Safety Document Group 3

Occupational Safety Document for Operating Desktop Drill Machines

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 PROFESSIONS)

Before you start using a desktop drill machine, the most important thing is to master the rules of occupational safety. This document provides a detailed guide on the necessary safety measures when operating a desktop drill machine. Learn how to avoid accidents and ensure safety in your work environment.

PART I: CURRENT STATE OF SAFETY FOR WORK RELATED TO DESKTOP DRILL MACHINES

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some Occupational Accidents While Operating a Desktop Drill Machine

When using a desktop drill machine, several common risks and occupational accidents can occur. Failure to follow safety rules and a lack of attention while operating the machine can lead to serious consequences. Below are some common types of accidents when using a desktop drill machine:

- Unwanted collisions or impacts: Leaving materials or tools near the desktop drill machine can lead to unwanted collisions when the machine is operating, creating danger for the user.

- Cuts, punctures to hands or fingers: Using a desktop drill machine without proper guards or wearing protective gear can lead to serious injuries such as cuts or punctures to the hands.

- Falling materials or debris: Drilling into unsecured materials can lead to the material falling, endangering those nearby.

- Loss of tool control: Using a desktop drill machine without proper control or training can lead to a loss of control over the tool during operation.

- Technical failures: Technical faults or machine breakdowns can also cause unwanted occupational accidents when using a desktop drill machine.

To avoid these accidents, desktop drill machine users must adhere to safety regulations, wear protective gear, and implement proper preventive measures during operation. Close attention and control while using a desktop drill machine are crucial to ensure the safety of everyone in the work environment.

PART II: OCCUPATIONAL SAFETY AND HEALTH WHEN OPERATING A DESKTOP DRILL MACHINE

I. Introduction

A. Overview of the importance of occupational safety when operating a desktop drill machine

Occupational safety is an extremely important factor when operating a desktop drill machine. Ensuring safety in the workplace is not only a legal obligation but also essential to protect the health and well-being of workers. When using a desktop drill machine, there are many potential risks, such as hand injuries, dangers from eye contamination or flying debris, or the risk of fire and explosion due to poor insulation.

Basic safety measures include ensuring the use of personal protective equipment like safety glasses and gloves, especially when working with materials that are brittle or prone to shattering. Additionally, ensuring the desktop drill machine is installed and operated correctly is extremely important to prevent unwanted accidents.

Workers must be trained in the safe use of the desktop drill machine and understand the potential risks to be able to respond when necessary. However, the most important thing is still to create a safe, friendly, and proactive work environment that prioritizes occupational safety.

B. Important safety protocols and regulations when operating a desktop drill machine

When operating a desktop drill machine, adhering to safety protocols and regulations is crucial to ensure worker safety and prevent unwanted accidents. These regulations include ensuring the desktop drill machine is installed and maintained correctly according to the manufacturer’s instructions. This involves using a power source that matches the desktop drill machine’s requirements and regularly checking the condition of the power cord and plug to avoid the risk of electrical shorts.

In addition, desktop drill machine users must be trained on how to use the equipment safely, including wearing adequate personal protective equipment such as safety glasses and a mask when necessary. Ensuring that loose clothing is not worn and that power cords are not left dangling is also an important factor to avoid getting entangled in the machine while it is operating.

Furthermore, one should not overlook reading the user manual and safety symbols on the desktop drill machine to fully understand its operation and safety warnings. If any safety issues are detected, the user should immediately stop using the machine and notify the appropriate person for inspection and repair.

II. Components and Functions of a Desktop Drill Machine

A. The different components of a desktop drill machine

A desktop drill machine consists of the following main components:

- First is the motor: This is the main component of the desktop drill machine, creating the power to rotate the drill spindle. The motor can be powered by electricity or compressed air, depending on the type of machine.

- Next is the drill spindle: This is the component responsible for rotating and driving the drill bit into the material. The spindle is usually made of hard carbon steel or an alloy.

- The table: This is the flat surface for placing the material to be drilled. The table can be adjusted for height and tilt to suit drilling needs.

- The drill handle (feed lever): This is the component that guides and holds the drill bit. The handle can adjust the depth and angle of the drill bit to achieve precise drilling results.

- The control system: This is the part that controls the drill’s operation, including buttons, switches, and a display screen. This system allows the user to adjust the speed and other parameters of the machine.

In addition, a desktop drill machine may have supplementary features such as a cooling system, a dust collection system, and other accessories to enhance efficiency and safety during use. Overall, these components work together to create a reliable and effective desktop drill machine for drilling tasks.

B. Structure and operating principle of a desktop drill machine

A desktop drill machine has a simple yet effective structure for drilling materials like wood, metal, or plastic. The main structure of the machine includes an electric or pneumatic motor, a drill spindle, a handle for control, and a table to place the material to be drilled.

The operating principle of a desktop drill machine is quite simple. First, the user places the material to be drilled on the table and adjusts the height and tilt angle appropriately. Then, the user selects a suitable drill bit and attaches it to the spindle. When the motor is activated through the control system, the spindle begins to rotate, driving the drill bit into the material.

During this process, the handle can be adjusted to lower or raise the drill bit according to the required depth for drilling. The desktop drill machine will continue to operate until the job is completed or the user stops it. While in operation, the desktop drill machine may be equipped with safety features such as an automatic stop mechanism to prevent overload or other safety measures to keep the work process safe and effective.

C. Applications in the mechanical industry of the desktop drill machine

The desktop drill machine is an important tool in the mechanical industry with many diverse applications. In this industry, a desktop drill machine is used to perform drilling tasks on materials such as metal, plastic, wood, and composites. The main applications of a desktop drill machine include drilling holes in metal plates for assembly, creating tapped and screw holes, or drilling holes on various surfaces for installing mechanical components.

A desktop drill machine is also used to prepare mechanical parts for subsequent processing such as grinding, lathing, or welding. Using a desktop drill machine helps increase accuracy and efficiency in the mechanical production process by ensuring holes and details are drilled precisely and uniformly. It is a versatile and essential tool in mechanical production workshops for performing precise tasks and saving time.

In addition, the desktop drill machine is also widely used in DIY and repair activities, where users can carry out craft projects or small repairs simply and conveniently. With its flexibility and ease of use, the desktop drill machine is an important and indispensable tool in the mechanical industry as well as in personal work environments.

D. Risks associated with operating a desktop drill machine

Operating a desktop drill machine can present several serious risks and dangers if safety rules are not followed and the machine is not used correctly. One of the main risks is the danger of hand or finger injuries during drilling. If adequate protective gear such as gloves is not worn and safety rules are not followed, the user can be injured by the drill bit or machine parts.

Furthermore, using a desktop drill machine to drill materials like metal can create dust and generate sparks, leading to a risk of fire or explosion if appropriate precautions are not taken. These factors can increase the risk of fire or explosion in the work environment.

In addition, a desktop drill machine can also cause accidents due to the user not controlling the machine accurately, leading to materials being violently spun or losing control. This can cause serious injuries to the user or those nearby.

Therefore, to minimize the risks associated with operating a desktop drill machine, users must follow safety instructions, wear adequate protective gear, and ensure the machine is regularly maintained. Training and mastering safety regulations are very important to avoid unwanted accidents while using a desktop drill machine.

III. Safety Inspection and Maintenance Before Operating a Desktop Drill Machine

A. Safety checks before operating a desktop drill machine

Before operating a desktop drill machine, performing safety checks is crucial to ensure the safety and efficiency of the work process. First, you need to thoroughly check the condition of the machine. Ensure that the desktop drill machine is plugged into the correct power source and the power cord is not damaged. Check the control buttons and switches to ensure they are working correctly.

Next, examine the condition of the drill bit and other parts of the machine. Make sure the drill bit is securely fastened and not damaged. Also, check the condition of personal protective equipment like safety glasses and gloves. Wear adequate protective gear before starting work to protect your eyes and hands from hazards.

In addition to these basic checks, you should also inspect the surrounding work area. Ensure there are no stray objects in the desktop drill machine’s operating area to prevent unwanted accidents.

B. Guide to periodic maintenance of a desktop drill machine

To ensure a desktop drill machine operates effectively and safely, periodic maintenance is very important. Here is a guide to periodic maintenance that you should perform:

Regularly clean and wipe down: Clean the desktop drill machine by wiping away dust and grease buildup on the surface. Ensure that vents and important parts are cleaned to prevent issues during operation.

Inspect and lubricate moving parts: Check parts such as the spindle, bearings, and drive belts, and lubricate them periodically. Lubrication ensures that parts move smoothly and do not cause excessive friction.

Inspect and change the drill bit: Check the condition of the drill bit and replace it when necessary. A dull or damaged drill bit can affect drilling performance and the safety of the machine.

Check the electrical system: Periodically inspect the power cord and other electrical accessories of the desktop drill machine to ensure there are no breaks or dangerous exposed wires.

Adjust and check for accuracy: Periodically adjust the desktop drill machine to ensure the accuracy of the drilling process. Re-check the squareness and drilling depth to ensure accurate work results.

IV. Safe Operating Procedure for a Desktop Drill Machine

A. Step-by-step guide to the safe operation of a desktop drill machine

To operate a desktop drill machine safely and effectively, you need to follow these steps:

- Prepare the work environment: Ensure the work area around the drill press is cleared, with no clutter or obstructions. Place the desktop drill machine on a flat and stable surface to prevent it from shaking during operation.

- Wear personal protective equipment: Before starting, make sure you have put on adequate personal protective equipment such as safety glasses, a mask, and gloves. These are basic but very important steps to protect your eyes and hands during work.

- Check the machine and electrical equipment: Before turning on the machine, re-check the power cord and other parts of the machine to ensure there is no damage or electrical leakage. Use a suitable power source and ensure adequate insulation.

- Position the material and adjust the machine: Place the material to be drilled on the table and adjust the height and tilt angle to suit the job. Ensure the drill bit has been selected and installed correctly before proceeding to drill.

- Operate the machine carefully: Turn on the machine according to the manufacturer’s instructions and use the handle to guide the drill bit into the material accurately and adjust the drilling depth as required for the job.

- Monitor and control the drilling process: Always stay focused and monitor the drilling process. If there are any unusual signs or if the machine malfunctions, stop the machine immediately and re-check.

- Turn off the machine and clean up after completion: When the work is done, make sure to turn off the machine’s power and clean up the work area. Clean the desktop drill machine and store it properly to ensure its longevity and safety.

Following these steps helps ensure you operate a desktop drill machine safely and effectively, avoiding unwanted accidents and incidents during your work.

B. Emergency procedures and incident response mechanisms when operating a desktop drill machine

When operating a desktop drill machine, preparing emergency procedures and incident response mechanisms is very important to ensure worker safety and avoid serious consequences. Here are some measures and mechanisms that can be applied:

- Stop the drill immediately: If you detect any sign of an incident or danger during operation, stop the drill immediately by turning off the power or pressing the emergency stop button (if available).

- Assess the situation: After stopping the machine, assess the situation and determine the cause of the incident. If necessary, check the material, machinery, and parts to determine the extent of the damage and risk.

- Call a professional: If the incident cannot be resolved by the operator, contact a professional immediately to take safe handling and recovery measures.

- Isolate the hazardous area: If there is a major risk, isolate the hazardous area by notifying others to avoid the area or by using appropriate safety measures.

- Use personal protective equipment: In an emergency, ensure everyone is wearing adequate personal protective equipment such as safety glasses and masks to protect their eyes and respiratory system.

- Implement corrective and repair measures: After assessing the incident, implement the necessary corrective and repair measures to ensure safety and prevent recurrence of the incident in the future.

Most importantly, always remain calm and follow safety procedures when handling emergency situations while operating a desktop drill machine. Preparation and practice beforehand are also important factors in minimizing risk and dealing effectively with incidents.

V. Risk Assessment and Hazard Management When Operating a Desktop Drill Machine

A. Identifying potential risks and hazards in operating a desktop drill machine

During the operation of a desktop drill machine, there are many potential risks and hazards that users need to identify to prevent and minimize danger. Some common risks and hazards include:

- Risk of hand and finger injury: When using a desktop drill machine, there is a high risk of hand and finger injury from the impact of the drill bit or machine parts. To avoid this, users must ensure they use personal protective measures such as wearing safety gloves and always concentrating when operating the machine.

- Risk of electric shock: A desktop drill machine is an electrical device, so the risk of electric shock is always present. Using a desktop drill machine in a damp environment or without ensuring proper insulation can be dangerous. To avoid this, use a safe power source and always check the condition of the power cord and plug before use.

- Risk of fire and explosion: When drilling into materials like metal, there is a risk of generating sparks and high temperatures, leading to a risk of fire or explosion if safety is not ensured. Therefore, always check the work environment and use preventive measures to avoid the risk of fire and explosion.

- Unstable motor and machine parts: Parts of the desktop drill machine, such as the motor and spindle, can malfunction if not regularly maintained. A failure during operation can cause serious danger. Therefore, regularly inspect and maintain the machine to ensure its parts operate stably and safely.

By identifying and understanding these potential risks and hazards, users can apply appropriate preventive and safety measures to protect themselves and others during the operation of a desktop drill machine.

B. Effective hazard prevention strategies when operating a desktop drill machine

1. Regular inspection and maintenance of the desktop drill machine for safe operation

To ensure the safe and effective operation of a desktop drill machine, regular inspection and maintenance are very important. First, regular checks should be performed on the desktop drill machine to ensure its operational status and safety. Please check the following steps:

- Check electricity and cables: Regularly inspect the power cord and plug to ensure there is no damage or breakage. Electrical equipment should be fully protected and well-insulated to avoid the risk of electric shock.

- Check moving parts: Inspect the spindle, motor, and other moving parts to ensure they are operating smoothly and show no signs of damage. Lubricate these parts periodically to keep the machine running smoothly and to avoid excessive friction.

- Check safety features: Ensure that safety mechanisms on the desktop drill machine, such as the emergency stop switch, are working well and correctly. Check the drill bit guard to ensure safety during operation.

- Maintenance and cleaning: Perform periodic maintenance such as cleaning dust and grease buildup on the machine. Ensure that vents and parts are cleaned to prevent malfunctions during operation.

- Replace old or damaged components: If you find any damaged or worn parts, replace them immediately to ensure the safety and performance of the machine.

By performing these regular inspection and maintenance steps, users can ensure the desktop drill machine always operates stably and safely, while also extending the machine’s life and avoiding unwanted incidents.

2. Adherence to occupational safety regulations for the safe operation of a desktop drill machine

To ensure the safe operation of a desktop drill machine, adherence to occupational safety regulations is very important. Before starting work with a desktop drill machine, users need to take the following steps to ensure safety:

- Training and coaching: Before using a desktop drill machine, ensure that the operator has been trained on its use and understands the safety principles when working with this equipment. Adequate training helps users acquire the necessary skills and know how to respond to dangerous situations.

- Wear personal protective equipment: Be equipped with adequate personal protective equipment such as safety glasses, a mask, gloves, and a safety helmet (if necessary). Wearing protective gear helps protect the user from injury risks during the operation of the desktop drill machine.

- Inspect the equipment before use: Before starting work, re-inspect the desktop drill machine to ensure it is working correctly and has no damage. If you find any problems, stop using it and inform the manager for inspection and repair.

- Adherence to safety rules during operation: Always follow safety rules such as not wearing loose clothing and not letting long hair hang loose when operating the desktop drill machine. Ensure there are no foreign objects or other people near the work area.

- Stop operation when there is an incident: If you encounter any incident during operation, stop immediately and notify the manager or a technician for support and handling.

In summary, adherence to occupational safety regulations and safe operating rules is necessary to protect yourself and others while using a desktop drill machine. These measures help minimize the risk of accidents and ensure a safe working environment.

3. Identifying and marking safe zones when operating a desktop drill machine

Before operating a desktop drill machine, identifying and marking a safe zone is very important to ensure the safety of surrounding workers. Here are the steps to take to identify and mark a safe zone:

- Identify the hazardous zone: First, identify the hazardous areas around the desktop drill machine, such as the rotating area of the drill bit, the direct work area, and the materials to be drilled. These areas have a high risk of injury and require special attention.

- Mark the safe zone: After identifying the hazardous areas, clearly mark the safe zone around the desktop drill machine. Use signs, barriers, or lines to indicate areas that workers should stay away from to avoid the risk of injury.

- Instruct workers: Ensure that all employees and workers in the area understand the safe zone and which places to avoid when the desktop drill machine is in operation. Provide clear and complete instructions to ensure compliance and safety.

- Regularly inspect and maintain the safe zone: To ensure the effectiveness of the safe zone, regularly inspect and maintain the signs, barriers, or lines to ensure their clarity and effectiveness.

By identifying and marking a safe zone when operating a desktop drill machine, we can minimize the risk of accidents and protect workers in the work environment. This is an important part of the safety measures during the use of a desktop drill machine.

4. Using personal protective equipment when operating a desktop drill machine

When operating a desktop drill machine, using personal protective equipment is very important to protect the health and safety of the worker. Personal protective equipment includes the following items:

- Safety glasses: Wear safety glasses to protect your eyes from flying debris, dust, and sparks that may be generated during drilling.

- Respiratory mask: Use a respiratory mask to prevent inhaling dust and chemical vapors from the material when drilling into surfaces.

- Safety gloves: Wear safety gloves to protect your hands from impacts and cuts when operating and changing the materials to be drilled.

- Safety helmet or hard hat: To protect your head from materials falling from above or impacts when working under the desktop drill machine.

- Protective clothing: Wear appropriate protective clothing to shield your body from dust, materials, and other harmful agents.

The full and correct use of personal protective equipment is an important part of the occupational safety process when operating a desktop drill machine. It helps to minimize the risk of accidents and protect the health of the worker in a hazardous work environment. Always follow the instructions and regulations on occupational safety when using machinery to ensure a safe and effective work environment.

5. Emergency procedures and response in case of an incident when operating a desktop drill machine

Before starting to operate a desktop drill machine, it is necessary to understand and practice the emergency procedure and response in case of an incident to ensure the safety of everyone in the work environment. Here are the steps to take when an incident occurs:

- Stop the drill immediately: If you detect any incident during operation, stop the drill immediately by pressing the emergency stop button or turning off the power. Stopping the machine will help prevent potential risks and ensure safety.

- Assess the situation: After stopping the machine, assess the situation to determine the cause of the incident. Check if anyone is injured or if there are any other potential risks.

- Notify the responsible person: Immediately inform the manager or the person in charge of safety in the area so they can provide support and take emergency measures.

- Use personal protective equipment: In case of an incident, ensure everyone in the area is wearing adequate personal protective equipment such as safety glasses, a mask, gloves, and a safety helmet to protect their health.

- Provide first aid if necessary: If someone is injured, use basic first aid skills to provide temporary care for the victim until the rescue team arrives.

Most importantly, always practice and prepare in advance to react quickly and effectively in case of an incident when operating a desktop drill machine. This is the way to ensure the safety and protect the health of everyone in the work environment.

6. Participate in occupational safety training courses for operating a desktop drill machine

Occupational safety and health training is not just a legal requirement but also a commitment to the safety and health of workers. It helps employees recognize and deal with risks and dangerous situations, thereby minimizing accidents, injuries, or fatalities in their daily work.

The risk of accidents is always present and can occur at any time in the work environment due to human error and the unpredictability of situations. This emphasizes the need for occupational safety training and constant vigilance.

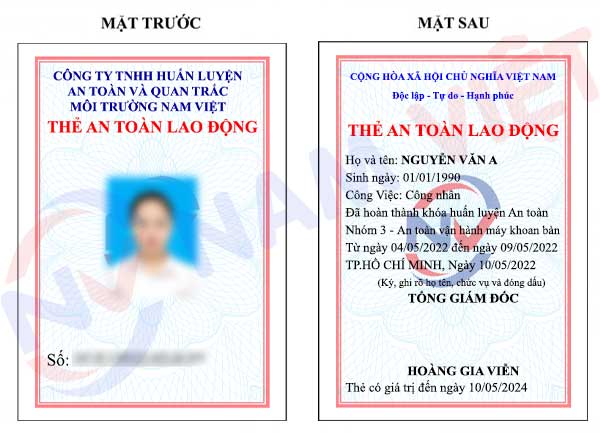

When participating in occupational safety training at the An Toan Nam Viet Center, workers will receive systematic training from theory to real-life risk scenarios. Accordingly, there will be measures to identify and prevent occupational accident risks that may occur during work. After the training course, trainees will take occupational safety tests to obtain an occupational safety certificate. From there, workers will have a firm grasp of safety knowledge as well as a valid certification for work.

VI. Factors Affecting Occupational Safety When Operating a Desktop Drill Machine

A. How weather conditions affect the operation of a desktop drill machine

Weather conditions can significantly affect the operation of a desktop drill machine. The following weather factors can have an impact on the work process and safety when using a desktop drill machine:

- Humidity: Humid weather conditions can increase the risk of electrical incidents or cause problems with adhesion and friction when drilling into materials like wood or metal. To minimize the impact of humidity, a dry work location should be chosen and anti-moisture equipment used when necessary.

- Temperature: Excessively high or low temperatures can also affect the performance and lifespan of the desktop drill machine. For example, if the machine operates at a very high temperature, it can lead to overheating and cause damage to the internal components. In this case, it is necessary to ensure the machine is operated in an environment with stable temperature conditions.

- Outdoor weather: If working outdoors, factors such as rain, snow, or harsh sun can also affect the drilling process and occupational safety. Preventive measures such as using waterproof materials, electrical protection, and ensuring the power cord and work location are protected from bad weather are necessary.

- Wind and other climatic conditions: Strong winds can cause a loss of balance or interrupt the operation process. Climatic conditions such as dust, sand, or water vapor in the air can also affect the performance and safety of the desktop drill machine.

In summary, assessing and understanding weather factors is very important during the operation of a desktop drill machine. One should always stay updated with the weather forecast and have appropriate preventive measures in place to ensure safety and performance in all weather conditions.

B. How the working environment affects the operation of a desktop drill machine

The working environment can have a significant impact on the operation of a desktop drill machine and worker safety. The following factors in the working environment can affect the drill press operation process:

- Ventilation: A poorly ventilated work environment can lead to increased temperatures and cause fatigue for the worker. High temperatures can increase the risk of the desktop drill machine overheating and reduce work efficiency.

- Humidity and dust: An environment with high humidity and a lot of dust can cause friction problems and reduce the lifespan of the desktop drill machine parts. Dust and water vapor can also affect the machine’s work performance and safety.

- Light and illumination: A poorly lit work environment or one with glaring light can impair the worker’s vision, creating a risk of accidents when operating the desktop drill machine.

- Narrow workspace: Desktop drill machines are often used in narrow spaces, requiring high flexibility and vigilance from the worker. A narrow space can reduce the ability to control the machine and increase the risk of collisions.

- Noise: A desktop drill machine creates high noise levels, especially when operated in an enclosed space. Noise can cause sleep loss, stress, and negatively affect the worker’s health.

To minimize the impact of the working environment on desktop drill machine operation, protective measures such as improving ventilation, protecting against dust and humidity, ensuring adequate lighting, and safety in narrow workspaces are necessary. In addition, workers need to be guided and trained so they can react and operate the machine in a difficult working environment safely and effectively.

C. How the technical condition of the desktop drill machine affects its operation

The technical condition of a desktop drill machine has a very large impact on the operation of the machine and safety during use. The following factors often affect the operation of a desktop drill machine:

- Drill bit sharpness: The drill bit needs to be sharp to be able to drill effectively and quickly. A dull drill bit can cause great friction, reducing drilling efficiency and increasing the risk of wear and tear.

- Adjustment and maintenance parts: The adjustment parts of the desktop drill machine such as the feed lever, belts, and joints need to be regularly maintained to ensure smooth and accurate operation.

- Electrical and control system: The condition of the electrical and control system of the desktop drill machine is very important. If there is an electrical problem, such as a sudden interruption or electrical interference, it can be dangerous for the operator and reduce the efficiency of the desktop drill machine.

- Main structures and load-bearing parts: Load-bearing parts such as the main spindle, bearings, and drive mechanism need to be inspected and maintained to ensure safety and stability during operation.

- Periodic maintenance and repair: Periodic maintenance and repair are very important to maintain the technical condition of the desktop drill machine. Periodic maintenance helps to detect problems early and minimize the risk of incidents during operation.

In summary, the technical condition of a desktop drill machine directly affects the efficiency and safety of its operation. Regular inspection, maintenance, and repair are necessary to ensure the desktop drill machine operates stably and safely in all working conditions.

D. How the safety knowledge and skills of the worker affect the operation of a desktop drill machine

The safety knowledge and skills of a worker play a very important role in operating a desktop drill machine safely and effectively. The following factors demonstrate the impact of safety knowledge and skills on the desktop drill machine operation process:

- Understanding of occupational safety: Knowledge of the risks and safety measures in the process of operating a desktop drill machine helps workers to identify and deal with dangerous situations accurately and promptly.

- Machine usage skills: Proficiency in using a desktop drill machine, including how to control the machine, change accessories, and perform basic maintenance, helps to increase the safety and efficiency of the operation process.

- Incident handling skills: When an incident occurs during operation, workers with safety knowledge and skills will know how to handle the incident quickly and accurately, minimizing the risk of accidents.

- Attitude and safety awareness: Safety knowledge and skills also contribute to creating a safe attitude and awareness in the worker’s job, thereby enhancing self-protection and ensuring the safety of themselves and their colleagues.

- Training and coaching: Regular training and coaching on occupational safety and machine operation are very important to enhance the knowledge and skills of workers, thereby ensuring a safe and effective working environment.

In summary, the safety knowledge and skills of workers play an important role in ensuring safety and efficiency in the process of operating a desktop drill machine. Investing in training and raising safety awareness will bring great benefits to both individuals and organizations in the work environment.

VII. Occupational Safety Training on Skills for Safe Operation of a Desktop Drill Machine

A. Why operators of desktop drill machines need occupational safety training

First, occupational safety training helps operators to fully understand and be aware of the risks and dangerous situations that can occur during the operation of a desktop drill machine. Recognizing these risks will help them take appropriate preventive and response measures to avoid accidents and injuries.

Second, occupational safety training provides operators with the necessary knowledge and skills to use a desktop drill machine safely and effectively. They will know how to control the machine, change accessories, and handle unusual situations professionally.

In addition, occupational safety training helps to raise awareness about safety in the operator’s job. They will understand the importance of adhering to safety rules, ensuring not only personal safety but also that of the entire work team.

Finally, providing occupational safety training is a legal obligation for organizations and businesses to ensure a safe working environment for employees. It helps to minimize the risk of occupational accidents, avoiding negative consequences for the health and economy of both the worker and the business.

B. Where to get occupational safety training for operating a desktop drill machine?

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

To ensure the effectiveness of the training, An Toan Nam Viet prepares meticulously, down to the smallest detail. From preparing tools, equipment, teaching aids to curriculum, materials, sound, and lighting.

The occupational safety trainers at An Toan Nam Viet are experts with many years of experience in the field. They even have research projects identifying hazards in all occupations and how to prevent them.

The instructors’ lectures are drawn from practical experience and are conveyed in a vivid, easy-to-visualize manner to the workers. These factors help workers feel comfortable during their study time and absorb the teaching knowledge well. Of course, the knowledge conveyed always adheres to Decree 44/2016/ND-CP. From there, they grasp many measures to prevent hazards and how to protect themselves. They also apply it most appropriately in their actual work.

VIII. The Significance of Occupational Safety in Operating a Desktop Drill Machine

A. The importance of maintaining occupational safety in the operation of a desktop drill machine

Maintaining occupational safety in the operation of a desktop drill machine is very important because it directly affects the health and safety of the worker, as well as the efficiency and effectiveness of the job.

First, occupational safety helps prevent accidents and injuries during the operation of the desktop drill machine. Adhering to safety rules and using protective equipment correctly will minimize the risk of injury to the worker.

Second, maintaining occupational safety also has a positive impact on work performance. When workers feel safe and are properly trained, they can work more effectively without worrying about incidents or accidents.

In addition, maintaining occupational safety enhances the professionalism and reputation of the organization. If the work environment is safe, employees will feel valued and will be willing to give their best to their work.

B. Important safety measures to know before operating a desktop drill machine

Before operating a desktop drill machine, knowing and applying safety measures is very important to ensure the safety of the operator and the work environment. The basic safety measures that need to be known include:

- Wear personal protective equipment: Before starting to operate the desktop drill machine, workers need to ensure they are wearing full personal protective equipment such as a helmet, safety glasses, a mask or respirator to protect their head, face, and eyes from potential impacts.

- Inspect the desktop drill machine before use: Before turning on the machine, it is necessary to carefully inspect the desktop drill machine to ensure that its parts are functioning normally and there are no problems. If you find any issues, you should notify the manager or a technician to carry out repairs.

- Understand the potential risks: The operator needs to be trained on the risks that can occur when using a desktop drill machine, such as the risk of impact, getting a hand caught, or the risk of fire and explosion. Recognizing and understanding these risks will help the operator apply appropriate safety measures.

- Maintain hygiene and cleanliness: A clean and tidy work environment is an important factor in ensuring safety. Keeping the work area clean helps to avoid the risk of tripping and other accidents.

- Follow the user manual: Read the desktop drill machine’s user manual carefully and follow the specific instructions. Following the instructions correctly will help the operator avoid dangerous errors and unwanted incidents.

Complete the occupational safety training course to be issued an occupational safety card by the training center to ensure proper documentation for work.

PART III: Further Reference

1. Group 3 Occupational Safety Test

2. Price Quote for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training document for operating a desktop drill machine

- Slide presentation for occupational safety training when operating a desktop drill machine

- Multiple choice test on occupational safety when operating a desktop drill machine