Occupational Safety Training For Stationery Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the movement of the market. For more accurate pricing support, please refer to the quotation or contact directly with our consultants.

Occupational safety is an important issue in stationery manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of enterprises. The Occupational Safety Training course is one of the effective solutions to raise awareness about preventing occupational accidents for workers participating in stationery manufacturing.

Table of Contents

Toggle1. Overview of Stationery

a. What is Stationery?

Stationery refers to products and tools used in office work such as paper, pens, notebooks, folders, binders, document holders, tape, paper clips, computers, printers, photocopiers, fax machines, telephones, projectors, laptops, lamps, chairs, desks, filing cabinets, file racks, and many other products.

Stationery products are commonly used to support daily office activities such as drafting, filing, note-taking, printing, and document presentation.

b. Stationery Manufacturers in Vietnam

Stationery manufacturers in Vietnam include:

- The Gioi Vi Tinh (TGVC): one of the largest companies in the field of providing office equipment, computers, computer components, printers, fax machines, and computer maintenance services in Vietnam.

- Law Library: a leading company in providing stationery and office services in Vietnam. The Law Library specializes in office products such as paper, pens, notebooks, printers, fax machines, and office equipment.

- Duy Tan Plastics: specializes in manufacturing and trading stationery products such as binders, file folders, document boxes, document trays, bookshelves, folders, document holders, storage boxes, paper boxes, file bags, paper bags, plastic bags, etc.

- Dai Viet: one of the major stationery manufacturers in Vietnam, specializing in products such as notebooks, ballpoint pens, pencils, photocopy paper, printing paper, binders, file folders, folders, sticky notes, etc.

- Tran Phu: a company specializing in high-end stationery products such as fountain pens, highlighters, pencils, ballpoint pens, binders, file folders, notebooks, printing paper, photocopy paper, etc.

c. Specific Jobs in a Stationery Manufacturing Factory

Group 1

- Executive Director, Deputy Executive Director, Department Heads in the stationery manufacturing factory.

Group 2

- Safety Officers: responsible for managing safety in the factory, designing safety procedures, monitoring and enforcing employees to follow safe working practices.

Group 3

- Pen, pencil, board, and marker manufacturing: processes include making pen caps, filling ink, assembling parts using machines, and quality checking.

- Paper manufacturing: processes include raw material processing, material separation, forming paper layers, drying, cutting, and packaging.

- Folder and file manufacturing: processes include framing, paper cutting, gluing, pressing, spine binding, inspection, and packaging.

- Student tool manufacturing: processes include cutting, framing, printing, applying decals, inspection, and packaging.

- Office tool manufacturing: processes include making plastic or metal components, assembly, and quality inspection.

- Ink manufacturing: processes include mixing, filtering, heating, adding chemicals, and bottling.

- Tape manufacturing: processes include creating adhesive layers, applying adhesive to fabric or paper, cutting, and packaging.

Group 4

- Office work, service, sales, marketing.

- Manufacturing management, quality management, human resources management, material management, financial and accounting management.

- Research and development of new products, designing product packaging samples.

d. Commonly Used Office Machines

Common office machines include:

- Printers: used to print office documents, from papers to posters, labels, cards, and other printed products.

- Photocopiers: one of the first types of printers used for copying documents.

- Copiers: used to quickly and easily duplicate office documents.

- Fax machines: used to transmit office documents between offices or partners.

- Bookbinding machines: used to bind books using glue or string.

- Paper cutters: used to cut paper into various sizes and shapes.

- Staplers: used to staple office documents into copies.

- Money counters: used to quickly and accurately count cash.

- Computers: used for data processing and creating office documents such as spreadsheets, presentations, and word processing.

- Projectors: used to display office documents, images, and videos during presentations and seminars.

2. Overview of Occupational Safety Training for Stationery Manufacturing

In this article, we focus on Group 3 because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. Learn more about other groups here.

a. What is Group 3 Occupational Safety Training?

- Group 3 Occupational Safety Training consists of sessions that equip workers with awareness on how to prevent workplace accidents.

- The occupational safety training course helps workers identify and avoid hazards, reducing the risk of workplace accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial Safety Training Duration

- Total training duration is at least 24 hours, including testing time.

- 8 hours of theory on policies and occupational safety and hygiene laws

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical exam at the end of the training course

The safety training center schedules multiple sessions depending on workers’ availability. Usually, there are 6 sessions over 3 days, provided the manufacturing company can allocate continuous training time.

Periodic Safety Training Duration

- Before the occupational safety card expires, workers seeking re-issuance must undergo periodic occupational safety training, with training duration at least 50% of the initial training duration.

Explanation: total periodic occupational safety training must be at least 12 hours, including testing. After completing the course and passing the exam, the worker’s occupational safety card will be reissued or extended.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Exam | |||

| I | Policies and occupational safety and hygiene laws | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | Occupational safety and hygiene standards and technical regulations. | 1 | 1 | ||

| 3 | Specific regulations from state management agencies regarding occupational safety when constructing, expanding, or renovating facilities, using, storing, or inspecting machines, equipment, materials, and hazardous substances. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; safety policies; functions of safety officers. | 1 | 1 | ||

| 5 | Safety rules, signage, use of safety equipment and personal protective equipment; first aid and occupational disease prevention skills. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, hazardous materials; risk analysis, assessment, and management; safe working procedures with machines and hazardous materials. | 6 | 4 | 2 | ||

| IV | End-of-course safety training exam | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of all 6 groups

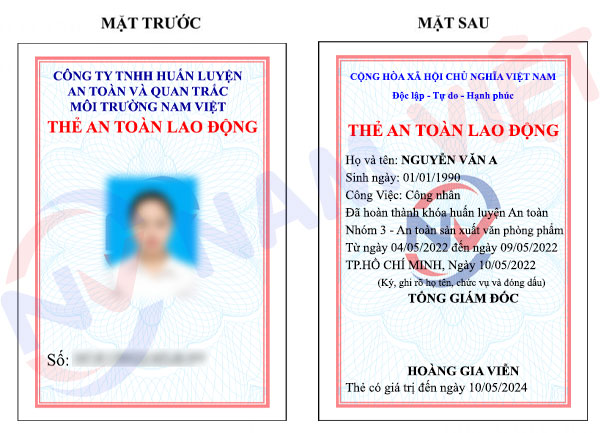

d. Occupational Safety Card

After completing the occupational safety training course and passing the exam, workers will be issued an occupational safety card (commonly referred to as a Group 3 safety certificate).

The Group 3 safety card clearly displays information such as full name, date of birth, job, and specific working environment, as well as training duration, official stamp, and signature confirming course completion.

According to Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have an employment contract, the employer must sign, stamp, and validate the Group 3 safety card after the employee completes the course and passes the exam.

- If the worker is freelance or temporary, without an employment contract, the training unit must sign, stamp, and validate the safety card after the worker completes the course and passes the exam.

3. Identifying Hazards Affecting Workers in Stationery Manufacturing

Hazards affecting workers in stationery manufacturing may include:

- Fire and Explosion Risk: During stationery manufacturing, machines use high electrical power, which can easily cause fire or explosion. Additionally, many flammable materials such as paper, cardboard, printing ink, and solvents used in the manufacturing process may also pose fire and explosion risks.

- Occupational Accident Risk: Stationery manufacturing workers may work with various machinery and equipment, including cutting, stamping, pressing, planing, drilling, welding, stapling tools, and electronic devices. Improper use or lack of attention to safety when operating these devices can lead to accidents such as cuts, hand injuries, crushing, stabbing, burns, electric shocks, etc.

- Chemical Hazard: Stationery manufacturing uses many toxic chemicals such as printing ink, adhesives, and solvents. Without proper protective equipment, workers may be exposed to these harmful substances through inhalation or direct skin contact, causing health problems such as skin itching, irritation, allergic reactions, headaches, fatigue, and breathing difficulties.

- Electrical Hazard: If electrical equipment in the factory is not regularly maintained or is poorly insulated and waterproofed, it can pose a risk of electric shock to workers during manufacturing.

- Dust Exposure Risk: Stationery manufacturing workers may work in environments with high dust from raw materials like paper and cardboard. Inhaling this dust may cause health problems such as shortness of breath, coughing, sore throat, and pneumonia.

4. Common Occupational Accidents for Workers in Stationery Manufacturing

Common occupational accidents for workers in stationery manufacturing include:

- Cuts and Injuries: When operating cutting tools and machinery during manufacturing, workers may suffer cuts or injuries.

- Eye-Related Injuries: Exposure to strong light or chemicals may affect workers’ eyes.

- Poisoning: Chemical products used in stationery manufacturing can cause poisoning if not handled properly.

- Temperature and Pressure Hazards: During manufacturing, temperature and pressure may cause accidents if not properly monitored and controlled.

- Mental Health Issues: Stationery manufacturing work often requires long periods of sitting and performing repetitive tasks, which may lead to mental health problems for workers.

5. Safety Measures When Participating in Stationery Manufacturing

Safety measures when participating in stationery manufacturing include:

- Use of Protective Equipment: Protective gear such as face shields, masks, gloves, chemical-resistant coats, and safety shoes helps reduce exposure to harmful substances, dust, and debris.

- Occupational Safety Training: Train employees on manufacturing processes and necessary safety measures, including how to use machinery, protective equipment, and respond to emergencies.

- Regular Machinery Maintenance: Periodically maintain machines and inspect equipment to ensure safe operation.

- Proper Use of Chemicals: Handle chemicals according to instructions and store them safely.

- Noise Reduction: To minimize noise-related accidents, factories should implement measures such as noise-canceling headphones, reducing noise from machinery, or limiting exposure time to high-noise areas.

- Waste Classification and Disposal: Proper waste handling reduces its impact on human health and the environment.

- Hygiene Checks: Maintain clean manufacturing areas and ensure personal hygiene of employees to minimize the risk of infections.

- Periodically conduct workplace environmental monitoring in factories to collect and analyze hazardous factors affecting workers, then adjust and reduce risks to prevent occupational diseases.

6. Benefits of Occupational Safety Training in Stationery Manufacturing

An Toan Nam Viet provides enterprises with the following benefits after completing occupational safety training courses in accordance with Decree 44/2016/ND-CP on occupational health and safety for companies:

- Workers can identify potential occupational hazards and take preventive measures to avoid accidents.

- Enterprises can establish risk prevention measures in manufacturing, operation, and maintenance processes.

- Reduce costs associated with potential workplace safety risks.

- Continuous manufacturing ensures higher labor productivity and product quality.

- Compliance with occupational safety regulations reduces legal risks.

- Enhances enterprise reputation and professionalism, thereby strengthening the brand.

Nam Viet’s training courses help prevent external risks affecting individuals, allowing them to avoid injuries or, in severe cases, fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

7. Customer Feedback After Completing Occupational Safety Training in Stationery Manufacturing

An Toan Nam Viet has many years of experience accompanying businesses across Vietnam, especially in southern provinces. This responsibility is extremely valuable to Nam Viet, which is why the Occupational Safety Training service is increasingly professional. Our growth is fueled by positive feedback and constructive suggestions from our clients. Below are some testimonials from our partners.

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service helped us simplify occupational safety and complete safety documentation for work processes. The consulting team was enthusiastic and timely with our inquiries. Five stars for Nam Viet.”

See more customer interviews after using the service from An Toan Nam Viet

8. An Toan Nam Viet’s Capacity in Occupational Safety Training

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam. Training sessions are conducted continuously at factories, manufacturing workshops, and construction sites nationwide (all 63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Safety under the Ministry of Labor – Invalids and Social Affairs, confirming the eligibility for occupational safety training. This strengthens our capacity in providing Occupational Safety Training.

Training Materials and Lectures

- Before being used in OHS training courses, materials are reviewed to ensure accuracy and practical effectiveness.

- Teaching methods are standardized according to An Toan Nam Viet guidelines, developed by experts in occupational health and safety training to ensure maximum knowledge retention for trainees.

Facilities

- Controlling classroom factors affecting training improves teaching efficiency and trainee learning outcomes.

- Our training facilities provide spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable and High-Quality Occupational Safety Training Center

At An Toan Nam Viet, professional dedication to occupational safety training is a top priority. We aim to equip workers with self-protection knowledge to ensure their safety during work, contributing to national development.

We meticulously prepare tools, teaching aids, curricula, materials, audio, and lighting to maximize training efficiency.

Our instructors are experts with extensive experience and research in identifying hazards across industries and how to prevent them.

Lectures are based on practical experience and delivered in a clear, engaging manner. Knowledge is aligned with Decree 44/2016/ND-CP, allowing trainees to understand preventive measures and self-protection strategies applicable to real work situations.

Our Training Center proudly offers professional and reliable occupational safety training with advantages:

- Competitive training costs without compromising quality.

- Flexible training schedules according to company manufacturing.

- Fast certification processing compliant with legal regulations.

- Experienced instructors.

- Controlled classroom environment enhances learning outcomes.

- Curricula tailored to company occupational safety requirements.

- Dedicated and professional support for clients.

10. Additional Reference Materials for Occupational Safety Training in Stationery Manufacturing

- Occupational Safety Materials for Stationery Manufacturing

- Occupational Safety Training Materials

- Occupational Safety Training Test Materials

- Occupational Safety Training Curriculum for Stationery Manufacturing

- Occupational Safety Quiz for Stationery Manufacturing

1 review for Occupational Safety Training For Stationery Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ huấn luyện an toàn lao động rất tốt nhé, giảng viên dạy rất sinh động dễ hiểu!