Protective gloves

Protective gloves are made from a variety of materials

Discover the diverse world of protective gloves in this article. Customize your selection based on the work environment to ensure optimal safety and performance. Let’s explore the various types of materials and the reasons for choosing them!

I. Introduction to the importance of using protective gloves in the work environment

In the work environment, the importance of using protective gloves cannot be overlooked. Gloves play a crucial role in protecting workers’ hands from hazards and factors that can cause harm. Selecting and using the appropriate gloves can reduce the risk of occupational accidents and occupational diseases, while also improving work performance and worker health.

First and foremost, protective gloves help prevent injuries to the hands in cases of contact with harmful factors such as chemicals, extreme temperatures, cuts, punctures, or abrasions. They also protect hands from allergens or skin irritants that may be encountered in the work environment.

Additionally, using gloves can help improve comfort and increase worker productivity. They protect hands from the impact of uncomfortable environmental factors, while also reducing stress and fatigue during the performance of work.

II. Presenting how to select materials based on the work environment and protection requirements

Selecting the material for protective gloves is a critical decision, dependent on the specific work environment and the protection required for each job. To ensure maximum effectiveness and safety, managers and workers need to follow these principles:

- Identify specific risks: First, clearly identify the main hazards the gloves need to protect against. This could be chemicals, temperature extremes, impacts, abrasions, or other factors.

- Understand the work environment: The choice of glove material must be based on the specific work environment. For example, a humid environment requires waterproof gloves, while a high-temperature environment needs heat-resistant gloves.

- Choose gloves according to standards: National or international safety and quality standards must be followed. This ensures that the glove material meets specific protection requirements.

- Check insulation and electrical resistance: For work environments with extreme temperatures or high voltage, gloves must have good thermal insulation or electrical resistance.

- Select the appropriate type of glove: There are many different types of gloves, including fabric gloves, gloves made from rubber, nitrile, PVC, and many others. Choose the type that matches the specific risk.

- Combine gloves when necessary: In some cases, using a combination of multiple types of gloves can provide better protection. For example, nitrile gloves for chemical protection and fabric gloves for thermal insulation.

III. Learn about protective gloves made from rubber and their advantages

Protective gloves are an important part of Occupational Safety Training, and choosing the right type of glove can determine safety and performance in the work environment. Gloves made from rubber have long been known and widely used in many industries due to their significant advantages.

Rubber is a flexible material, making rubber gloves suitable for many different purposes. This includes protecting workers from contact with harmful chemicals, oils, greases, and strong cleaning agents. Rubber also helps create an insulating layer, protecting workers from extreme temperatures.

Protective gloves made from rubber often have high durability and elasticity, allowing workers to perform tasks requiring flexibility without hindrance. This is especially important in work environments that demand precision and sensation, such as in the medical or food industries.

This type of glove can be customized to provide appropriate protection based on the specific work environment and potential risks. This ensures that workers are able to work effectively in a safe environment.

IV. Discover how nylon is used in protective gloves and its advantages

Protective gloves play a vital role in ensuring worker safety and can contribute significantly to achieving Occupational Safety Certification in the work environment. One of the common materials used to produce protective gloves is nylon, which offers many notable advantages.

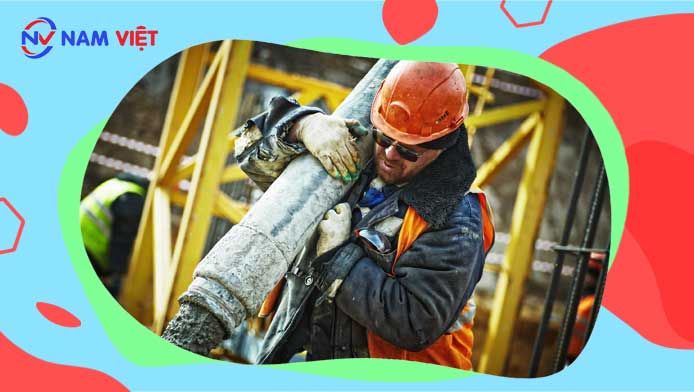

Nylon is an extremely durable and flexible material. This is particularly useful in situations requiring durability and flexibility, such as when performing tasks that need precision or involve impact on rough surfaces. Nylon protective gloves are often used in the construction industry and manual labor jobs.

Another advantage of nylon is its good water and chemical resistance. This means that nylon gloves can protect workers from contact with harmful liquids and toxic chemicals. This is especially important in work environments that demand safety amidst many potential hazards.

Furthermore, nylon is a material that is easy to clean and maintain, helping to ensure that the gloves always guarantee safety for the workers. This is particularly important in medical and food environments.

V. Learn about the elegance of leather gloves and why they are suitable for many work environments

Gloves are an important part of ensuring occupational safety in the work environment. They not only protect workers from hazardous elements but can also express sophistication and elegance. One of the popular and refined types of gloves is leather gloves, and they have many advantages that are undeniable.

Leather gloves are often made from high-quality real or synthetic leather. This creates sophistication and elegance in their design and decoration. For jobs requiring delicacy and precision, leather gloves are the perfect choice.

A key advantage of leather gloves is their good protection capability. Leather is a sturdy material, capable of resisting water and protecting workers from potentially dangerous elements. This is especially important in industries like construction and mechanics, where the risk of impact or contact with harmful liquids is common.

Leather gloves are also suitable for many different work environments. They can be used in industry, healthcare, food service, and many other fields. This demonstrates their versatility and ability to adapt to many different types of jobs.

VI. List some other materials that protective gloves can be made from and when to choose them

In selecting protective gloves, knowing about the different materials they can be made from is important. The diversity in materials provides flexibility for workers to choose gloves suitable for their work environment and specific tasks.

- Nitrile: Nitrile gloves are often used in environments with many chemicals. They resist oil, grease, and other chemicals, making them suitable for the medical, food, and chemical fields.

- Vinyl: Vinyl gloves are often cheaper than other types of gloves and are commonly used in food contact applications or in the healthcare industry.

- Kevlar: Kevlar gloves are known for their durability and cut resistance. They are often used in jobs requiring high safety, such as grass cutting, mechanical work, and construction.

- Neoprene: Neoprene gloves resist oil, chemicals, and are highly durable. They are often used in the chemical and science industries.

- Latex: Although latex gloves offer good protection and flexible movement, they can cause allergies in some people. They are commonly used in the medical and food industries.

When choosing a material for protective gloves, it is important to identify the work environment and specific protection requirements. One material may be suitable in a certain context, but not always suitable for all situations. Additionally, always adhering to occupational safety regulations and guidelines is also important to ensure gloves are used correctly and effectively.

VII. Guide on how to combine types of materials to create the perfect protective gloves for various work environments

When you face many different work environments, choosing the appropriate protective gloves can become complicated. A smart way to ensure optimal performance is to combine types of materials to create gloves suitable for multiple purposes.

- Identify the work environment and protection requirements: First, you need to clearly understand the work environment and the specific risks you will face. This includes identifying the types of chemicals, temperatures, mechanical hazards, or other special risks.

- Use a combination of materials: With an understanding of the work environment, you can combine types of protective glove materials to create optimal protection. For example, you can combine nitrile gloves (for chemical resistance) with Kevlar gloves (for high durability) to protect hands from both chemicals and cuts/tears.

- Comply with regulations: Always comply with occupational safety regulations and guidelines when combining types of gloves. This ensures you are using them correctly and safely.

- Test and inspect: Ensure that the gloves are tested and inspected regularly. Replace gloves when they are damaged or expired.

- Train employees: Finally, ensure that your employees are trained on how to use and combine protective gloves correctly.

VIII. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a prestigious and high-quality center specializing in occupational safety training (in various languages such as English, Chinese, Japanese, Korean….) in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected and certified by the Bureau of Safety of the Ministry of Labor – Invalids and Social Affairs as qualified to conduct occupational safety and health training activities. This further solidifies our capacity in occupational safety training.

Materials and Lectures

- Before occupational safety training materials are used in OSH training courses, they are reviewed and approved to ensure that the lectures are always accurate in knowledge and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet‘s teaching standards, which is a method researched and refined by experts in occupational safety and health training work during the teaching process to bring the highest knowledge absorption efficiency for trainees.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching performance and the effectiveness of trainees’ knowledge absorption.

- Our training course support facilities always arrange spacious classrooms that meet standards for area, lighting, training equipment …etc…

IX. Nationwide Work Environment Monitoring Center

Nam Viet’s work environment monitoring center is a professional unit specializing in monitoring and measuring the quality of the work environment in all provinces across Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR WORK ENVIRONMENT MONITORING SERVICES

In addition to providing monitoring services, the center also supports clients in planning, handling, and tracking work environment issues. With the motto “the customer is the center”, we always bring customer satisfaction, meet all customer needs, and commit to providing the best solutions for businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of work environment monitoring in Ho Chi Minh City with the following objectives:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable things possible.

- With a team of experienced and specialized Masters and Engineers who wish to protect the environment and benefit businesses.

- Coming to the Nam Viet Environmental Monitoring team, your company will receive professional service from experts in the monitoring field. At the same time, you will get the best cost incentives.

The work environment monitoring process at Nam Viet includes the following basic steps:

- Before conducting work environment monitoring, our company always ensures that machinery and equipment for work environment monitoring are calibrated and verified according to legal regulations.

- Correctly and fully implement the work environment monitoring process committed to the Department of Health.

- Honestly report the work environment monitoring results to the employer.

- In case the work environment monitoring results do not ensure safety for employees, Nam Viet company will support proposing remedial solutions, and the labor establishment will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health check-ups for early detection of occupational diseases and work-related diseases for employees in positions with unsafe work environments.

- Provide in-kind allowances for employees according to labor laws.