Occupational Safety Training for Pile Driving and Drilling Rig Operation

99,000 ₫

Note: The above price is calculated for one person. Prices may vary depending on the number of trainees participating in the course and market fluctuations. For more accurate pricing information, please refer to the price list or contact our consultants directly.

Occupational safety is an important issue when operating a pile drilling rig and needs to be addressed promptly to ensure the health and safety of workers while also enhancing the reputation of businesses here. The Occupational Safety Training course is one of the effective solutions to raise awareness of accident prevention among workers when operating pile drilling rigs.

Table of Contents

Toggle1. Overview of Pile Driving Drilling Truck

a. What is a Pile Driving Drilling Truck?

Pile driving drilling truck, or concrete pile driver, is a specialized vehicle used for drilling and driving concrete piles.

Pile driving drilling trucks are widely used in construction projects, especially in high-rise buildings and bridges. They allow for quick and efficient installation of concrete piles, saving both time and construction costs.

Here are some advantages of pile driving drilling trucks:

- Fast construction speed: They can drill and drive concrete piles quickly, saving time and cost.

- High pile quality: They can install concrete piles with high precision, ensuring quality.

- Safety: Equipped with safety systems to protect operators and surrounding personnel.

However, pile driving drilling trucks also have some limitations, such as high investment costs and the need for regular maintenance.

Choosing the right pile driving drilling truck depends on factors such as soil conditions, pile type, and construction requirements.

b. Operating principle of the pile driving drilling truck

The operation of a pile driving drilling truck is based on two main stages: pile hole drilling and pile driving.

Pile hole drilling stage

During this stage, the drill rod is controlled to move up and down and rotate to drill the pile hole. The drill bit breaks the soil and creates a hole according to the design.

Pile driving stage

In this stage, the concrete pile is placed into the drilled hole, and the pile driving pump is controlled to drive the pile into the ground. The driving force ensures the pile penetrates soil and rock layers, securing it firmly in place.

Steps for installing concrete piles using a pile driving drilling truck

The steps include:

- Prepare the construction site: Clear and secure the site.

- Set up the truck: Position the pile driving drilling truck at the designated location.

- Drill the pile hole: Control the drill rod to move up and down and rotate to drill the hole.

- Insert the concrete pile: Place the pile into the drilled hole.

- Drive the pile: Operate the pile driving pump to drive the pile into the ground.

- Inspect the pile: Check to ensure the pile meets technical and quality standards.

c. Industries using pile driving drilling trucks

Pile driving drilling trucks are widely used across several industries, including:

- Construction: Most commonly used in high-rise and bridge projects for quick and efficient concrete pile installation, saving time and cost.

- Industrial: Used in factories for installing concrete piles in warehouses, workshops, and other facilities.

- Agriculture: Used in irrigation and rural infrastructure projects to install concrete piles for dikes, embankments, bridges, and culverts.

2. Overview of Safety Training for Operating Pile Driving Drilling Trucks

a. What is labor safety training?

- Labor safety training for operating pile driving drilling trucks consists of sessions that equip workers with awareness and methods to prevent occupational accidents. Workers directly operating these trucks fall into Group 3.

- The safety training course helps workers identify and avoid hazards, reducing the risk of workplace accidents.

REGISTER FOR LABOR SAFETY TRAINING SERVICE

b. Training duration

Initial safety training duration:

- Total training time is at least 24 hours, including testing.

- 8 hours theory on safety and labor hygiene policies and laws

- 8 hours theory on basic knowledge of occupational safety and hygiene

- 4 hours theory on specialized training content

- 2 hours practical training on specialized content

- 2 hours final theory test

The safety training center schedules sessions depending on workers’ availability. Usually, 6 sessions over 3 days, assuming the company can allocate continuous training time.

Periodic safety training duration:

- Before the labor safety card expires, workers must complete periodic safety training if they want renewal. Periodic training time must be at least 50% of the initial training duration.

Explanation: The total periodic safety training time is at least 12 hours, including testing. After completion and passing the test, workers will have their safety cards renewed.

c. Training content

| No. | TRAINING CONTENT | TRAINING HOURS | |||

| Total | Including | ||||

| Theory | Practical | Test | |||

| I | Occupational safety policies and laws | 8 | 8 | 0 | 0 |

| 1 | Overview of the legal framework on occupational safety and hygiene. | 6 | 6 | ||

| 2 | Standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of government agencies for construction, expansion, or renovation of facilities, production, use, storage, and inspection of machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; safety and hygiene policies for employees; functions and duties of safety networks. | 1 | 1 | ||

| 5 | Safety rules, signage, and use of personal protective equipment; skills for first aid, accident prevention, and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, substances producing hazards; risk assessment and management for occupational safety; safe procedures for handling machines, equipment, and hazardous substances. | 6 | 4 | 2 | ||

| IV | Final training assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content for all 6 groups

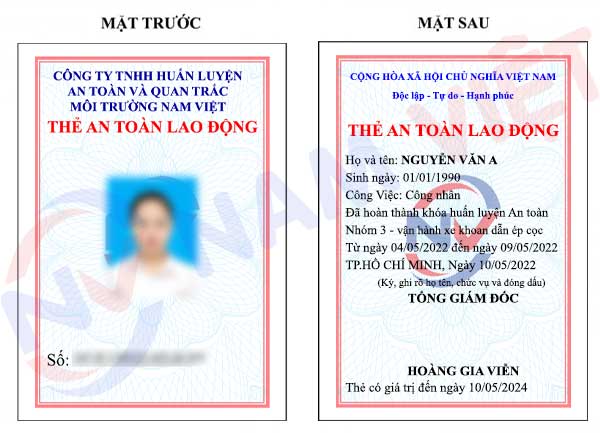

d. Labor safety card

After completing the labor safety training and passing the test, workers will be issued a labor safety card (commonly known as a Group 3 safety certificate).

The Group 3 safety card displays information such as full name, date of birth, job, and working environment. It also includes training duration, official stamp, and signature confirming course completion.

According to regulations in Clause 2 of Article 24, Decree 44/2016/ND-CP, there are two cases:

- If there is an employment contract between employer and employee, the employer must sign and stamp the safety card for Group 3 workers after completing the training and passing the test.

- If the worker is freelance or temporary, the training organization must sign and stamp the safety card after completing the training and passing the test.

3. Hazards When Operating a Piling and Drilling Rig

Piling and drilling rigs are large, specialized vehicles that can pose numerous hazards if not operated correctly. Here are some common hazards when operating a piling and drilling rig:

- Traffic accidents: Piling and drilling rigs are large trucks that can be dangerous on the road. Common causes of traffic accidents involving these rigs include:

- Driver fatigue or lack of focus

- Speeding or exceeding the allowed speed

- Failure to comply with traffic rules

- Adverse weather conditions

- Driver injuries: Drivers of piling and drilling rigs are at higher risk of injury compared to other vehicle operators. Common causes of driver injuries include:

- Traffic accidents

- Workplace accidents

- Occupational diseases

- Damage to cargo: Cargo on the rig can be damaged due to collisions, vibrations, or environmental factors.

- Environmental pollution: Piling and drilling rigs are sources of emissions, noise, and waste.

4. Measures to Prevent Workplace Accidents When Operating Piling and Drilling Rigs

Workplace accidents while operating piling and drilling rigs are a serious issue and can cause injuries or fatalities to the driver and those nearby. To prevent such accidents, the following measures should be implemented:

- Training and instruction: Rig operators must be properly trained on safe operation. Training should include knowledge and skills regarding:

- Traffic safety rules

- Safe driving techniques

- Vehicle inspection and maintenance

- Use of personal protective equipment (PPE)

- Vehicle inspection and maintenance: Piling and drilling rigs must be regularly inspected and maintained to ensure safe operation. Regular maintenance helps identify and fix potential hazards.

- Compliance with safety rules: Operators should follow safety guidelines while driving, including:

- Driving within the allowed speed limit

- Avoiding alcohol or stimulants while driving

- Getting adequate rest before driving

- Using safety equipment while operating the vehicle

- Creating a safe working environment: Employers should ensure a safe environment for rig operators, including:

- Ensuring the rig is equipped with proper safety devices

- Providing sufficient PPE for operators

- Identifying and mitigating potential workplace hazards

- Periodic inspections of piling and drilling rigs to detect safety issues such as mechanical wear or malfunctions, thereby reducing the risk of workplace accidents.

5. Benefits of Occupational Safety Training

An Toàn Nam Việt provides businesses with the following benefits upon completing occupational safety training courses as stipulated in Decree 44/2016/ND-CP on occupational health and safety:

- Workers can identify potential hazards and take preventive measures to avoid workplace accidents.

- Businesses can establish risk prevention measures in production, operation, and maintenance processes.

- Reduction in costs associated with safety risks.

- Uninterrupted production improves labor productivity and product quality.

- Compliance with occupational safety laws reduces legal risks.

- Enhances business credibility and professionalism, boosting the company’s brand.

Nam Việt’s training courses provide strategies to prevent external hazards from affecting individuals, helping them avoid injuries or even fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

6. Customer Feedback After Completing the Training

An Toàn Nam Việt has years of experience supporting businesses across Vietnam, particularly in the southern provinces. This responsibility is highly valued, and our occupational safety training is continuously professionalized. Our growth is fueled by positive feedback and constructive suggestions from our business partners. Below are some testimonials from clients we have served.

See more customer interviews after using our services at An Toàn Nam Việt

7. An Toàn Nam Việt’s Occupational Safety Training Capability

An Toàn Nam Việt is a reputable occupational safety training center in Vietnam, conducting training continuously at factories, workshops, and construction sites nationwide (all 63 provinces).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License:

- An Toàn Nam Việt has been inspected and certified by the Department of Safety under the Ministry of Labor, Invalids, and Social Affairs, affirming our qualifications to conduct occupational safety and hygiene training, further strengthening our training capabilities.

Training Materials:

- Before use in training courses, all safety training materials are reviewed to ensure accuracy and effectiveness.

- Teaching methods are standardized according to An Toàn Nam Việt’s guidelines, developed by occupational safety experts to maximize knowledge retention.

Facilities:

- Controlling classroom factors enhances teaching efficiency and student learning outcomes.

- Our training facilities provide spacious, well-equipped classrooms with proper lighting and teaching tools.

8. Nationwide Reputable Safety Training Center

At An Toàn Nam Việt, we prioritize occupational safety education. Teaching workers how to protect themselves equips them for safe livelihoods and contributes to national development.

We meticulously prepare all aspects of training, from tools and teaching aids to materials, sound, and lighting.

Our instructors are experienced experts, some with research in hazard identification across industries and prevention techniques. Lessons are practical, engaging, and easy to understand, always aligned with Decree 44/2016/ND-CP.

This enables workers to apply safety measures effectively in real work scenarios.

Our safety training center proudly provides professional occupational safety training with advantages such as:

- Competitive pricing without compromising quality.

- Flexible training schedules according to company production needs.

- Quick and compliant issuance of safety training certificates.

- Experienced instructors with years in the field.

- Classrooms optimized for effective teaching and learning.

- Course materials tailored for occupational safety in enterprises.

- Dedicated and professional service for accurate and prompt support.

9. Additional Occupational Safety Training Resources

- Safety materials for operating piling and drilling rigs

- Complete occupational safety training materials

- Occupational safety training tests

- Multiple-choice test for operating piling and drilling rigs

- Training slides for operating piling and drilling rigs

1 review for Occupational Safety Training for Pile Driving and Drilling Rig Operation

No comments yet

phanminhhang341

Very good safety training service