Safety management

Labeling and identifying hazardous areas in the work environment

In the work environment, safety is always the top priority. This article will guide you on how to identify and mark hazardous areas, helping to protect health and ensure safety for workers.

I. Explanation of the importance of identifying and labeling hazardous areas

Identifying Critical Hazardous Areas is an important part of ensuring occupational safety in the workplace. The importance of this cannot be underestimated, as it directly affects the safety and health of workers, as well as the sustainability of the business.

- Protecting workers: Identifying and labeling hazardous areas helps workers recognize and understand potentially risky situations, so they can take personal protective measures and limit the risk of injury.

- Risk to property and production: Not only does it affect workers, but identifying hazardous areas also ensures the protection of property and production processes from fire, loss, or damage.

- Legal compliance: Many countries require businesses to comply with occupational safety regulations. Identifying and labeling hazardous areas is an important part of legal compliance, helping businesses avoid fines and legal liability.

- Creating safety awareness: Labeling hazardous areas creates continuous awareness of occupational safety in the minds of workers and management. This promotes safe behaviors and creates a safer work environment.

- Enhancing efficiency: Safety and efficiency are not two opposing factors. In fact, a safe work environment often creates good conditions for increasing labor productivity through increased focus, reduced disruptions, and fewer errors.

II. Specific guidance on the process of identifying hazardous areas in the workplace

To accurately identify hazardous areas in the workplace, it is necessary to follow a specific process and involve many different departments.

1. Information gathering: Start by gathering information related to work processes, equipment, and the work environment. This includes understanding the tasks performed, potential hazards, and factors that could endanger workers.

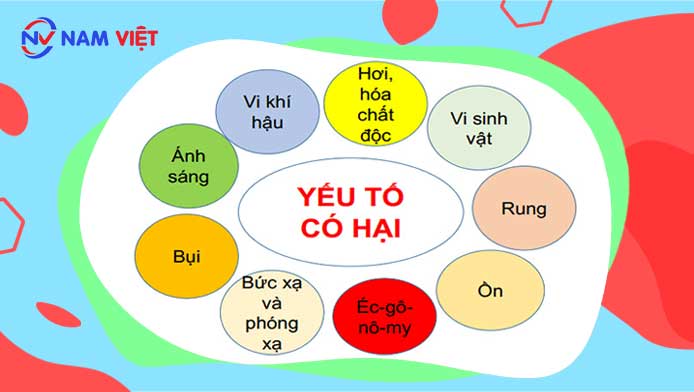

2. Identify hazardous factors: Based on the collected information, identify specific factors that can cause harm. This may include machinery, chemicals, environmental conditions such as temperature, pressure, humidity, as well as special situations like working at heights, working in a noisy environment, or exposure to genetically modified agents.

3. Determine the location and scope of the hazardous area: To define the hazardous area, clearly determine the location and scope of each hazardous factor. Determine whether the factor has a local impact or could affect the wider work environment.

4. Assess the level of risk: Determine the risk level of each factor using indicators such as the probability of occurrence, the severity of potential consequences, and the possibility of avoiding the hazard. This helps prioritize the handling of hazardous areas.

5. Establish safety measures: Based on the risk assessment, determine the necessary safety measures to protect workers and property. This may include improving work processes, using protective equipment, training workers, and establishing safety rules and regulations.

After establishing safety measures, it is important to continuously monitor and evaluate their effectiveness. This ensures that the hazardous area remains controlled and the level of safety is sufficient. You can see more detailed information about occupational safety training content under Decree 44.

III. Explaining why identifying hazardous areas is closely related to worker health

Protecting worker health is one of the most important goals of every business and organization. Identifying and assessing hazardous areas is closely related to worker health and is of great importance, and it is often a critical part of the occupational safety training process.

First, it is recognized that failing to identify and control hazardous areas can lead to occupational accidents, injuries, or even death for workers. This not only causes personal pain and damage but also affects the morale of the entire organization.

Occupational safety training helps workers recognize and understand the potential hazards in their work environment. This is not just to comply with legal regulations, but also to create a safer work environment. Safety measures, such as using personal protective equipment and following safety procedures, are all built upon the identification and assessment of hazardous areas. This ensures that workers are protected and do not have to face unnecessary risks.

IV. Discussing the use of safety labels and charts to warn of hazardous areas

Safety labeling and the use of safety charts are a crucial part of the Occupational Safety Certification process and play an important role in warning of hazardous areas in the workplace. This not only helps workers recognize risks but also ensures they can work safely and effectively.

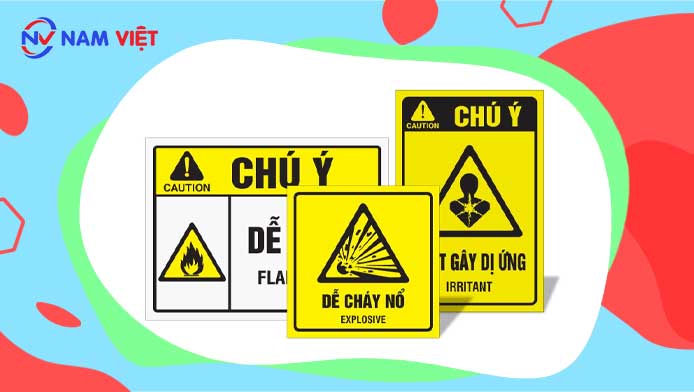

Safety labels are an important part of marking and identifying hazardous areas. Labels can include diagrams depicting dangerous situations, safety charts for specific jobs, or instructions on using personal protective equipment. This label provides important information about potential risks and how to prevent them.

Using safety charts is an effective way to visualize and present dangerous situations and safety procedures. They can include workflow diagrams, process charts, and diagrams describing specific safety rules. These charts help workers better understand the work process and how to avoid dangerous situations.

During the Occupational Safety Certification process, teaching and practicing the use of safety labels and charts is very important. Workers need to know how to read and understand these charts to ensure their own safety and that of their colleagues. At the same time, maintaining and updating labels and charts is an ongoing process to ensure that information is always provided completely and accurately.

V. Sharing ways workers can effectively avoid hazardous areas

The skill of avoiding hazardous areas is an important aspect of Occupational Safety Certification and plays a vital role in protecting the health and lives of workers.

- Master safety rules: Learn and follow basic safety rules, including using personal protective equipment, adhering to instructions and safe work procedures.

- Focus on the job: When working, concentrate on the task and avoid distractions from other factors like mobile phones or unnecessary conversations.

- Adhere to work optimization: Work according to established procedures and safety rules to minimize risks.

- Use personal protective equipment (PPE): Ensure full and correct use of PPE such as helmets, safety glasses, heat-resistant clothing, gloves, safety shoes, etc.

- Report dangerous situations immediately: If you spot a hazardous area or an unsafe situation, report it immediately to your manager or the company’s safety department.

- Perform maintenance and equipment checks: Ensure that machinery and equipment are functioning correctly and are regularly maintained to prevent breakdowns.

- Follow safety instructions when moving: When working in different locations or moving within the workplace, follow the specific safety guidelines for that area.

- Participate in training: Learn and fully participate in the necessary safety training courses for your job.

VI. Mentioning regulations and laws related to identifying and marking hazardous areas

Increasing understanding of the Occupational Safety Law and related regulations for identifying and marking hazardous areas is extremely important to ensure safety in the workplace.

- Occupational Safety Law: This is the basic legal foundation for occupational safety and workers’ rights. This law regulates the identification, marking, and protection of hazardous areas, as well as the safety measures to be implemented.

- Regulations on Marking Hazardous Areas: Specific regulations related to marking hazardous areas, including the colors and symbols to be used to warn workers of risks.

- Safety Marking Procedure: This procedure includes instructions on how to identify hazardous areas, use safety charts and labels, and how to perform marking accurately.

- Occupational Safety Decrees: In addition to the Occupational Safety Law, many countries also have specific decrees and regulations on occupational safety depending on the industry and work environment.

- Environmental Protection Regulations: In some cases, marking hazardous areas is also related to environmental protection, and it may be necessary to comply with specific environmental protection regulations.

- Occupational Safety Certification: Certificates and training courses on occupational safety may require workers to understand and comply with regulations related to hazardous areas.

Clearly understanding the regulations and laws related to hazardous areas helps ensure compliance and a correct implementation of safety measures, thereby minimizing the risk of occupational accidents and protecting worker health. You can see more detailed information about occupational safety training duration under Decree 44.

VII. Encouraging readers to implement safety measures in their workplace immediately

Practicing safety in the workplace is not only important but also a responsibility of every individual. This not only ensures your own safety but also protects the health and lives of yourself, your colleagues, and those around you.

- Protect Your Health: Safety is the most important thing. Adhering to safety rules and measures helps prevent occupational accidents and protect your health.

- Protect Lives: Safety measures can prevent life-threatening situations. Wearing protective gear, following safety rules, and understanding hazardous areas can keep you safe.

- Protect Colleagues: Not just you, but your colleagues also have the right to work in a safe environment. Implementing safety measures helps protect them from dangerous situations.

- Ensure Regulatory Compliance: In many cases, adhering to safety measures is required by law. Violations can lead to legal consequences and job loss.

- Create a Better Work Environment: Safety is everyone’s responsibility. When everyone practices safety measures, the work environment becomes better, more efficient, and more friendly.

- Create Good Habits: Practicing safety is not just a task but also a good habit. This habit helps you automatically protect yourself and others every time you work.

VIII. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality center specializing in occupational safety training (in various languages such as English, Chinese, Japanese, Korean….) in Vietnam today. With occupational safety training sessions held continuously at factories, plants, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected and granted a certificate of eligibility for occupational safety and health training activities by the Department of Work Safety of the Ministry of Labor – Invalids and Social Affairs. This further solidifies our operational capacity in occupational safety training.

Materials and lectures

- Before occupational safety training materials are used in OS training courses, they are reviewed and approved to ensure that the lectures are always factually correct and effective when applied.

- The teaching methods of our instructors are standardized according to An Toan Nam Viet‘s teaching standards, which is a method researched and refined by experts in occupational safety and health training during the teaching process to bring the highest knowledge acquisition efficiency for trainees.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching efficiency and the trainees’ effectiveness in acquiring knowledge.

- Our facilities supporting the training course always provide spacious classrooms that meet standards for area, lighting, training equipment, etc.

IX. Nationwide Occupational Environment Monitoring Center

Nam Viet’s Occupational Environment Monitoring Center is a professional unit for monitoring and measuring the quality of the working environment in all provinces in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICES

In addition to providing monitoring services, the center also supports clients in planning, handling, and tracking occupational environment issues. With the motto “customer is the center,” we always bring satisfaction to our clients, meet all their needs, and commit to providing the best solutions for their businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of occupational environment monitoring in Ho Chi Minh City with the following objectives:

- We always value our brand reputation and the quality of our products and services.

- We provide our customers with the best and most suitable solutions possible.

- With a team of experienced and specialized Masters and Engineers with a desire to protect the environment and benefit businesses.

- Coming to Nam Viet Environmental Monitoring team, your company will receive professional service from experts in the monitoring field. At the same time, you will get the best cost incentives.

The occupational environment monitoring process at Nam Viet includes the following basic steps:

- Before conducting occupational environment monitoring, our company always ensures that machinery and equipment for monitoring are adjusted and calibrated in accordance with legal regulations.

- Correctly and fully implement the occupational environment monitoring process as committed to the Department of Health.

- Truthfully report the occupational environment monitoring results to the employer.

- In case the occupational environment monitoring results do not ensure safety for workers, Nam Viet company will assist in providing remedial solutions and the labor establishment will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health check-ups for early detection of occupational diseases and work-related illnesses for workers in positions with unsecured working environments.

- Provide compensation in kind for workers according to labor laws.