Safety Document Group 3

Occupational Safety Document for Cap Manufacturing

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 INDUSTRIES)

Discover special occupational safety documents for the cap manufacturing industry, which addresses specific risks and in-depth preventive measures. From risk management to machine safety.

PART I: CURRENT STATE OF SAFETY IN THE CAP MANUFACTURING INDUSTRY

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some occupational accidents in cap manufacturing plants

Cap manufacturing plants often face many risks related to occupational safety due to complex production processes and the use of high-tech machinery. Below are some notable occupational accidents that have occurred in this industry:

- Machinery accidents: During the operation of cap production machinery, some accidents have occurred due to technical failures or improper use. These accidents often cause serious injuries to workers and require timely intervention from fire and medical teams.

- Chemical hazards: During the production process, use, and storage of chemicals, there is a risk of leaks, explosions, or exposure to toxic substances. Accidents related to chemicals can cause serious consequences for the health of workers and endanger the surrounding environment.

- Fire and explosion risk: Cap manufacturing plants often have work processes involving high temperatures and flammable materials. Therefore, the risk of fire and explosion always exists, especially when safety and prevention measures are not followed.

Occupational accidents in cap manufacturing plants not only affect the health and safety of workers but also pose a great challenge to plant management and regulatory agencies in improving safety measures and reducing risks.

PART II: OCCUPATIONAL SAFETY AND HEALTH IN CAP PRODUCTION

I. Occupational safety and health for employees operating fabric cutting machines to prepare for cap processing

1. Job characteristics of operating a fabric cutting machine to prepare for cap processing

Operating a fabric cutting machine in the process of preparing for cap processing requires professionalism and necessary skills. The fabric cutting machine is an important part of the production process, and understanding the characteristics of this job is key to ensuring accuracy and efficiency in production. First, operating the machine requires a solid knowledge of how to adjust the machine to ensure the fabric is cut to the correct size and shape for each cap model. Using measuring tools and adjustment devices to ensure high accuracy is necessary.

In addition, understanding the type of fabric and its properties is also an important factor. Different types of fabric may require different settings and handling on the cutting machine. This may include changing the cutting pressure, speed, and other parameters to ensure the fabric is cut accurately and smoothly. Regular inspection and maintenance of the machine are also very important to ensure continuous operation and avoid unexpected problems during the production process.

Finally, observation skills and meticulousness also play an important role in this. The employees operating the cutting machine need to pay attention to every small detail, such as the fabric pattern, the cutting line, and even the signs of any technical problems on the machine. In this way, they can detect and fix problems in a timely manner, ensuring that the production process runs smoothly and effectively.

2. Types of accidents during the operation of a fabric cutting machine to prepare for cap processing

During the operation of a fabric cutting machine to prepare for cap processing, there are several types of accidents that employees need to be aware of and prevent. One of the most common accidents is issues related to occupational safety, including collisions, cuts, and crushing of hands. Accidents can occur when working with the moving parts of the machine, especially if safety rules are not followed or if proper protective equipment is not used.

In addition, accidents due to technical failures can also occur, including machine malfunctions, equipment breakdowns, or the improper use of tools. Employees need to be trained to recognize and handle technical problems safely and effectively.

Furthermore, accidents can occur when working with cutting materials, such as when cutting fabric or handling auxiliary materials. A lack of care in this process can lead to cuts, punctures, or injuries.

To avoid these accidents, it is very important to follow safety procedures, ensure adequate labor protection, and train employees on accident prevention measures. At the same time, regular inspection and maintenance of the machine also play an important role in preventing technical incidents that could be dangerous.

3. Causes of accidents when operating a fabric cutting machine to prepare for cap processing

There are many causes of accidents when operating a fabric cutting machine to prepare for cap processing. One of the main causes is a lack of knowledge and skills of the operating staff. If they are not properly trained on how to use the machine and safety measures, they may make unwanted errors during work.

Second, technical problems such as machine malfunctions or equipment breakdowns can also cause accidents. If the machine is not regularly maintained or repaired promptly when needed, there is a risk of failure during operation.

Another cause is a lack of care or negligence on the part of the employee. Not following safety procedures, not using proper protective equipment, or not paying attention to the work environment can also lead to unwanted accidents.

4. Measures to prevent accidents when operating a fabric cutting machine to prepare for cap processing

To minimize the risk of accidents when operating a fabric cutting machine to prepare for cap processing, applying preventive measures is very important. Among them, occupational safety training plays a crucial role as a basis for meticulousness and understanding of safety measures. First, employees need to be trained on how to use the cutting machine and protective equipment correctly. This includes guidance on how to adjust the machine, how to work safely with moving parts, and how to use protective equipment such as safety glasses and gloves.

In addition, regular inspection and maintenance of the machine are also very important to ensure smooth and safe operation. Employees need to be trained to recognize signs of abnormal machine operation and know how to report incidents to the technical manager.

Furthermore, establishing a safe work procedure and strictly adhering to safety rules is necessary. This includes ensuring that no materials are in the path of the cutting machine’s operation and minimizing environmental factors that can cause danger, such as noise and poor lighting.

5. Occupational safety regulations when operating a fabric cutting machine to prepare for cap processing

Occupational safety regulations when operating a fabric cutting machine to prepare for cap processing are essential to ensure a safe work environment and protect the health of employees. First, the use of protective equipment is mandatory. All employees must ensure they wear safety glasses to protect their eyes from dust and stray cutting materials.

Next, adherence to safety procedures is necessary. Before operating the machine, employees need to thoroughly check the machine and the work environment to ensure that no hazards exist. They also need to ensure that the cutting materials are placed correctly and that no materials are in the path of the machine’s operation.

In addition, training and coaching are very important. All employees must be trained on how to use the machine and protective equipment safely and effectively. They also need to be trained on how to recognize warning signs and measures to safely troubleshoot.

6. Handling emergency accident situations when operating a fabric cutting machine to prepare for cap processing

Handling an emergency accident situation when operating a fabric cutting machine to prepare for cap processing requires meticulousness and a quick response from the staff. In the event of an accident, proposing emergency measures is most important. First, the employee must stop the machine immediately to prevent any potential risks from the continued operation of the machine.

Next, the worker needs to assess the situation and provide medical care to the accident victim if necessary. This may include calling for an ambulance and providing basic first aid to the victim until professional medical help arrives.

In addition, reporting the accident to the manager is important to take corrective measures and prevent recurrence. Employees need to provide detailed information about the accident situation and the measures taken to handle the situation.

II. Occupational safety and health for employees operating sewing machines to sew fabric pieces together to form parts of the cap, including the crown and brim

1. Job characteristics of operating a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

The characteristic of the job of operating a sewing machine to create parts of a cap, including the crown and brim, is a technical process that requires precision and care. The sewing machine operator needs to have a solid knowledge of the types of fabric and materials used to ensure the suitability and durability of the final product. They must have a clear understanding of factors such as the thickness, elasticity, and stiffness of the fabric to adjust the sewing machine accordingly.

In addition, adjusting the sewing machine to create the parts of the cap requires skill and experience. The worker must be able to change the settings of the sewing machine to meet the specific requirements of the product, including the stitch line, size, and thickness of the cap. They must also monitor the sewing process to detect and correct technical errors if any, such as a broken thread or a jammed sewing machine.

Besides, working in a production environment requires attention to detail and the ability to work effectively in a potentially high-pressure environment. The sewing machine operator needs to be able to work according to the production schedule and adhere to occupational safety procedures to ensure a safe and effective work environment.

2. Types of accidents during the operation of a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

During the operation of a sewing machine to produce parts of a cap, such as the crown and brim, there are several common types of accidents that workers need to be wary of:

One of the common accidents is being cut or injured from contact with the cutting parts of the sewing machine. The blades and cutting mechanisms can cause serious injuries if safety measures are not followed when operating the machine.

In addition, accidents due to improper operation of the machine can also occur. A lack of concentration, inexperience, or non-compliance with safety procedures can lead to the sewing machine jamming, damaging the fabric, or causing other technical problems.

Health-related accidents can also occur from working in a production environment. For example, inhaling fabric dust and chemicals from the fabric can cause respiratory problems and allergies.

3. Causes of accidents when operating a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

There are several main causes of accidents during the operation of a sewing machine to produce parts of a cap such as the crown and brim. One of the significant causes is a lack of knowledge and experience in how to operate the machine. Workers may have difficulty adjusting the sewing machine correctly to suit the specific type of fabric and product being produced.

Another cause is a lack of concentration and vigilance during work. Operating a sewing machine requires a high degree of concentration to recognize and resolve technical issues in a timely manner. A lack of concentration can lead to not paying attention to warning signals or not reacting to dangerous situations.

Furthermore, a lack of compliance with safety procedures is also a significant cause of accidents. Not using personal protective equipment, not following safe operating rules, and not performing regular maintenance can increase the risk of accidents in the work environment.

4. Measures to prevent accidents when operating a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

To ensure the safety of employees when operating a sewing machine to produce parts of a cap, including the crown and brim, several important accident prevention measures should be applied.

First, ensuring that all employees are fully trained on how to operate the machine safely and effectively is very important. This training includes guidance on the use of personal protective equipment, risk identification, and emergency situation handling.

Second, performing monitoring of the working environment is extremely important to assess and mitigate risks related to the health and safety of employees. This monitoring includes measuring factors such as noise levels, the amount of fabric dust in the air, and potentially harmful chemicals.

In addition, maintaining machinery and equipment in good working condition is also an important measure. Regular maintenance and safety checks will help prevent technical failures and reduce the risk of accidents.

5. Occupational safety regulations when operating a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

Occupational safety regulations when operating a sewing machine to produce parts of a cap, such as the crown and brim, are an important part of ensuring a safe and healthy work environment. These regulations include a series of measures to protect the health and safety of employees:

- Use of personal protective equipment: All employees are required to use personal protective equipment such as masks, safety glasses, and gloves to protect against potential risks like fabric dust and injuries from machinery.

- Safety training: All employees must be trained on safety rules when operating a sewing machine, including how to use safety equipment and emergency measures in case of an incident.

- Inspection and maintenance of machinery: Machinery needs to be inspected periodically to ensure it operates correctly and safely. Regular maintenance helps prevent incidents and reduce the risk of accidents.

- Implementation of safety procedures: Safety procedures need to be established and strictly adhered to. This includes identifying and eliminating potential risks, ensuring the work area is clean, and organizing the work area safely.

6. Handling emergency accident situations when operating a sewing machine to sew fabric pieces together to form parts of a cap, including the crown and brim

Handling an emergency accident situation during the operation of a sewing machine is an important skill that all employees should be trained in and actively practice. When an accident occurs, quick and accurate handling can minimize losses and the risk of further serious consequences. Here are some important steps to take:

- Protect yourself and others: As soon as an accident occurs, ensure your own safety and that of those around you by stopping the sewing machine and disconnecting the power if possible. Make sure no one is near the hazardous area.

- First aid: Call the emergency number or ambulance system immediately if necessary. Provide accurate and detailed information about the situation requiring assistance.

- Stay calm: In an emergency situation, staying calm is important to be able to make correct decisions and take appropriate actions.

- Implement rescue measures: Follow the safety procedures and manufacturer’s instructions to rescue the victim in the safest way possible.

- Report and record: After the situation is under control, report the accident to management and record the details of the event to serve as a basis for adjusting and improving work processes in the future.

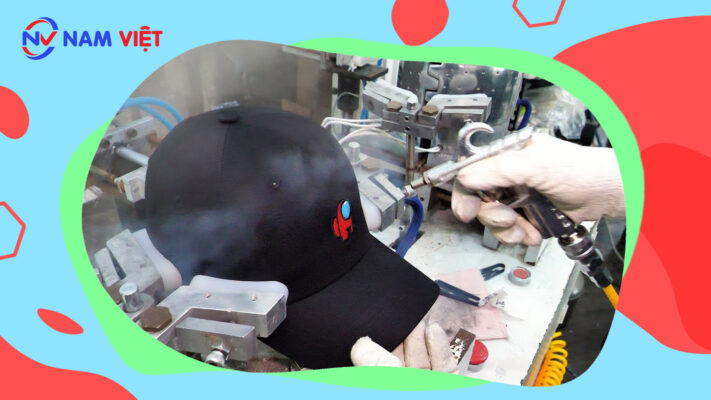

III. Occupational safety and health for employees operating embroidery machines to embroider images or logos on caps

1. Job characteristics of operating an embroidery machine to embroider images or logos on caps

Operating an embroidery machine to print images or logos on caps requires precision and professional skill. This process includes many specific steps, starting from preparing the materials to finishing the final product.

First, it is necessary to prepare the cap and choose the appropriate type of thread for embroidery. Then, the cap will be securely attached to the embroidery machine to ensure it does not move during operation.

Next, it is necessary to program the embroidery machine to ensure that the image or logo is embroidered with the correct size and resolution. This requires an understanding of the embroidery machine control software and the ability to adjust technical parameters.

When all the settings are complete, the embroidery machine operator will proceed with the embroidery process. They need to monitor the embroidery machine carefully to ensure that the process proceeds without any incidents and that the final product achieves the desired quality.

2. Types of accidents during the operation of an embroidery machine to embroider images or logos on caps

During the operation of an embroidery machine to print images or logos on caps, several types of accidents can occur. One of the most common accidents is material displacement, when the cap is not securely attached or is not evenly tensioned on the embroidery machine. This can lead to inaccurate printing or an unbalanced image.

Another accident can be due to a programming error, when the technical parameters are not set correctly. This can cause uneven embroidery or image errors on the final product.

In addition, accidents can occur due to wear and tear or breakdown of the embroidery machine. Using a machine that is not guaranteed or not regularly maintained can lead to technical problems, affecting the quality of the printed product.

Furthermore, accidents related to occupational safety are also an important issue. Failure to follow safety rules when operating the machine can lead to serious accidents for the worker, including injuries from machinery or pain that causes them to lose concentration and make errors during operation.

3. Causes of accidents when operating an embroidery machine to embroider images or logos on caps

There are many causes of accidents during the operation of an embroidery machine to print images or logos on caps. One of the main causes is a lack of knowledge and skill in operating the machine. People who are not adequately trained on how to use the embroidery machine may have difficulty setting up the machine and solving technical problems.

A lack of regular maintenance and inspection is also a common cause of accidents. If the machine is not properly maintained, parts can wear out or break down, leading to unstable operation and a potential risk of accidents.

Programming errors can also cause accidents. When the technical parameters are not set correctly or are not compatible with the material and image to be embroidered, problems such as uneven embroidery, misaligned embroidery, or even damage to the material can occur.

Another cause can be a lack of occupational safety management. If procedures and safety rules are not followed, the risk of accidents for employees will increase, including both bodily injury and machine damage.

4. Measures to prevent accidents when operating an embroidery machine to embroider images or logos on caps

To prevent accidents when operating an embroidery machine to print images or logos on caps, several safety measures need to be taken. First, it is very important to ensure that all employees are thoroughly trained on how to use the embroidery machine and safety procedures. The training should include how to operate the machine, emergency procedures in case of an incident, and how to ensure personal safety.

Second, regular maintenance of the machine is necessary to ensure it operates stably and safely. Checking and maintaining the machine’s parts helps prevent incidents due to breakdown or wear and tear.

In addition, programming the embroidery machine also needs to be done carefully and accurately. Ensuring that the technical parameters are set correctly and are compatible with the material and image to be embroidered will minimize the risk of errors during operation.

5. Occupational safety regulations when operating an embroidery machine to embroider images or logos on caps

Occupational safety regulations when operating an embroidery machine to print images or logos on caps are extremely important to ensure the safety of employees and minimize the risk of accidents. These regulations often include many aspects:

Personal protective equipment is an important factor. Employees must be required to use safety glasses to protect their eyes from dust and debris that may be generated during the embroidery process. In addition, using gloves can help protect the skin of the hands from direct contact with the embroidery machine and its hard parts.

Adherence to safety rules and procedures is also an important part of the regulations. Employees need to be trained to know how to operate the embroidery machine safely and effectively. This includes knowing how to use the emergency switches, how to turn off the machine, and how to handle emergency situations.

In addition, maintaining machinery and equipment is an indispensable part of the safety regulations. The embroidery machine needs to be inspected and maintained periodically to ensure stable and safe operation. If any problems are found, the machine needs to be repaired immediately to avoid the risk of accidents.

6. Handling emergency accident situations when operating an embroidery machine to embroider images or logos on caps

Handling an emergency accident situation when operating an embroidery machine to print images or logos on caps requires quickness and problem-solving skills. In the event of an accident, a quick and correct response can minimize losses and risks to employees.

First, it is most important to immediately turn off the machine and cut the power to ensure the safety of employees and prevent the incident from spreading. Next, it is necessary to check the situation and provide first aid to anyone who is injured. This may include calling for emergency services and providing basic first aid to the victim.

After that, it is necessary to report the incident to the management and the company’s occupational safety department. Reporting the incident not only helps improve work processes but also ensures that preventive measures can be applied to prevent similar accidents in the future.

IV. Occupational safety and health for employees packaging finished caps

1. Job characteristics of packaging finished caps

The characteristics of the job of packaging finished caps are an important process in the production line. To ensure the quality and efficiency of the final product, this process requires meticulousness, precision, and thorough preparation. The job involves placing the cap in the correct position on the product and packaging them safely and effectively.

One of the important points is consistency in packaging. Workers need to ensure that each product is packaged according to the standards of size, shape, and position. This ensures that all final products have the same quality and appearance, creating consistency in the final product.

In addition, packaging also requires attention to detail. Workers need to carefully check each product before packaging to ensure that there are no errors or defects. This helps to avoid sending out imperfect products and keeps the production process running smoothly.

2. Types of accidents during the process of packaging finished caps

During the process of packaging finished caps, there are several common types of accidents that can occur, requiring attention and appropriate preventive measures. One of the common accidents is issues related to the use of machinery and equipment. These accidents can include collisions, cuts, crushing, or being pulled up by the machine when operating machinery unsafely.

In addition, material handling also poses a risk of accidents. Unwanted impacts can occur during the transportation, cutting, or stacking of products, causing injuries to workers.

Other accidents may be related to the use of handheld tools such as scissors, knives, or cutters. A lack of care or insufficient training can lead to cuts or punctures to the hands, fingers, or other parts of the body.

3. Causes of accidents when packaging finished caps

There are many causes that can lead to accidents during the process of packaging finished caps. One of the main causes is a lack of training and understanding of occupational safety. When workers are not fully trained on how to use machinery and packaging tools safely, they can easily have accidents due to improper use.

In addition, an unsafe work environment is also a significant cause. Working in a cramped space, with poor lighting, or a lack of ventilation can create unsafe conditions and easily lead to accidents.

Factors related to management and supervision can also contribute to causing accidents. If there is no close supervision or no system of regular inspection and maintenance for equipment and machinery, the risk of accidents will increase significantly.

4. Measures to prevent accidents when packaging finished caps

To prevent accidents during the process of packaging finished caps, several measures need to be taken regularly and seriously. First of all, ensuring that all employees are fully trained on occupational safety is extremely important. Regular training sessions help provide the necessary knowledge and skills to work safely and effectively.

Second, maintaining a safe work environment is key. This may include improving lighting, ventilation, and workspace, as well as removing obstacles and other potential hazards in the work environment.

Third, supervision and regular inspection are also very important. By ensuring that all equipment and machinery are regularly maintained and inspected, the risk of incidents due to technical failure can be minimized.

5. Occupational safety regulations when packaging finished caps

Occupational safety regulations when packaging finished caps play an important role in ensuring safety and preventing accidents for employees. One of the most important regulations is to ensure that all employees are fully trained on occupational safety before starting work.

In addition, compliance with regulations on the use of personal protective equipment is mandatory. Employees must ensure that they are using types of equipment such as helmets, safety glasses, gloves, and safety shoes when working in the cap packaging environment.

Specific regulations on how to use and maintain machinery and equipment must also be strictly followed. Employees must be trained on how to use machinery safely and effectively, as well as how to inspect and maintain them periodically.

6. Handling emergency accident situations when packaging finished caps

In the event of an emergency accident during the process of packaging finished caps, handling the situation quickly and effectively is very important to ensure the safety of all employees and prevent negative consequences.

First, the worker must immediately report the accident to the manager or the company’s occupational safety department. Detailed information about the accident, such as the victim’s condition and a specific description of the event, needs to be provided to prepare for handling the situation.

Next, immediate first aid measures must be taken to ensure the safety of the victim and those around them. Employees need to be trained on how to handle emergency situations, including how to provide first aid and call for an ambulance if necessary.

After that, conducting an investigation into the cause of the accident is extremely important to prevent similar problems from happening in the future. Modifications or improvements to the work process can be implemented based on the results of the investigation.

PART III: Further Reference

1. Occupational Safety Test Group 3

2. Price List for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training documents for cap production

- Slide presentation for occupational safety training in cap production

- Multiple choice test for occupational safety in cap production