Identification and prevention

Hazard Identification by Recognizing Abnormalities

In the workplace, detecting “abnormalities” can be the key to dealing with potential hazards. Discover how to identify them in this article.

I. Introduction to the importance of detecting abnormalities in the workplace

In the work environment, recognizing and detecting abnormalities is a critical aspect that cannot be overlooked. This is especially true in the fields of occupational safety and risk management. Paying attention to abnormalities can help prevent workplace accidents, protect worker health, and maintain stability in the production process.

Identifying abnormalities can relate to many different aspects, including equipment, work processes, worker behavior, and environmental conditions. When we understand the importance of recognizing abnormalities, we can apply preventive and control measures to ensure safety and efficiency in daily work.

Another important aspect is the acuity in detecting abnormalities, especially in potentially risky situations. Systematizing the process of checking and monitoring abnormalities can help businesses prevent accidents before they happen and optimize the production process.

II. Discussion on why abnormal changes can be a sign of danger

Abnormalities are often important warning signals in the workplace. This stems from the fact that abnormal changes can be signs of potential hazards.

- Health and Safety of Workers: The appearance of abnormalities in the workplace can affect the health and safety of workers. For instance, abnormal changes in the work environment can cause workplace accidents or create risks for health instability.

- Production Efficiency: Abnormal changes often come with disruptions in the production process. If not detected and handled promptly, they can cause delays and losses in production. This can affect the organization’s performance and lead to financial losses.

- Risk Management: Abnormalities are often signs of potential risks. By identifying and assessing these changes, organizations can focus on managing risks more effectively. This helps minimize the risk of incidents and ensures compliance with safety and environmental protection regulations.

- Product and Service Quality: In many cases, abnormalities can affect the quality of the product or service provided by the organization. Detecting and correcting abnormalities can help ensure that products or services meet quality and safety standards.

The ability to recognize and respond to abnormalities is a crucial factor for the sustainability and success of an organization. It helps the organization adapt to change and create a safe and effective work environment. You can see more details about occupational safety training content according to Decree 44.

III. Specific guide on how to identify abnormal factors in daily work

To identify abnormalities in the office environment and ensure occupational safety, occupational safety training is an important part.

- Review Changes: Always monitor changes occurring in the workplace. This can include changes in work processes, equipment, or the physical environment. Make sure all these changes have been assessed for their impact on occupational safety.

- Review Accident Statistics: Use data on workplace accidents to identify abnormalities. If there is a sudden increase in the number of accidents or a specific type of accident, it could be a signal of an abnormality in the work environment.

- Risk Analysis: Conduct periodic risk analyses to identify risk factors. This includes identifying job positions that have high potential risk for workers and ensuring preventive measures are applied.

- Feedback From Workers: Encourage workers to report abnormal situations they encounter. Create an open environment where workers can share any safety concerns they have.

- Use an Incident Reporting System: Provide workers with a system to report incidents or abnormalities. This helps track and resolve safety issues quickly and effectively.

- Check Training: Ensure that everyone in the organization has been fully trained in occupational safety and has the knowledge to identify abnormalities. This is especially important for managers and those with key roles in ensuring safety.

IV. How to develop the ability to observe details in the workplace

The skill of keen observation is a crucial factor in ensuring occupational safety in the workplace. In particular, an Occupational Safety Certificate can play an important role in developing this ability.

- Be Proactive in Learning: Participate in an Occupational Safety course or certification. This will provide you with knowledge about the important factors in ensuring occupational safety and help you better understand the importance of observation skills.

- Focus on Details: Concentrate on the small details in the work environment. This includes examining factors such as equipment, work processes, and the physical environment.

- Use Support Tools: Use support tools like checklists or incident reporting systems to help you identify abnormalities. This can help you manage information effectively.

- Practice Regularly: Practice observation regularly in the workplace. This helps you develop the habit of observation and improve your ability to recognize abnormal situations.

- Collaborate With Colleagues: Working with colleagues can help you share knowledge and experience in observation. They may have different perspectives and notice abnormalities that you might have missed.

- Adhere to Safety Rules: Always follow safety rules and instructions at work. This helps you ensure that you are working safely and have the ability to recognize any abnormal situations that may occur.

V. List some potential risks that ignoring abnormalities can cause

Ignoring abnormalities in the workplace can cause many potential risks for individuals, colleagues, and the organization.

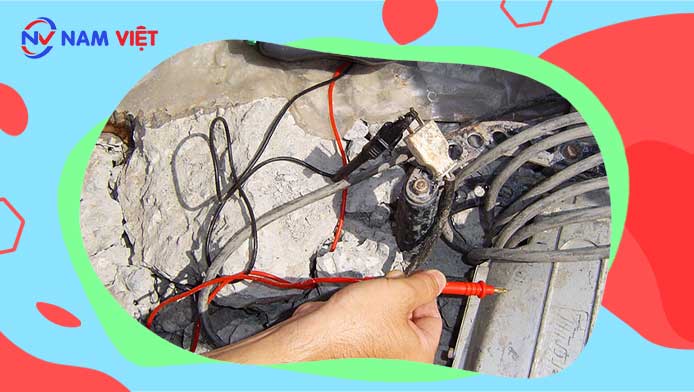

- Workplace Accidents: Abnormalities can be signs of workplace accident risks. Malfunctioning machinery, unsafe work processes, or inadequate working conditions can cause serious accidents.

- Performance Loss: Abnormalities can affect work performance. This can lead to disruptions in the work process, reduce productivity, and cause losses for the organization.

- Health Conditions: An unsafe or abnormal work environment can affect the health of workers. This includes issues related to occupational hygiene, environmental pollution, and mental stress.

- Legal Risks: Ignoring abnormalities can increase legal risks for the organization. If an accident occurs or a worker is injured, the organization may face lawsuits and legal penalties.

- Damage to Reputation and Prestige: A workplace accident or serious incident can cause significant damage to the organization’s reputation and prestige. Failure to ensure safety and detect abnormalities can cause customers, partners, and the community to lose trust.

- Increased Costs: Workplace accidents and the consequences of ignoring abnormalities can lead to increased costs. Medical expenses, compensation, and equipment repairs can place significant financial pressure on the organization.

VI. Provide strategies and tools to deal with hazards once abnormalities are identified

Once an abnormality is identified in the workplace, reacting and responding correctly becomes a crucial part of ensuring the occupational safety and health of workers.

- Create a Hazard Assessment Plan: Determine the necessary measures to respond to the specific hazard. This includes identifying the necessary resources, planning to mobilize the workforce, and defining relevant safety procedures.

- Escalate the Issue: If the hazard threatens life or serious safety, issuing a warning and escalating the issue is necessary. This may include using an alarm system, calling authorities, or organizing an emergency meeting.

- Implement Temporary Safety Measures: Where necessary, apply temporary safety measures to minimize risk. This may include closing off the hazardous area, providing protective equipment, or changing work procedures.

- Training and Safety Mindset: Create opportunities for workers to participate in occupational safety training courses. Encourage them to participate in the risk assessment process and propose improvements.

- Risk Management: Implement risk management by monitoring and evaluating abnormal changes. This helps determine if current measures are effective or need adjustment.

- Record and Report: Ensure that all information related to the hazard and the response measures are properly recorded and reported. This supports a continuous learning and improvement process.

VII. Conclusion on using the identification of abnormalities to protect happiness and safety in daily work

Happiness and safety are two crucial elements that cannot be missing in any worker’s environment. Using the identification of abnormalities in the work environment plays an important role in protecting both of these factors.

When workers and managers are both sharp in recognizing abnormal changes, they can work together to implement the necessary safety measures to ensure the work environment is always safe and happy. Identifying early signs can prevent accidents and occupational diseases, while also creating better conditions for development and advancement in work.

Furthermore, acuity in recognizing abnormalities can help identify and minimize stress and pressure in the workplace. These contribute significantly to creating a positive work culture and discovering happiness in daily work.

Emphasize that identifying abnormalities is not only the responsibility of managers but also the responsibility of all workers. The active participation of everyone in ensuring safety and happiness at work will create a better working environment for everyone. You can see more details about occupational safety training duration according to Decree 44.

VIII. Occupational Safety Training Capability of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality center specializing in occupational safety training (in many different languages such as English, Chinese, Japanese, Korean….) in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational safety training license

- An Toan Nam Viet has been inspected and granted a certificate of eligibility for occupational safety and health training activities by the Department of Work Safety of the Ministry of Labor – Invalids and Social Affairs. This further strengthens our occupational safety training operational capacity.

Documents and lectures

- Before occupational safety training materials are used in occupational safety training courses, they are reviewed and approved to ensure that the lectures are always accurate in terms of knowledge and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet’s teaching standards, which is a method that experts in occupational safety and health training have researched and refined during the teaching process to bring the highest knowledge acquisition efficiency for students.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching efficiency and the effectiveness of students’ knowledge acquisition.

- Our training course support facilities always arrange spacious classrooms that meet standards for area, lighting, training equipment, etc.

IX. Nationwide workplace environment monitoring center

Nam Viet’s workplace environment monitoring center is a professional unit for monitoring and measuring the quality of the working environment in all provinces in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR WORKPLACE ENVIRONMENT MONITORING SERVICE

In addition to providing monitoring services, the center also supports clients in planning, handling, and tracking workplace environment issues. With the motto “the customer is the center,” we always bring satisfaction to customers, meet all customer needs, and commit to providing the best solutions for businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of workplace environment monitoring in Ho Chi Minh City with the following objectives:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable things possible.

- With a team of experienced and specialized Masters and Engineers who desire to protect the environment and bring benefits to businesses.

- Coming to Nam Viet’s Environmental Monitoring team, your company will receive professional service from experts in the monitoring field. At the same time, you will get the best cost incentives.

The process of implementing workplace environment monitoring at Nam Viet includes the following basic steps:

- Before performing workplace environment monitoring, our company always ensures that machinery and equipment used for monitoring are calibrated and verified in accordance with legal regulations.

- Implement the workplace environment monitoring process correctly and completely as committed to the Department of Health.

- Truthfully report the workplace environment monitoring results to the employer.

- If the workplace environment monitoring results do not ensure safety for employees, Nam Viet Company will support providing remedial solutions, and the labor facility will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health check-ups to detect occupational diseases and work-related illnesses early for employees in positions with non-compliant working environments.

- Provide in-kind benefits to employees according to the provisions of labor law.