Freight

Safety sensors are used to prevent accidents during transportation

In factory production and operation environments, ensuring the safety of employees and mobile equipment is a top priority. Safety sensors used to prevent accidents when moving goods within the factory play a crucial role in minimizing risks and enhancing production efficiency.

I. The state of road safety today and opportunities for improvement

In today’s era, the state of road safety presents many challenges and opportunities for improvement. The increasing traffic density and diversity of vehicles create a complex road environment. Factors such as high speed, traffic law violations, and lack of attention from road users all contribute to the current state of road safety.

To improve this situation, it is necessary to focus on building safe transport infrastructure, while promoting compliance with traffic laws from both drivers and pedestrians. Modern technology, such as traffic information systems and autonomous vehicles, can play a significant role in reducing accident risks.

Furthermore, enhancing education and raising awareness about traffic safety within the community is key to reducing accident rates. Through this, we can seize the opportunity to build a safer traffic environment, improve everyone’s quality of life, and ensure the sustainable development of society.

II. How safety sensors work in preventing collisions

Safety sensors play a crucial role in preventing collisions and ensuring safety in many fields, especially in the industrial and transportation sectors. These sensors are often integrated into control systems to monitor the surrounding environment and detect potential hazards.

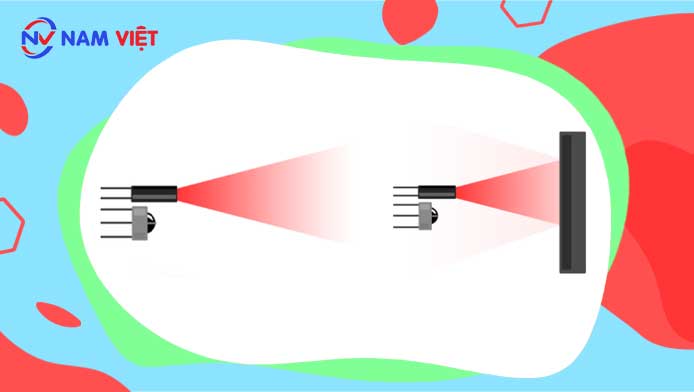

The operation of safety sensors is usually based on the principle of measuring and analyzing data from the environment. For instance, ultrasonic sensors can use ultrasonic waves to measure distance and detect objects during movement. Infrared sensors can detect temperature and motion, helping to determine the presence of people or objects within the sensor’s range.

When a sensor detects a collision risk, it can activate warning systems, reduce speed, or stop operation to avoid unwanted collisions. The combination of sensor technology and automated control systems helps enhance safety and reduce accident risks, especially in environments requiring precision and quick response.

III. New safety features integrated into cars thanks to sensors

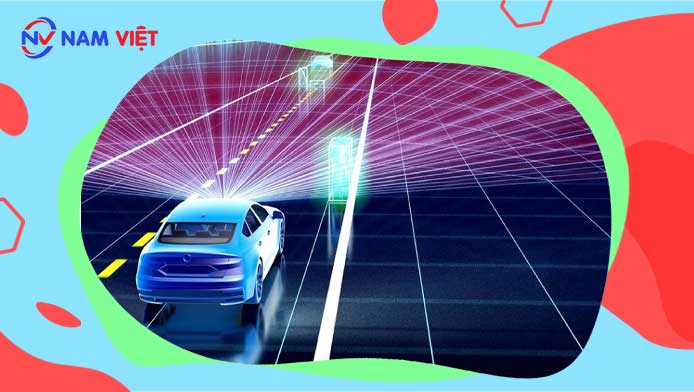

New safety features in cars are focusing on integrating sensors to enhance prevention capabilities and protect drivers and passengers. Modern sensors not only help reduce accident risks but also increase comfort while driving.

Thanks to advanced sensor technologies, cars today can detect collision risks, manage the distance between the car and surrounding vehicles, and even help drivers avoid dangerous situations. Features like collision sensors, automated steering sensors, and lane departure warning systems are all important advancements that help improve safety in traffic.

This emphasizes the importance of continuous occupational safety training for those working in the car manufacturing and assembly industry. This training not only helps them understand sensor technology but also ensures they have the necessary knowledge and skills to integrate new safety features into cars effectively and synchronously.

IV. Facing challenges and the importance of safety sensor performance

Facing the challenges and importance of safety sensor performance, ensuring that sensors operate effectively is a top priority in modern industry. Occupational Safety Certificates now play an important role in training and assessing the skills of those working with safety sensors.

Sensor performance is directly related to their ability to detect and react correctly to dangerous situations. This poses a challenge for safety sensors: they need to meet high accuracy and respond quickly in diverse and sometimes harsh environments.

An Occupational Safety Certificate is not just a proof of skills and understanding of safety sensors, but also a tool to help ensure that those working in this field are provided with adequate knowledge to address modern challenges and ensure optimal safety performance.

V. Learning effective interaction between drivers and sensors

Learning effective interaction between drivers and sensors is an important part of Occupational Safety training. In today’s traffic environment, sensors play a crucial role in providing information and warning drivers about potential dangerous situations.

Drivers need to be trained on how to understand and react correctly to data from sensors. This includes the ability to read and understand information provided by sensors, as well as the ability to react quickly and safely in specific situations. At the same time, they also need to know how to interact with the sensor system to ensure they function correctly and without issues.

Modern Occupational Safety programs not only focus on equipping knowledge about sensors but also concentrate on developing interaction skills between drivers and safety technology. This ensures that drivers are not just users of sensors but also individuals capable of effective interaction, helping to enhance safety and performance on the road.

VI. The future to predict the development of safety sensor technology

The future of safety sensor technology promises many significant advancements. Predicting this development requires continuous innovation and the integration of many different factors to meet the ever-increasing demands for safety and performance on the road. Researchers and engineers are focusing on developing smart sensors with the ability to predict and prevent accidents before they happen.

Integrating artificial intelligence and machine learning is an important part of this future. Sensor systems will be able to analyze data from the surrounding environment and predict dangerous situations, helping drivers and automated safety systems react in time.

In addition, the future will also see the development of diverse sensors, capable of measuring not only basic parameters like speed and distance but also complex factors such as the psychological state of the driver and vehicle operator. This will help optimize the driving experience and ensure maximum safety on the road.

VII. The important role of driver training related to safety sensors

Driver training is not just the process of learning basic vehicle control, but also closely related to understanding and interacting with safety sensors. In the increasingly complex context of automotive technology, drivers need to clearly understand how sensor systems work to fully utilize safety features.

Driver training needs to focus on teaching how to interact with sensors such as distance sensors, driver-assist sensors, and safety sensors during daily driving. Drivers need to know how to read and understand information from these sensors to react flexibly and safely in emergency situations.

At the same time, training should also emphasize the importance of maintaining knowledge about safety and sensor technology over time. This ensures that drivers are not just vehicle operators but also people capable of using related safety technology features most effectively and safely.

VIII. Occupational Safety Training Capability of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality center specializing in occupational safety training (in various languages such as English, Chinese, Japanese, Korean….) in Vietnam today. With occupational safety training sessions held continuously at workshops, factories, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training License

- An Toan Nam Viet has been inspected and certified by the Department of Work Safety, Ministry of Labor – Invalids and Social Affairs as eligible to conduct occupational safety and hygiene training. This further strengthens our occupational safety training capabilities.

Materials and Lectures

- Before occupational safety training materials are used in OST training courses, they are reviewed and approved to ensure lectures are always accurate in knowledge and effective when applied.

- The teaching methods of our instructors are standardized according to An Toan Nam Viet‘s teaching standards, a method researched and refined by experts in occupational safety and hygiene training during the teaching process to bring the highest knowledge absorption efficiency to students.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching efficiency and students’ knowledge absorption.

- Our training course support facilities always provide spacious classrooms that meet standards for area, lighting, training equipment, etc.

IX. National Occupational Environment Monitoring Center

Nam Viet’s Occupational Environment Monitoring Center is a professional unit specializing in monitoring and measuring the quality of the working environment across all provinces in Vietnam. With an experienced team of monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICES

In addition to providing monitoring services, the center also supports clients in planning, addressing, and tracking occupational environment issues. With the motto “the customer is the center,” we always strive for customer satisfaction, meet all customer needs, and commit to providing the best solutions for businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of occupational environment monitoring in Ho Chi Minh City, with the following objectives:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable solutions possible.

- With a team of experienced and specialized Masters and Engineers who wish to protect the environment and benefit businesses.

- Coming to Nam Viet’s Environmental Monitoring team, your company will receive professional service from experts in the monitoring field, along with the best cost incentives.

The occupational environment monitoring process at Nam Viet includes the following basic steps:

- Before conducting occupational environment monitoring, our company always ensures that machinery and equipment used for monitoring are adjusted and calibrated according to legal regulations.

- Correctly and fully implement the occupational environment monitoring process as committed to the Department of Health.

- Truthfully report the occupational environment monitoring results to the employer.

- In cases where the monitoring results do not ensure worker safety, Nam Viet company will assist in providing remedial solutions, and the facility will proceed as follows:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health check-ups to detect occupational diseases and work-related illnesses early for workers in positions with unsafe working environments.

- Provide in-kind benefits to workers according to labor laws.