Safety Document Group 3

Occupational Safety Document for Operating Ultrasound Machine

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SUITE (6 GROUPS, OVER 300 INDUSTRIES)

Are you learning about occupational safety for operating ultrasound machines? This document provides detailed guidance on safety measures, and how to inspect and maintain ultrasound equipment. Learn how to protect your health and that of your colleagues when working with modern ultrasound technology.

PART I: CURRENT STATUS OF SAFETY WORK RELATED TO ULTRASOUND MACHINES

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some occupational accidents when operating an ultrasound machine

In the field of medical diagnostic imaging, the use of ultrasound machines is common to identify problems within the body. However, operating an ultrasound machine also carries the risk of serious occupational accidents. Below are some common accidents that occur when working with ultrasound machines:

- Work posture issues: Having to stand or sit for long periods to adjust the ultrasound machine can cause back, neck, or shoulder pain. Incorrect posture can also lead to muscle and bone injuries.

- Noise hazards: Ultrasound machines emit high-frequency sounds that can be harmful to hearing if adequate protective equipment is not available. Ultrasound machine operators need to be equipped with ear protection.

- Risks from liquids and chemicals: Working with ultrasound gel and cleaning agents can cause skin allergies or dermatitis if proper protective gear is not worn.

- Voltage and electrical safety issues: The risk of electrical incidents or damage to electrical equipment can occur if periodic maintenance and inspections are not performed.

- Accidents due to equipment and hardware: Technical failures or damage to the ultrasound machine can lead to a risk of injury from steam explosions, liquid leaks, or unexpected equipment responses.

Medical staff and technicians working with ultrasound machines need to be fully trained in occupational safety and accident prevention measures to minimize risks and protect their health during their work.

PART II: OCCUPATIONAL SAFETY AND HEALTH WHEN OPERATING AN ULTRASOUND MACHINE

I. Introduction

A. Overview of the importance of occupational safety when operating an ultrasound machine

Occupational safety is an extremely important factor when operating an ultrasound machine. Implementing safety measures related to the use of ultrasound machines not only protects the health of medical staff but also ensures the quality of patient care and the efficiency of the diagnostic process.

When operating an ultrasound machine, staff need to be trained on how to use the machine and related safety measures. Specific instructions such as how to wear protective gear, and how to handle and operate the machine safely are regulated to minimize the risk of accidents and protect the skin from the effects of ultrasound waves.

In addition, the periodic maintenance and inspection of ultrasound machinery and equipment are very important to ensure they operate effectively and safely. Care in maintenance helps prevent incidents and ensures that the machinery operates stably, minimizing the risk of harm to staff and patients.

B. Important safety protocols and regulations when operating an ultrasound machine

Adhering to safety protocols and regulations is very important when operating an ultrasound machine to ensure the safety of staff and patients. These protocols cover many aspects such as ensuring the proper operation of the machine and protecting against the unwanted effects of ultrasound waves.

First, implementing basic safety measures is very important. Staff need to be trained on how to use the ultrasound machine correctly and wear protective gear such as safety glasses and ultrasound-resistant gowns to protect their eyes and skin from the effects of ultrasound waves.

Second, the periodic inspection and maintenance of machinery is also a key factor. Ensuring that the ultrasound machine always operates correctly and meets safety standards will minimize the risk of accidents and ensure the quality of diagnosis.

II. Components and Functions of an Ultrasound Machine

A. The different components of an ultrasound machine

An ultrasound machine consists of the following main components:

- Transducer: This is the most important component of the ultrasound machine, responsible for emitting ultrasound waves and receiving the reflected waves from the body. The transducer converts between electricity and ultrasound waves to create an image.

- Computer and display screen: The signals from the transducer are sent to a computer for processing and image creation. The display screen allows the user to view and evaluate the images generated from the ultrasound waves.

- Control system and adjustment knobs: The ultrasound machine is controlled by control systems and adjustment knobs on the machine’s surface. These knobs allow the user to change settings to suit specific examination needs.

- Ultrasound conductive gel: To create high-quality images, ultrasound conductive gel is used to help transmit ultrasound waves from the transducer into the skin and body more effectively.

- Image output: The ultrasound machine can also connect to other devices such as printers or computers to store and share the images created from the ultrasound process.

All these components work together to create high-quality ultrasound images, aiding in the process of medical diagnosis and treatment.

B. Structure and operating principle of an ultrasound machine

An ultrasound machine operates on the principle of ultrasound waves and their reflection from structures inside the body. The ultrasound machine includes a transducer, which is the main component. This transducer is capable of emitting ultrasound waves and receiving the reflected waves from structures in the body. When ultrasound waves enter the body, they encounter tissue layers of different densities and are reflected back in different ways. The thickness and density of the structures in the body affect the degree of reflection of the ultrasound waves.

The information from these reflected waves is collected by the transducer and converted into electrical signals. These signals are then sent to a computer for processing. The computer analyzes these signals and creates a 2D or 3D image of the internal structures, based on the different levels of reflection of the ultrasound waves.

To create a quality image, the ultrasound user typically uses a conductive gel to minimize reflection from the air layer between the skin surface and the transducer. This process helps to increase the accuracy and sharpness of the image produced. This structure and operating principle make the ultrasound machine an important tool in medical diagnosis, allowing visualization of internal body structures without the need for surgery.

C. Applications in the medical industry of an ultrasound machine

An ultrasound machine is a technology widely used in the medical field with many important applications. In the medical industry, ultrasound is used to diagnose and monitor medical conditions in the human body effectively and non-invasively. One of the main applications of ultrasound is the imaging of internal organs such as the heart, liver, kidneys, pancreas, uterus, ovaries, prostate, as well as bones, blood vessels, and soft tissues.

Ultrasound is a useful tool in the preliminary diagnosis of cardiovascular diseases by observing arteries and veins, tumors, and signs of irregular blood flow. In addition, in the field of obstetrics, ultrasound is very important for examining the fetus, detecting problems such as congenital disorders, the position of the fetus, and assessing the health of both the fetus and the mother.

D. Risks associated with operating an ultrasound machine

Operating an ultrasound machine is not entirely safe and can present some risks. During use, sound wave interference can occur, leading to a decrease in image quality or suspicion about the safety of cells in the body. The use of inappropriate ultrasound pressure can cause injuries such as skin burns or vascular obstruction.

In addition, the use of the ultrasound machine must be precisely adjusted to avoid sound variations that cause interference. Exposure to ultrasound waves can lead to an increase in temperature, damaging surrounding tissues, especially in long-term treatments or in sensitive areas of the body.

Although modern ultrasound devices have been designed to minimize these risks, operators still need to follow specific guidelines for machine adjustment and use appropriate power levels. When using an ultrasound machine, caution and precision are necessary to ensure safety and effectiveness in medical diagnosis and treatment.

III. Safety Inspection and Maintenance Before Operating an Ultrasound Machine

A. Safety inspection before operating an ultrasound machine

Before operating an ultrasound machine, performing a safety check is very important to ensure performance and avoid potential problems. First, the physical conditions of the machine should be checked, including inspecting the power cord, power adapter, and other accessories to ensure they are functioning normally and are not hazardous.

Next, checking the machine’s technical parameters is necessary. This includes checking the operating pressure and temperature of the ultrasound machine to ensure they meet safety standards and do not cause harm to the user or patient.

In addition, the operator needs to check the machine’s default settings and ensure that these parameters are adjusted appropriately for the type of client and purpose of use. For example, if using an ultrasound machine for diagnosing cardiovascular diseases, it is necessary to ensure that the appropriate settings and wave frequencies are selected to achieve high-quality and safe images.

B. Guide to periodic maintenance of an ultrasound machine

Periodic maintenance of an ultrasound machine is very important to ensure the device’s performance and reliability in medical applications. First, the surface of the ultrasound machine should be cleaned to remove dust and grease that can affect its operation. Use mild, alcohol-free cleaning solutions to clean the machine carefully.

Next, check the probes and connecting cables to ensure they are not damaged or bent. The probes should be checked for image quality and performance to ensure they function correctly during examination and diagnosis.

In addition, the machine settings should be re-examined, including recalibrating technical parameters such as wave frequency, depth, and output power to ensure they still meet quality and safety standards.

IV. Safe Operating Procedure for an Ultrasound Machine

A. Step-by-step guide to the safe operating procedure for an ultrasound machine

The safe operating procedure for an ultrasound machine is carried out in specific steps to ensure performance and avoid risks for the patient and the operator. First, before starting, the operator needs to recheck the machine to ensure the settings are correct. This includes checking the power and calibrating technical parameters such as wave frequency and sound depth.

Next, the operator needs to prepare the patient’s skin surface by applying conductive gel to the area to be examined. This helps create good contact between the probe and the skin, improving image quality and reducing the risk of injury.

Then, the operator should move the probe over the area to be examined in the appropriate direction and speed to obtain clear and detailed images. During this process, attention should be paid to the depth and angle of the probe to optimize the image.

Upon completion of the examination, the operator should turn off the machine and wipe the probe clean with a soft cloth to remove the conductive gel and store the machine in a clean, dry condition.

B. Emergency handling measures and incident response mechanisms when operating an ultrasound machine

During the operation of an ultrasound machine, emergency handling measures and incident response mechanisms are very important to ensure safety and avoid potential problems. First, if the ultrasound machine malfunctions or shows any unusual phenomena such as unclear images, the operator should immediately stop the examination and recheck the equipment.

If any safety-related incident occurs, such as the patient experiencing pain or distress, the operator should immediately stop the examination and take the necessary measures to resolve the situation.

In addition, in case of an emergency such as the patient experiencing a serious complication due to the ultrasound examination, the operator should be confident and patient.

V. Risk Assessment and Hazard Management When Operating an Ultrasound Machine

A. Identifying potential risks and hazards in operating an ultrasound machine

During the operation of an ultrasound machine, identifying potential risks and hazards is very important to ensure the safety of the patient and the operator. One of the main risks is that inappropriate ultrasound pressure can cause damage to surrounding soft tissue or lead to vascular obstruction. This is particularly important to note when applying ultrasound in interventional procedures such as treating vascular stenosis.

In addition, using too much pressure or moving the ultrasound probe too quickly on the skin can cause skin burns or tissue cell damage. To avoid these consequences, the operator needs to ensure that ultrasound is applied gently and with control.

Other potential risks may include using the ultrasound machine at a high power level for too long, causing an undesirable increase in body temperature. This is especially important for cases where ultrasound is used on sensitive areas such as the eyes, ears, or other sensitive body parts.

B. Effective hazard prevention strategies when operating an ultrasound machine

1. Regular inspection and maintenance of the ultrasound machine for safe operation

Regular inspection and maintenance of the ultrasound machine play a crucial role in ensuring the safe operation of the equipment in the medical field. First, periodic inspection activities aim to ensure that the ultrasound machine operates at high performance and meets safety standards. This includes checking technical parameters such as wave frequency, sound depth, and pressure to ensure they remain stable and accurate.

Next, the machine’s probes and accessories also need to be inspected to ensure they are not damaged and still meet technical requirements. Inspecting the probes also helps ensure image quality and the accuracy of the diagnostic process.

In addition, periodic maintenance also includes cleaning and preserving the equipment. Cleaning the machine surface and accessories with appropriate cleaning solutions helps remove dust and grease, thereby increasing the durability and lifespan of the machine.

2. Adherence to occupational safety regulations for the safe operation of an ultrasound machine

To ensure the safe operation of an ultrasound machine in a medical environment, adherence to occupational safety regulations is very important. First, the operator needs to be trained on the principles and safety procedures when working with an ultrasound machine. This includes understanding and applying regulations on protecting one’s own health and safety and that of those around.

Second, the operator should always wear appropriate personal protective equipment such as a protective gown, gloves, and safety glasses when in direct contact with the ultrasound machine. This helps protect against risks such as skin and eye reactions from contact with the conductive gel.

In addition, the operator needs to comply with regulations on the use of equipment and the operational activities of the ultrasound machine, including how to adjust machine settings and perform periodic inspection procedures. This helps to minimize the risk of accidents and ensure safety during the use of the ultrasound machine.

3. Identifying and marking the safe zone when operating an ultrasound machine

Before operating an ultrasound machine, identifying and marking a safe zone is very important to ensure the safety of the operator and the patient. First, the operator needs to identify the areas to be examined and place the ultrasound probes in the appropriate positions on the patient’s body. This ensures that only the examined areas will be exposed to ultrasound waves, avoiding unnecessary exposure to other areas.

Next, the operator needs to mark the safe zones by using markers or other measures to indicate the positions that have been examined or the areas that need to be examined next. This helps to avoid re-examining areas and ensures that the entire process is carried out systematically.

In addition, locating internal organs and soft tissues is also an important part of identifying the safe zone. The operator needs to have knowledge of the body part they are examining to be able to place the ultrasound probe in the correct position and avoid other important organs.

4. Use of personal protective equipment when operating an ultrasound machine

During the operation of an ultrasound machine, the use of personal protective equipment is very important to ensure the safety of the operator and the patient. First, the operator should always wear safety glasses to protect their eyes from the effects of ultrasound waves and conductive gel. This helps prevent problems such as skin and eye irritation.

Second, wearing gloves is an important step to protect the skin and avoid direct contact with conductive gel and biological fluids. Gloves also help prevent infection and protect the operator’s health.

In addition, the operator should ensure they wear appropriate protective clothing such as a protective coat to protect the body from dust and fluids. This helps maintain a clean and safe working environment.

5. Emergency procedures and response in case of an incident when operating an ultrasound machine

In the event of an incident while operating an ultrasound machine, a timely emergency procedure and response are very important to ensure the safety of the patient and the operator. First, if the operator detects any unusual signs during the use of the machine, they should immediately stop and recheck the equipment to determine the cause of the incident.

In the case of a serious incident, such as the patient experiencing a peripheral reaction, the operator should immediately stop the examination and request emergency medical intervention. At the same time, they need to report the incident to the medical management authorities for support and timely handling.

In addition, operators need to be trained on how to respond to emergency situations such as power outages, machine failures, or any other technical incidents. Maintaining calm and applying safety measures is very important in handling incidents and ensuring everyone’s safety.

6. Participate in occupational safety training courses when operating an ultrasound machine

Occupational safety and health training is not only a legal requirement but also a commitment to the safety and health of workers. It helps employees recognize and deal with risks and hazardous situations, thereby reducing accidents, injuries, or fatalities in their daily work.

The risk of accidents is always present and can occur at any time in the work environment due to the possibility of human error and the unpredictability of all situations. This emphasizes the need for occupational safety training and continuous vigilance.

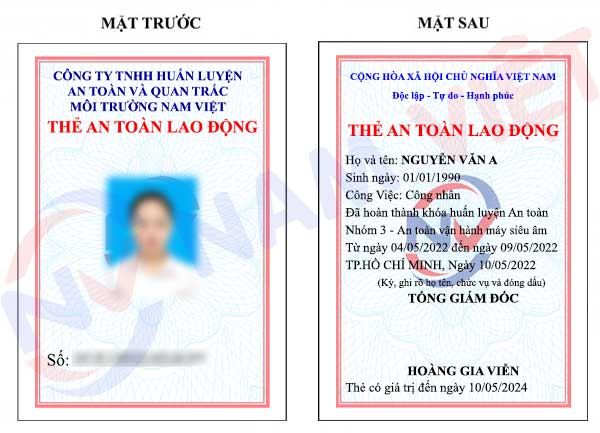

When participating in occupational safety training at Nam Viet Safety Training Center, workers will be systematically trained from theory to real-life risk scenarios. Accordingly, there will be measures to identify and prevent occupational accident risks that may occur during work. After the training course, trainees will take occupational safety tests to obtain an occupational safety certificate. From there, workers will have a clear understanding of safety knowledge as well as a valid certification for employment.

VI. Factors Affecting Occupational Safety When Operating an Ultrasound Machine

A. How do weather conditions affect the operation of an ultrasound machine?

Weather conditions can significantly affect the operation of an ultrasound machine in a medical environment. In particular, the humidity and temperature of the environment can cause problems with the performance and reliability of the equipment. First, high humidity can increase the likelihood of condensation forming in the parts of the ultrasound machine, affecting the image quality and resolution of the device. This can impair the accuracy of diagnosis and affect the overall performance of the machine.

In addition, the ambient temperature can also affect the operation of the ultrasound machine. Temperatures that are too high or too low can reduce the stability of the electronic components inside the machine, leading to performance issues or even failure. Therefore, maintaining the temperature and humidity within an ideal range is extremely important to ensure the stable and effective operation of the ultrasound machine.

In cases where the ultrasound machine needs to be moved through different areas with varying weather conditions, the operator needs to be mindful and adjust the environmental conditions to ensure the machine operates optimally. In addition, periodic maintenance and protecting the machine from external weather elements are necessary to increase the lifespan and durability of the ultrasound equipment.

B. How does the working environment affect the operation of an ultrasound machine?

The working environment has a significant impact on the operation of an ultrasound machine in the medical field. First, the cleanliness of the working environment is an important factor. The ultrasound machine needs to be operated in a clean space to avoid dust and impurities that can affect the performance and image quality of the device. Protecting the machine from dust and a polluted environment is necessary to ensure the stability and reliability of the ultrasound machine.

Second, the humidity and temperature of the working environment can also affect the ultrasound machine. High humidity can increase the risk of condensation forming inside the machine, affecting components and image quality. In addition, ambient temperatures that are too high or too low can also cause problems with the machine’s operational performance.

In addition to the factors above, lighting and noise in the working environment can also affect the process of operating the ultrasound machine. Ensuring a quiet and sound-wave-interference-free working environment is very important to obtain accurate and reliable images from the ultrasound machine.

C. How does the technical condition of the ultrasound machine affect its operation?

The technical condition of the ultrasound machine plays a crucial role in ensuring image quality, diagnostic accuracy, and the operational efficiency of the machine. A well-functioning ultrasound machine will provide the following benefits:

- High image quality: Clear, detailed, and low-noise ultrasound images help doctors easily observe and accurately diagnose medical conditions.

- Diagnostic accuracy: The ultrasound machine has high accuracy in diagnosing diseases related to cardiology, obstetrics and gynecology, gastroenterology, hepatobiliary, and urology.

- Operational efficiency: The machine operates stably with few incidents, saving time and repair costs.

Conversely, if the ultrasound machine has technical problems, it can lead to consequences such as:

- Poor image quality: Noisy, blurry, and hard-to-observe ultrasound images affect the accuracy of the diagnosis.

- Diagnostic errors: A malfunctioning ultrasound machine can lead to diagnostic errors, affecting the treatment of the disease.

- Costly repairs: An ultrasound machine that frequently breaks down will be expensive to repair and maintain.

Therefore, regular preservation and maintenance of the ultrasound machine are very important to ensure it always operates in the best condition. Machine maintenance should be performed by skilled and experienced technicians.

D. How do the safety knowledge and skills of the worker affect the operation of an ultrasound machine?

The safety knowledge and skills of the worker play an extremely important role in operating an ultrasound machine effectively and safely for both the patient and the operator. A worker with full knowledge and skills will ensure the following factors:

1. Using the ultrasound machine correctly:

- Clearly understand the operating principles, structure, and function of the machine’s parts.

- Master the operating procedures and standard manipulations when using the machine.

- Be able to adjust technical parameters appropriately for each medical case.

2. Ensuring patient safety:

- Know how to select the appropriate probe for each ultrasound location.

- Apply the correct pressure and posture when moving the probe on the patient’s body.

- Comply with hygiene and safety regulations when using the ultrasound machine.

3. Protecting oneself from potential harm:

- Clearly understand the potential risks when exposed to ultrasound waves.

- Know how to use preventive measures to protect oneself, such as wearing a lead apron and using safety glasses.

- Regularly monitor health to detect any unusual signs early.

In addition, workers operating ultrasound machines also need to have a professional, careful, and meticulous work attitude and always update their knowledge in the field of medical imaging. By doing so, they can contribute to improving the quality of diagnosis and treatment, while ensuring safety for themselves and their patients.

VII. Occupational Safety Training on Skills for Safe Operation of an Ultrasound Machine

A. Why do operators of ultrasound machines need to be trained in occupational safety?

Operating an ultrasound machine poses many potential risks to the user if they are not properly trained in occupational safety. Therefore, training is extremely important to ensure the safety of the operator, the patient, and those around.

- Exposure to ultrasound waves: Long-term exposure to ultrasound waves can cause some health effects such as fatigue, stress, and even genetic damage. Occupational safety training will help operators know how to use the ultrasound machine correctly, minimizing exposure time to the waves.

- Risk of fire and explosion: Ultrasound machines use a large power source, thus posing a risk of fire and explosion if not operated correctly. Training will provide knowledge about electrical safety, how to prevent and handle fire and explosion situations for operators.

- Risk of cross-contamination: Using a common ultrasound probe for multiple patients without proper disinfection can lead to the risk of cross-contamination of infectious diseases. Training will guide the proper disinfection procedure for the ultrasound probe, ensuring safety for both the operator and the patient.

- Accidents due to working posture: Standing or sitting in the wrong posture for long periods while operating an ultrasound machine can lead to musculoskeletal disorders. Training will provide knowledge about ergonomics, helping operators to have the correct working posture to protect their health.

In addition, occupational safety training also helps ultrasound machine operators to understand the occupational safety regulations issued by the authorities, raise their sense of responsibility in their work, and contribute to protecting the working environment.

B. Where to get occupational safety training for operating an ultrasound machine?

An Toan Nam Viet is a reputable and high-quality center specializing in occupational safety training in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

To ensure the effectiveness of the training, An Toan Nam Viet prepares carefully and meticulously, down to the smallest detail. From preparing tools, equipment, teaching aids to curriculum, materials, sound, and lighting.

The occupational safety training instructors at An Toan Nam Viet are experts with many years of experience in the field. They even have research works identifying hazards in all industries and how to prevent them.

The instructor’s lectures are drawn from practical experience and are conveyed in the most vivid and easy-to-understand way to the workers. These factors help workers feel comfortable during the learning period and absorb the taught knowledge well. Of course, the knowledge conveyed always adheres to Decree 44/2016/ND-CP. From there, they grasp many measures to prevent hazards and how to protect themselves. At the same time, they also apply it most appropriately in their actual work.

VIII. The Significance of Occupational Safety in Operating an Ultrasound Machine

A. The importance of maintaining occupational safety in operating an ultrasound machine

Maintaining occupational safety in operating an ultrasound machine is an extremely important issue, benefiting the operator, the patient, and the medical facility. Ensuring occupational safety will help:

- Protect the health of the operator: Exposure to ultrasound waves, noise, chemicals, and other risks in the work environment can be harmful to the operator’s health if not strictly controlled. Maintaining occupational safety will help minimize these risks, protecting the operator’s health in the long run.

- Ensure patient safety: Improper use of an ultrasound machine can cause complications for patients. Maintaining occupational safety will help ensure that the ultrasound machine is used according to proper procedures, complying with medical standards, thereby minimizing risks to patients.

- Enhance the reputation of the medical facility: A safe working environment that complies with occupational safety regulations will contribute to enhancing the reputation of the medical facility, building trust with patients, and attracting high-quality human resources.

- Increase work efficiency: When safety is guaranteed at work, operators will feel more comfortable and at ease, thereby increasing work efficiency.

- Avoid waste: Occupational accidents or medical incidents due to violations of occupational safety can lead to financial losses and affect the reputation of the medical facility. Maintaining occupational safety will help limit these damages.

B. Important safety measures to know before operating an ultrasound machine

Before operating an ultrasound machine, the user needs to master the following safety measures to ensure the safety of themselves, patients, and those around:

1. Read the user manual carefully: Each ultrasound machine has its own user manual, providing detailed information on operation, maintenance, and necessary safety measures. The user needs to read the manual carefully before operating the machine to understand its functions, procedures, and important notes.

2. Participate in training courses: Occupational safety training courses on operating ultrasound machines organized by competent medical authorities will provide users with the necessary knowledge and skills to use the machine safely and effectively.

3. Inspect the machine before use: Before each use, the operator needs to conduct a general inspection of the ultrasound machine, including the power source, connecting cables, probe, and screen to ensure the machine is functioning normally. If any unusual signs are detected, it should be reported to the technical department for repair before use.

4. Use correctly: The operator needs to use the ultrasound machine according to the user manual and adhere to safe operating procedures. The following points should be noted:

- Wash hands thoroughly before using the machine.

- Wear gloves and a mask during use.

- Use appropriate ultrasound gel.

- Adjust the ultrasound wave intensity appropriately for each case.

- Do not let metal objects come into contact with the ultrasound probe.

- Do not use mobile phones or other electronic devices while operating the machine.

5. Clean and disinfect the machine after use: After each use, the operator needs to clean and disinfect the ultrasound machine according to the user manual to ensure hygiene and prevent cross-contamination.

6. Report incidents: If any incident occurs during the operation of the ultrasound machine, the operator needs to report it immediately to the technical department for resolution.

Complete the occupational safety training course to be issued an occupational safety card by the safety training center to complete the required documentation for work.

PART III: Further Reading

1. Group 3 Occupational Safety Test

2. Price List for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training document for operating an Ultrasound machine

- Slide presentation for occupational safety training on operating an Ultrasound machine

- Occupational safety quiz for operating an Ultrasound machine