Occupational safety training in construction material production

99,000 ₫

Note: The above price is calculated for one person, and the price may fluctuate depending on the number of trainees participating in the course and market movements. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in building material production factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness about accident prevention for workers participating in building material production.

Table of Contents

Toggle1. Overview of Construction Materials

a. What are construction materials?

Construction materials are substances used to build and assemble structures, houses, and infrastructure. They are used to form the framework, components, and surfaces of construction projects. Construction materials can include natural materials, synthetic materials, or a combination of both.

b. Machinery used in construction materials production

There are various types of machinery used in the production of construction materials. Below are some commonly used machines in the construction industry:

- Concrete mixer: Used to mix cement, sand, gravel, water, and additives to produce concrete. Mixers can be horizontal or vertical shaft type, with different capacities and sizes depending on the project scale.

- Concrete press: Used to press and compact concrete in molds, creating load-bearing components such as bricks, concrete slabs, or concrete piles.

- Stone crusher: Used to crush and grind stones into smaller particles for producing construction materials such as sand, gravel, 0-5mm stone, and 5-20mm stone.

- Brick extruder: Used to extrude and shape bricks from clay. The extruder can be manual or automatic, improving efficiency and product quality.

- Tile and stone cutter: Used to cut and shape tiles and stones according to desired dimensions and forms. Types include manual and automatic tile/stone cutting machines.

- Brick-making machine: Used to create bricks from clay and brick mixtures, compressing them into standard-sized blocks.

- Rebar assembly machine: Used to assemble and connect steel reinforcement components in construction projects.

- Drilling and chiseling machines: Used to drill and chisel holes on construction material surfaces such as concrete, bricks, stone, and wood.

- Concrete brick machine: Used to mold and compress concrete bricks during production.

c. Construction materials manufacturers in Vietnam

Vietnam has many companies producing construction materials for the building industry. Below are some notable and large-scale construction material manufacturers in Vietnam:

- Viglacera Corporation: One of the leading companies in brick and ceramic production in Vietnam. Viglacera also produces products such as ceramic tiles, polished tiles, non-fired bricks, industrial ceramics, and interior ceramics.

- Binh Minh Plastic JSC: Known under the brand BM Windows, Binh Minh Plastic is a leading company producing and supplying composite plastics, PVC, and other construction plastic products such as doors, windows, pipes, partitions, and plastic trims.

- Hoa Phat Group: A diversified conglomerate, Hoa Phat also has a branch producing construction materials. The company manufactures and supplies construction steel products such as steel coils, structural steel, high-strength construction steel, and steel pipes.

- Ton Hoa Sen: One of the leading manufacturers and suppliers of steel sheets and related products such as cold-rolled steel, galvanized steel, color steel, and corrugated steel sheets.

- Song Da Group: Song Da has multiple subsidiaries operating in construction and construction material production, including cement, concrete, and building materials from gravel, sand, and stone.

- Viglacera Float Glass Company: A member company of Viglacera Corporation, specializing in producing and supplying construction glass, decorative glass, and heat-resistant glass.

d. Specific jobs in a construction materials factory

Group 1

- Executive director, deputy executive director, and department heads in the construction materials factory.

Group 2

- Safety officer: manages safety within the factory, designs safety procedures, supervises and ensures workers comply with safe work practices.

Group 3

- Raw material preparation: Receiving and inspecting raw materials, including cement, sand, gravel, bricks, stones, and other additives. Selecting and preparing suitable materials for the production process.

- Production process: Carrying out specific production steps to create construction materials, such as mixing cement, sand, gravel, and water to make concrete; extruding clay into bricks; pressing and compacting concrete into reinforced components; crushing and grinding stones into sand and gravel, and other processes depending on the product.

- Quality control: Inspecting production to ensure technical and quality standards are met. This may include checking density, strength, water absorption, hardness, compressive strength, and other requirements for each material type.

- Packing and storage: Packaging products into smaller units and storing them under appropriate conditions to ensure safety and quality preservation.

- Transport and distribution: Packaging products for transportation and distribution to sales points or construction sites.

Group 4

- Office, service, sales, and marketing jobs.

- Production management, quality management, human resource management, materials management, financial accounting management.

- Production planning: Adjusting production schedules, selecting materials, determining production steps, and setting daily, weekly, or monthly production targets.

- Research and product development: Conducting research to create new products, improve production technology, enhance quality, and increase production efficiency.

e. Common construction materials

There are many commonly used construction materials in the building industry. Below are some popular construction materials:

- Cement: A widely used binding material in construction, commonly used to make concrete, mortar, and other building products.

- Concrete: A strong, high-load material made from mixing cement, sand, gravel, water, and additives. Used for foundations, floors, walls, columns, and other structures.

- Brick: A traditional building material made from clay or fired clay. Used for walls, foundations, partitions, and other structures.

- Aerated brick: A lightweight building material made from sand, cement, and foam. Offers good insulation and is suitable for walls and partitions.

- Steel: A high-strength material commonly used for structural frames, columns, beams, and load-bearing structures.

- Wood: Widely used for structural and decorative purposes, including building frames, floors, doors, stairs, and more.

- Glass: Used for windows, doors, partitions, and decorative surfaces, allowing light transmission and creating a sense of openness.

- Ceramics: Industrial ceramics used for flooring, wall cladding, and other decorative surfaces in construction projects.

2. Overview of occupational safety training for construction materials production

In this article, we focus on Group 3, because Group 3 is directly involved in production and faces the highest occupational safety risks. For other groups, see here.

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training consists of sessions that equip workers with awareness of workplace accident prevention.

- The training helps workers identify and avoid hazards, reducing the risk of accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial safety training

- Total training time is at least 24 hours, including exam time.

- 8 hours of theory on policies and laws on occupational safety and hygiene

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours for the final theory test

The safety training center will divide the time into multiple sessions depending on workers’ schedules, typically 6 sessions over 3 days if the company arranges continuous training.

Periodic safety training

- Before the occupational safety card expires, workers must undergo periodic occupational safety training, with duration at least 50% of the initial training time.

Explanation: The total periodic safety training time is at least 12 hours, including exam time. After completing the training and passing the test, workers will have their occupational safety card renewed.

c. Training course content

| No. | TRAINING CONTENT | TRAINING TIME (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | Standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of government agencies regarding occupational safety during construction, expansion, or renovation of facilities, and for the use, storage, and inspection of machinery, equipment, materials, and substances with strict safety requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and workers; occupational safety policies and regimes; roles of safety staff network. | 1 | 1 | ||

| 5 | Occupational safety rules, signs, instructions, use of safety equipment and personal protective equipment; first aid skills and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, substances generating hazards; risk analysis, assessment, and management; safe work procedures with machinery, equipment, and substances with strict safety requirements. | 6 | 4 | 2 | ||

| IV | Final training test | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content for all 6 groups

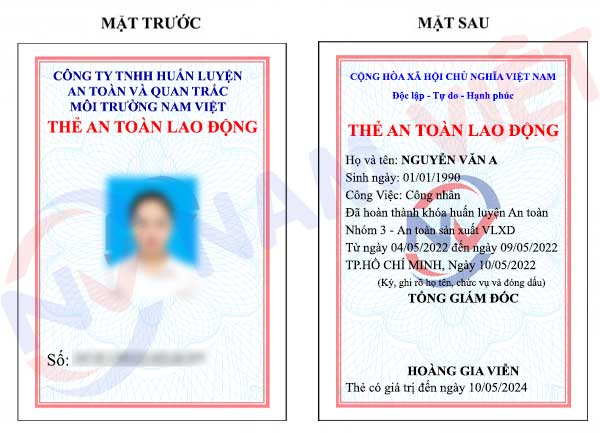

d. Occupational safety card

After completing the occupational safety training and passing the test, workers will be issued an occupational safety card (commonly called a Group 3 safety certificate).

The Group 3 card displays information such as name, date of birth, job position, and specific working environment. It also includes training duration, red stamp, and signature confirming completion.

According to Clause 2 of Article 24, Decree 44/2016/NĐ-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and seal the card for Group 3 trainees after they complete training and pass the test.

- If the worker is freelance or seasonal, without a labor contract, the training unit must sign, stamp, and seal the card after the worker completes training and passes the test.

3. Identifying hazards affecting workers in construction material production

During construction material production, there are several potential hazards that can affect workers. Below are some key hazards that need to be recognized:

- Chemical hazards: The production of construction materials may involve chemicals such as cement, additives, solvents, and dyes. Exposure to these substances can cause skin irritation, allergies, rhinitis, pneumonia, and other health issues. Additionally, the use of machinery and equipment can generate harmful dust and chemical fumes.

- Physical hazards: During production, there may be hot materials, electrical wires, operating machinery, moving components, and heavy objects. These can pose risks of collisions, falls from height, impacts, cuts, crushing, and other injuries.

- Heat hazards: Construction material production can produce high temperatures from processes such as firing, heating, and thermal treatment. High temperatures can cause fires, burns, and other health issues if proper safety measures are not applied.

- Mechanical hazards: Machinery and equipment in construction material factories may experience mechanical failures such as malfunctions, leaks, explosions, brake failures, and other incidents. These can endanger workers in the work area.

- Noise hazards: Production processes like concrete mixing, stone crushing, and machinery operation can generate high levels of noise. Prolonged exposure to noise can damage hearing, cause stress, insomnia, and negatively impact overall health.

- Transport and lifting hazards: Transporting and lifting construction materials can pose risks to workers. Falling materials, collisions, falls from height, and malfunctions of lifting equipment can cause injuries and serious accidents.

4. Common occupational accidents for workers in construction material production

There are several types of occupational accidents commonly occurring during construction material production. Examples include:

- Falling material accidents: This is a common accident in the construction industry. Workers can be injured by materials falling from heights, such as concrete slabs, bricks, stones, or heavy tools and equipment.

- Cutting and piercing accidents: During cutting, drilling, or processing construction materials, workers may be injured by blades, drill bits, or other sharp tools. Accidental piercing of hard materials like steel, wood, or stone can also occur.

- Collision accidents: In crowded work environments with machinery, collisions can happen. This includes collisions between transport vehicles such as forklifts, cranes, or trucks, as well as collisions between machinery and workers.

- Falls from height: When working on elevated platforms, scaffolds, construction lifts, or high-rise structures, workers are at risk of falls from height causing serious injuries.

- Electrical accidents: During the use of electrical devices, power supplies, and switches, workers may experience electric shocks or other electricity-related accidents.

- Chemical accidents: The construction material industry uses many chemicals such as cement, solvents, and additive compounds. Accidents can occur from direct contact, inhalation of toxic gases, or fires and explosions.

5. Safety measures when participating in construction material production

When participating in construction material production, applying safety measures is essential to ensure the safety and health of workers. Key safety measures include:

- Safety training: Ensure that all workers involved in construction material production are trained in safe working procedures, hazard recognition, and proper use of personal protective equipment (PPE).

- Use of personal protective equipment (PPE): Ensure workers properly use PPE such as helmets, gloves, safety glasses, masks, fire-resistant clothing, and safety shoes. Proper PPE usage minimizes the risk of injuries and health hazards.

- Chemical management: Ensure proper storage, use, and transport of chemicals like cement, additives, and solvents. Provide safety documentation and ensure workers understand and follow safety measures when handling chemicals.

- Equipment and machinery management: Conduct regular inspections and maintenance to ensure safe and efficient operation. Provide adequate instructions and adhere to safety regulations when working with machinery.

- Work area management: Ensure that work areas in construction material factories are organized and safe. Clearly define pathways, emergency exits, and work zones, and keep them clean.

- Periodically conduct occupational environment monitoring in factories to collect and analyze harmful factors affecting workers, adjusting to reduce hazards and prevent occupational diseases.

6. Benefits of occupational safety training in construction material production

An Toan Nam Viet provides businesses with the following benefits after completing occupational safety training in accordance with Decree 44/2016/NĐ – CP on occupational safety and hygiene:

- Workers can recognize potential occupational hazards and take preventive measures to avoid accidents.

- Businesses can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs associated with safety risks.

- Uninterrupted production increases labor productivity and product quality.

- Comply with labor safety regulations, avoiding legal risks.

- Enhance credibility and professionalism, improving the company’s brand reputation.

Nam Viet’s training courses are a solution to prevent external hazards that could cause injury or, in severe cases, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer feedback after completing occupational safety training in construction material production

An Toan Nam Viet has many years of experience supporting enterprises across Vietnam, especially in the southern provinces. Our occupational safety training is increasingly professional, driven by positive feedback and suggestions from our partners. Below are testimonials from clients we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“My first experience with An Toan Nam Viet was impressive due to the 24/7 support from the consulting team. The class organization was quick and convenient for our company. Thank you very much for Nam Viet’s service!”

See more customer interviews after using the service from An Toan Nam Viet

8. An Toan Nam Viet’s occupational safety training capacity

An Toan Nam Viet is a leading center for professional and high-quality occupational safety training in Vietnam, conducting training continuously at workshops, factories, or construction sites nationwide (all 63 provinces).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational safety training license

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety under the Ministry of Labor, Invalids and Social Affairs, granting certification for occupational safety training. This reinforces our training capability.

Training materials and lectures

- Before training materials are used in occupational safety training courses, they are reviewed to ensure accuracy and effectiveness.

- Teaching methods of instructors follow An Toan Nam Viet standards, developed by experts in occupational safety to maximize learning effectiveness.

Facilities

- Control of classroom factors enhances teaching efficiency and student learning outcomes.

- Our training facilities provide spacious classrooms with standard lighting, training equipment, and more.

9. Nationwide reputable occupational safety training center

At An Toan Nam Viet, we prioritize occupational safety training. We aim to equip workers with knowledge to protect themselves, contributing to national development.

To ensure effective training, we meticulously prepare every detail, from tools and teaching equipment to curriculum, materials, audio, and lighting.

Our instructors are experienced experts, including research on hazard identification and prevention across industries. Their lectures are practical, vivid, and easy to understand. Knowledge is aligned with Decree 44/2016/NĐ-CP.

Through training, workers learn to prevent hazards and protect themselves, applying knowledge effectively in their work.

Our training center proudly provides professional occupational safety training with advantages including:

- Competitive training costs with guaranteed quality.

- Flexible training schedules adapted to company production.

- Quick certification procedures in compliance with legal regulations.

- Instructors with many years of experience.

- Controlled classroom environment to maximize teaching efficiency and learning outcomes.

- Lectures tailored to workplace safety for enterprises.

- Dedicated, professional service supporting clients accurately and promptly.

10. Additional reference materials for occupational safety training in construction material production

- Occupational safety training materials for stone material production

- Occupational safety training materials for construction material production

- Occupational safety training materials set

- Occupational safety training test set

- Construction material production occupational safety training curriculum

- Construction material production occupational safety quiz

1 review for Occupational safety training in construction material production

No comments yet

namchinh.haiphong341

Dịch vụ huấn luyện an toàn lao động rất tốt nhé, giảng viên dạy rất sinh động dễ hiểu!