Occupational Safety Training for Operating Cement Crushers

99,000 ₫

Note: The above price is calculated per person and may vary depending on the number of trainees participating in the course and market fluctuations. For more accurate pricing support, please refer to the pricing list or contact our consulting staff directly.

Occupational safety is an important issue when operating cement grinding machines and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses here. The Occupational Safety Training is one of the effective solutions to raise awareness on how to prevent occupational accidents for workers operating cement grinding machines.

Table of Contents

Toggle1. Overview of the Cement Grinding Machine

a. What is a Cement Grinding Machine?

The cement grinding machine (Cement Ball Mill Grinding machine) is a device used in the cement production process to grind and mix raw materials to produce cement powder. This equipment usually includes a grinding box with rotating blades and steel balls or rods inside.

When the raw materials are fed in, the steel balls or rods move inside the grinding box and grind the materials into fine powder. This process increases the contact surface area between particles, producing a more uniform and finer cement powder that meets the requirements of the cement manufacturing process.

b. Operating Principle of the Cement Grinding Machine

The operating principle of the cement grinding machine is based on the principles of friction and impact forces to grind and mix raw materials into cement powder.

Below are the basic steps of the cement grinding machine operation:

- Loading raw materials: Materials such as clinker, additives, and grinding materials are loaded into the machine through one or more input ports.

- Grinding and mixing: The materials are ground and mixed inside the grinding box using rotating blades and steel balls or rods. The blades generate friction and impact forces between the raw material particles and the steel balls or rods, grinding them into fine powder.

- Particle size control: By controlling the rotation speed of the grinding box and the size of the sieve holes, the particle size of the produced cement powder can be adjusted.

- Discharging the product: After grinding and mixing thoroughly, the cement powder is discharged from the grinding machine through an output port.

- Quality control: The grinding and mixing process is usually controlled automatically or manually to ensure the quality and efficiency of the final product.

Through these steps, the cement grinding machine helps produce high-quality cement powder necessary for construction and infrastructure projects.

c. Requirements for Workers Before Operating the Cement Grinding Machine

- Training and education: Workers need to be trained on the operating procedures of the cement grinding machine, including safe operation and accident prevention measures.

- Understanding machinery: They need basic knowledge about how the cement grinding machine works, including how to use its parts, inspect conditions, and basic troubleshooting methods.

- Mental and physical health: Workers must ensure they have adequate mental and physical health to perform the job safely and effectively.

- Time management skills: Operating the cement grinding machine may require effective time management to ensure tasks are performed correctly and on schedule.

- Quick reflexes: In case of incidents or unexpected situations, workers need the ability to react quickly and correctly to handle and minimize accident risks.

- Knowledge of occupational safety: They need to understand basic occupational safety measures and how to apply them when working with the cement grinding machine.

- Focus and carefulness: Operating the cement grinding machine requires high concentration and caution to avoid unwanted accidents.

- Teamwork skills: In some cases, operating the machine may require teamwork, so workers must be able to work effectively in a group environment.

2. Overview of Safety Training for Operating the Cement Grinding Machine

a. What is Occupational Safety Training?

- Occupational safety training for operating the cement grinding machine consists of sessions that equip workers with awareness on how to prevent occupational accidents. Workers directly involved with the cement grinding machine belong to Group 3.

- The safety training course helps workers recognize and avoid hazards, reducing risks of occupational accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial safety training duration:

- Total training time is at least 24 hours, including exam time.

- 8 hours of theory on policies and laws related to occupational safety and hygiene.

- 8 hours of theory on basic knowledge of occupational safety and hygiene.

- 4 hours of theory on specialized training content.

- 2 hours of practical training on specialized content.

- 2 hours of theory exam at the end of the course.

The safety training center will schedule training sessions depending on workers’ availability. Typically, there are 6 sessions held over 3 days, provided the company arranges continuous learning time.

Periodic safety training duration:

- Before the occupational safety card expires, workers must undergo periodic safety training lasting at least 50% of the initial safety training duration to renew their card.

Explanation: The total time for periodic occupational safety training is at least 12 hours, including exam time. After completing the periodic training and passing the exam, workers will have their occupational safety cards reissued or extended.

c. Training Course Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Exam | |||

| I | System of policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the legal documents system on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene in construction, expansion, or renovation of works and facilities for production, use, storage, and inspection of machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies and regimes on occupational safety and hygiene for workers; functions and duties of safety and hygiene staff. | 1 | 1 | ||

| 5 | Occupational safety rules, signs, instructions, use of safety equipment and personal protective equipment; skills in first aid for occupational accidents and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge about types of machines, equipment, substances generating hazardous and harmful factors; risk analysis, evaluation, and management of occupational safety and hygiene; safe working procedures with machines, equipment, and substances requiring strict safety and hygiene. | 6 | 4 | 2 | ||

| IV | Safety training final exam | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more about training content of 6 groups

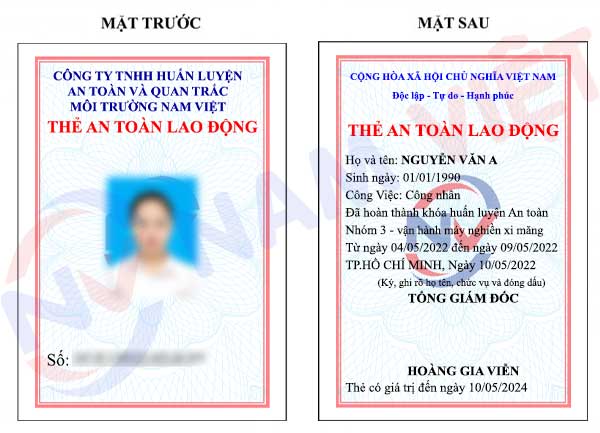

d. Occupational Safety Card

After completing the occupational safety training course and passing the exam, workers will be issued an occupational safety card (commonly called the occupational safety certificate for Group 3).

The Group 3 safety card clearly displays information such as full name, date of birth, specific job and work environment. It also includes training duration, an official red stamp, and a signature confirming course completion.

According to regulations on issuing safety cards stated in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and endorse the safety card for Group 3 workers after they complete training from an occupational safety training unit and pass the exam.

- If the worker is freelance, seasonal, or does not have a labor contract, the training unit must sign, stamp, and endorse the safety card after the worker completes training and passes the exam from the occupational safety training unit.

3. Hazards for Workers When Operating Cement Grinding Machines

- Risk of Collision and Crushing: Cement grinding machines have fast-moving parts such as rotors, blades, and other components that can cause collision and crushing hazards if workers do not follow safety rules and maintain safe distances.

- Cement Dust and Chemicals: The cement grinding process generates dust, which poses health risks to workers. Cement dust can cause respiratory problems and skin irritation, as well as respiratory diseases when inhaled for long periods.

- Fire and Explosion Risk: Grinding and handling cement can create a fire and explosion hazard if not carefully managed. Cement dust can become explosive when combined with air and high temperatures.

- Risk of Accidents from Mobile Equipment: During maintenance or repair of cement grinders, the use of mobile equipment such as cranes and forklifts can create collision and accident risks for workers and other personnel.

- Injuries from Falling Materials: While operating the grinder, materials may fall from heights into the work area, posing a risk of injury from falling objects.

- Machine Malfunction and Breakdown Risks: Cement grinding machines may experience malfunctions or mechanical failures that threaten worker safety if not regularly maintained and inspected.

- Noise and Vibration: Cement grinders produce noise and vibrations that can cause fatigue and stress for workers, as well as hearing and vibration-related injuries.

4. Measures to Control Occupational Accidents When Operating Cement Grinding Machines

- Training and Education: Provide comprehensive training on safe operation procedures of cement grinding machines and proper use of personal protective equipment (PPE). Train new employees and offer periodic refresher courses to update knowledge and skills.

- Risk Management: Assess and manage potential risks during cement grinder operation, including identifying hazardous zones, possible accident causes, and appropriate control measures.

- Use of Personal Protective Equipment (PPE): Ensure all workers have full PPE and use it correctly, including helmets, safety goggles, gloves, dust-proof clothing, and safety shoes.

- Regular Inspection and Maintenance: Conduct regular inspections and maintenance of cement grinding machines to ensure all components function properly and do not pose accident risks.

- Limit Exposure to Dust and Chemicals: Use dust control measures such as dust extraction systems and safe handling of chemicals to minimize exposure to harmful dust and chemicals.

- Identify and Mark Hazardous Areas: Mark hazardous zones around the cement grinder, such as areas near moving parts and material contact zones.

- Safety Monitoring and Inspection: Carry out regular safety inspections and monitoring to ensure all safety measures are properly implemented and all workers comply with safety procedures.

- Information and Communication: Provide regular communication and information about occupational safety, including sharing experiences and lessons learned from accidents or near misses.

- Monitoring and Evaluation: Perform regular monitoring and evaluate safety performance to identify areas for improvement and apply preventive measures.

- Periodic Inspection of cement grinding machines to early detect safety issues such as mechanical wear or breakdowns, thereby reducing occupational accident risks.

5. Benefits of Occupational Safety Training

An Toàn Nam Việt provides your business with the following great benefits after completing occupational safety training courses as regulated in Decree 44/2016/ND-CP on Occupational Safety and Hygiene work, for companies, factories, and enterprises.

- Workers can recognize potential accident hazards and take preventive measures to avoid occupational accidents.

- Your business establishes risk prevention measures in production, operation, and maintenance processes.

- Reduce costs related to occupational safety incidents.

- Uninterrupted production process helps increase labor productivity and product quality.

- Compliance with occupational safety laws reduces legal risks.

- Builds reputation and professionalism in all aspects, thereby enhancing your brand.

Nam Việt’s training courses are the solution to prevent external hazards that may cause injury or even death to individuals.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

6. Customer Feedback After Completing the Training Course

An Toàn Nam Việt has many years of experience accompanying numerous businesses in Vietnam in general and in the southern provinces in particular. This responsibility is invaluable to Nam Việt, and thus our Occupational Safety Training is increasingly professional. Our growth is driven by positive feedback and suggestions from our partners. Below are testimonials from our valued clients.

Hoa Đất Construction and Trading Joint Stock Company

“Nam Việt’s service greatly helped us simplify occupational safety and complete safety documentation for our work process. The consulting team is enthusiastic and timely in responding to our questions. 5 stars for Nam Việt.”

See more customer interviews after using An Toàn Nam Việt’s services

7. An Toàn Nam Việt’s Occupational Safety Training Capability

An Toàn Nam Việt is a reputable and quality occupational safety training center in Vietnam today. Our safety training sessions are continuously held at manufacturing plants, factories, or construction sites nationwide (all 63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toàn Nam Việt has been inspected and certified by the Department of Safety under the Ministry of Labor – Invalids and Social Affairs for eligibility to conduct occupational safety and hygiene training, reinforcing our strong capacity in safety training.

Materials and Lectures

- Before occupational safety training materials are used in safety training courses, they are reviewed and approved to ensure accuracy and effectiveness.

- The instructors’ teaching methods follow the standards of An Toàn Nam Việt, developed by experts in occupational safety and hygiene training to maximize knowledge absorption.

Facilities

- Controlling environmental factors in classrooms enhances training efficiency and learners’ knowledge absorption.

- Our training support facilities provide spacious classrooms that meet standards in area, lighting, and training equipment, etc.

8. Nationwide Reputable and Quality Safety Training Center

At An Toàn Nam Việt, we prioritize professional dedication to occupational safety training. For us, imparting knowledge so workers can protect themselves safely on their livelihood journey contributes to nation-building.

To ensure effective training, we meticulously prepare every small detail — from tools, teaching equipment to curriculum, materials, sound, and lighting.

Our occupational safety trainers are experts with many years of experience, including research on hazard identification across industries and prevention methods.

Instructors deliver practical and vivid lessons easily understood by workers. These factors help learners feel comfortable during training and absorb the knowledge effectively. Of course, the knowledge imparted strictly follows Decree 44/2016/ND-CP.

This enables learners to understand hazard prevention and self-protection measures and apply them suitably in their work.

Our training center proudly provides reputable, professional occupational safety training services with these advantages:

- Competitive training costs while ensuring training quality.

- Flexible training schedules aligned with company production status.

- Fast and legal-compliant procedures for issuing occupational safety training certificates.

- Experienced trainers with many years in the field.

- Classrooms controlled for factors affecting training efficiency and learners’ knowledge absorption.

- Lessons tailored to occupational safety work at enterprises.

- An Toàn Nam Việt works dedicatedly and professionally to provide accurate and prompt customer support.

9. Additional Occupational Safety Training Materials

- Occupational Safety Materials for Operating Cement Grinding Machines

- Occupational Safety Training Materials Collection

- Occupational Safety Training Test Set

- Occupational Safety Quiz for Operating Cement Grinding Machines

- Occupational Safety Training Slides for Operating Cement Grinding Machines

No comments yet

Review Occupational Safety Training for Operating Cement Crushers

There are no reviews yet.