Safety shoes

Choosing the Right Industrial Safety Shoes: Tips and Guidelines

In a hazardous work environment, choosing the right safety shoes can determine your safety. This article will reveal the secrets to help you choose intelligently and effectively, so you can always protect yourself every day.

I. Introduction to the importance of safety shoes in the work environment

Safety shoes play an extremely important role in ensuring the safety and protecting the health of workers in the work environment. Specially designed to meet specific safety requirements, safety shoes not only help prevent workplace accidents but also minimize the risk of injury to the feet and other parts of the body.

In many work environments, workers often face hazardous elements such as falling heavy objects, slippery liquids, cuts, or strong impacts. Safety shoes are designed with hard, quality materials, penetration-resistant soles, and linings that keep the foot stable, helping to protect against injuries that can occur in hazardous work environments. Furthermore, safety shoes often come with a steel toe cap or similar material to protect against cutting or impact hazards.

In addition to directly protecting the feet and preventing slips, safety shoes can also help prevent direct contact with toxic chemicals, grease, or irritating liquids. They are an important part of personal protective equipment to ensure a safe work environment, helping to reduce the risk of injury in many different types of jobs.

II. Classification of safety shoe types and how to choose based on specific jobs

When it comes to choosing the right type of safety shoes, this process requires careful consideration, based on the specific job you are performing. In reality, there are many different types of safety shoes, designed to meet specific requirements and hazards in the work environment.

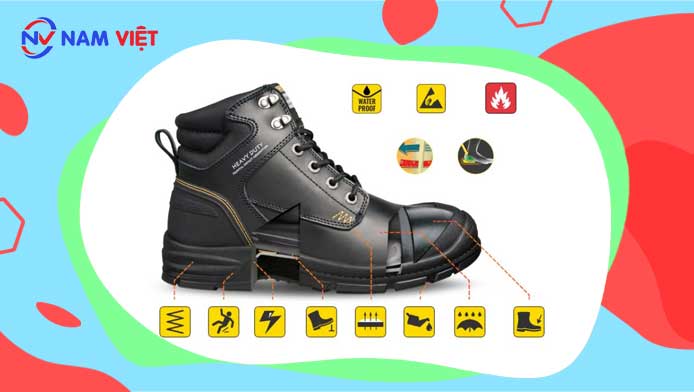

- Puncture-resistant safety shoes: Equipped with a steel plate in the sole, they help protect feet from penetration hazards from heavy objects or sharp items. This is a good choice for work in the construction industry, working with hard materials.

- Slip-resistant shoes: Have slip-resistant rubber soles, suitable for people working in environments with a risk of slipping and falling, such as kitchens or the food service industry.

- Chemical-resistant shoes: Made from chemical-resistant material, they protect against contact with toxic chemicals and grease. Suitable for work in the chemical or oil and gas industries.

- Heat-resistant shoes: Designed to withstand high temperatures, suitable for workers working near fire or in hot environments.

- Special safety shoes for electrical work: Are insulated and help protect workers against the risk of electric shock. Especially important in the electrical industry.

- Steel-toe safety shoes: Have a force-resistant steel toe, helping to protect toes from impacts. Often used in the construction industry.

- Anti-static shoes: Prevent static build-up in work environments such as electronics manufacturing or working near computers.

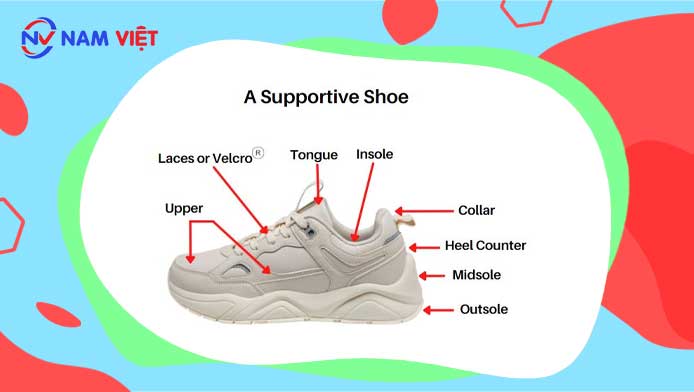

III. Learn about important factors such as material, sole, and protective features

To ensure occupational safety, the choice of safety shoes must be based on many important factors. Below are the factors to consider when choosing safety shoes, and all of them are related to occupational safety training:

- Material: The type of material the shoe is made from is very important. The material must be suitable for the work environment and specific hazards. For example, in the chemical industry, chemical-resistant material is essential. Meanwhile, people working in the construction industry may need puncture-resistant or waterproof safety shoes.

- Sole: The type of sole plays an important role in reducing the risk of slipping and increasing grip. Safety shoes often have slip-resistant rubber soles. For those working in environments needing protection from nails or sharp metal, a penetration-resistant sole is a good choice.

- Protective features: Some special protective features may include a steel toe, puncture-resistant sole, electrical insulation, or heat resistance. This ensures that the shoes can meet the specific hazards that workers may face.

IV. Explaining why choosing the right size and comfort is so important

Size and comfort are two important factors when choosing safety shoes in any work environment, and they are closely related to occupational safety certification.

Size: Choosing shoes with the appropriate size is a crucial part of ensuring that workers can complete their jobs safely. Shoes that are too small can cause a tight feeling, lead to foot pain, and affect the ability to move naturally. Conversely, shoes that are too large can cause slips and a risk of falling. Precision in measuring the size and choosing the right shoe helps workers remain stable and confident during work.

Comfort: Comfort is another important factor for occupational safety certification. Workers often have to wear shoes for long periods in the work environment. If the shoes are not comfortable, they can become tired, have difficulty concentrating, and experience reduced work performance. Comfort not only affects the health and morale of workers but also ensures they follow safety rules and perform safety procedures correctly.

V. Guide to inspecting and maintaining safety shoes to ensure optimal performance

To ensure safety shoes are always reliable and perform at their best, inspection and maintenance are crucial. They help reduce the risk of workplace accidents and keep workers safe.

Inspecting Safety Shoes:

- External check: First, visually inspect the shoes to determine if there is any damage. Check for any cracks, tears, or damage on the shoe’s surface.

- Check the sole: Ensure the sole is still in good condition and not slipping or worn out. This is an important part of ensuring safety when moving on slippery surfaces.

- Check laces and fasteners: If the shoes have laces or fasteners, check if they are broken or weak. Laces and fasteners must be kept tight to ensure the shoes remain secure.

Maintaining Safety Shoes:

- Clean and dry: After use, wipe the shoes clean and let them air dry. This helps prevent rot and increases the shoe’s lifespan.

- Store properly: Keep the shoes in a dry, cool place and avoid direct sunlight. Keep the shoes in a safe place, avoiding impacts or dirt.

- Store in the correct shape: To prevent safety shoes from losing their shape, they should be stored properly and not be deformed or crushed.

VI. Presenting safety standards and how they apply to shoe selection

Understanding safety standards is a crucial factor when choosing safety shoes. Safety standards define the requirements and benchmarks that safety shoes must follow to ensure safety and effectiveness. Here are some important safety standards and how they apply to choosing shoes:

1. ASTM Standards (American Society for Testing and Materials): This standard specifies requirements for the material, design, and performance of safety shoes, such as waterproof shoes, oil-resistant shoes, puncture-resistant shoes, and many other types. Check if the shoes you choose comply with the appropriate ASTM standard for your job.

2. ANSI Standards (American National Standards Institute): The ANSI standard specifies requirements for the impact and electrical shock resistance of safety shoes. If you work in an environment with a risk of impact or electrical shock, look for shoes that comply with ANSI standards.

3. OSHA Standards (Occupational Safety and Health Administration): OSHA regulates requirements for safety shoes in many industries and jobs. This includes requirements for soles, slip-resistant materials, anti-static properties, and many other aspects.

4. ISO Standards (International Organization for Standardization): ISO standards specify requirements for the quality and performance of safety shoes. They define how to measure soles, water resistance, and many other criteria.

Understanding these standards and how they apply to your job is important to ensure you are choosing suitable and reliable safety shoes. Always learn about the specific safety requirements of your job and make sure the shoes you choose meet all relevant standards.

VII. Providing some tips and resources for smart safety shoe shopping

To make an intelligent decision when shopping for safety shoes, here are some helpful suggestions and resources you should consider:

1. Research Reputable Brands: Before buying safety shoes, you should research reputable and well-known brands in the industry. Brands like Timberland PRO, Carhartt, Red Wing, and Caterpillar often provide quality products. Their official websites usually have detailed product information and user reviews.

2. Occupational Safety Training Programs: If you participate in an occupational safety training program, take the opportunity to learn about safety shoes. Ask the instructor or expert about the types of shoes suitable for your job.

3. Check Reviews and Comments: Look for websites or online stores that specialize in safety shoes. Read reviews and comments from other users about specific products. This helps you understand more about the actual performance of the shoes and if they are suitable for your job.

4. Consult Government Guidance Materials: Government agencies and occupational safety organizations often provide guides and instructions on selecting safety shoes. The website of the Occupational Safety and Health Administration (OSHA) or a similar organization in your country is an important resource.

5. Discuss with Colleagues: If you work in a specific industry, talk to experienced colleagues. They can provide useful information about the types of shoes they have used and that have proven suitable for the job.

VIII. Occupational Safety Training Capability of An Toan Nam Viet

An Toan Nam Viet is a center specializing in occupational safety training (in many different languages such as English, Chinese, Japanese, Korean….) that is reputable and high-quality in Vietnam today. With occupational safety training sessions held continuously at factories, plants, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected and certified by the Department of Safety of the Ministry of Labor – Invalids and Social Affairs as eligible to conduct occupational safety and health training activities. This further strengthens our capability in occupational safety training.

Documents and lectures

- Before occupational safety training materials are used in OSH training courses, they are reviewed and censored to ensure that the lectures are always factually correct and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet’s teaching standards, which is a method that experts in occupational safety and health training have researched and consolidated during the teaching process to bring the highest knowledge acquisition efficiency for trainees.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching efficiency and the effectiveness of knowledge acquisition for trainees.

- Our facilities supporting the training course always provide spacious classrooms that meet standards for area, lighting, training equipment …etc…

IX. Nationwide occupational environment monitoring center

Nam Viet’s occupational environment monitoring center is a professional unit specializing in monitoring and measuring the quality of the working environment across all provinces in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICES

In addition to providing monitoring services, the center also supports customers in planning, handling, and tracking occupational environment issues. With the motto “the customer is the center,” we always bring customer satisfaction, meet all customer needs, and commit to providing the best solutions for businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of occupational environment monitoring in Ho Chi Minh City with the following objectives:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable things possible.

- Along with a team of Masters and Engineers with rich experience and expertise, we desire to protect the environment and bring benefits to businesses.

- Coming to Nam Viet’s Environmental Monitoring team, your company will receive professional service with experts in the monitoring field. At the same time, you will get the best cost incentives.

The process of conducting occupational environment monitoring at Nam Viet includes the following basic steps:

- Before conducting occupational environment monitoring, our company always ensures that machinery and equipment for monitoring are calibrated and verified according to legal regulations.

- Correctly and fully implement the occupational environment monitoring process as committed to the Department of Health.

- Truthfully report the occupational environment monitoring results to the employer.

- In case the occupational environment monitoring results do not ensure safety for employees, Nam Viet company will support proposing remedial solutions, and the labor establishment will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health check-ups for early detection of occupational diseases and work-related illnesses for employees in positions with unsecured working environments.

- Provide in-kind benefits to employees according to labor laws.