Occupational Safety Training for Operating Double-Sided Glue Rolling Machines

99,000 ₫

Note: The above price is calculated for one person and may vary depending on the number of trainees participating in the course and market fluctuations. For more accurate pricing information, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue when operating a double-sided glue rolling machine and must be addressed promptly to ensure workers’ health and safety, as well as enhance the reputation of businesses here. The Occupational Safety Training course is one of the effective solutions to raise awareness on how to prevent workplace accidents for workers when operating a double-sided glue rolling machine.

Table of Contents

Toggle1. Overview of the Double Sided Automatic Wood Glue Spreading Machine

a. What is a Double Sided Automatic Wood Glue Spreading Machine?

The Double Sided Automatic Wood Glue Spreading Machine is equipment used in the wood processing industry to automatically apply glue or adhesive on both sides of wooden materials. This machine is commonly applied in the production processes of furniture, wooden doors, plywood, and other wood products.

Structure:

- Conveyor Belt: Feeds the wooden boards into the glue spreading area and out after completion.

- Glue Tank: Stores glue and can be adjusted to control the amount of glue dispensed.

- Glue Rollers: Rollers responsible for applying glue to the surface of the wooden boards. Some machines have rollers for both sides of the boards.

- Adjustment System: Allows adjustment of glue layer thickness and machine operating speed.

b. Operating Principle of the Double Sided Automatic Wood Glue Spreading Machine

The operating principle of the Double Sided Automatic Wood Glue Spreading Machine is to automate the glue application process on both sides of wooden boards to ensure uniformity and efficiency in bonding. Below is a detailed description of how this machine operates:

Material Feeding

- Receiving Conveyor: Wooden boards are placed onto the machine’s conveyor. This conveyor can usually be adjusted in speed to match the production process.

Glue Supply

- Glue Tank: The machine has a glue tank where glue is stored and maintained at a stable temperature and viscosity.

- Pumping System: Glue is pumped from the tank to the rollers via supply tubes.

Glue Application

- Glue Rollers: The machine has two sets of glue rollers, each dedicated to one side of the wooden board. These rollers are usually made of stainless steel or coated with special materials to prevent glue from sticking and to allow easy cleaning.

- Upper Roller: Applies glue to the top surface of the board as it passes through.

- Lower Roller: Applies glue to the bottom surface of the board as it passes through.

- Glue Amount Adjustment System: Rollers typically have adjustments to control the glue amount applied, ensuring a uniform and precise glue layer.

Board Processing

- Glue Layer Thickness Adjustment: Some machines can adjust the glue layer thickness to meet product requirements.

- Processing: After glue application, boards continue to subsequent stages such as joining, pressing, or drying to complete the production process.

Product Output

- Output Conveyor: After glue application, boards are delivered out via the output conveyor, ready for the next steps in the production process.

Automation and Control

- Control Panel: The machine usually has a control panel to adjust parameters such as conveyor speed, glue amount, and glue layer thickness.

- Sensors: Some machines are equipped with sensors to monitor and automatically adjust factors like glue amount and speed to ensure product quality.

c. Industries Using the Double Sided Automatic Wood Glue Spreading Machine

Wood Processing Industry

- Furniture Production: The double sided glue spreading machine is essential in producing furniture such as tables, chairs, cabinets, and shelves. Even glue application on both sides of boards enhances adhesion and ensures product quality.

- Wooden Door Production: In wooden door manufacturing, the machine bonds wooden layers or frames, creating highly durable doors with guaranteed quality.

Plywood and Veneer Industry

- Plywood: Used to apply glue to both sides of wooden layers during plywood production, ensuring even glue distribution for durable, high-quality plywood products.

- Veneer: Similar to plywood, the machine applies glue to layers in veneer production, ensuring strong adhesion between layers.

Industrial Wood Processing

- Household Products: Used in producing household wood products such as kitchen cabinets, bookshelves, and other wooden items, ensuring adhesion and durability.

- Industrial Wood Production: Factories producing MDF, HDF, and other engineered wood boards use this machine in their processes.

Construction and Architecture

- Building Material Production: Used to create high-quality wooden products for the construction industry, such as laminated boards for structures or decorative materials.

Handicrafts and High-End Wooden Products

- Handicraft Products: Helps produce intricate and high-quality wooden handicrafts, ensuring durability and aesthetics.

2. Overview of the Safety Training Course for Operating the Double Sided Automatic Wood Glue Spreading Machine

a. What is Occupational Safety Training?

- Occupational safety training for operating the double sided glue spreading machine equips workers with awareness of accident prevention. Workers who work directly with this machine fall under Group 3.

- The safety training course helps workers identify and avoid hazards, minimizing the risks of workplace accidents.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial safety training duration:

- Total training time is at least 24 hours, including testing time.

- 8 hours of theory on safety and occupational hygiene laws and policies.

- 8 hours of theory on basic occupational safety and hygiene knowledge.

- 4 hours of theory on specialized training content.

- 2 hours of practice on specialized training content.

- 2 hours of theory testing at the end of the course.

The safety training center will schedule multiple sessions depending on worker availability. Typically, there are 6 training sessions over 3 days, provided continuous learning time is arranged by the company.

Periodic safety training:

- Before the occupational safety card expires, workers must attend a periodic occupational safety training course. The periodic training duration must be at least 50% of the initial training duration.

Explanation: The total duration of periodic occupational safety training is at least 12 hours, including testing. After completing and passing the test, the safety card will be renewed.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Safety and Occupational Hygiene Laws and Policies | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of safety and occupational hygiene standards and technical regulations. | 1 | 1 | ||

| 3 | Specific regulations from state management agencies on safety and occupational hygiene for new construction, expansion, or renovation of facilities for producing, using, storing, or maintaining machinery, equipment, materials, and substances with strict safety requirements. | 1 | 1 | ||

| II | Basic Occupational Safety and Hygiene Knowledge | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; safety and occupational hygiene policies for workers; functions and duties of the safety and hygiene network. | 1 | 1 | ||

| 5 | Occupational safety and hygiene rules, signs, and instructions; use of safety equipment and personal protective equipment; first aid skills for workplace accidents; prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized Training Content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, and substances generating hazardous and harmful factors; risk analysis, assessment, and management in occupational safety and hygiene; safe work procedures with machinery, equipment, and substances requiring strict safety and hygiene measures. | 6 | 4 | 2 | ||

| IV | Final Safety Training Test | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more about the training content for the 6 groups

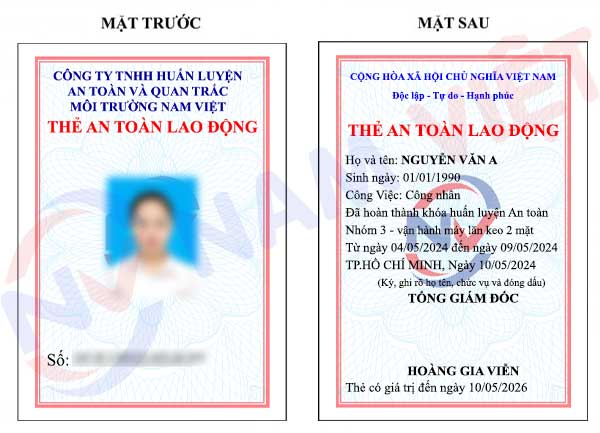

d. Occupational Safety Card

After completing the occupational safety training and passing the test, the worker will be issued an occupational safety card (commonly known as a Group 3 Safety Certificate).

This Group 3 safety card will clearly display information such as full name, date of birth, job, and specific work environment. It will also include training duration, official stamp, and signature confirming completion.

According to regulations specified in Clause 2 of Article 24 of Decree 44/2016/NĐ-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and seal the safety card for Group 3 trainees after completing the course and passing the test from the training unit.

- If the worker is a freelancer, seasonal worker, or does not have a labor contract, the training unit must sign, stamp, and seal the safety card after the trainee completes the course and passes the test.

1. Dangerous factors for workers when operating a creasing machine

Risks from rotating and moving parts

- Entanglement risk: Rotating parts such as the creasing rollers can catch clothing, gloves, or hair, leading to entanglement and injury.

- Shearing or cutting hazard: The machine’s blades and rollers can cause cuts or lacerations if the operator’s hands or other body parts come into contact with them.

- Crushing hazard: The pressure and force from the rollers can crush body parts caught in the machine.

Electrical risks

- Electric shock: Faulty wiring, damaged insulation, or exposure to wet conditions can lead to electrical shocks.

- Short circuit or fire: Overloading or poor maintenance may cause electrical malfunctions, short circuits, or fires.

Ergonomic risks

- Repetitive strain injury: Continuous repetitive motions without proper ergonomics can cause musculoskeletal disorders.

- Improper posture: Standing or working in awkward positions for extended periods may lead to back, neck, or shoulder pain.

No comments yet

Review Occupational Safety Training for Operating Double-Sided Glue Rolling Machines

There are no reviews yet.