Safety Document Group 3

Occupational safety documents for operating cement ball mill grinding machines

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 PROFESSIONS)

Discover the safety secrets of operating a cement ball mill through this in-depth document. Confidently operate the cement ball mill efficiently and safely thanks to detailed instructions, from inspection procedures to accident prevention measures. Protect yourself and your colleagues in a high-risk work environment.

PART I: CURRENT STATE OF SAFETY IN WORK RELATED TO CEMENT BALL MILL GRINDING MACHINES

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some occupational accidents when operating a cement ball mill grinding machine

1. Accident resulting in 7 fatalities at Yen Bai Cement Plant (April 22, 2024):

- Cause: The grinding machine unexpectedly started during maintenance due to an error in operating the electric motor.

- Consequence: 7 workers died on the spot.

2. Worker’s hand caught in cement grinding machine accident (March 15, 2024):

- Cause: The worker violated safety procedures, putting his hand in a hazardous area while the machine was operating.

- Consequence: The worker was seriously injured, losing several fingers.

3. Worker thrown from cement grinding machine accident (November 20, 2023):

- Cause: The grinding machine vibrated violently due to a technical problem, causing the worker to be thrown off.

- Consequence: The worker sustained minor injuries.

4. Fire and explosion at Dong Loc Cement Plant (July 12, 2023):

- Cause: The fire started in the cement grinding area due to a short circuit.

- Consequence: No human casualties, but significant property damage.

Occupational accidents when operating a cement grinding machine can cause serious consequences in terms of people and property. Therefore, ensuring occupational safety during the operation of a cement grinding machine is extremely important.

PART II: OCCUPATIONAL SAFETY AND HEALTH WHEN OPERATING A CEMENT BALL MILL GRINDING MACHINE

I. Introduction

A. Overview of the importance of occupational safety when operating a cement ball mill grinding machine

Occupational safety is an undeniably important factor in the operation of a cement grinding machine. Understanding and applying appropriate safety measures not only protects the health of employees but also minimizes the risk of accidents and incidents, while increasing production efficiency.

In a work environment associated with a cement grinding machine, ensuring safety includes controlling the risk of fire and explosion, minimizing collisions and abrasion, ensuring occupational hygiene, and using personal protective equipment correctly. In particular, training and raising awareness of occupational safety during the operation of a cement grinding machine is the key to building a safe and effective work environment.

B. Important safety protocols and regulations when operating a cement ball mill grinding machine

Safety protocols and regulations when operating a cement grinding machine play an important role in ensuring the safety of employees and the company’s assets. First, it is extremely important to follow the safety instructions and regulations of the grinding machine manufacturer. This includes a clear understanding of how to operate, maintain, and repair the machine according to the manufacturer’s instructions.

Furthermore, a regular inspection and maintenance schedule also plays an important role in ensuring safety when operating a cement grinding machine. Employees need to be trained to recognize warning signs and take necessary maintenance measures to avoid unwanted incidents and accidents.

In addition, compliance with safety regulations of regulatory agencies and national organizations is also an indispensable factor. This includes implementing fire and explosion prevention measures, ensuring electrical safety and other environmental factors during the operation of a cement grinding machine. At the same time, ensuring that employees are trained and provided with personal protective equipment also plays an important role in minimizing the risk of accidents and protecting their health.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

II. Components and Functions of a Cement Ball Mill Grinding Machine

A. Different components of a cement ball mill grinding machine

A cement grinding machine is a complex device consisting of many different components. The most basic part is the grinding drum, where the cement is put in to be ground. The grinding drum is usually made of steel and has high strength and friction resistance.

In addition, the cement grinding machine also includes a shaft and gear system for transmission, ensuring that the cement grinding process is efficient. These shafts are often equipped with powerful motors to generate the necessary grinding force.

To control the grinding process, the machine is often equipped with an automatic or manual control system, which helps to adjust the rotational speed of the grinding drum and the amount of cement being fed in.

Finally, the cement grinding machine also has accessories such as a cooling system to reduce temperature and a dust filter system to clean the air during operation. All these components work together to create an efficient and safe cement grinding process.

B. Structure and operating principle of a cement ball mill grinding machine

The cement grinding machine has a complex structure but operates on a simple principle. Its structure usually includes a large grinding drum containing balls or rollers and a shaft and gear system for transmission.

The operating principle of the cement grinding machine is the collision and grinding between the balls or rollers in the grinding drum and the cement material. When the grinding drum rotates, the balls or rollers also rotate and move inside the drum, creating impact and grinding force on the cement material inside.

The grinding process takes place when the cement material is fed into the grinding drum through an inlet pipe, and then it is gradually ground into smaller particles over time. The balls or rollers are usually made of hard materials such as steel, which helps to crush the cement material into smaller particles.

The shaft and gear transmission system helps to maintain the grinding process without interruption, and at the same time adjusts the rotational speed of the grinding drum to ensure optimal grinding efficiency.

C. Applications of the cement ball mill grinding machine in the manufacturing industry

The cement grinding machine is widely used in the cement manufacturing industry to grind and mix the necessary raw materials to create the final product. The cement grinding process helps to grind raw materials such as limestone, clay, cement clinker, and other additives into a fine powder, creating a homogeneous cement mixture and achieving the desired product quality.

In addition, the cement grinding machine is also used in other construction material manufacturing industries such as the production of bricks, blocks, and lightweight construction materials. The grinding process helps to create cement powder or a cement-sand mixture with high quality and uniformity, providing high-quality raw materials for the production process.

The cement grinding machine is also used in fertilizer production plants, where it is necessary to grind and mix complex raw materials such as phosphate and potassium to create a complete fertilizer.

D. Risks associated with operating a cement ball mill grinding machine

Improper operation of a cement grinding machine can pose many significant risks. One of the biggest risks is the risk of occupational accidents. The cement grinding process often requires contact between surfaces and hard materials, which can cause serious incidents if safety procedures are not followed correctly.

In addition, risks related to fire and explosion also need to be considered. The cement grinding machine often operates at high temperatures and has the potential to generate flammable dust and gas. The combination of temperature, dust, and gas can create a flammable and explosive environment if not managed and controlled closely.

Furthermore, improper operation of a cement grinding machine can lead to wear and tear and damage to the equipment. Continuous abrasion due to collisions between surfaces can cause rapid damage to components, leading to machine downtime and significant repair costs.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

III. Safety Inspection and Maintenance Before Operating a Cement Ball Mill Grinding Machine

A. Safety inspection before operating a cement ball mill grinding machine

Before operating a cement grinding machine, conducting a safety inspection is a crucial step to ensure that all conditions meet safety standards. First, inspect the basic parts of the machine such as the grinding drum, shaft, gears, and accessories to ensure they are functioning normally and have no signs of damage.

Next, inspect the electrical and control systems to ensure they are working correctly and there is no risk of electrical failure. Pay special attention to the electrical wires, fuses, and other electrical protection devices.

Then, inspect the cooling and dust filtering systems to ensure they are working efficiently and there are no issues that could pose a risk of fire, explosion, or air pollution.

Finally, check and ensure that all personal protective equipment such as helmets, masks, gloves, and safety shoes are available and are being used correctly by employees.

B. Guide to regular maintenance of a cement ball mill grinding machine

Regular maintenance is an important part of maintaining the performance and lifespan of a cement grinding machine. First, the maintenance process should begin with inspecting and cleaning the main parts such as the grinding drum, shaft, gears, and transmission system. Remove any debris that may cause obstruction or wear.

Next, it is necessary to inspect and replace worn or damaged parts such as bearings, drive belts, and seals. Ensure that all parts are properly maintained and on schedule.

The maintenance guide also includes inspecting the cooling and cleaning systems to ensure they are working efficiently and are not clogged. Clean or replace the filter and other necessary parts to ensure the circulation of coolant and cleaning fluid.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

IV. Safe Operating Procedure for a Cement Ball Mill Grinding Machine

A. Step-by-step guide on the safe operating procedure for a cement ball mill grinding machine

The operating procedure for a cement grinding machine must be carried out carefully and safely to ensure production efficiency and protect the health of employees. First, before starting operation, thoroughly inspect all parts of the machine to ensure they are functioning normally and have no signs of damage.

Next, ensure that all safety procedures have been followed, including wearing the correct personal protective equipment such as a helmet, mask, gloves, and safety shoes.

When starting operation, ensure that the machine has been configured correctly and that safety measures such as rotational speed and the amount of material being fed in are being followed.

During operation, always keep your eyes focused and monitor the machine’s operating indicators. If you detect any problems, stop the machine immediately and take the necessary corrective actions.

B. Emergency handling measures and incident response mechanism when operating a cement ball mill grinding machine

During the operation of a cement grinding machine, it is very important to have incident handling and an emergency response mechanism to ensure safety and avoid unwanted damage. When an incident is detected, the machine operator should stop the machine immediately and notify the manager or the authorized technical department.

Emergency handling measures may include inspecting and repairing damaged parts, turning off the machine’s power, and cutting off the power supply if necessary to ensure safety. At the same time, it is also necessary to notify all relevant employees of the incident and instruct them to take precautions and act according to safety instructions.

In addition, it is necessary to have a pre-established incident response mechanism to ensure that everyone knows how to react in an emergency. This includes training and educating employees on safety measures and incident response procedures, as well as preparing fire fighting and first aid equipment.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

V. Risk Assessment and Hazard Management when Operating a Cement Ball Mill Grinding Machine

A. Identifying potential risks and hazards in operating a cement ball mill grinding machine

During the operation of a cement grinding machine, identifying potential risks and hazards is extremely important to ensure the safety of employees and equipment. One of the common risks is the risk of collision and abrasion due to contact between surfaces in the machine. This can lead to machine damage or even injury to employees.

Furthermore, the risk of fire and explosion is also a potential hazard in the operation of a cement grinding machine. The grinding machine often operates at high temperatures and creates flammable dust and gas. The combination of temperature, dust, and gas can create a flammable and explosive environment if not managed carefully.

Furthermore, the risk of injury from dust inhalation also needs to be considered. The grinding of cement creates a large amount of dust, which can cause health problems for employees if they are exposed to this dust without wearing appropriate personal protective equipment.

B. Effective hazard prevention strategies when operating a cement ball mill grinding machine

1. Regular inspection and maintenance of the cement ball mill grinding machine for safe operation

Regular inspection and maintenance are an indispensable part of ensuring the safe operation of a cement grinding machine. First, it is necessary to design and implement a regular maintenance schedule, including inspecting the main parts of the machine such as the grinding drum, shaft, gears, and transmission system.

Next, perform regular inspection and maintenance of the electrical and control systems, ensuring they are working correctly and not posing a risk to employees.

In addition, inspect and maintain the cooling and cleaning systems to ensure they are working efficiently and not causing safety-related issues such as fire, explosion, or air pollution.

2. Adherence to occupational safety regulations for the safe operation of a cement ball mill grinding machine

Adherence to occupational safety regulations is an indispensable part of ensuring the safe and efficient operation of a cement grinding machine. First, employees need to be trained on basic safety rules and proper work procedures with the grinding machine. This includes the correct use of personal protective equipment and a clear understanding of the risks and preventive measures.

Furthermore, it is also very important to follow the regulations and instructions of the grinding machine manufacturer. These regulations often provide detailed instructions on how to operate, maintain, and repair the machine safely and effectively.

In addition, it is impossible to ignore the safety regulations of regulatory agencies and national organizations. This includes implementing fire and explosion prevention measures, ensuring electrical safety and other environmental factors during the operation of a cement grinding machine.

3. Identifying and marking safe zones when operating a cement ball mill grinding machine

Identifying and marking safe zones during the operation of a cement grinding machine is an important part of the safety measures. First, it is necessary to identify and mark the safe zone around the grinding machine, including areas that employees should avoid to prevent accidents or injuries.

The safe zones should be identified based on the potential risks and the specific work procedures of the machine. This may include areas with a risk of collision, fire, or machine failure.

After identifying the safe zones, they should be marked with signs or markings on the floor so that employees can easily recognize and follow the safety rules.

In addition, it is important to train and inform employees about the safe zones to ensure that they understand and comply with the safety regulations when working near a cement grinding machine.

4. Using personal protective equipment when operating a cement ball mill grinding machine

Using personal protective equipment is an important part of ensuring safety when operating a cement grinding machine. First, employees should be equipped with a helmet to protect their heads from the risk of impact and falling materials from above.

Next, a mask is an important piece of equipment to prevent the inhalation of dust and harmful vapors generated during the cement grinding process, protecting the employee’s respiratory tract.

Protective gloves help to protect the employee’s hands from the risk of cuts and impacts during handling of the grinding machine parts.

For areas with a risk of collision or abrasion, safety shoes provide protection for the feet and reduce the risk of injury.

Finally, the use of safety glasses helps to protect the eyes from dust, UV rays, and materials that may be ejected during machine operation.

5. Emergency procedures and response in case of an incident when operating a cement ball mill grinding machine

Emergency procedures and response in case of an incident are an important part of ensuring safety when operating a cement grinding machine. When an incident occurs, the machine operator should stop the machine immediately and notify the manager or the authorized technical department.

Then, it is necessary to inspect and assess the incident to determine the scope and cause of the problem. If necessary, take emergency measures such as turning off the machine’s power and cutting off the power supply to ensure the safety of employees.

Next, it is necessary to notify all relevant employees of the incident and instruct them to take precautions and act according to safety instructions. At the same time, it is also necessary to plan and implement measures to remedy the incident quickly and effectively.

6. Attending occupational safety courses when operating a cement ball mill grinding machine

Occupational safety and health training is not only a legal requirement but also a commitment to the safety and health of workers. It helps employees recognize and deal with risks and dangerous situations, thereby minimizing accidents, injuries, or deaths in their daily work.

The risk of accidents is always present and can occur at any time in the work environment due to human error and the inability to foresee all situations. This emphasizes the need for occupational safety training and continuous vigilance.

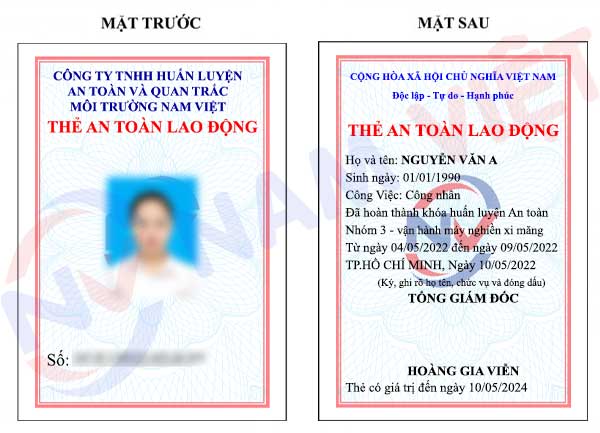

When participating in occupational safety training at An Toan Nam Viet Center, workers will be thoroughly trained from theory to real-life risk cases. Accordingly, there will be measures to identify and prevent occupational accident risks that may occur during work. After the training course, trainees will take occupational safety tests to obtain an occupational safety certificate. From there, the worker will have a clear understanding of safety knowledge as well as valid certification for work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

VI. Factors Affecting Occupational Safety when Operating a Cement Ball Mill Grinding Machine

A. How do weather conditions affect the operation of a cement ball mill grinding machine?

Weather conditions can affect the operation of a cement grinding machine in many ways. First, temperature and humidity can affect the machine’s performance. In a tropical or high-humidity environment, cooling and drying the material can be difficult, leading to reduced performance and an increased risk of machine failure.

The weather can also cause safety-related problems, such as the risk of fire and explosion in a tropical or arid climate. This is especially true for the use of cooling and dust filtering systems, as environmental factors can reduce their performance or cause them to fail.

Furthermore, severe weather such as strong winds or heavy rain can also affect the operating process by interrupting the transportation of materials or the cooling of the machine.

B. How does the work environment affect the operation of a cement ball mill grinding machine?

The work environment has a significant impact on the operation of a cement grinding machine. First, a dusty work environment can cause health problems for employees, especially when inhaling cement dust, which can cause respiratory problems and damage the lungs.

The temperature and humidity of the environment can also affect the performance of the grinding machine. Temperatures that are too high or too low can reduce the machine’s working efficiency, while high humidity can increase the risk of incidents and machine failure.

In addition, the work environment can affect the safety of employees. The presence of flammable or explosive substances or other hazardous materials in the work environment increases the risk of fire and explosion and causes accidents.

C. How does the technical condition of the cement ball mill grinding machine affect its operation?

The technical condition of a cement grinding machine has a great impact on its operation. First, the grinding machine needs to be regularly maintained and serviced to ensure that the parts operate smoothly and efficiently. If the machine has technical problems such as mechanical failure, shaft damage, or severe wear and tear, it can lead to reduced performance or even a complete shutdown.

Furthermore, the technical parameters of the grinding machine also need to be adjusted and checked periodically to ensure that the machine operates stably and meets production requirements. Otherwise, it can cause problems such as errors in the grinding process, inconsistency in product quality, and an increased risk of incidents.

Finally, upgrading and improving the technical features of the grinding machine can also improve the performance and efficiency of the operating process. This may include replacing old parts, upgrading the control system, or applying new technology to enhance performance.

D. How does the safety knowledge and skills of the worker affect the operation of a cement ball mill grinding machine?

The safety knowledge and skills of the worker have a great impact on the operation of a cement grinding machine. First, it is extremely important to understand the potential risks and preventive measures. The worker must know how to identify and handle dangerous situations safely, such as the risk of collision, explosion, or injury from dust inhalation.

Furthermore, having the skill to operate the machine accurately and safely is important to ensure performance and avoid unwanted incidents. This includes knowing how to use the control devices and understanding the machine’s operating instructions.

In addition, adhering to occupational safety rules and wearing proper personal protective equipment also plays an important role in protecting the health and safety of the worker during machine operation.

In summary, the safety knowledge and skills of the worker are key factors in ensuring the safety and performance of the cement grinding machine operation. Training and improving these factors are very important to minimize the risk of accidents and enhance production efficiency.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

VII. Occupational Safety Training on the Safe Operation of a Cement Ball Mill Grinding Machine

A. Why do operators of a cement ball mill grinding machine need to be trained in occupational safety?

Cement grinding machine operators need to be trained in occupational safety for many important reasons. First, occupational safety training helps them to identify and assess the potential risks in the machine operating process, from the risk of fire and explosion to the risk of collision and occupational accidents.

Second, occupational safety training provides them with the necessary knowledge and skills to prevent and deal with dangerous situations. They will know how to properly use personal protective equipment and apply safety measures when working near a grinding machine.

In addition, occupational safety training helps the operator to understand the machine operating procedure and the specific safety measures required during that process. This not only helps to minimize the risk of accidents but also enhances work efficiency and confidence in the job.

B. Where to get occupational safety training for operating a cement ball mill grinding machine?

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites throughout the country (63 provinces in Vietnam).

To ensure effective training, An Toan Nam Viet prepares carefully and meticulously down to the smallest detail. From preparing tools, equipment, teaching aids to textbooks, materials, sound, and lighting.

The occupational safety training instructors of An Toan Nam Viet are experts with many years of experience in the field. They even have research projects identifying hazards in all occupations and how to prevent them.

The instructor’s lectures are drawn from practice and conveyed in the most vivid and easy-to-understand way to the workers. These factors help workers feel comfortable during their studies and absorb the teaching knowledge well. Of course, the knowledge conveyed always adheres to Decree 44/2016/ND-CP. From there, they will learn many measures to prevent hazards and how to protect themselves. At the same time, they will also apply it most appropriately in their actual work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

VIII. The Significance of Occupational Safety in Operating a Cement Ball Mill Grinding Machine

A. The importance of maintaining occupational safety in operating a cement ball mill grinding machine

Maintaining occupational safety during the operation of a cement grinding machine is extremely important for many reasons. First of all, occupational safety ensures the health and safety of employees, minimizing the risk of accidents and injuries during work. This is not only good for the individual but also creates a positive work environment and supports the development of the business.

Next, maintaining occupational safety helps to minimize the risk of machine damage and material loss. By following safety regulations and measures, the operator can reduce the risk of damaging the machine and extend the life of the equipment.

In addition, maintaining occupational safety also helps to enhance production efficiency and product quality. Employees working in a safe environment feel more confident and focused on their work, helping to increase production efficiency and minimize errors in the production process.

B. Important safety measures to know before operating a cement ball mill grinding machine

Before operating a cement grinding machine, it is extremely important to master safety measures to ensure the safety of employees and equipment. First, ensure that all employees have been trained in occupational safety and are aware of the potential risks in the machine operating process.

Second, inspecting the machine and protective equipment before starting operation is an important step. Ensure that the grinding machine and related parts are regularly maintained and do not have any technical problems that could cause danger.

Furthermore, always follow safety rules when operating the machine, including wearing proper personal protective equipment such as a helmet, mask, gloves, and safety shoes.

Complete occupational safety training to be issued an occupational safety card by the occupational safety training center to properly supplement your work records.

PART III: Further Reference

1. Group 3 Occupational Safety Test

2. Price List for Occupational Safety Training Services

3. Download Document

- Download occupational safety training document for operating a cement ball mill grinding machine

- Occupational safety multiple choice test for operating a cement grinding machine

- Occupational safety training slides for operating a cement grinding machine