Occupational Safety Training for Metal Lathe Operation

99,000 ₫

Note: The above price is calculated for one person and may fluctuate depending on the number of participants in the course and market movements. For more accurate pricing support, please refer to the pricing table or contact our consulting staff directly.

Occupational safety is an important issue when operating metal lathes and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses here. The Occupational Safety Training course is one of the effective solutions to raise awareness about accident prevention for workers operating metal lathes.

Table of Contents

Toggle1. Overview of Metal Lathe Machines

a. What is a Metal Lathe Machine?

A metal lathe machine is a type of machine tool specifically used for machining and manufacturing metal parts by removing a portion of material from an initial metal block to create specific shapes and sizes. This process is carried out using a special cutting tool called a metal lathe cutting tool.

Metal lathe machines can be used to process many types of metal parts, from shafts, screws, discs, rotating plates, to large heads for various machinery and tools. Metal lathes typically have the capability to rotate and move the cutting tool around the metal material to create parts with high precision.

Common types of metal lathe machines include conventional lathes, CNC (Computer Numerical Control) lathes, and automatic lathes. Metal lathes are an important part of the metal manufacturing industry and are widely used in producing diverse metal products.

b. Applications of Metal Lathe Machines in Manufacturing

Metal lathe machines have many important applications in the metal and machinery manufacturing field. Here are some main applications:

- Shaft and screw machining: Metal lathes are commonly used to machine shafts and screws, making them suitable in size and precision for mechanical and machinery applications.

- Machinery parts manufacturing: Metal lathes are used to produce machinery components such as bearings, gears, pulleys, and other parts in machinery production.

- Disc and rotating plate machining: Discs and rotating plates are produced by machining metal sheets using a metal lathe. This is usually done to create rotating and turning components in devices and machinery.

- Special product manufacturing: Metal lathes are also used to create special products such as coupling pipes, assembly bearings, and metal parts with complex shapes and sizes.

- Die manufacturing: In the casting industry, metal lathes are often used to machine dies, helping to produce high-precision casting molds for metal part production.

- Custom product manufacturing: Metal lathes can produce custom products based on special designs, meeting diverse customer needs in industry and manufacturing.

c. Industries Using Metal Lathe Machines

Metal lathes are widely used in many different industries, especially in metal and machinery manufacturing. Here are some main industries where metal lathes play a crucial role:

- Machinery manufacturing: Metal lathes are used to produce machinery components, from bearings to gears and screws, helping create key parts of devices and machines.

- Automotive industry: In car manufacturing, metal lathes are used to produce engine parts, steering systems, and other metal components in vehicles.

- Aerospace industry: Metal lathes play an important role in producing parts and components for airplanes, spacecraft, and related equipment.

- Casting industry: In casting, metal lathes are often used to machine and finish metal molds, producing precise cast parts.

- Energy manufacturing: Metal lathes are used to produce components and equipment for the energy sector such as turbines, rotors, and critical parts in renewable and thermal power systems.

- Tool and equipment manufacturing: Industrial tool and equipment manufacturers use metal lathes to produce their products, including cutting tools, measuring instruments, and other industrial devices.

- Aerospace production and maintenance: In manufacturing and maintaining space vehicles like rockets and satellites, metal lathes are used to produce extremely precise parts and components.

These are just some examples of industries where metal lathes are widely applied. Metal lathes play an important role in many different manufacturing fields, contributing to producing high-quality metal products and meeting diverse technical requirements.

2. Overview of Safety Training for Metal Lathe Operation

a. What is Occupational Safety Training?

- Occupational safety training for metal lathe operation consists of sessions that equip workers with awareness of how to prevent workplace accidents. Workers who directly operate metal lathes belong to group 3.

- The safety training course helps workers identify and avoid hazards, reducing risks of workplace accidents during operations.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial safety training duration

- Total training time is at least 24 hours, including testing time.

- 8 hours of theory on policies, laws regarding safety and occupational hygiene

- 8 hours of theory on basic knowledge of safety and occupational hygiene

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical test at the end of the course

The safety training center will divide the time into multiple sessions depending on the workers’ schedule. Typically, there are 6 training sessions over 3 days, provided the company can arrange continuous study time.

Periodic safety training duration

- Before the occupational safety card expires, workers who wish to renew must undergo a periodic occupational safety training, with training duration at least 50% of the initial training duration.

Explanation: total periodic occupational safety training duration is at least 12 hours, including testing. After completing the course and passing the test, workers will be reissued or renewed their occupational safety card.

c. Training Course Content

| No. | TRAINING CONTENT | TRAINING TIME (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents system regarding occupational safety and hygiene. | 6 | 6 | ||

| 2 | Standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when constructing, expanding, or renovating facilities for production, use, storage, and inspection of machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and workers; safety and hygiene policies for workers; functions and duties of the safety network. | 1 | 1 | ||

| 5 | Occupational safety and hygiene regulations, safety signs, and instructions, using safety equipment and personal protective equipment; first aid skills for workplace accidents, prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of types of machines, equipment, substances causing hazards; risk analysis, assessment, and management for occupational safety and hygiene; safe working procedures with machines, equipment, and substances with strict safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Final test of safety training course | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

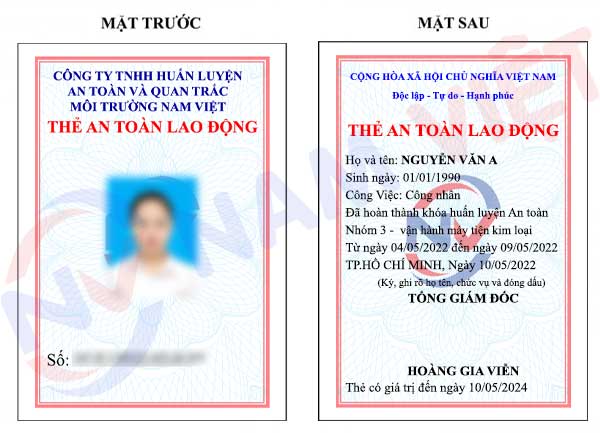

d. Occupational Safety Card

After completing the occupational safety training course and passing the test, workers will be issued a safety card (commonly called occupational safety certificate group 3).

The group 3 safety card shows information such as full name, date of birth, specific job and working environment, training duration, official stamp, and signature confirming course completion.

According to regulations on issuing safety cards stated in Clause 2 Article 24 of Decree 44/2016/ND-CP, there are 2 cases:

- If the employer and the worker have a labor contract, the employer must sign, stamp, and validate the safety card for the trained worker after completing the training and passing the test from the training center.

- If the worker is freelance or seasonal, without a labor contract, the training unit must sign, stamp, and validate the safety card after completing the training and passing the test from the occupational safety training center.

3. Hazards when operating a metal lathe

Operating a metal lathe can involve many hazards and risks. Below are some of the main hazards when working with a metal lathe:

- Cuts and injuries from cutting tools: Metal lathe tools can rotate at high speed and have great force, which can cause serious injuries if the operator does not follow safety rules. Injuries may include cuts, tears, crushing, and even the loss of fingers or a whole hand.

- Impact and falling materials: During operation, metal materials may be struck or fall, causing injury to workers. Using personal protective equipment and a safe workspace can minimize this risk.

- Flying metal and metal dust: When turning metal, chips and dust can be generated. Without proper safety glasses or face shields, workers may suffer eye injuries or inhale metal dust, which is harmful to health.

- Voltage and temperature: Some metal lathes require high voltage to operate. Ignoring electrical safety rules can lead to electric shock or fire. High temperatures during metalworking can also cause fires or health hazards.

- Noise and vibration: Metal lathes generate noise and vibration during operation. Continuous exposure to noise and vibration can damage hearing and cause other health problems.

- Chemicals and lubricants: Using chemicals and lubricants to maintain the lathe can also pose risks of spills and workplace contamination.

To minimize hazards when operating a metal lathe, workers must follow all safety rules, use personal protective equipment, and be trained in the safe and effective use of the metal lathe. Manufacturer regulations and instructions must also be strictly followed.

4. Measures to control workplace accidents when operating a metal lathe

To control workplace accidents when operating a metal lathe and ensure worker safety, a range of safety measures must be implemented. Below are some important measures to control occupational risks:

- Training: Ensure all workers are properly trained on how to use the metal lathe and basic safety rules. Training should include operating the machine, changing cutting tools, and responding in emergencies.

- Use personal protective equipment: Ensure workers use appropriate PPE such as safety glasses, helmets, hearing protection, gloves, and heat-resistant clothing (if necessary). This equipment protects against hazards such as flying metal and injuries.

- Machine inspection and periodic maintenance: Ensure metal lathes are regularly inspected and maintained for safe and effective operation. Cutting tools should also be checked and sharpened as needed.

- Access control: Limit access to the metal lathe area to trained personnel with relevant responsibilities. Unauthorized persons should not enter this area.

- Material and tool management: Ensure materials and tools are stored and arranged safely to prevent collisions, falls, or injuries.

- Work progress monitoring: Track work processes to detect and address safety issues as soon as they occur.

- Emergency preparedness: Provide firefighting equipment and guide workers on procedures in case of emergencies such as fire or serious injury.

- Follow manufacturer regulations and instructions: Always adhere to all safety regulations and instructions from the metal lathe manufacturer.

- Report incidents: Require workers to immediately report any incidents or accidents to management and/or the company’s safety department for corrective measures and future prevention.

- Periodic inspection of metal lathes to detect safety issues such as damage, wear, or mechanical failure early, thereby reducing the risk of occupational accidents.

5. Benefits of occupational safety training

An Toàn Nam Việt provides your company with the following benefits after completing occupational safety training courses according to Decree 44/2016/ND – CP on occupational health and safety for companies, factories, and businesses.

- Workers can identify potential hazards and take preventive measures to avoid workplace accidents.

- Your company can establish risk prevention measures in production, operation, and maintenance processes.

- Minimize costs when safety risks occur in the workplace.

- Uninterrupted production increases labor productivity and product quality.

- Compliance with labor safety laws, avoiding legal risks.

- Enhance credibility and professionalism in all aspects, thereby elevating your brand.

Nam Viet’s training courses are a solution to prevent external risks that could endanger individuals, helping them avoid injuries or worse, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

6. Customer feedback after completing training

An Toàn Nam Việt has many years of experience accompanying numerous businesses in Vietnam, especially in the southern provinces. This responsibility is very valuable, which is why Nam Viet’s Occupational Safety Training is increasingly professional. The motivation for An Toàn Nam Việt’s growth comes from both positive feedback and suggestions from partner companies. Below are feedback from our served partners.

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service greatly helped us simplify occupational safety and complete safety documentation for work processes. The consulting team was enthusiastic and timely in answering our questions. 5 stars for Nam Viet.”

See more customer interviews after using the service from An Toàn Nam Việt

7. Occupational Safety Training Capacity of An Toàn Nam Việt

An Toàn Nam Việt is a reputable and high-quality occupational safety training center in Vietnam. Training sessions are continuously conducted at production workshops, factories, or construction sites nationwide (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License

- An Toàn Nam Việt has been inspected and certified by the Department of Occupational Safety of the Ministry of Labor – Invalids and Social Affairs and granted a certificate of eligibility for occupational safety and hygiene training. This further strengthens our occupational safety training capabilities.

Documents and Lectures

- Before being used in OHS training courses, training materials are reviewed and verified to ensure lectures are accurate and effective.

- Instructors’ teaching methods are standardized according to An Toàn Nam Việt standards, developed by experts in occupational safety and hygiene training to maximize knowledge absorption for learners.

Facilities

- Controlling classroom factors affecting training improves teaching efficiency and learners’ knowledge absorption.

- Our training support facilities provide spacious classrooms meeting standards for area, lighting, training equipment, etc.

8. Reputable nationwide occupational safety training center

At An Toàn Nam Việt, we prioritize professionalism in occupational safety training. For us, imparting self-protection knowledge to workers is a contribution to building the country.

To ensure effective training, we meticulously prepare every detail, from tools, teaching equipment to manuals, documents, sound, and lighting.

Our occupational safety instructors are experts with many years of experience. They even have research projects identifying hazards across industries and prevention methods.

Lectures are based on practical experience and delivered in an engaging, easy-to-understand manner for workers. This ensures learners are comfortable and effectively absorb knowledge. Content is always aligned with Decree 44/2016/ND-CP.

This allows workers to understand preventive measures and self-protection techniques, applying them appropriately in their work.

Our training center prides itself on providing reputable, professional occupational safety training with the following advantages:

- Competitive training costs without compromising quality.

- Flexible training schedules to suit company production needs.

- Fast and legal-compliant certification procedures.

- Experienced instructors with many years in the field.

- Classroom control factors improve teaching efficiency and learner knowledge absorption.

- Lectures tailored to occupational safety practices in enterprises.

- An Toàn Nam Việt works diligently and professionally to support customers accurately and quickly.

9. Further occupational safety training materials

- Occupational safety materials when operating a lathe

- Occupational safety training materials set

- Occupational safety training test set

- Occupational safety multiple-choice test when operating a lathe

- Occupational safety training slides for operating a lathe

1 review for Occupational Safety Training for Metal Lathe Operation

No comments yet

phanminhhang341

Dịch vụ tốt!!!