Identification and prevention

Identifying and Carefully Managing Explosion Risks in the Workplace

In a high-risk work environment, understanding flammable and explosive substances is more important than ever. This article will guide you on how to identify and manage risks carefully to ensure maximum safety in your work environment.

I. Understanding work environments with explosion risks and why it’s important

In the work environment, a high-risk environment refers to situations that have the potential to cause harm to the health and safety of workers. This environment is often associated with special industries, where caution and safety knowledge are paramount.

Work environments with explosion risks often appear in fields such as the chemical industry, oil and gas, construction, and many other sectors. In these environments, incidents can lead to explosions, the release of toxic substances, or other dangerous situations. Therefore, understanding this environment is a crucial part of ensuring the safety and protecting the health of workers.

Simply put, it’s to ensure everyone’s life and health. Understanding the risks and knowing how to prevent them is the best way to avoid accidents and disasters. Without knowledge and awareness of the high-risk environment, workers and people in this environment face many potential dangers. You can see more details about occupational safety training content under Decree 44.

II. What creates these substances and why are they dangerous?

Flammable substances often have the ability to ignite at low temperatures and naturally participate in combustion reactions. This typically occurs when the substance can generate enough heat, energy, and oxygen to sustain a burning process. Common examples of flammable substances include gasoline, oil, alcohol, and many other organic compounds. They can cause fires and explosions if not stored and used carefully.

As for explosive substances, their special characteristic is the ability to create a large amount of gas and high temperature in a short time. This usually happens because explosive substances contain compounds or molecules capable of rapid decomposition and energy release. Types of explosives like dynamite, TNT, or nitrate compounds are typical examples. Their explosion can cause serious consequences, from injuries to people and damage to the environment to the destruction of property and lives.

III. Learn how to identify and assess risks from flammable and explosive substances

Identifying and assessing risks from flammable and explosive substances is an important part of ensuring safety in the work environment.

Identifying Flammable Substances:

- Check physical characteristics: Determine a substance’s flammability by checking its flashpoint and temperature limits.

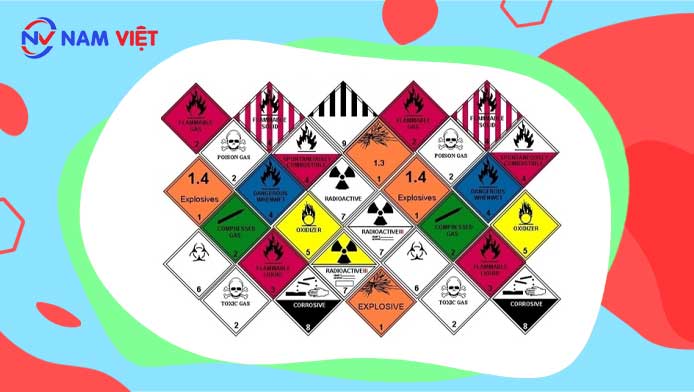

- Use flammability diagrams: Flammability diagrams let you know which types of substances are flammable and under what conditions.

- Look for warning signs: Flammable substances often have a quite distinctive odor and can easily burn or ignite.

Identifying Explosive Substances:

- Check chemical structure: Determine the chemical structure of the substance to know if it can decompose rapidly and release energy.

- Use identifying signs: Some explosives have identifying signs such as odor, color, or specific physical properties.

- Be cautious with nitrate compounds: Nitrate compounds are often explosive, and identifying and handling them requires special care.

IV. Why risk management is the focus and how to implement it carefully

Safety management is a crucial aspect of the working environment factors, especially when it involves working with flammable and explosive substances.

Why Safety Management is Important:

- Protecting Workers: Risk management ensures worker safety, minimizing the risk of occupational accidents and injuries.

- Protecting Property and Environment: Safety management also ensures the protection of the company’s property and the surrounding environment from accidents and incidents that may occur due to the use of flammable or explosive substances.

- Legal Compliance: Businesses must comply with laws and regulations related to occupational safety and risk management. Violations can lead to serious legal consequences.

How to Implement Safety Management Carefully:

- Risk Assessment: First, identify and assess the risks from flammable and explosive substances in the work environment. Determine the type of substance, quantity, and usage.

- Risk Classification: Determine the level of risk, from low risk to high risk. This helps determine where stronger safety measures need to be applied.

- Develop Safety Measures: Based on the risk assessment, develop specific safety measures. This includes using protective equipment, establishing safe work procedures, and training employees.

- Training and Awareness: Ensure that all employees have sufficient knowledge and awareness of occupational safety, especially when working with hazardous substances.

- Periodic Inspection and Evaluation: Conduct periodic inspections to ensure that safety measures are still being followed and are effective.

V. Learn about methods and tools to ensure safety in the work environment

Safety inspection methods are an important part of risk management and ensuring safety in the work environment.

- Periodic Inspections: Regular checks are a key part of safety management. This includes inspecting equipment, machinery, and infrastructure to ensure they are still functioning correctly and safely.

- Technical Safety Inspections: These are in-depth checks of safety equipment, machinery, and technology. This may include inspecting fire suppression systems, fire alarm systems, and automatic control systems.

- Safety Pre-Checks: This is a quick check to identify basic safety issues. Workers can perform this pre-check daily before starting work.

- Protective Equipment Inspection: Check personal protective equipment such as safety glasses, masks, gloves, and protective clothing to ensure they are new and functioning correctly.

- Use Testing Equipment: Specialized testing devices such as gas detectors, spectrometers, and pressure testers can be used to check for hazardous factors in the work environment.

- Work Environment Inspection: Check environmental factors such as temperature, humidity, and lighting to ensure they are within a safe range for workers.

- Chemical Inspection: For work environments using chemicals, checking and monitoring chemicals is an important part of ensuring safety.

VI. Discover the serious consequences if risks are not identified and managed correctly

Neglecting to identify and manage risks correctly in the work environment can lead to serious consequences.

- Occupational Accidents: Failure to identify and manage risks can lead to occupational accidents, causing injury or even death to workers. This not only affects the health and lives of workers but also causes great losses for the business.

- Environmental Incidents: In industrial environments, ignoring risks can lead to serious environmental incidents. Incidents like chemical spills, fires, or environmental pollution can cause long-lasting consequences and severe environmental damage.

- Property Loss: Not managing risks can lead to fires, machinery damage, or other material losses. This means financial and property loss for the business.

- Legal Liability: Businesses may face legal liability if they do not adequately and accurately identify and manage risks. Lawsuits related to occupational accidents or environmental pollution can cause significant financial losses.

- Impact on Reputation: Incidents and accidents can damage a business’s reputation. This consequence can affect the ability to attract customers, partners, and employees.

- Increased Costs: Dealing with the aftermath of incidents and accidents often requires very large costs. These costs include medical treatment, reconstruction, repairs, compensation, and legal penalties.

In summary, failing to identify and manage risks correctly can cause many serious consequences for an organization. To ensure the safety and sustainability of the business, investing in risk management is very important. You can see more details about occupational safety training duration under Decree 44.

VII. Shares from people working in hazardous environments help you better understand the importance of this

Sharing safety experiences from those working in hazardous environments is invaluable for understanding the importance of risk management and occupational safety.

- Risk Awareness: People working in hazardous environments often have a better understanding of the potential risks. They know how to identify and assess risks quickly, helping to avoid dangerous situations.

- Adherence to Safety Rules: Experience shows that adhering to safety rules is very important. Those working in hazardous environments often always comply with personal protective measures and safety regulations.

- Creative Solutions: When facing risks, these individuals often have to find creative solutions to protect themselves and their colleagues. This can lead to innovation in improving occupational safety.

- Teamwork Ability: In hazardous environments, teamwork is very important. Their experience in collaborating and supporting colleagues can provide a good model for safe work.

- Importance of Training: These individuals often understand that training is a vital part of maintaining occupational safety. They can share about training courses and encourage others to participate.

- Spirit of Self-Protection: Experience shows that a spirit of self-protection is important. They are often proactive when encountering risks and do not hesitate to use protective equipment.

VIII. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality occupational safety training center (in many different languages such as English, Chinese, Japanese, Korean….) in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational safety training license

- An Toan Nam Viet has been inspected and granted a certificate of eligibility for occupational safety and health training activities by the Department of Work Safety of the Ministry of Labor – Invalids and Social Affairs. This further strengthens our occupational safety training capacity.

Documents and lectures

- Before occupational safety training materials are used in OHS training courses, they are reviewed and censored to ensure that the lectures are always accurate in knowledge and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet‘s teaching standards, which is a method that experts in occupational safety and health training have researched and summarized during the teaching process to bring the highest knowledge acquisition efficiency for trainees.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching performance and the effectiveness of trainees’ knowledge acquisition.

- Our training center facilities always provide spacious classrooms that meet standards for area, lighting, training equipment, etc.

IX. Nationwide Occupational Environment Monitoring Center

Occupational Environment Monitoring Center of Nam Viet is a professional unit for monitoring and measuring the quality of the working environment in all provinces in Vietnam. With a team of experienced monitoring specialists, the center uses modern measuring equipment, ensuring accuracy and reliability.

REGISTER FOR OCCUPATIONAL ENVIRONMENT MONITORING SERVICE

In addition to providing monitoring services, the center also supports clients in planning, handling, and tracking occupational environment issues. With the motto “the customer is the center”, always bringing customer satisfaction, meeting all customer needs, and committing to providing the best solutions for businesses.

With investment in techniques, technology, and human resources, Nam Viet’s monitoring center has become one of the reputable units in the field of occupational environment monitoring in Ho Chi Minh City with the following goals:

- We always value our brand reputation and the quality of our products and services.

- We provide customers with the best and most suitable things possible.

- With a team of experienced Masters and Engineers with expertise and a desire to protect the environment and benefit businesses.

- Coming to the Nam Viet Environmental Monitoring team, your company will receive professional service from experts in the monitoring field. At the same time, you will get the best cost incentives.

The process of implementing occupational environment monitoring at Nam Viet includes the following basic steps:

- Before performing occupational environment monitoring, our company always ensures that machinery and equipment for occupational environment monitoring are calibrated and verified in accordance with legal regulations.

- Implement the occupational environment monitoring process correctly and fully as committed to the Department of Health.

- Honestly report the occupational environment monitoring results to the employer.

- In case the occupational environment monitoring results are not safe for employees, Nam Viet company will support proposing remedial solutions and the employing establishment will implement the following:

- Implement measures to improve working conditions to minimize the impact of harmful factors and prevent occupational diseases.

- Organize health checks for early detection of occupational diseases and work-related illnesses for employees in positions with unsafe working environments.

- Provide in-kind allowances for employees according to the provisions of labor law.