats, insulated jackets, and waterproof coats. They are designed to protect the skin and body from risks of exposure to liquids, toxic substances, or extreme temperatures.

- Safety Goggles: Safety goggles protect the eyes from dirt, chemicals, ultraviolet rays, and other hazards. They are commonly used in manufacturing and by welders.

- Protective Gloves: Protective gloves ensure safety for hands and fingers when working with rough materials, sharp edges, chemicals, or high or low temperatures.

- Safety Shoes: Safety shoes often have slip-resistant soles, puncture-resistant soles, and waterproof or chemical-resistant materials depending on the work environment. They protect the feet and legs from impact and injury risks.

- Shoulder Pads and Safety Belts: Pads and safety belts help reduce the load on shoulders and back when lifting heavy objects. They are commonly used in the transportation and construction industries.

V. Discussing the importance of training employees on occupational safety

Training on occupational safety is a crucial aspect of ensuring safety and health for workers in the work environment. Investing in training employees on occupational safety not only helps protect them from the risk of accidents but also brings many other benefits:

- Reduces the risk of workplace accidents: Occupational safety training helps employees recognize and understand the potential hazards in their work. They learn how to use protective equipment correctly to minimize accident risks.

- Creates a safety foundation: Training is an opportunity to create a safety foundation in the work environment. Employees learn how to respond to dangerous situations, implement safety procedures, and follow protective rules.

- Raises safety awareness: Training helps create safety awareness in the minds of employees. They will understand the importance of following safety rules and apply this knowledge to their daily work.

- Meets legal requirements: In many countries, occupational safety training is a legal requirement. Ensuring employees are trained not only helps businesses comply with the law but also reduces the risk of legal liability when accidents occur.

- Increases work efficiency and performance: Employees with knowledge of occupational safety often work more effectively and focus on the tasks they are performing. This can increase work efficiency and reduce time off due to accidents.

- Improves morale and employee satisfaction: Employees feel that the business cares about their health and safety through occupational safety training. This can improve their morale and satisfaction.

VI. The link between occupational safety, increased productivity, and employee health

Optimizing productivity and employee health is always an important goal for every business. Occupational safety plays a significant role in promoting the link between these factors.

- Reduces the risk of workplace accidents: Protecting employees from workplace accidents is a top priority. The risk of accidents can lead to time off, resulting in decreased productivity. Good protection can help save time and resources.

- Improves health conditions: Occupational safety is not only related to accidents but also to overall health. Measures such as wearing masks to prevent pneumonia or using safety shoes to support the back and legs can help reduce the risk of injuries and work-related stress.

- Increases safety awareness: Occupational safety through training and safety procedures helps create safety awareness in the minds of employees. They will follow safety rules and understand their importance.

- Creates an integrated work environment: Creating a work environment that promotes safety and health increases productivity. This includes improving equipment, efficient work processes, and ensuring everyone follows safety rules.

- Builds trust and employee satisfaction: When employees feel they are cared for and protected, they feel happy and satisfied with their job. This can lead to increased performance and commitment to better work.

In summary, occupational safety is not just about legal compliance, but also has a positive impact on employee productivity and health. Investing in occupational safety not only helps businesses minimize accident risks but also creates a positive work environment and encourages employees to develop in a safe environment and work better.

VII. Assessing current challenges and prospects in the field of occupational safety

Currently, the field of occupational safety faces a range of present and future challenges.

Current Challenges:

- New technology and changes in work: The rapid development of technology and changes in work styles can create new risks and require advanced protective measures.

- Pandemics and emergencies: The spread of diseases like COVID-19 has changed the way we work and created new challenges in protecting employee health.

- Changes in regulations and laws: Regulations and laws on occupational safety change frequently, requiring businesses to update and comply with new rules.

Future Prospects:

- Use of Artificial Intelligence (AI) and Big Data: AI and big data can be used to predict and prevent the risk of workplace accidents, providing businesses with opportunities to optimize occupational safety.

- Integration of WEARABLE and IoT technology: Using wearable devices and IoT connectivity to monitor the health and safety status of employees can help enhance occupational safety.

- Strengthening social cooperation: Businesses can collaborate with organizations and society to promote occupational safety and build a safe work environment.

VIII. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a center specializing in occupational safety training (in many different languages such as English, Chinese, Japanese, Korean….) that is reputable and high-quality in Vietnam today. With occupational safety training sessions taking place continuously at workshops, factories, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected by the Department of Safety of the Ministry of Labor – Invalids and Social Affairs and granted a certificate of eligibility for occupational safety and hygiene training activities. This further solidifies our capacity for occupational safety training.

Documents and Lectures

- Before occupational safety training materials are used in occupational safety training courses, they are reviewed and approved to ensure that the lectures are always accurate in knowledge and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet’s teaching standards, which are methods that experts in occupational safety and hygiene training have researched and refined during the teaching process to bring the highest knowledge acquisition efficiency to students.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching performance and student knowledge acquisition efficiency.

- Our training course support facilities always provide spacious classrooms that meet standards for area, lighting, training equipment, etc.

IX. Nationwide Occupational Environment Monitoring Center

The Occupational Environment Monitoring Center of Nam Viet is a professional unit for monitoring and measuring the quality of the occupational environment in all provinces in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICES

In addition to providing monitoring services, the center also supports clients in planning, handling, and monitoring occupational environment issues. With the motto “the customer is the center,” we always bring customer satisfaction, meet all customer needs, and commit to providing the best solutions for businesses.

With investment in engineering, technology, and human resources, Nam Viet’s monitoring center has and is becoming one of the reputable units in the field of occupational environment monitoring in Ho Chi Minh City with the following goals:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable things possible.

- Along with a team of experienced and specialized Masters and Engineers with a desire to protect the environment and benefit businesses.

- Coming to the Nam Viet Environmental Monitoring team, your company will receive professional service with experts in the monitoring field. At the same time, you will get the best cost incentives.

The process of implementing occupational environment monitoring at Nam Viet includes the following basic steps:

- Before performing occupational environment monitoring, our company always ensures that machinery and equipment for monitoring are adjusted and calibrated according to legal regulations.

- Implement the occupational environment monitoring process correctly and fully as committed to the Department of Health.

- Honestly report the occupational environment monitoring results to the employer.

- In case the occupational environment monitoring results are not safe for workers, Nam Viet company will support proposing remedial solutions and the labor facility will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health checks for early detection of occupational diseases and work-related diseases for workers in positions with unsafe working environments.

- Provide in-kind compensation for workers according to labor laws.