Safety Document Group 3

Occupational Safety Document for Operating Piling and Drilling Rig Machines

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 PROFESSIONS)

Discover the detailed instructions and necessary procedures to ensure safety when operating a piling and drilling rig machine. This document provides measures to prevent hazards and safety regulations that must be followed, helping to minimize risks and ensure safety for all employees involved in this work.

PART I: CURRENT STATE OF SAFETY FOR WORK RELATED TO PILING AND DRILLING RIG MACHINES

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some Occupational Accidents While Operating a Piling and Drilling Rig Machine

Operating machinery like a piling and drilling rig not only requires professional skills but also demands caution and strict adherence to safety rules. Although many measures have been applied to minimize the risk of accidents, serious occupational accidents still occur during the operation of these rigs. Below are some common accidents that workers may encounter when working with this drilling machine:

- Risk of collision and crushing: During operation, collisions with obstacles or other machinery in the work area can occur. A collision can lead to serious injury or even death if not prevented in time.

- Risk of tripping and falling from height: Workers often have to work at heights on unstable ground or on surfaces leveled with temporary foundations. A lack of caution can lead to the risk of tripping or falling from a height, causing serious injury or death.

- Accidents related to materials and tools: During operation, the use of tools and materials can create a risk of accidents if they are not used correctly or if they are not stored safely.

- Risk of explosion and fire: The use of drilling machines can create sparks or provide enough electrical energy to cause explosions or fires if safety regulations for working near flammable and explosive substances are not followed.

- Risk of toxic contamination and exposure: The drilling process can generate dust, gases, and toxic vapors that, if not properly controlled, can cause health problems for employees.

These accidents highlight the importance of strict adherence to safety rules, proper training, and the use of personal protective equipment to minimize risks and protect the health of workers when operating a piling and drilling rig.

PART II: OCCUPATIONAL SAFETY AND HEALTH WHEN OPERATING A PILING AND DRILLING RIG MACHINE

I. Introduction

A. Overview of the importance of occupational safety when operating a Piling and Drilling Rig machine

Occupational safety is an extremely important factor in all industrial activities, especially in the operation of machinery such as piling and drilling rigs. Adhering to safety rules not only keeps workers safe but also minimizes the risk of accidents and injuries, while increasing work efficiency and project quality.

The operation of a piling and drilling rig requires a high level of expertise and solid knowledge of both technical aspects and safety procedures. Workers must be fully trained on how to use the machinery, recognize and prevent potential risks, as well as know how to respond to emergency situations.

Protecting the health and safety of workers is not only the responsibility of the individual worker but also the responsibility of the operator and project managers. Establishing and strictly adhering to safety rules, providing appropriate personal protective equipment, and periodically inspecting working conditions are necessary measures to ensure a safe and healthy working environment for all employees.

B. Important safety protocols and regulations when operating a Piling and Drilling Rig machine

- Periodic inspection and maintenance: Before starting each shift, workers need to thoroughly inspect the condition of the drilling rig, ensuring that all components and systems are functioning normally. Periodic maintenance is also a crucial part of keeping the machinery operating stably and minimizing the risk of breakdowns.

- Use of Personal Protective Equipment (PPE): Workers must be fully equipped with PPE such as helmets, safety glasses, gloves, and safety shoes to protect themselves from potential hazards during work.

- Training and education: All employees must be fully trained on the use and operation of the piling and drilling rig. This includes recognizing potential hazards and knowing how to respond to emergency situations.

- Adherence to work environment safety regulations: Operators must ensure that the work environment is kept clean and safe, including controlling hazardous substances, minimizing the risk of fire and explosion, and providing safety information to workers.

- Implementation of safe work procedures: Safety procedures such as ensuring safety when disassembling or installing machine parts, considering the vehicle’s position and speed during movement, as well as regulations on the use of safety harnesses when working at height must be strictly followed.

II. Components and Functions of a Piling and Drilling Rig Machine

A. The different components of a Piling and Drilling Rig machine

- Main frame: This is the core component of the drilling rig, responsible for bearing loads and providing a foundation for drilling and pile driving activities.

- Engine and drive system: The engine and drive system provide the necessary power to operate the various parts of the drilling rig, including the drill spindle and the pile driving system.

- Drilling unit: The drilling unit includes components such as the drill spindle, drill head, and auxiliary drilling tools, used to drill holes or prepare the ground before driving piles.

- Pile driving system: An important part of the drilling rig, the pile driving system includes pistons and cylinders that work to drive piles into the ground effectively and evenly.

- Control system: The control system is the brain of the drilling rig, regulating and controlling the machine’s activities, including the drilling and pile driving processes.

- Cooling and lubrication system: To ensure smooth and efficient operation, the drilling rig needs to be equipped with cooling and lubrication systems to keep the parts running smoothly and without wear.

B. Structure and operating principle of a Piling and Drilling Rig machine

- Main frame: The core part of the drilling rig, the main frame provides a solid foundation for installing various components and bearing loads during operation.

- Pile driving system: Includes pistons and cylinders that work to create a powerful thrust to drive piles into the ground. The operating principle of this system is to use hydraulic pressure to create a pressing force, helping to drive piles deep into the ground effectively.

- Drilling unit: Usually attached to the front of the drilling rig, the drilling unit includes a drill spindle and drill head, used to drill holes or prepare the ground before driving piles.

- Drive system: The engine and drive system provide the necessary power to operate the various parts of the drilling rig, including the drill spindle and the pile driving system.

- Control system: The brain of the drilling rig, the control system regulates and controls the machine’s activities, including the drilling and pile driving processes, to ensure performance and safety during work.

C. Applications in the construction industry of the Piling and Drilling Rig machine

- Bridge and port construction: In bridge and port construction, driving piles into the ground to reinforce the foundation is very important. Piling and drilling rigs are used to drive piles deep into the ground, creating a solid foundation for building bridges and ports with high strength and stability.

- High-rise building construction: In the construction of high-rise buildings, reinforcing the ground foundation is very important to ensure the safety and stability of the structure. Piling and drilling rigs are used to drive piles into the ground, creating a sturdy foundation for building tall buildings.

- Civil and industrial construction: In civil and industrial construction projects, piling and drilling rigs are used to improve the ground foundation and enhance the strength of the structure. Applications include the construction of houses, factories, workshops, and other buildings.

- Infrastructure construction: Piling and drilling rigs are also used in the construction of infrastructure such as railways, highways, culverts, and water supply and drainage systems to reinforce and improve the ground foundation.

D. Risks associated with operating a Piling and Drilling Rig machine

- Occupational accidents: The operation of a piling and drilling rig requires a high level of attention and professional skill. Accidents can occur due to collisions with obstacles, falls from height, or improper use of tools and materials.

- Risk of fire and explosion: The use of drilling machines can create sparks or sufficient electrical energy to cause fires or explosions if safety regulations for working near flammable and explosive substances are not followed.

- Risk of toxic contamination: The drilling process can generate dust, gases, and toxic vapors that, if not properly controlled, can cause health problems for workers.

- Environmental risks: Drilling can have a negative impact on the surrounding environment, including effects on flora, fauna, and water sources.

- Technical failures: Technical failures such as machinery breakdown, oil leaks, or control system errors can pose a safety risk and disrupt the work process.

III. Safety Inspection and Maintenance Before Operating a Piling and Drilling Rig Machine

A. Safety checks before operating a Piling and Drilling Rig machine

- Check basic systems: Ensure that all basic systems of the drilling rig such as the engine, drive system, control system, and braking system are functioning normally.

- Check the condition of the drilling unit: Inspect the parts of the drilling unit such as the drill spindle and drill head to ensure they are not damaged or excessively worn.

- Check the pile driving system: Ensure that the pile driving system, including pistons and cylinders, is operating powerfully and shows no signs of oil leakage.

- Check personal protective equipment (PPE): Ensure that all workers are fully equipped with PPE such as helmets, safety glasses, gloves, and safety shoes before starting work.

- Check the work environment: Inspect the work environment to ensure there are no potential hazards such as flammable substances, toxic materials, or the risk of falling from height.

B. Guide to periodic maintenance of a Piling and Drilling Rig machine

- Engine system maintenance: Check and change the engine oil according to the schedule specified in the manufacturer’s user manual. Checking and cleaning the oil filter is also an important part of periodic maintenance.

- Drive system inspection: Inspect and adjust drive belts, and check and change the gearbox oil periodically to ensure the drive system operates smoothly and effectively.

- Pile driving system maintenance: Inspect and maintain the pile driving system, including checking and changing the oil in the hydraulic system and inspecting parts like pistons and cylinders to ensure stable operation.

- Control system inspection and maintenance: Inspect and control the components of the control system, ensuring that they are operating correctly and show no signs of malfunction.

- Brake system inspection and maintenance: Inspect and adjust the brake system periodically to ensure safety when operating the piling and drilling rig.

IV. Safe Operating Procedure for a Piling and Drilling Rig Machine

A. Step-by-step guide to the safe operation of a Piling and Drilling Rig machine

- Pre-work preparation: Before starting work, ensure that all workers have been fully trained on the use and operation of the drilling rig. Re-check personal protective equipment and ensure that all safety devices are fully equipped.

- Safety check: Perform a safety check before operating the drilling rig, including checking the braking system, drive system, pile driving system, and control system. Ensure that all equipment is operating correctly and safely.

- Determine the location and working conditions: Identify the location for drilling and piling and ensure there are no potential hazards such as steep slopes, great depths, or an unsafe work environment.

- Follow the operating procedure: Adhere to the specified operating procedures, including performing drilling and piling operations correctly and safely, while keeping the rig operating at a safe speed and pressure.

- Monitor and control: Monitor the operation process and control parameters such as pressure, speed, and drilling depth to ensure that all activities are carried out safely and effectively.

- Post-work maintenance: After completing the work, perform periodic maintenance to ensure that the drilling rig is best preserved and ready for the next job.

B. Emergency procedures and incident response mechanisms when operating a Piling and Drilling Rig machine

- Stop operation immediately: In case an incident is detected, stop the operation of the drilling rig immediately to prevent the risk from spreading and to ensure everyone’s safety.

- Report the incident: Report the incident immediately to the manager or the company’s safety department for necessary support and guidance.

- Move workers out of the hazardous area: Move all workers out of the hazardous area and ensure their safety first.

- Respond to the risk of fire and explosion: In case of a fire or explosion risk, use fire extinguishing equipment or isolate the area to prevent the fire from spreading.

- Use safety equipment: Use safety equipment such as reflective vests, helmets, and safety glasses to protect yourself from risks and injuries.

- Implement the incident response plan: Implement the pre-defined incident response plan to minimize damage and ensure everyone’s safety.

- Evaluate and learn: After the incident is resolved, evaluate and learn from the experience to improve the operating procedure and prevent recurrence in the future.

V. Risk Assessment and Hazard Management When Operating a Piling and Drilling Rig Machine

A. Identifying potential risks and hazards in operating a Piling and Drilling Rig machine

- Risk of occupational accidents: Accidents can occur due to collisions with obstacles, falls from height, or improper use of tools and materials, especially when working at height.

- Risk of fire and explosion: The use of drilling machines can create sparks or sufficient electrical energy to cause fires or explosions if safety regulations for working near flammable and explosive substances are not followed.

- Risk of toxic contamination: The drilling process can generate dust, gases, and toxic vapors that, if not properly controlled, can cause health problems for workers.

- Environmental risks: Drilling can have a negative impact on the surrounding environment, including effects on flora, fauna, and water sources.

- Technical failures: Technical failures such as machinery breakdown, oil leaks, or control system errors can pose a safety risk and disrupt the work process.

B. Effective hazard prevention strategies when operating a Piling and Drilling Rig machine

1. Regular inspection and maintenance of the Piling and Drilling Rig machine for safe operation

- Check basic systems: Ensure that all basic systems of the drilling rig such as the engine, drive system, control system, and braking system are functioning normally.

- Check the condition of the drilling unit: Inspect the parts of the drilling unit such as the drill spindle and drill head to ensure they are not damaged or excessively worn.

- Check the pile driving system: Inspect and maintain the pile driving system, including checking and changing the oil in the hydraulic system and inspecting parts like pistons and cylinders to ensure stable operation.

- Check the control system: Inspect and control the components of the control system, ensuring that they are operating correctly and show no signs of malfunction.

- Check the brake system: Inspect and adjust the brake system periodically to ensure safety when operating the piling and drilling rig.

2. Adherence to occupational safety regulations for the safe operation of a Piling and Drilling Rig machine

- Training and coaching: Ensure that all employees are fully trained on the use and operation of the piling and drilling rig before working. Training on occupational safety and incident response procedures is also a crucial part of the training process.

- Use of personal protective equipment (PPE): Ensure that all employees are fully equipped with personal protective equipment such as helmets, safety glasses, gloves, and safety shoes to protect them from potential hazards during work.

- Pre-operation safety check: Perform a safety check before operating the drilling rig, including checking the braking system, drive system, pile driving system, and control system to ensure that all equipment is operating correctly and safely.

- Risk assessment and response plan: Assess and identify potential risks during operation and develop response plans to minimize the risk of accidents and protect employee health.

- Adherence to environmental regulations: Adhere to regulations regarding the work environment, including the safe handling and disposal of waste and protecting the surrounding environment.

3. Identifying and marking safe zones when operating a Piling and Drilling Rig machine

- Identify hazardous zones: Assess and identify hazardous zones in the work area, including areas with a risk of collision, falling from height, or working near operating equipment.

- Establish safe zones: Define and establish safe zones around the piling and drilling rig to ensure that no one is near a hazardous work position.

- Mark safe zones: Use signs or other marking materials to indicate safe zones and warn employees of potential hazards.

- Training and notification: Ensure that all employees are trained on the safe zones and informed about hazard prevention measures.

- Maintain safe zones: Check and maintain safety measures such as marking safe zones and notifications to ensure they are always maintained and effective.

4. Using personal protective equipment when operating a Piling and Drilling Rig machine

- Helmet: A helmet is specially designed to protect the head from impact and falling objects.

- Safety glasses: Safety glasses help protect the eyes from dust, debris, and other hazards during work.

- Safety gloves: Safety gloves help protect the hands from sharp materials, chemicals, and high temperatures.

- Reflective vest: A reflective vest helps increase the visibility of employees in low-light conditions or in work areas near vehicle traffic.

- Safety shoes: Puncture-resistant safety shoes with non-slip soles help protect the feet from the risk of injury when working on rough ground or near operating machinery.

5. Emergency procedures and response in case of an incident when operating a Piling and Drilling Rig machine

- Stop operation immediately: In case an incident is detected, stop the operation of the drilling rig immediately to prevent the risk from spreading and to ensure everyone’s safety.

- Report the incident: Report the incident immediately to the manager or the company’s safety department for necessary support and guidance.

- Move workers out of the hazardous area: Move all workers out of the hazardous area and ensure their safety first.

- Respond to the risk of fire and explosion: In case of a fire or explosion risk, use fire extinguishing equipment or isolate the area to prevent the fire from spreading.

- Use safety equipment: Use safety equipment such as reflective vests, helmets, and safety glasses to protect yourself from risks and injuries.

- Implement the incident response plan: Implement the pre-defined incident response plan to minimize damage and ensure everyone’s safety.

- Evaluate and learn: After the incident is resolved, evaluate and learn from the experience to improve the operating procedure and prevent recurrence in the future.

6. Participate in occupational safety training courses for operating a Piling and Drilling Rig machine

Occupational safety and health training is not just a legal requirement but also a commitment to the safety and health of workers. It helps employees recognize and deal with risks and dangerous situations, thereby minimizing accidents, injuries, or fatalities in their daily work.

The risk of accidents is always present and can occur at any time in the work environment due to human error and the unpredictability of situations. This emphasizes the need for occupational safety training and constant vigilance.

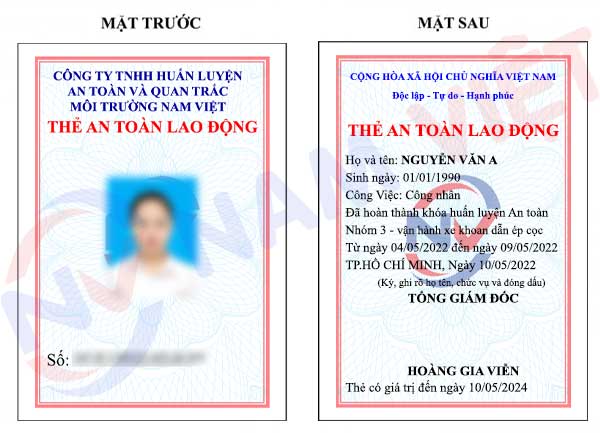

When participating in occupational safety training at the An Toan Nam Viet Center, workers will receive systematic training from theory to real-life risk scenarios. Accordingly, there will be measures to identify and prevent occupational accident risks that may occur during work. After the training course, trainees will take occupational safety tests to obtain an occupational safety certificate. From there, workers will have a firm grasp of safety knowledge as well as a valid certification for work.

VI. Factors Affecting Occupational Safety When Operating a Piling and Drilling Rig Machine

A. How weather conditions affect the operation of a Piling and Drilling Rig machine

- Rain: Rain can increase the risk of slipping and reduce the controllability of the machinery, especially on slippery ground surfaces.

- Strong wind: Strong wind can reduce the stability of the drilling rig and increase the risk of impact, especially when working at height.

- Snow and ice: Snow and ice can reduce the mobility of the drilling rig and increase the risk of slipping and accidents.

- Extreme temperatures: Extreme temperatures, both hot and cold, can affect the operation of mechanical and electronic components on the drilling rig.

- High humidity: High humidity can cause corrosion and wear on the parts of the drilling rig and reduce work efficiency.

B. How the working environment affects the operation of a Piling and Drilling Rig machine

- Land and terrain: Uneven land and terrain can affect the mobility and stability of the drilling rig. Especially in rough or slippery terrain conditions.

- Climate: Climate, including temperature, humidity, and wind speed, can affect the operation and performance of the drilling rig, as well as the health of the workers.

- Surrounding environment: The surrounding environment such as noise, dust, smoke, and toxic gases can affect the health of employees and work performance.

- Lighting conditions: Poor lighting conditions can reduce the visibility and work ability of employees, especially in outdoor work areas or in the evening.

- Humidity and corrosion: High humidity and corrosive factors can cause wear on the parts of the drilling rig and reduce the lifespan and performance of the machinery.

C. How the technical condition of the Piling and Drilling Rig machine affects its operation

- Performance: A piling and drilling rig needs to be regularly maintained and thoroughly inspected to ensure optimal operating performance. If there is any failure in the main components such as the pile driving system, braking system, or drive system, it can reduce work performance and increase the risk of accidents.

- Safety: Poor technical condition can increase the risk of incidents and accidents during operation. Parts that are not functioning correctly can create dangerous situations for workers nearby.

- Fuel consumption: If a piling and drilling rig is not regularly maintained and repaired when necessary, fuel consumption can increase significantly, raising operating costs and harming the environment.

- Lifespan and maintenance: The technical condition also affects the lifespan of the drilling rig. Regular maintenance and replacement of worn parts are necessary to ensure the rig always operates stably and safely.

D. How the safety knowledge and skills of the worker affect the operation of a Piling and Drilling Rig machine

- Understanding of safety procedures: Workers need to have a solid knowledge of the safety procedures related to operating a piling and drilling rig, including how to use personal protective equipment, safety rules at work, and accident prevention measures.

- Machine operation skills: Having accurate and effective operating skills is a crucial factor in ensuring the safe operation of the drilling rig. Knowing how to control the machinery correctly helps to minimize the risk of incidents and accidents.

- Knowledge of maintenance and repair: Understanding the basic maintenance and repair procedures helps workers to detect and resolve technical issues early, avoiding incidents and ensuring the machinery always operates stably.

- Safety awareness: Safety awareness is an important factor in all work activities. Workers must always adhere to safety regulations, implement preventive measures, and report incidents as soon as they are detected.

VII. Occupational Safety Training on Skills for Safe Operation of a Piling and Drilling Rig Machine

A. Why operators of Piling and Drilling Rig machines need occupational safety training

- Reduce the risk of accidents: Occupational safety training helps operators to recognize and assess potential risks and know how to react correctly in dangerous situations, thereby minimizing the risk of accidents.

- Increase understanding of procedures and equipment: Training provides the necessary knowledge and skills about operating procedures, use, and maintenance of the drilling rig, helping operators to work more effectively and safely.

- Comply with legal regulations: Trained operators in occupational safety understand the legal regulations and safety standards, helping them to comply and implement safety measures correctly.

- Protect health: Training helps operators to recognize and avoid health-related risks, protecting themselves from harmful factors such as noise, dust, and toxic substances.

- Improve performance and work quality: Trained operators in occupational safety will have a broader understanding of the procedures and equipment, thereby improving performance and work quality.

B. Where to get occupational safety training for operating a Piling and Drilling Rig machine?

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

To ensure the effectiveness of the training, An Toan Nam Viet prepares meticulously, down to the smallest detail. From preparing tools, equipment, teaching aids to curriculum, materials, sound, and lighting.

The occupational safety trainers at An Toan Nam Viet are experts with many years of experience in the field. They even have research projects identifying hazards in all occupations and how to prevent them.

The instructors’ lectures are drawn from practical experience and are conveyed in a vivid, easy-to-visualize manner to the workers. These factors help workers feel comfortable during their study time and absorb the teaching knowledge well. Of course, the knowledge conveyed always adheres to Decree 44/2016/ND-CP. From there, they grasp many measures to prevent hazards and how to protect themselves. They also apply it most appropriately in their actual work.

VIII. The Significance of Occupational Safety in Operating a Piling and Drilling Rig Machine

A. The importance of maintaining occupational safety in the operation of a Piling and Drilling Rig machine

- Protecting health and life: Occupational safety ensures that employees working in the operating environment are protected from the risk of accidents and work-related health problems.

- Minimizing the risk of accidents: Occupational safety measures, such as using personal protective equipment and adhering to safety procedures, help to minimize the risk of accidents and unwanted incidents during work.

- Increasing work performance: A safe working environment encourages the concentration and confidence of employees, thereby increasing work performance and quality.

- Maintaining the company’s reputation and image: Maintaining a safe working environment enhances the company’s reputation and image in the eyes of both customers and the community.

- Complying with legal regulations: Maintaining occupational safety is not only a moral responsibility but also a legal obligation, helping the company to comply with the safety regulations and standards set by the authorities.

B. Important safety measures to know before operating a Piling and Drilling Rig machine

- Use personal protective equipment: Ensure everyone working on the construction site wears adequate personal protective equipment such as helmets, safety glasses, gloves, fire-resistant clothing, safety shoes, and safety harnesses when necessary.

- Periodic inspection and maintenance: Perform technical inspections and periodic maintenance for the drilling rig to ensure that the machinery operates stably and safely.

- Adherence to safety procedures: Understand and adhere to the specific safety procedures set out by the manufacturer and the instructions of the site manager.

- Training and guidance: Ensure everyone working on the site is trained on safe operating procedures and knows how to respond to emergency situations. Complete an occupational safety training course to be issued an occupational safety training center’s occupational safety card to consolidate your records in accordance with regulations when working.

- Monitor working conditions: Monitor and assess environmental factors at work such as weather conditions, terrain, and potential risks to apply effective preventive measures.

- Communication: Promote effective communication among all employees working on the site, especially in exchanging information about safety and updating the work situation.

PART III: Further Reading

1. Group 3 Occupational Safety Test

2. Price Quote for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training document for operating a Piling and Drilling Rig machine

- Slide presentation for occupational safety training when operating a piling and drilling rig

- Multiple choice test on occupational safety when operating a piling and drilling rig