Occupational Safety Training for Drill Press Operation

99,000 ₫

Note: The price above is calculated per person and may fluctuate depending on the number of participants in the course and market conditions. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue when operating a bench drill and must be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses here. The Occupational Safety Training course is one of the effective solutions to raise awareness of how to prevent workplace accidents for workers operating a bench drill.

Table of Contents

Toggle1. Overview of the Desktop Drill Machine

a. What is a Desktop Drill Machine?

A desktop drill machine is a mechanical tool or device used to drill or create holes in various materials such as wood, metal, plastic, or bricks. The main feature of a desktop drill is that it is designed to be mounted on a workbench or a fixed surface, allowing the user to drill more easily and accurately. Desktop drills usually have a powerful motor and a drill spindle with adjustable depth and position.

Desktop drills are widely used in many applications, including furniture manufacturing, woodworking, repair and construction, and various industrial sectors. For tasks requiring high precision or multiple consecutive holes, desktop drills are often preferred over standard handheld drills.

b. Operating Principle of a Desktop Drill Machine

The operating principle of a desktop drill machine is quite simple and consists of the following basic components:

- Motor: The desktop drill is equipped with an electric or pneumatic motor to rotate the drill spindle. This motor provides the energy to rotate the spindle and perform the drilling process.

- Drill Spindle: The spindle is a long shaft, usually made of steel or alloy, located at the top of the drill and connected to the motor. The spindle can be adjusted for depth and position to ensure drilling at the desired size and location.

- Drill Bit: The drill bit is the end part of the spindle, designed to cut through the target material. Drill bits can be replaced to suit specific materials such as wood, metal, or other materials.

- Work Table: The desktop drill has a flat or fixed surface where the material to be drilled is placed. The work table can be adjusted in height or angle to meet specific job requirements.

c. Industries Using Desktop Drill Machines

Desktop drills are widely used across many industries and applications due to their precision and consistent drilling performance. Key industries and applications include:

- Woodworking: In furniture manufacturing, woodcraft, and carpentry, desktop drills are used to make holes for nails, screws, assembling wooden components, and decorative details.

- Metalworking: Both metal fabrication and repair sectors use desktop drills to create holes in metal sheets or other metal products.

- Construction and Maintenance: Desktop drills are used to drill holes in doors, windows, wooden panels, and other construction materials.

- Manufacturing and Production: The manufacturing industry uses desktop drills for drilling in production processes, assembly, and maintenance of various products and machinery.

- Machinery Manufacturing: Desktop drills are also used to produce components for different machines and equipment.

- Tile and Ceramic Processing: In tile, ceramic, and enamel industries, desktop drills are used to create holes for product components.

- Electrical and Electronics: In electronic production and repair, desktop drills are used to drill holes in circuit boards and other electronic components.

- Food Processing: In the food industry, desktop drills can be used to drill holes in food products or related equipment.

2. Overview of Safety Training for Operating Desktop Drill Machines

a. What is Occupational Safety Training?

- Occupational safety training for operating desktop drill machines is a series of sessions designed to raise awareness of workplace hazards and prevent accidents. Workers directly operating desktop drills belong to Group 3.

- The training course helps workers identify and avoid hazards, reducing the risk of workplace accidents.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial Safety Training

- The total training duration is at least 24 hours, including the test time.

- 8 hours of theory on safety policies and labor hygiene laws

- 8 hours of theory on basic occupational safety knowledge

- 4 hours of theory on specialized training content

- 2 hours of practical exercises on specialized content

- 2 hours of theoretical assessment at the end of the course

The safety training center will schedule multiple sessions depending on workers’ availability. Typically, there are six sessions over three days if the company can arrange continuous training.

Periodic Safety Training

- Before the occupational safety card expires, workers who wish to renew it must complete periodic occupational safety training with a duration of at least 50% of the initial training time.

Explanation: The total periodic safety training time is at least 12 hours, including testing. Upon completing the course and passing the assessment, workers will have their safety card renewed.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Safety Policies and Occupational Hygiene Laws | 8 | 8 | 0 | 0 |

| 1 | Overview of the legal documents system on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of safety and hygiene standards and technical regulations. | 1 | 1 | ||

| 3 | Specific regulations from government authorities on safety and hygiene when constructing, expanding, or renovating facilities, and for producing, using, storing, or inspecting machines, equipment, materials, and substances requiring strict safety and hygiene standards. | 1 | 1 | ||

| II | Basic Knowledge of Occupational Safety and Hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and duties of employers and employees; safety policies for workers; roles of safety officers. | 1 | 1 | ||

| 5 | Workplace safety regulations, signage, use of safety equipment and personal protective gear; first aid skills, occupational disease prevention. | 1 | 1 | ||

| III | Specialized Training Content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, hazardous materials; risk assessment and management; safe working procedures with machines, equipment, and materials with strict safety requirements. | 6 | 4 | 2 | ||

| IV | Final Safety Assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

d. Occupational Safety Card

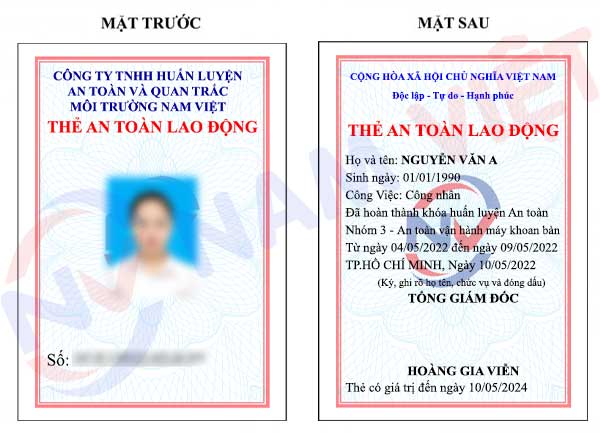

After completing the occupational safety training and passing the test, workers will receive an occupational safety card (commonly called Group 3 safety certificate).

The Group 3 card displays the worker’s name, date of birth, job, and specific working environment. It also shows training duration, official stamp, and signature confirming course completion.

According to Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have an employment contract, the employer must sign, stamp, and seal the safety card after the employee completes training from the safety training unit and passes the test.

- If the worker is freelance or temporary, without a contract, the training unit must sign, stamp, and seal the safety card after the worker completes the course and passes the test.

3. Hazards When Operating a Desktop Drill

Operating a desktop drill can pose various hazards if safety rules are not followed or attention is not paid. Here are some common hazards when using a desktop drill:

- Impact injuries: Without wearing safety glasses or eye protection, debris, dust, or wood/metal fragments can fly off while the drill is operating, causing eye injuries.

- Hand injuries: From being pinched or cut by the drill bit or other parts of the machine.

- Drilling accidents: If the drill bit binds or clamps the material, it can cause sudden accidents, sometimes resulting in loss of control of the machine.

- Loss of balance: If the workbench or drill is not properly installed or stable, it can lead to imbalance and loss of machine control.

- Careless operation: Using the drill without focus or ignoring safety rules can cause errors and accidents.

- Unsafe clothing: Wearing loose clothing, belts, or ties can get caught in the machine, causing injury.

- Using inappropriate tools and drill bits: Using a drill bit unsuitable for the material can cause accidents or damage the machine.

- Poorly maintained equipment: The drill must be regularly maintained and inspected to ensure safe and efficient operation.

To avoid these hazards, users should follow the manufacturer’s safety guidelines, wear personal protective equipment such as safety glasses, and stay focused on the task. Proper training and guidance are also essential to ensure safety when operating a desktop drill.

4. Measures to Prevent Workplace Accidents When Operating a Desktop Drill

To prevent workplace accidents when operating a desktop drill, users should follow these safety measures:

- Training and guidance: Ensure that all users of the desktop drill are properly trained on machine use, safety rules, and accident response procedures. Regular training sessions should be conducted to maintain understanding and adherence to safety rules.

- Personal protective equipment: Ensure all workers wear appropriate PPE, including safety glasses, helmets, dust-resistant jackets, and hearing protection if needed.

- Machine inspection: Before use, check the drill to ensure it is functioning correctly, free of technical faults, and properly maintained. Any issues should be repaired before operation.

- Use the correct drill bit: Ensure the drill bit is suitable for the material and properly installed. Old or broken bits should be replaced immediately.

- Check the workbench: Make sure the bench is correctly installed, stable, and level. An unstable bench can lead to loss of machine balance.

- Follow safety rules: Operate the drill attentively and follow safety rules, such as keeping hands away from the drill bit, avoiding loose clothing or long belts, and never leaving the machine running unattended.

- Maintain a safe working position: Users should always keep a safe distance and not place hands or body in the machine’s danger zone.

- Keep materials and drill bits at a safe distance: Ensure cut materials and drill bits are away from the operator to prevent injury from flying debris or drill accidents.

- Workplace safety checks: Ensure the working environment is clean, ventilated, and safe to prevent dust and toxic fumes accumulation.

- Be prepared for accidents: Users should know how to respond to accidents, including shutting down the machine immediately and seeking medical assistance if needed.

- Periodic inspection of the desktop drill to detect safety issues such as wear or mechanical faults, thereby reducing the risk of workplace accidents.

5. Benefits of Occupational Safety Training

An Toàn Nam Việt provides the following benefits to businesses upon completing occupational safety training courses as required by Decree 44/2016/ND-CP on occupational health and safety:

- Workers can identify potential hazards and take preventive measures to avoid workplace accidents.

- Businesses can establish risk prevention measures in production, operation, and maintenance processes.

- Reduction of costs associated with safety incidents.

- Uninterrupted production increases labor productivity and product quality.

- Compliance with occupational safety laws and avoidance of legal risks.

- Enhances the company’s reputation and professionalism, elevating the brand’s image.

Nam Việt’s training courses help individuals avoid hazards that could lead to injuries or, in severe cases, fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

6. Customer Feedback After Completing the Training

An Toàn Nam Việt has accumulated years of experience supporting numerous businesses across Vietnam, especially in the southern provinces. This responsibility is invaluable to Nam Việt, which is why our Occupational Safety Training is increasingly professional. Our growth is fueled by positive feedback and suggestions from our business partners. Below are testimonials from clients we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“My first experience using An Toàn Nam Việt was surprisingly good due to the 24/7 support from the consulting team. The class organization was quick and convenient for our company. Thank you very much for Nam Viet’s service!”

See more customer interviews after using our services from An Toàn Nam Việt

7. Occupational Safety Training Competence of An Toàn Nam Việt

An Toàn Nam Việt is a reputable and high-quality occupational safety training center in Vietnam. Our occupational safety training sessions are continuously held at production workshops, factories, or construction sites across the country (all 63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

License for occupational safety training

- An Toàn Nam Việt has been inspected and certified by the Safety Department of the Ministry of Labor, Invalids and Social Affairs as meeting the conditions to conduct occupational safety and hygiene training. This further reinforces our strong capability in occupational safety training.

Training Materials and Lectures

- Before being used in occupational safety training courses, all training materials are carefully reviewed and approved to ensure accuracy of knowledge and effectiveness in application.

- The teaching methods of our instructors are standardized according to An Toàn Nam Việt’s teaching criteria, developed by experts in occupational safety and hygiene training to maximize knowledge absorption for trainees.

Facilities

- Controlling factors in the classroom environment that affect training enhances teaching efficiency and trainee learning outcomes.

- Our training facilities are spacious and meet standards for area, lighting, and training equipment, among others.

8. Nationwide Reputable Occupational Safety Training Center

At An Toàn Nam Việt, we prioritize professional dedication to occupational safety training. For us, imparting knowledge to workers on how to protect themselves equips them with safety skills essential for their livelihoods, contributing to national development.

To ensure effective training, we meticulously prepare every detail, from teaching tools, equipment, curriculum, documents, sound, and lighting.

Our occupational safety instructors are experienced specialists in the field, with research on hazard identification across industries and preventive methods.

Lectures are delivered vividly and practically to ensure trainees easily understand and retain knowledge. The content strictly follows Decree 44/2016/NĐ-CP.

This enables trainees to understand safety measures, self-protection techniques, and apply them appropriately in their work environment.

Our training center proudly offers professional and reputable occupational safety training with the following advantages:

- Competitive training costs while ensuring quality.

- Flexible training schedule adapted to company production.

- Fast and compliant procedures for issuing training certificates.

- Experienced instructors with many years in the field.

- Classrooms optimized for teaching efficiency and knowledge absorption.

- Lectures tailored to workplace safety practices in enterprises.

- An Toàn Nam Việt provides dedicated and professional support for clients promptly and accurately.

9. Additional Occupational Safety Training Materials

- Occupational Safety Training Document Set

- Occupational Safety Materials for Operating Desktop Drill Machines

- Occupational Safety Training Test Set

- Occupational Safety Quiz for Operating Desktop Drill Machines

- Slide Deck for Occupational Safety Training on Desktop Drill Machines

1 review for Occupational Safety Training for Drill Press Operation

No comments yet

phanminhhang341

Dịch vụ tốt!!!