Safety Document Group 3

Occupational Safety Document for Silk Production

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 PROFESSIONS)

Discover the occupational safety document for silk production, where art and science combine. This document provides detailed guidance on safety measures, risk reduction, and health protection for workers involved in the silk production process. Ensure a safe and effective working environment with this comprehensive and in-depth document.

PART I: CURRENT STATE OF SAFETY IN THE SILK PRODUCTION INDUSTRY

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some occupational accidents in silk factories

In the silk production industry, factories often face unwanted risks and occupational accidents. These accidents not only cause human losses but also affect the production process and the reputation of the business. Below are some notable occupational accidents that have occurred in silk factories, providing an overview of the state of occupational safety in this industry and emphasizing the need for safety measures and employee education.

- Chemical Poisoning Incidents: In some cases, employees in silk factories have been poisoned due to exposure to chemicals used in the production process. These chemicals can cause serious health problems if not used correctly or without appropriate protective measures.

- Machinery Accidents: Silk factories often use complex equipment and machinery to produce and process silk. Accidents can occur due to technical failures, lack of maintenance, or improper use, leading to injuries or even death.

- Risk of Electric Boiler Explosions: During the silk drying process, there is a risk of electric boiler explosions if safety measures are not followed. Accidents due to boiler explosions can have severe consequences for employees and the production facility.

- Hazards from Silk Processing Machines: The machines used to process and clean silk can create hazards if not operated correctly. Accidents can occur due to collisions, being pulled in, or getting caught between machine parts.

Occupational accidents in silk factories are a reminder that maintaining a safe working environment is extremely important. For this industry, investing in safety measures and educating employees about potential risks is necessary to protect the health and safety of all staff during the silk production process.

PART II: OCCUPATIONAL SAFETY AND HEALTH IN SILK PRODUCTION

I. Occupational safety and health for employees removing impurities from silkworm cocoons and processing them into silk threads

1. Characteristics of the work of removing impurities from silkworm cocoons and processing them into silk threads

The process of removing impurities and processing cocoons into silk threads requires careful and specialized steps. Initially, silkworm cocoons are harvested and soaked in hot water or treated with chemicals to dissolve the binding agent (sericin) attached to the silkworm’s body. Then, the silk is reeled out and placed on frames to form long, continuous threads.

This process requires delicate technique and high manual skill, as each silk thread must be controlled for size and uniformity. After the silk threads are obtained, they are processed through a process called winding and dyeing. In this process, the silk threads are wound into small skeins and then dyed with natural or chemical dyes to create the desired colors.

Finally, the silk threads are dried and polished to create a beautiful and soft silk product, ready for use in many applications from fashion to industrial manufacturing.

2. Types of occupational accidents during the process of removing impurities from silkworm cocoons and processing them into silk threads

During the process of removing impurities from silkworm cocoons and processing them into silk threads, workers often face many risks of occupational accidents. One of the most common risks is the danger of getting hurt or cut when using sharp tools to harvest silk from the cocoons.

Chemical handling also poses a toxic risk to the health of workers if they do not follow proper safety procedures. In addition, working in an industrial environment can cause health problems such as pneumonia or respiratory issues due to cocoon dust. The work environment can also pose a risk of physical injury due to the fast and necessary movements when handling cocoons and silk threads.

To minimize this risk, safety measures such as proper training, use of protective equipment, and control of the work environment are necessary to protect the health and safety of workers in this industry.

3. Causes of occupational accidents when removing impurities from silkworm cocoons and processing them into silk threads

Occupational accidents when removing impurities from silkworm cocoons and processing them into silk threads can arise from many different causes. One of the main causes is a lack of knowledge and training in occupational safety.

Workers may not be adequately trained on how to use tools and safety equipment, or they may not recognize the potential risks when working in a hazardous environment such as handling toxic chemicals. Another cause is working in an unsafe environment, where poor working conditions and a lack of safety management can lead to unwanted accidents.

A lack of attention and focus can also contribute to accidents, especially when tasks require precision and delicacy, such as using sharp tools to harvest silk from cocoons. Faced with these risks, providing adequate training and raising awareness about occupational safety is essential to minimize accidents and protect the health of workers.

4. Preventive measures against occupational accidents when removing impurities from silkworm cocoons and processing them into silk threads

To prevent occupational accidents when removing impurities from silkworm cocoons and processing them into silk threads, occupational safety training is a necessary and effective measure. First of all, workers need to be trained on the proper use of safety tools and equipment, including masks, gloves, and protective gear to minimize the risk of injury and prevent exposure to toxic chemicals. In addition, ensuring a safe work environment is also important.

This may include rearranging the workspace to minimize the risk of collisions or using dust extraction equipment to clean the work air. Furthermore, regular supervision and inspection also play an important role in ensuring compliance with occupational safety procedures. By implementing these preventive measures and ensuring that everyone involved in the process is trained and knowledgeable about occupational safety, the risk of accidents can be significantly reduced.

5. Occupational safety regulations when removing impurities from silkworm cocoons and processing them into silk threads

Occupational safety regulations during the process of removing impurities from silkworm cocoons and processing them into silk threads are an important part of risk management and protecting the health of workers. Workers need to be trained on the proper use of personal protective equipment such as masks, gloves, and safety glasses to protect against exposure to impurities and toxic chemicals.

In addition, specific regulations on the use and maintenance of tools and equipment are necessary to ensure the safety of everyone involved in the work process. Another part of the regulations is to ensure a clean and safe work environment, including controlling dust and chemicals in the work air.

Finally, risk management also requires regular monitoring and risk assessment to ensure that everyone complies with occupational safety regulations and has the safest possible work environment.

6. Handling emergency occupational accidents when removing impurities from silkworm cocoons and processing them into silk threads

In the event of an occupational accident when removing impurities from silkworm cocoons and processing them into silk threads, handling the emergency is very important to ensure the safety of the workers. First, the worker should immediately stop and report the accident to the nearest manager or medical staff. Next, they should provide immediate first aid to the injured victim, using basic first aid skills such as how to hold a wound, stop bleeding, and call for an ambulance if necessary.

Meanwhile, protecting oneself and others from the ongoing risk of an accident should also be prioritized, by stopping operations and isolating the accident area if necessary. Finally, after handling the emergency, conducting a detailed investigation into the cause of the accident is very important to prevent recurrence and improve occupational safety measures in the future.

II. Occupational safety and health for employees winding silk threads into large skeins in preparation for weaving

1. Characteristics of the work of winding silk threads into large skeins in preparation for weaving

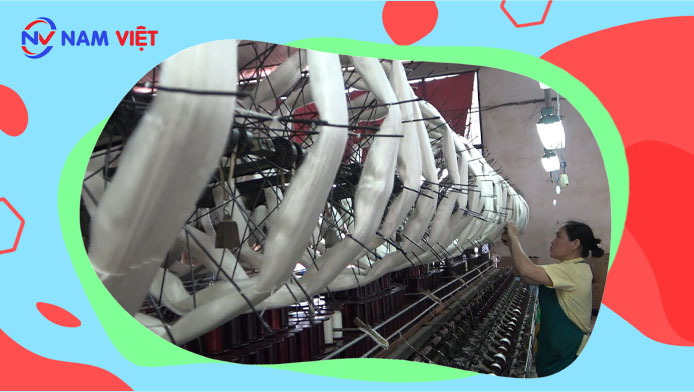

The process of winding silk threads into large skeins is an important step in the silk fabric production chain. This work is often done manually or through modern automatic machinery. The silk skeins created must adhere to specific standards for size and weight to ensure they are suitable for the subsequent weaving process.

The process of winding silk threads requires the meticulousness and skill of the worker, especially when handling thin and sensitive silk threads. Before winding, the silk threads are often carefully inspected to remove any threads that are not of sufficient quality or have defects. Then, the silk threads are arranged and wound tightly into skeins, avoiding tangling and loss during transport and storage.

Winding silk threads requires high precision and concentration, especially when performed on automatic machinery. Workers often have to adjust the machinery to ensure that the silk thread is wound tightly and evenly.

2. Types of occupational accidents during the process of winding silk threads into large skeins for weaving

During the process of winding silk threads into large skeins in preparation for weaving, the risk of occupational accidents can occur. One of the common accidents is when workers do not ensure safety when working with silk winding machinery. The fragile silk thread can easily cause problems that injure workers, such as cuts, scrapes, or being flicked out if not wound carefully.

In addition, working in an environment with silk fiber dust can also cause health problems, such as pneumonia or respiratory issues. Employees must be fully equipped with personal protective equipment such as masks, gloves, and safety glasses to minimize this risk.

To prevent occupational accidents, occupational safety training and the use of protective equipment are extremely important. Safety measures such as regular machine inspections, maintaining workplace hygiene, and adhering to safety procedures are necessary to protect the health and safety of workers during the silk winding process.

3. Causes of occupational accidents when winding silk threads into large skeins for weaving

There are many causes of occupational accidents during the process of winding silk threads into large skeins for weaving. One of the main causes is a lack of knowledge and skill of the worker on how to use the silk winding machinery. A lack of training or insufficient knowledge can lead to unsafe handling of machinery, increasing the risk of accidents.

In addition, an unsafe working environment is also a noteworthy cause. Working in a confined space, with poor lighting, or inadequate ventilation can increase the risk of accidents. Silk fiber dust is also a problem, not only causing discomfort but also potentially leading to health problems like pneumonia or allergies.

Furthermore, working under time pressure can cause workers to lose concentration and care, thereby leading to errors and accidents. Fatigue and stress also reduce the ability to concentrate and increase the risk of occupational accidents.

4. Preventive measures against occupational accidents when winding silk threads into large skeins for weaving

To ensure the safety of workers during the process of winding silk threads into large skeins, several occupational accident prevention measures need to be implemented. First, ensuring a safe and comfortable working environment is very important. This includes using an occupational environment monitoring system to measure factors such as light, temperature, humidity, and the concentration of silk fiber dust. By monitoring and adjusting these factors, the risk of health and safety problems for workers can be minimized.

Second, providing adequate and correct personal protective equipment is also very important. Workers need to be equipped with masks, gloves, safety glasses, and appropriate clothing to protect against risks such as pneumonia, dermatitis, or physical injury.

In addition, comprehensive training and instruction on occupational safety are also very important. All workers must be instructed on how to use machinery safely and carefully, as well as being guided on the emergency measures to be taken when an accident occurs.

5. Occupational safety regulations when winding silk threads into large skeins for weaving

Occupational safety regulations during the process of winding silk threads into large skeins are extremely important to ensure the safety and prevent accidents for workers. First, all employees must be trained in occupational safety and specific work procedures. This training includes how to use the silk winding machinery safely, recognize and handle dangerous situations, as well as rescue measures in case of need.

In addition, regulations on the use of personal protective equipment must be strictly followed. All workers must ensure they wear a helmet, gloves, safety glasses, and appropriate clothing when working with the silk winding machinery. This helps protect them from risks such as pneumonia, injury, or cuts.

At the same time, management needs to conduct periodic inspections and maintenance of machinery to ensure they operate safely and efficiently. Any incident or technical problem should be reported and repaired immediately to prevent potential accidents.

6. Handling emergency occupational accidents when winding silk threads into large skeins for weaving

In the event of an occupational accident when winding silk threads into large skeins, handling the emergency is very important to ensure the safety of all employees and minimize damage. First, the worker must immediately stop and send a warning signal to prevent any potential risks.

After that, calling or immediately notifying the fire department or ambulance is the next important step. The information provided must be accurate and detailed, including the specific location of the accident and the victim’s condition.

While waiting for assistance from the fire department, providing first aid to the injured person is also a priority. Employees need to be trained in basic first aid measures such as CPR, trauma first aid, and pain management for the victim while keeping them stable and comfortable.

III. Occupational safety and health for employees operating looms to weave silk skeins into fabric

1. Characteristics of the work of operating a loom to weave silk skeins into fabric

Operating a loom to weave silk skeins into fabric requires expertise and care. This process involves many steps from preparing the raw materials to producing the finished fabric. First, the machine operator needs to check and adjust the machine according to the characteristics of the type of silk thread being used.

Then, they load the silk thread into the machine and ensure it runs smoothly. Adjusting parameters such as thread tension, speed, and pressure is important to achieve the desired fabric quality. During operation, the worker needs to monitor for problems and clean the machine regularly to ensure optimal performance and avoid technical issues.

They also need to check the final product to ensure that the fabric meets standards for smoothness and durability. This requires patience, technical skill, and the ability to work accurately to create high-quality silk fabrics that meet market demands.

2. Types of occupational accidents during the process of operating a loom to weave silk skeins into fabric

During the process of operating a loom to weave silk thread into fabric, there are several occupational accident risks that workers need to be aware of and prevent. One of the common risks is accidents related to the mechanical parts of the machine, such as rotating shafts or fans, which can cause injury if not operated correctly or without sufficient protection.

In addition, cleaning the machine while it is in operation is also a major risk, as it can lead to collisions or being pulled into the moving parts of the machine. The chemical products used in the weaving process can also be hazardous if not used correctly or without adequate personal protective measures.

At the same time, working in an environment with high temperature and humidity can lead to health risks, including heatstroke and exhaustion. To minimize these risks, safety training and adherence to procedures are extremely important to protect the health and safety of workers.

3. Causes of occupational accidents when operating a loom to weave silk skeins into fabric

There are many causes of occupational accidents during the process of operating a loom to weave silk thread into fabric. One of them is a lack of training and safety awareness of the workers. When they are not fully trained on how to operate the machine and safety measures, the risk of an accident increases.

Carelessness or negligence during operation is also a common cause. Failure to pay attention to warning signs from the machine, or working while fatigued, can also lead to accidents. In addition, the machinery can also experience unexpected technical problems, such as breakdowns or loss of control, leading to a risk of accidents for the workers.

The work environment also plays an important role, with factors such as high temperature, humidity, and confinement, which can increase the health and safety risks for workers. To minimize these risks, attention must be paid to safety training, caution, and regular monitoring of the machinery and work environment.

4. Preventive measures against occupational accidents when operating a loom to weave silk skeins into fabric

To prevent occupational accidents when operating a loom to weave silk thread into fabric, it is necessary to implement proper safety measures. First of all, providing comprehensive training on how to operate the machine and safety measures is important. Workers need to be instructed on how to use the machine safely and efficiently, as well as how to react correctly in an emergency.

Regular inspection and maintenance of the machine is also an important measure to ensure it operates stably and minimizes the risk of sudden breakdowns. In particular, the use of personal protective equipment such as helmets, safety glasses, and fire-resistant clothing helps protect workers from potential hazards from the machine and the work environment.

In addition, maintaining a clean and well-ventilated work environment also helps minimize risks related to temperature and humidity. All of these measures together contribute to creating a safe work environment and reducing the risk of occupational accidents when operating a silk loom.

5. Occupational safety regulations when operating a loom to weave silk skeins into fabric

Occupational safety regulations when operating a loom to weave silk thread into fabric are an indispensable part of the production environment. First, workers need to be trained on safety procedures and accident prevention measures. They must have a clear understanding of how to use personal protective equipment such as helmets, safety glasses, and fire-resistant clothing.

The regulations must also ensure that workers know how to react correctly in an emergency and how to report dangerous situations. In addition, the regulations should also specify the periodic inspection and maintenance of machinery to ensure that it operates stably and safely.

Accident prevention measures must be implemented regularly and seriously, and compliance with these regulations is not only the responsibility of the workers but also of the management and the manufacturer. This ensures a safe working environment and helps minimize the risk of occupational accidents during the operation of a silk loom.

6. Handling emergency occupational accidents when operating a loom to weave silk skeins into fabric

Handling an emergency occupational accident during the process of operating a loom to weave silk thread into fabric requires decisiveness and knowledge of occupational safety. When an accident occurs, the first thing is to immediately stop the machine’s operation and report the incident to the manager or the occupational safety department. After that, it is necessary to ensure the safety of the victim and those around by providing immediate first aid and calling for an ambulance or taking the victim to the nearest hospital if necessary.

In cases where the victim is trapped in the machine, do not try to free them but wait for professional help to avoid causing more serious consequences. At the same time, it is necessary to investigate the cause of the accident to prevent recurrence and improve occupational safety measures in the future. Preparing a plan and conducting regular training for employees on how to handle emergencies is also very important to ensure everyone knows how to respond when needed.

IV. Occupational safety and health for employees in the finishing process to improve the softness and shine of silk

1. Characteristics of the work of finishing to improve the softness and shine of silk

To improve the softness and shine of silk, the finishing process requires meticulous care and technique. First, the silk is carefully separated from the silkworm, then treated with herbs or chemicals to remove impurities and increase cleanliness.

Next, the material synthesis process takes place, in which the silk is impregnated with the necessary substances to enhance its softness and shine. Finishing techniques such as dyeing and pressing are also applied to create the desired color and style, without affecting the softness and shine of the final product.

Finally, the product is finished through a final drying and finishing process to ensure high quality and softness, while retaining the natural shine of the silk.

2. Types of occupational accidents during the process of finishing to improve the softness and shine of silk

During the finishing process to improve the softness and shine of silk, manufacturers may face significant occupational accident risks. Common types of accidents include exposure to toxic chemicals when processing silk, causing health problems such as skin irritation, pneumonia, or eye injuries.

In addition, the use of complex equipment and machinery can create a risk of injury or cuts for employees working in the production environment. To minimize these accidents, applying occupational safety measures and training employees on the safe use of chemicals and equipment is very important. At the same time, designing a comfortable and safe workspace also plays an important role in reducing the risks of occupational accidents during the silk finishing process.

3. Causes of occupational accidents when finishing to improve the softness and shine of silk

Occupational accidents during the finishing process to improve the softness and shine of silk are often caused by a combination of many factors. One of the main causes is working in an environment with toxic chemicals. Direct contact with or inhalation of chemicals such as acids and alkalis during the finishing process can cause skin irritation, eye pain, or lung damage, leading to accidents and even affecting the long-term health of workers.

In addition, the use of unsafe or improper equipment and machinery is also a significant cause of occupational accidents. A lack of knowledge or skill of the worker when using the equipment can lead to serious accidents such as cuts, collisions, or falls. To prevent these accidents, training and educating workers on occupational safety and equipment use is extremely important.

4. Preventive measures against occupational accidents when finishing to improve the softness and shine of silk

To prevent occupational accidents when finishing to improve the softness and shine of silk, implementing safety measures is extremely important. First, ensuring the use of personal protective equipment such as gloves, masks, and safety glasses is necessary when in contact with chemicals and finishing equipment. At the same time, adhering to safe work procedures and manufacturer’s instructions also plays an important role.

In addition, training employees on how to use equipment and chemicals correctly also helps minimize the risk of occupational accidents. In particular, regular inspection and maintenance of equipment and machinery also play an important role in ensuring a safe working environment and reducing the risk of accidents.

Attention to and awareness of occupational safety is not only the responsibility of the worker but also of the manufacturer, and cooperation between these parties is necessary to create a safe and effective working environment.

5. Occupational safety regulations when finishing to improve the softness and shine of silk

Occupational safety regulations in the finishing process to improve the softness and shine of silk play an important role in protecting the health and safety of workers. According to these regulations, the use of personal protective equipment is mandatory, including gloves, masks, safety glasses, and reflective vests that comply with regulations.

In addition, ensuring a clean and well-ventilated work environment is also carefully regulated. Manufacturers must provide adequate guidance and training to employees on the safe use of chemicals and equipment, as well as emergency measures in case of an accident.

At the same time, periodic inspection and maintenance of equipment and machinery are also regulated to ensure safety and efficiency during the work process. Strict compliance with occupational safety regulations not only protects the health of workers but also ensures the stability and efficiency of the production process.

6. Handling emergency occupational accidents when finishing to improve the softness and shine of silk

In the event of an occupational accident while finishing to improve the softness and shine of silk, handling the emergency is extremely important to protect the health and lives of workers. First, workers should immediately report the accident to the manager or the occupational safety department of the production facility.

Next, providing first aid to the victim is the top priority. Ensure that the victim is moved out of the dangerous area and taken to an emergency room quickly and safely. At the same time, securing the accident site and collecting detailed information about the incident is also very important for later analysis and to implement measures to prevent similar accidents.

Finally, notifying the authorities and implementing investigation and safety inspection measures to ensure that the hazardous situation has been rectified and to prevent future accidents. Alertness and timely response in handling occupational accidents are important to minimize the serious consequences that can occur.

V. Occupational safety and health for employees operating a dyeing machine for silk

1. Characteristics of the work of operating a dyeing machine for silk

Operating a dyeing machine for silk requires great care and high professional skill. This process includes many complex steps, from preparing raw materials and mixing chemicals to adjusting the technical parameters on the machine. Before starting the dyeing process, workers need to carefully inspect the machinery and ensure it operates smoothly. Then, they must ensure that the raw materials and chemicals are added to the machine in the correct proportions to ensure the quality of the final color.

Workers must also perform regular quality checks throughout the dyeing process to ensure that the final product achieves the desired color and does not harm the user. While the machine is operating, workers need to monitor it closely to detect and immediately rectify any problems that may occur.

Finally, after the dyeing process is complete, they must clean the work area and maintain the machinery to ensure safety and efficiency in subsequent uses.

2. Types of occupational accidents during the process of operating a dyeing machine for silk

During the process of operating a dyeing machine for silk, occupational accidents can occur due to many different reasons. One of the main causes is technical failure, when the machinery has an unexpected problem or malfunction, which can lead to an accident for the worker.

A lack of understanding of the process or non-compliance with safety regulations is also a factor that causes common accidents. Inattention during work or violation of safety rules can also lead to accidents. In addition, the use of chemicals without adhering to safety measures is also a potential cause of occupational accidents during the dyeing process.

Faced with these risks, training employees on occupational safety and ensuring compliance with safety rules is very important to reduce the risk of accidents and protect the health of workers.

3. Causes of occupational accidents when operating a dyeing machine for silk

There are many causes of occupational accidents during the process of operating a dyeing machine for silk. One of the main causes is a lack of understanding or non-compliance with occupational safety procedures and regulations.

When employees are not fully trained on how to use machinery safely or do not implement accident prevention measures, the risk of accidents increases. A lack of attention and vigilance can also lead to accidents, especially when working in an environment with many hazardous factors. Carelessness or a lack of concern for machine maintenance is another cause of accidents, as machinery that is not maintained and inspected regularly can lead to sudden breakdowns.

Finally, the use of chemicals without adhering to proper procedures and safety measures is also a significant cause of accidents during the dyeing process. To reduce the risk of accidents, it is necessary to enhance employee training, promote a spirit of vigilance, and strictly adhere to safety regulations.

4. Preventive measures against occupational accidents when operating a dyeing machine for silk

To prevent occupational accidents when operating a dyeing machine for silk, implementing safety measures is extremely important. First, it is necessary to ensure that all employees are trained on how to use machinery safely and have a clear understanding of occupational safety procedures.

Providing appropriate personal protective equipment such as masks, gloves, and safety glasses should also be done, and it should be ensured that all employees comply with their use. Regular inspection and maintenance of machinery is also an important measure to ensure it operates safely and efficiently.

Furthermore, the use of chemicals must strictly adhere to the relevant safety procedures and measures, including the use of the correct type of chemical, safe storage, and proper transportation. Finally, creating a safe work environment and encouraging a spirit of vigilance and personal responsibility in adhering to safety regulations is very important to ensure the safety of all employees during their work.

5. Occupational safety regulations when operating a dyeing machine for silk

Occupational safety regulations when operating a dyeing machine for silk are an indispensable part of the production environment. First, all employees must be fully trained on safety procedures and accident prevention measures before approaching the machinery.

Personal protective equipment is also an important factor, including masks, gloves, safety glasses, and chemical-resistant gowns. The use of this equipment must be strictly adhered to. At the same time, regular inspection and maintenance of machinery is also an indispensable part to ensure it operates safely and efficiently.

Chemicals used in the dyeing process must also be stored and used according to regulations, and employees must be trained on how to handle them safely. Finally, compliance with the regulations and instructions of the machine manufacturer is also an important part of the occupational safety regulations, ensuring that everyone works in a safe and healthy environment.

6. Handling emergency occupational accidents when operating a dyeing machine for silk

In the event of an occupational accident while operating a dyeing machine for silk, emergency handling is very important to ensure the safety of all employees. First, as soon as an accident occurs, it is necessary to immediately notify the manager and the on-site fire or medical team to ensure that help is provided in a timely manner.

While waiting for help, it is necessary to immediately stop using the machinery and move the affected employee out of danger. If possible, first aid should be provided to the victim in an emergency and it should be ensured that they receive the necessary medical care immediately.

At the same time, a detailed report of the accident must be made, including information on the cause and the measures that have been taken to handle the situation. Finally, after handling the emergency, a detailed investigation must be conducted to find out the root cause of the accident and propose improvement measures to prevent a recurrence in the future.

PART III: Further Reference

1. Group 3 Occupational Safety Test

2. Quotation for Occupational Safety Training Services

3. Download documents

- Download occupational safety training materials for silk production

- Slide presentation for occupational safety training in silk production

- Quiz on occupational safety in silk production