Occupational Safety Training for Silk Manufacturing

99,000 ₫

Note: The above price is calculated for one person and may vary depending on the number of participants in the course and market fluctuations. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in silk manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness among workers on how to prevent work accidents when participating in silk manufacturing.

Table of Contents

Toggle1. Overview of Silk

a. What is Silk?

- Silk is a fiber produced by silkworms, insects belonging to the Bombycidae family. Silk fibers are generated from the silk glands of silkworms. They are strong, elastic, and smooth, serving as the main material for producing textile products such as traditional dresses, skirts, clothing, and many other fashion items. Silk is considered the finest fiber and has a higher economic value compared to other natural fibers.

- Silk is a rare product obtained from silkworm fibers. It has high luster and strength, used for high-end fashion products such as traditional dresses, skirts, scarves, and handicrafts.

- In Vietnam, silk production is mainly concentrated in regions with a long tradition of sericulture such as Ha Nam, Thanh Hoa, Nghe An, Binh Dinh, Ninh Thuan, Lam Dong, Binh Thuan, Kon Tum, and Dak Lak. Vietnamese silk products are highly appreciated for their quality and exported to markets including Europe, the United States, Japan, and South Korea.

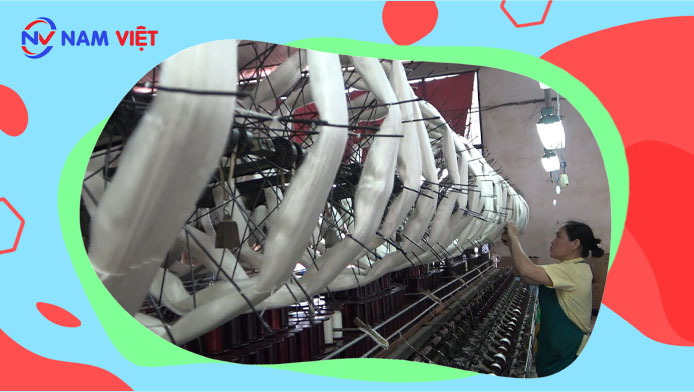

b. Machinery for Silk Production

The silk production process involves multiple stages such as dyeing, washing, pressing, winding, and finally weaving into products. Therefore, the following machinery and equipment are used:

- Silk washing and pressing machines: used to wash and press silk to remove impurities and water.

- Silk winding machines: used to wind silk into rolls for easier use in weaving.

- Silk weaving machines: used to weave silk into products such as scarves, clothes, and fabrics.

- Silk dyeing machines: used to dye silk before weaving.

However, the use of machinery and equipment in silk production must also ensure worker safety. Protective measures such as wearing personal protective equipment, following operational and maintenance procedures, and properly inspecting and repairing machines must be observed.

c. Notable Silk Producers in Vietnam

Some notable silk producers in Vietnam include:

- Vietnam Silk Corporation (Vilisco): one of the leading silk producers in Vietnam with over 20 years of industry experience. Vilisco is headquartered in Hanoi and has several branches in other provinces.

- Van Phuc Silk Village: a traditional village famous for silk production in Hanoi. With over 1,000 years of history, Van Phuc has become an attractive destination for visitors interested in traditional culture and high-quality silk products.

- Thai Tuan Silk: founded in 1990, Thai Tuan Silk is one of the leading companies in the production and trading of silk products in Vietnam.

- Phuoc Loc Tho Silk: a prominent silk producer in Binh Dinh province. Established in 1980, the company has become a trusted and popular brand.

- Asia Silk (To Tam A Chau): founded in 2003, Asia Silk is one of the leading companies in silk production and trading in Vietnam, particularly in Nghe An province.

d. Specific Jobs in Silk Production Plants

Group 1

- Executive Director, Deputy Executive Director, Department Heads in silk production plants.

Group 2

- Safety officers: manage safety within the plant, design safety procedures, monitor, and ensure staff compliance with safe working protocols.

Group 3

- Silk collection: typically performed by gathering wild silkworms or raising them under controlled conditions.

- Silk extraction: silk is extracted from silkworm cocoons using machines or manually.

- Silk processing: after extraction, silk is processed to remove impurities and dirt. The fibers are then used to create products such as clothing, skirts, scarves, etc.

- Silk fabric production: processed silk is woven into fabrics using machines or manual methods.

- Product finishing: after fabric production, further steps like cutting, sewing, and decorative finishing are applied.

Group 4

- Office, support, sales, and marketing jobs.

- Production management, quality management, human resources, material management, accounting and finance management.

- Research and development of new products, product design, and packaging design.

2. Overview of Labor Safety Training for Silk Production

In this article, we focus on Group 3 because Group 3 directly participates in production and faces the highest occupational safety risks. Refer to other groups here.

a. What is Group 3 Labor Safety Training?

- Group 3 labor safety training consists of sessions that equip workers with awareness on preventing occupational accidents.

- The training helps workers recognize and avoid hazards, reducing the risk of workplace accidents during work.

REGISTER FOR LABOR SAFETY TRAINING SERVICE

b. Training Duration

Initial Safety Training

- Total training duration is at least 24 hours, including examination time.

- 8 hours theoretical on policies and occupational safety laws

- 8 hours theoretical on basic occupational safety and hygiene knowledge

- 4 hours theoretical on specialized training content

- 2 hours practical on specialized content

- 2 hours final theory examination

The training center schedules sessions according to workers’ availability. Typically, there are 6 sessions over 3 days if the company can arrange continuous training time.

Periodic Safety Training

- Before the labor safety card expires, workers must undergo periodic labor safety training if they want a card renewal. The periodic training duration must be at least 50% of the initial training duration.

Explanation: the total duration of periodic labor safety training is at least 12 hours, including examination. Upon completion and passing the test, workers will receive a renewed labor safety card.

c. Training Content

| No. | TRAINING CONTENT | DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Policies and occupational safety laws | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents regarding occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations from state management agencies on safety, hygiene when constructing, expanding, or renovating facilities, using and maintaining machinery and materials with strict safety requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; policies on occupational safety and hygiene; roles of safety network personnel. | 1 | 1 | ||

| 5 | Safety regulations, signs, instructions, using protective equipment, first aid skills, and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, devices, hazardous substances; risk assessment and management; safe working procedures for machines, devices, and materials with strict safety requirements. | 6 | 4 | 2 | ||

| IV | Final safety training assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content for all 6 groups

d. Labor Safety Card

After completing the training and passing the test, workers will receive a labor safety card (commonly called Group 3 labor safety certificate).

The Group 3 card clearly shows the worker’s name, date of birth, specific job and working environment, training duration, official stamp, and signature confirming training completion.

According to Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the worker has an employment contract with the employer, the employer must sign, stamp, and validate the card for the Group 3 trainee after completing training and passing the test.

- If the worker is freelance or temporary without a contract, the training unit must sign, stamp, and validate the card after completing training and passing the test.

3. Identifying Hazards Affecting Workers in Silk Production

The silk production process involves several potential hazards, particularly concerning the health of workers. The hazards affecting workers during silk production may include:

- During silk production, workers may be exposed to various chemicals such as potassium hydroxide, sulfuric acid, ammonia, acetic acid… These chemicals can cause irritation to the skin, eyes, respiratory tract, and pose health risks if not handled properly.

- Workers are exposed to high temperatures, especially during the silk boiling stage. Without proper protective equipment, workers may suffer severe burns.

- Silk production involves separating silkworm pupae and silk fibers, so workers may come into contact with dust and silk fibers. Prolonged inhalation of dust and fibers can cause headaches, breathing difficulties, and allergic reactions.

- Workers must operate various equipment and machinery, including cutting machines, crushing machines, weaving machines, and dyeing equipment. Improper use or lack of protective equipment can create safety hazards.

- If electrical equipment in the factory is not regularly maintained, properly insulated, or waterproofed, it can pose an electrocution risk to workers during production.

4. Common Occupational Accidents in Silk Production

During silk production, workers may encounter the following occupational accidents:

- Cutting accidents: Certain stages of silk production require knives to separate silk from wild silkworm cocoons. Improper use, lack of guards, or unsafe handling can lead to unfortunate accidents.

- Machinery accidents: Workers use various machines such as silk weaving machines, winding machines, and air blowers. Failure to follow safety regulations may result in occupational accidents.

- Chemical accidents: Workers handle chemicals such as sulfuric acid, hydrochloric acid, and acetic acid. Without protective equipment or adherence to safety procedures, workers may suffer harmful chemical injuries.

- Hazardous waste accidents: Silk production generates hazardous waste such as toxic gases and contaminants. Improper management or disposal can harm workers’ health.

5. Safety Measures for Silk Production

Silk production requires careful attention and specialized skills. To ensure worker safety, the following safety measures should be applied:

- Use personal protective equipment (PPE) such as respirators, gloves, safety glasses, helmets, breathing tubes, and work uniforms to protect workers’ health during operations.

- Ensure electrical safety and fire prevention: regularly inspect electrical equipment, supply power according to regulations, check and clean gas supply equipment periodically, and store chemicals in dry, ventilated areas to prevent fire hazards.

- Use machinery and equipment correctly and safely: Production staff must receive full training on proper machine operation, adhering to labor safety regulations.

- Closely monitor production processes: Production procedures should be supervised to promptly detect errors and ensure worker safety.

- Regularly inspect and maintain equipment and machinery: Ensure machinery operates safely and efficiently by performing regular checks, maintenance, and repairs as needed.

- Train employees: Staff should be trained on labor safety to understand regulations and safety measures during silk production.

- Apply labor safety regulations: National labor safety rules should be fully implemented, including working hours, safe and clean work environments, and proper ventilation.

- Periodically conduct workplace environmental monitoring in factories, collecting and analyzing hazardous factors, then adjust to reduce risks to prevent occupational diseases for workers.

6. Benefits of Labor Safety Training in Silk Production

An Toan Nam Viet provides the following benefits to enterprises upon completing labor safety training in accordance with Decree 44/2016/ND – CP on occupational safety and hygiene for companies and enterprises:

- Workers can identify potential risks of occupational accidents and take preventive measures to avoid them.

- Enterprises can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs associated with safety incidents at work.

- Uninterrupted production increases labor productivity and product quality.

- Comply with labor safety laws, avoiding legal risks.

- Enhance enterprise reputation and professionalism, strengthening brand value.

Nam Viet’s training programs serve as solutions to prevent and mitigate external hazards for individuals, helping them avoid injuries or even fatal accidents.

REGISTER FOR LABOR SAFETY TRAINING SERVICE

7. Customer Feedback After Completing Silk Production Safety Training

An Toan Nam Viet has many years of experience supporting enterprises across Vietnam, particularly in southern provinces. This responsibility is extremely valuable to Nam Viet, which is why our Labor Safety Training programs are increasingly professional. Our growth is driven by positive feedback and suggestions from businesses. Below are some testimonials from our partners:

See more customer interviews after using our services at An Toan Nam Viet

8. Labor Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality labor safety training center in Vietnam. Our training sessions are conducted continuously at production workshops, factories, or construction sites across the country (all 63 provinces of Vietnam).

REGISTER FOR LABOR SAFETY TRAINING SERVICE

Labor Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Labor Safety under the Ministry of Labor – Invalids and Social Affairs, granting certification for occupational safety and hygiene training. This further strengthens our labor safety training capacity.

Materials and Lectures

- Before being used in labor safety training courses, training materials are reviewed to ensure knowledge accuracy and practical effectiveness.

- Instructors follow standardized teaching methods of An Toan Nam Viet, developed by occupational safety experts to maximize knowledge retention for trainees.

Facilities

- Controlling classroom factors that affect training enhances teaching efficiency and knowledge absorption.

- Our training facilities include spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Labor Safety Training Center

At An Toan Nam Viet, labor safety training is our top priority. Teaching workers to protect themselves is a contribution to national development.

We meticulously prepare every detail for effective training, from tools and teaching equipment to materials, sound, and lighting.

Our instructors are experienced experts, often with research on identifying hazards across industries and prevention methods.

Lectures are practical, vivid, and easy to understand, ensuring comfortable and effective learning, strictly aligned with Decree 44/2016/ND-CP.

Workers learn preventive measures and self-protection, applying them effectively in real work situations.

Our training center is proud to provide professional, reputable labor safety training with the following advantages:

- Competitive training costs with guaranteed quality.

- Flexible training schedule adapted to company production.

- Fast, legal certification process for labor safety training.

- Experienced instructors with long-term expertise.

- Classrooms controlled to enhance teaching efficiency and knowledge absorption.

- Lectures tailored to enterprise labor safety requirements.

- Dedicated, professional support for clients promptly and accurately.

10. Additional References for Silk Production Labor Safety Training

- Silk Production Labor Safety Materials

- Labor Safety Training Material Set

- Labor Safety Training Test Set

- Silk Production Labor Safety Quiz

- Silk Production Labor Safety Training Slides

1 review for Occupational Safety Training for Silk Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ huấn luyện an toàn lao động rất tốt nhé, giảng viên dạy rất sinh động dễ hiểu!