Occupational Safety Training For Microwave Oven Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the movement of the market. For more accurate pricing support, please refer to the quotation or contact directly with our consultants.

Occupational safety is an important issue in microwave oven manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of enterprises. The Occupational Safety Training course is one of the effective solutions to raise awareness about preventing occupational accidents for workers participating in microwave oven manufacturing.

Table of Contents

Toggle1. Overview of Microwave Ovens

a. What is a Microwave Oven?

A microwave oven is a type of household electrical appliance used to cook, heat, and grill food quickly through the activation of molecules in the food by microwave radiation. Microwave ovens are usually compact, convenient, and widely used in households, offices, and food stores.

b. Types of Machinery for Microwave Oven Manufacturing

The types of machinery used in microwave oven manufacturing include:

- Steel sheet cutting machine: This machine is used to cut steel into sheets of suitable sizes and shapes to make components of the microwave oven.

- Steel bending machine: This machine is used to bend steel sheets into various forms to make the components of the microwave oven.

- Spot welding machine: This machine is used to weld metal parts together to form microwave oven components.

- Surface processing machine: This machine is used to process the surface of microwave oven components, including grinding, polishing, and sandblasting.

- Painting machine: This machine is used to spray paint onto metal parts to create a smooth surface and protect against corrosion.

- Plastic processing machine: This machine is used to process plastic parts of the microwave oven, including molding and injection molding.

- Assembly machine: This machine is used to assemble metal and plastic parts into a complete microwave oven.

All of these machines are combined to create diverse and high-quality microwave oven product lines.

c. Microwave Oven Manufacturing Enterprises in Vietnam

Currently, Vietnam has several microwave oven manufacturing enterprises, including:

- Samsung Electronics Vietnam: Samsung is one of the largest and most famous brands in the world in the electronics sector, including microwave ovens. Samsung Electronics Vietnam has manufacturing factories in Ha Noi and Bac Ninh.

- LG Electronics Vietnam: LG is a fairly popular brand and is also known as one of the leading microwave oven manufacturers in Vietnam. LG Electronics Vietnam has manufacturing factories in Hai Phong and Ha Noi.

- Panasonic Vietnam: Panasonic is also a well-known brand in the electronics industry with many popular microwave oven products. Panasonic Vietnam has a manufacturing factory in Ha Noi.

- Electrolux Vietnam: Electrolux is a major brand in the household appliance manufacturing industry with high-quality microwave oven products. Electrolux Vietnam has a manufacturing factory in Tay Ninh.

- Sharp Vietnam: Sharp is also a fairly well-known brand with many high-quality microwave oven products. Sharp Vietnam has a manufacturing factory in Tay Ninh.

d. Specific Jobs in Microwave Oven Manufacturing Factories

Group 1

- Chief Executive Officer, Deputy Chief Executive Officer, Department Managers in microwave oven manufacturing factories.

Group 2

- Safety Officers: managing safety in the factory, designing safety procedures, monitoring, and urging employees to comply with safe working procedures.

Group 3

- Procurement of materials and accessories: To manufacture microwave ovens, high-quality materials and accessories are required such as stainless steel sheets, electronic components, electrical parts, fan systems, and other equipment. The factory usually has a management and procurement department to ensure the supply of high-quality materials and accessories for manufacturing.

- Material processing: Materials are cut, bent, punched, welded, ground, and polished to create microwave oven parts such as the oven cabinet, door, tray, and other components.

- Assembly: The components are assembled into a complete product. The factory usually has automated or semi-automated production lines to assemble parts into their proper places in the production process.

- Inspection and quality control: Products are inspected and quality controlled throughout the manufacturing process to ensure product quality meets technical and safety requirements.

- Packing and transportation: After being inspected and quality controlled, the product will be packed and transported to agents or customers worldwide.

Group 4

- Office work, service, sales, marketing.

- Production management, quality management, human resources management, material management, financial and accounting management.

- Design: Design engineers are responsible for creating technical drawings and simulation designs to ensure that microwave ovens meet technical and safety requirements.

2. Overview of Occupational Safety Training in Microwave Oven Manufacturing

Within the scope of this article, we focus on issues related to group 3, because group 3 is directly involved in the manufacturing process and is exposed to the highest occupational safety risks. Refer to other groups here

a. What is Group 3 Occupational Safety Training?

- Occupational safety training group 3 consists of lessons that provide awareness on how to prevent occupational accidents for employees.

- The occupational safety training course will help employees recognize and avoid hazards, thereby reducing the risk of occupational accidents while working.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial occupational safety training duration

- Total training duration is at least 24 hours, including examination time.

- 8 hours of theoretical study on safety and occupational hygiene policies and laws.

- 8 hours of theoretical study on basic knowledge of occupational safety and hygiene.

- 4 hours of theoretical study on specialized training content.

- 2 hours of practical training on specialized content.

- 2 hours of final theoretical examination to conclude the course.

The safety training center will arrange the time into several training sessions depending on the scheduling of employees. However, typically, there will be 6 training sessions, the course will last 3 days, provided that the manufacturing enterprise can arrange continuous training time.

Periodic occupational safety training duration

- Before the occupational safety card expires, employees who wish to renew must undergo a periodic occupational safety training course, with the periodic training duration being at least 50% of the initial training duration.

Explanation: the total periodic occupational safety training duration is at least 12 hours, including examination time. After completing the periodic training and passing the test, employees will be reissued or have their occupational safety card renewed.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Examination | |||

| I | System of policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the legal document system on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when building new, expanding, or renovating facilities for manufacturing, using, storing, and inspecting machinery, equipment, materials, and substances requiring strict occupational safety and hygiene. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies and regimes on occupational safety and hygiene for employees; functions and tasks of the occupational safety and hygiene network. | 1 | 1 | ||

| 5 | Occupational safety and hygiene regulations, signs, safety instructions, and use of safety equipment, personal protective equipment; operations and skills for first aid in occupational accidents and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of types of machinery, equipment, and substances generating hazardous and harmful factors; analysis, assessment, and risk management of occupational safety and hygiene; safe working procedures with machinery, equipment, and substances requiring strict occupational safety and hygiene. | 6 | 4 | 2 | ||

| IV | Examination of occupational safety training content at the end of the course | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

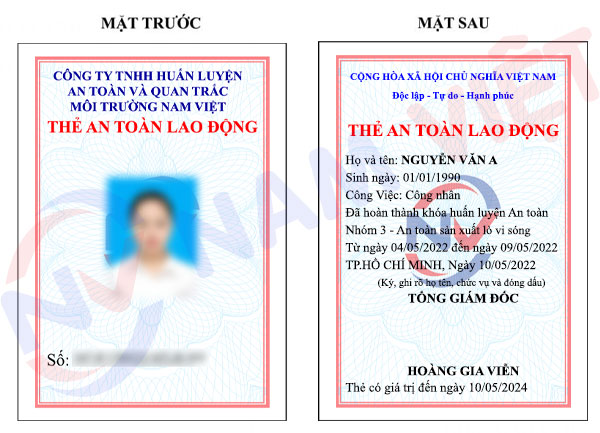

d. Occupational Safety Card

After completing the occupational safety training course and passing the examination, employees will be issued an occupational safety card (commonly referred to as a occupational safety certificate group 3).

The group 3 safety card will clearly display information such as: full name, date of birth, job, and specific working environment. It will also include the training duration, a red stamp, and a signature confirming completion of the training course.

According to the regulations on issuing safety cards stated in clause 2 of article 24 of Decree 44/2016/ND-CP, it is divided into two cases:

- If the employer and the employee have a labor contract, the employer must sign, stamp, and seal the safety card for group 3 employees after they have completed the occupational safety training course and passed the examination.

- If the employee is a freelancer, seasonal worker, or does not have a labor contract, the training unit must sign, stamp, and seal the safety card for the employee after they have completed the occupational safety training course and passed the examination.

3. Identifying Hazards Affecting Workers In Microwave Oven Manufacturing

Some hazards affecting workers during the microwave oven manufacturing process include:

- Electrical hazards: Employees may suffer electric shock or fire and explosion due to electricity use.

- Cutting hazards: Machinery in the microwave oven manufacturing process may generate sharp cutting blades, posing safety risks to employees.

- Fire and explosion hazards: During the manufacturing process, chemical products used may easily ignite or explode, harming workers and the factory.

- Toxic hazards: In the manufacturing process, workers may be exposed to toxic chemicals, negatively affecting their health.

- Occupational accident hazards: While operating machinery, employees may encounter occupational accidents such as entrapment or collisions with materials used in the manufacturing process.

4. Types Of Occupational Accidents Commonly Occurring To Workers In Microwave Oven Manufacturing

Some types of occupational accidents commonly occurring to workers in microwave oven manufacturing include:

- Injuries from collisions, cuts, punctures: These are frequent accidents when using cutting, drilling, grinding, pressing, bending, and fastening tools for components.

- Burns: In microwave oven manufacturing, workers must handle heated components such as molds, bases, nozzles, and insulating materials. Without proper protective equipment or careful work, workers may suffer burns.

- Chemical reactions: Chemicals used in the microwave oven manufacturing process may cause allergies, irritation, or vomiting. Those working with such chemicals must follow necessary safety measures.

- Electric shock: Workers must work with electronic components, which may cause electrical accidents, including electric shock or fire and explosion.

- Dust exposure: During manufacturing, workers may be exposed to dust and other harmful substances. Without proper protective equipment, they may suffer respiratory diseases or allergies.

- Internal traffic accidents: Workers involved in operating vehicles to transport goods within microwave oven factories may encounter internal traffic accidents.

5. Safety Measures When Participating In Microwave Oven Manufacturing

Safety measures when participating in microwave oven manufacturing may include:

- Ensure the use of personal protective equipment: Workers must fully use personal protective equipment such as helmets, safety glasses, gloves, safety shoes, masks, and protective clothing when working with machinery in microwave oven factories.

- Regular inspection and maintenance of equipment: Equipment and machinery in microwave oven factories must be regularly inspected and maintained to ensure good operation and worker safety.

- Training and educating workers: Employees in microwave oven factories need training and education on how to use personal protective equipment, how to work with machinery, and safe working methods.

- Organize fire prevention and fighting drills: Fire prevention and fighting training sessions and how to use firefighting equipment should be organized regularly so workers can handle emergencies when incidents occur.

- Improve working conditions: To minimize hazards for workers, microwave oven factories should ensure safe, comfortable, and well-lit working environments.

- Use safe materials and technologies: Apply safe materials and technologies to minimize hazards for workers.

- Develop and maintain safety procedures: Microwave oven factories should develop and maintain safety procedures for all tasks, from manufacturing to transportation and assembly of products.

- Periodically organize occupational environment monitoring in factories, collect and analyze harmful factors for workers, then adjust and reduce hazards to prevent occupational diseases.

6. Benefits Of Occupational Safety Training In Microwave Oven Manufacturing

An Toan Nam Viet provides businesses with excellent benefits after completing occupational safety training courses in accordance with Decree 44/2016/ND-CP on occupational safety and hygiene for companies, factories, and enterprises.

- Workers can identify potential risks of occupational accidents and apply preventive measures to avoid accidents.

- Businesses can establish preventive measures in production, operation, and maintenance processes.

- Reduce costs when safety risks occur in the workplace.

- Uninterrupted production helps increase labor productivity and product quality.

- Comply with legal regulations on occupational safety, avoiding legal risks.

- Create credibility and professionalism in all aspects, thereby enhancing the business brand.

The training courses of Nam Viet are solutions to prevent and resist external impacts on each individual so they can avoid dangers leading to injury or, more seriously, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback After Completing Occupational Safety Training In Microwave Oven Manufacturing

An Toan Nam Viet has many years of experience in the mission of accompanying many businesses in Vietnam in general and in southern provinces in particular. That responsibility for Nam Viet is extremely valuable, which is why occupational safety training is increasingly emphasized professionally. The driving force for An Toan Nam Viet’s strong development today comes from positive feedback and suggestions from businesses. Below are the feedbacks from our partners we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“The first time using services at An Toan Nam Viet I was very surprised by the 24/7 enthusiastic support of the consulting team. The organization of classes was very quick and convenient for our company, thank you very much Nam Viet!”

Hoa Dat Construction And Trading Joint Stock Company

“Nam Viet’s service has greatly helped us in simplifying occupational safety and completing safety records for the working process. The consulting team is enthusiastic and timely in answering our questions. 5 stars for Nam Viet.”

See more customer interviews after using services of An Toan Nam Viet

8. Occupational Safety Training Capacity Of An Toan Nam Viet

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam today. With occupational safety training sessions regularly held at factories, plants, or construction sites nationwide (63 provinces and cities in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

License for occupational safety training

- An Toan Nam Viet has been inspected and issued a certificate of eligibility for occupational safety and hygiene training activities by the Department Of Occupational Safety Of The Ministry Of Labor – Invalids And Social Affairs. This further strengthens the training capacity of our occupational safety training.

Documents and lectures

- Before occupational safety training documents are introduced into occupational safety training courses, they have been reviewed and approved to ensure accuracy and effectiveness when applied.

- The teaching methods of lecturers are standardized according to the training standards of An Toan Nam Viet, developed by occupational safety experts to ensure the highest knowledge acquisition efficiency for learners.

Facilities

- Controlling classroom factors affecting training increases teaching performance and knowledge acquisition efficiency of learners.

- Training support facilities of ours always provide spacious classrooms meeting standards of area, lighting, training equipment, etc.

9. Reputable And Quality Nationwide Occupational Safety Training Center

At An Toan Nam Viet, we always place the occupational safety training profession as a top priority. For us, imparting knowledge of self-protection to workers so they have safety knowledge in their working lives is contributing to national development.

To ensure effective training, we carefully prepare every detail, from teaching tools, equipment, curriculum, documents, sound, and lighting.

Our occupational safety training lecturers are experts with many years of experience in the field. They even have research projects identifying hazards in all industries and how to prevent them.

Lectures are drawn from practice and delivered in the most vivid, easy-to-understand way to workers. These factors make workers comfortable during training and better absorb the knowledge we provide. Of course, the knowledge delivered always complies with Decree 44/2016/ND-CP.

From there, workers gain many preventive measures against hazards and ways to protect themselves, applying them most appropriately in actual work.

Our occupational safety training center is proud to provide reputable and professional occupational safety training services with the following advantages:

- Competitive training costs while ensuring training quality.

- Flexible training schedules according to business production conditions.

- Quick occupational safety training certificate issuance procedures in accordance with the law.

- Experienced training lecturers with many years in the field.

- Classrooms controlled for factors affecting training, increasing teaching performance and learner efficiency.

- Lectures compiled to match occupational safety tasks at enterprises.

- An Toan Nam Viet works dedicatedly and professionally to support customers accurately and quickly.

10. Additional References For Occupational Safety Training In Microwave Oven Manufacturing

- Occupational Safety Training Documents

- Occupational Safety Documents In Microwave Oven Manufacturing

- Occupational Safety Training Test Questions

- Occupational Safety Training Curriculum In Microwave Oven Manufacturing

- Occupational Safety Multiple-Choice Test In Microwave Oven Manufacturing

1 review for Occupational Safety Training For Microwave Oven Manufacturing

No comments yet

namchinh.haiphong341

Giảng viên dạy rất sinh động dễ hiểu!