Occupational Safety Training for Helmet Manufacturing

99,000 ₫

Note: The above price is calculated per person and may vary depending on the number of participants in the course and market fluctuations. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in helmet manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness of accident prevention for workers involved in helmet manufacturing.

Table of Contents

Toggle1. Overview of Helmets

a. What is a Helmet?

- A helmet is a personal protective equipment used to minimize the risk of head injuries and trauma caused by impacts, traffic accidents, or activities related to heights. Helmets can be made from various materials but must ensure elasticity, durability, and optimal shock absorption. For motorbike riders, helmets are one of the most important factors to reduce risk in traffic accidents.

- The helmet manufacturing industry is one of the rapidly growing safety material sectors in Vietnam. According to the Ministry of Industry and Trade, in 2020, Vietnam produced approximately 42 million helmets, an increase of nearly 7% compared to 2019. Among them, motorbike helmets accounted for the largest proportion with 36.8 million units, followed by construction helmets with 3.2 million units, and medical device helmets with 2.5 million units.

- Vietnam has several major helmet manufacturing companies, notably NRS Vietnam Co., Ltd, Galaxy Helmets Co., Ltd, HJC Vietnam Co., Ltd, AP Racing Company Limited, Komine Vietnam Co., Ltd, Shiro Helmets factory, and Yakkay Helmets factory.

b. Machinery for Helmet Manufacturing

The machinery used in helmet manufacturing includes:

- Cutting, tearing, and stamping machines: used to cut, tear, and stamp helmet components from materials such as ABS plastic, polycarbonate, fiberglass, etc.

- Heat printing machines: used to print images and logos on helmets.

- Welding and joining machines: used to weld and join helmet components together using materials like ABS plastic, polycarbonate, fiberglass, etc.

- Spray painting machines: used to paint helmet surfaces to create different colors and designs.

- Testing machines: used to check the quality and durability of helmets before being released to the market.

These machines are specifically designed to ensure user safety and achieve high production efficiency.

c. Typical Helmet Manufacturing Companies

Some notable helmet manufacturing companies in Vietnam include:

- Vinh Long Helmets: One of the pioneering companies in the helmet manufacturing industry in Vietnam, with over 20 years of experience, currently the largest helmet manufacturer in Vietnam.

- HJC Helmets: A globally recognized helmet brand, present in Vietnam for many years. HJC Helmets are produced with advanced technology and favored by many motorbike riders.

- Asaki: A helmet brand from Malaysia, popular in Vietnam. Asaki products are manufactured with high quality and reasonable prices.

- Kieu Anh: A Vietnamese helmet brand available in the market for many years. Kieu Anh products are made with modern technology and guaranteed quality.

- LS2 brand: A helmet brand from Spain, present in Vietnam for many years. LS2 products are produced using advanced technology at reasonable prices.

d. Specific Roles in Helmet Manufacturing Factories

Group 1

- CEO, Deputy CEO, and department heads in the helmet manufacturing factory.

Group 2

- Safety officers: manage factory safety, design safety procedures, supervise and ensure employees comply with safe working procedures.

Group 3

- Material preparation: All necessary materials, including ABS plastic, polycarbonate, EPS foam, PVC film, helmet shells, inner linings, and straps, are prepared for the manufacturing process.

- Molding and material processing: Plastic materials are placed into molding machines to create different helmet components, which are then processed for smooth and glossy surfaces.

- Assembly and product finishing: Components are assembled in order to create the finished product. Products are then quality-checked and packaged for shipment to distributors and customers.

- Quality inspection: Products are inspected throughout the production process and before packaging to ensure compliance with safety and quality standards. Non-compliant products are discarded.

- Machine maintenance: Machines in the helmet manufacturing factory are regularly maintained to ensure efficient operation and prevent occupational accidents.

Group 4

- Office, support, sales, and marketing work.

- Quality management, human resource management, materials management, financial and accounting management.

- Production management: ensures smooth factory operations, timely completion of tasks, and adherence to safety and quality standards.

- Feature design: Engineers design helmet features for durability, safety, ventilation, high protection, balance, and aesthetic appeal.

e. Common Helmet Designs in the Market

Currently, there are many helmet designs in the market to suit user needs and preferences. Popular designs include:

- Three-quarter helmets: Larger than half helmets, covering the back of the head. Typically used for cruiser, touring, and chopper motorcycles.

- Half helmets: Protect the top of the head and ears. Commonly used for sports motorcycles.

- Full-face helmets: Cover the entire head, including face and chin. Used for long-distance sport motorcycles or racing bikes.

- Offroad helmets: Designed for off-road vehicles, providing full head protection in challenging terrains.

Other types include bicycle helmets, ear-cover helmets, electric motorbike helmets, children’s helmets, etc.

2. Overview of Occupational Safety Training for Helmet Manufacturing

This article focuses on issues related to Group 3, because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. For information about other groups, see here.

a. What is Group 3 Occupational Safety Training?

- Group 3 occupational safety training consists of sessions that raise awareness and teach workers how to prevent occupational accidents.

- The training course helps workers recognize hazards and avoid risks to minimize workplace accidents.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial safety training

- Total training duration is at least 24 hours, including assessment time.

- 8 hours of theoretical study on safety policies and labor hygiene laws

- 8 hours of theoretical study on basic occupational safety and hygiene knowledge

- 4 hours of theoretical study on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical assessment at the end of the course

The safety training center schedules multiple sessions depending on worker availability. Typically, there are 6 sessions over 3 days, provided the manufacturing company allows continuous training.

Periodic safety training

- Before the occupational safety card expires, workers who want reissuance must undergo periodic occupational safety training for a duration of at least 50% of the initial training duration.

Explanation: The total periodic occupational safety training duration is at least 12 hours, including assessment time. After completing the course and passing the assessment, workers are reissued and have their occupational safety cards extended.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Assessment | |||

| I | Safety policies and labor hygiene laws | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents related to occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations by state authorities on safety and hygiene when building, expanding, or renovating factories, facilities, or inspecting machinery, equipment, materials, and substances requiring strict occupational safety and hygiene. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge about hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies on occupational safety and hygiene; roles and duties of safety networks and officers. | 1 | 1 | ||

| 5 | Occupational safety rules, signs, safety equipment, personal protective equipment; basic first aid and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, and hazardous substances; risk analysis, assessment, and management; safe working procedures with machinery and substances requiring strict occupational safety and hygiene. | 6 | 4 | 2 | ||

| IV | End-of-course safety training assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content for all 6 groups

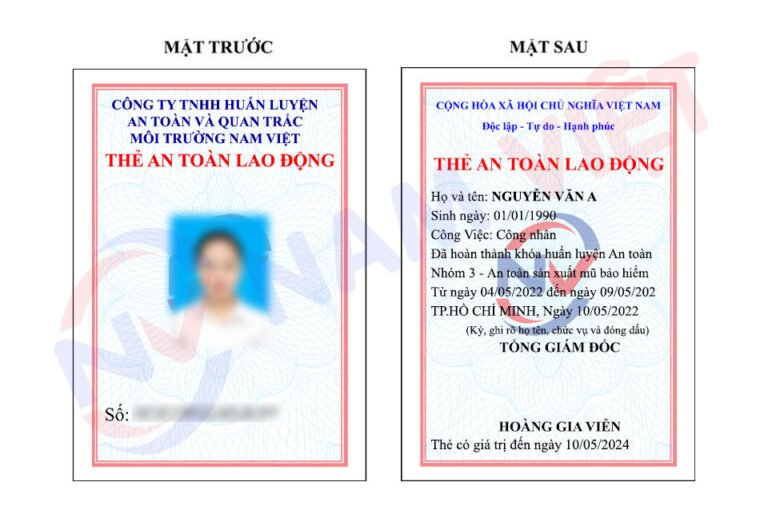

d. Occupational Safety Card

After completing the occupational safety training and passing the assessment, workers are issued a Group 3 occupational safety card (commonly called Group 3 safety certificate).

The card displays information such as full name, date of birth, specific job and working environment, training duration, official seal, and signature confirming completion.

According to regulations on card issuance specified in Clause 2 of Article 24, Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and certify the Group 3 occupational safety card after the worker completes the training and passes the assessment.

- If the worker is freelance or seasonal and does not have a labor contract, the training unit must sign, stamp, and certify the card after the worker completes the training and passes the assessment.

3. Recognizing Hazards for Workers in Helmet Manufacturing

Some hazards that workers in the helmet manufacturing industry may encounter include:

- Noise generated by helmet manufacturing machinery can affect workers’ hearing if proper protective measures are not implemented.

- The risk of piercing or injury while handling cutting, stamping, pressing, and processing tools may occur if production procedures are not followed and proper personal protective equipment is not used.

- Working with materials such as plastic and Kevlar may pose a burn risk if adequate protection is not used.

- Handling helmet components or other materials may cause scratches and foreign objects that could enter workers’ eyes.

- The use of chemicals during production may pose a risk of chemical poisoning if safety measures are not properly followed.

4. Common Occupational Accidents in Helmet Manufacturing

Common occupational accidents during helmet manufacturing may include:

- Hand injuries: Workers may injure their hands when using cutting, bending, or helmet assembly tools.

- Eye injuries: Laser beams and dust can damage eyes, causing cataracts, conjunctivitis, or blind spots.

- Chemical poisoning: Chemicals such as adhesives, solvents, and dyes can cause poisoning when in contact with skin or inhaled.

- Hand lacerations: Workers may cut their hands while using manufacturing tools if safety procedures are not followed.

- Electric shock: Some helmet manufacturing equipment may pose electrical hazards.

- Fire and explosion: Helmet manufacturing often uses flammable materials, so fire and explosion risks are high.

- Hearing damage: Loud sounds from manufacturing machinery can damage hearing or cause hearing loss.

5. Safety Measures for Helmet Manufacturing

To ensure safety for workers in helmet manufacturing, the following safety measures should be applied:

- Workers should be trained in production processes, safe machinery use, equipment handling, and emergency response.

- Workers should be provided with full protective equipment, including helmets, safety glasses, protective sleeves, safety shoes, masks, etc.

- Manufacturing equipment and machinery should be inspected and maintained regularly to ensure worker safety.

- Occupational safety principles must be strictly followed. Work environments should be ventilated, quiet, and free of harmful substances.

- Production procedures must be approved and clearly understood by workers to prevent accidents.

- Product quality control is essential to ensure the safety of end-users.

- Regular safety inspections and health monitoring for workers should be conducted, and results should be documented and stored to ensure ongoing production safety.

- Emergency response plans and procedures should be implemented and trained to ensure safety and stability during production.

- Periodic workplace environmental monitoring in factories should collect and analyze harmful factors for workers, adjusting conditions to reduce risks and prevent occupational diseases.

6. Benefits of Occupational Safety Training in Helmet Manufacturing

An Toan Nam Viet provides your business with the following benefits after completing occupational safety training courses according to Decree 44/2016/ND – CP on Occupational Safety and Hygiene:

- Workers can recognize potential occupational hazards and take preventive measures to avoid accidents.

- Your company can establish risk prevention measures in production, operation, and maintenance processes.

- Reduces costs associated with safety incidents.

- Uninterrupted production increases labor productivity and product quality.

- Compliance with labor safety regulations minimizes legal risks.

- Enhances credibility and professionalism, boosting your company’s brand image.

Nam Viet’s courses help individuals prevent external hazards and avoid injuries or even fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback after Completing Helmet Manufacturing Safety Training

An Toan Nam Viet has years of experience supporting businesses across Vietnam, especially in the southern provinces. Our responsibility to partners is highly valued, which is why our Occupational Safety Training is increasingly professional. Our growth is fueled by positive feedback and suggestions from partner companies. Below are some testimonials from clients we have served.

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service helped us greatly in simplifying occupational safety and completing safety documentation for operations. The consulting team responded promptly to our inquiries. 5 stars for Nam Viet!”

See more customer interviews after using our services at An Toan Nam Viet

8. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality center for occupational safety training in Vietnam today. Safety training sessions are continuously conducted at factories, manufacturing plants, or construction sites nationwide (all 63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Safety under the Ministry of Labor, Invalids and Social Affairs, granting the certificate to operate occupational safety and hygiene training. This further strengthens our occupational safety training capabilities.

Training Materials and Lectures

- Before being included in occupational safety training courses, training materials are reviewed and approved to ensure accuracy and effective knowledge transfer.

- Our instructors’ teaching methods are standardized according to An Toan Nam Viet standards, based on research and best practices in occupational safety and hygiene training to maximize learning effectiveness for participants.

Facilities

- Controlling classroom factors that affect training sessions increases teaching efficiency and knowledge retention.

- Our training facilities provide spacious classrooms meeting standards for area, lighting, and training equipment, etc.

9. Nationwide Reputable Safety Training Center

At An Toan Nam Viet, we prioritize occupational safety training as our core mission. Imparting knowledge to workers so they can protect themselves is a vital contribution to the nation’s workforce development.

To ensure training effectiveness, we meticulously prepare every detail, from tools and teaching devices to curricula, materials, sound, and lighting.

Our occupational safety instructors are experts with years of experience. They have also conducted research to identify hazards across industries and methods to prevent them.

Lectures are practical, vivid, and easy for workers to understand. This enables a comfortable learning experience and effective knowledge absorption, always in compliance with Decree 44/2016/ND-CP.

As a result, workers learn prevention measures and self-protection methods and can apply them appropriately in their daily work.

Our safety training center is proud to provide professional, reputable occupational safety training with the following advantages:

- Competitive training costs without compromising quality.

- Flexible training schedules adapted to company production requirements.

- Quick certification procedures compliant with legal regulations.

- Instructors with extensive industry experience.

- Classrooms optimized for effective teaching and knowledge retention.

- Training content tailored to enterprise occupational safety needs.

- An Toan Nam Viet works dedicatedly and professionally to provide precise and fast support to clients.

10. Additional References for Helmet Manufacturing Safety Training Materials

- Helmet Manufacturing Occupational Safety Materials

- Complete Occupational Safety Training Materials

- Occupational Safety Training Test Materials

- Helmet Manufacturing Occupational Safety Quiz

- Helmet Manufacturing Occupational Safety Training Slides

1 review for Occupational Safety Training for Helmet Manufacturing

No comments yet

namchinh.haiphong341

Triển khai nhanh gọn và chu đáo, tôi rất hài lòng!