Occupational Safety Training for Golf Ball Manufacturing

99,000 ₫

Note: The above price is calculated per person and may vary depending on the number of trainees participating in the course and market fluctuations. For more accurate pricing support, please refer to the price list or contact our consultants directly.

Occupational safety is an important issue in golf ball manufacturing plants and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses. The Occupational Safety Training course is one of the most effective solutions to raise awareness of accident prevention for workers involved in golf ball manufacturing.

Table of Contents

Toggle1. Overview of Golf Balls

a. What is a Golf Ball?

A golf ball is a type of ball used in the sport of golf. It is an essential part of the game and has specific characteristics to meet the technical requirements of the sport.

Main characteristics of a golf ball:

- Shape and Size:

- The golf ball is spherical in shape with a standard diameter of about 42.67 mm (1.68 inches) and a weight of about 45.93 grams (1.62 ounces).

- Surface:

- The surface of a golf ball is designed with numerous small indentations called “dimples.” These dimples help improve the ball’s flight and control by reducing drag and creating a stable airflow around the ball.

- Structure:

- A golf ball typically has a multi-layer structure, including an inner core, a mantle layer, and an outer cover. This structure affects bounce, flight distance, and feel when struck.

- Materials:

- The layers of a golf ball can be made from various materials such as rubber, urethane, and polymer compounds. The cover is usually made from urethane or ionomer, depending on the ball type and intended use.

Types of golf balls:

- Two-piece golf balls:

- Usually have a rubber core and an ionomer cover. This type generally increases distance and suits players with powerful swings.

- Three-piece golf balls:

- Have an additional mantle layer between the core and the cover. This type balances distance and control, often favored by skilled golfers.

- Four-piece or multi-layer golf balls:

- More complex designs with multiple layers enhance control and feel, typically used by professional golfers.

b. Types of Machines Used in Golf Ball Manufacturing

1. Core Molding Machine

- Function: Molds the rubber core or other materials to form the center of the golf ball.

- Process: The core is molded into precise shape and size using molds and high temperature.

2. Injection Molding Machine

- Function: Molds the mantle layer around the core, usually from polymers or rubber.

- Process: The mantle material is melted and injected into a mold surrounding the pre-shaped core.

3. Core and Cover Cutting Machine

- Function: Cuts core and mantle layers into parts for the next production stage.

- Process: Precisely cuts layers to ensure uniform size and design compliance.

4. Cover Molding Machine

- Function: Molds the outer cover of the golf ball.

- Process: The cover, typically made from urethane or ionomer, is molded onto the ball using high heat and pressure.

5. Dimple Punching Machine

- Function: Creates dimples on the golf ball surface.

- Process: The golf ball passes through a machine where dimples are punched into the cover with precision tools.

6. Quality Control Machine

- Function: Checks the golf ball’s quality parameters, including size, weight, and dimple uniformity.

- Process: Uses precision measuring tools and testing devices to ensure the ball meets quality standards.

7. Packaging Machine

- Function: Packages golf balls into ready-to-ship product sets.

- Process: The golf balls are packed into boxes or packages ready for distribution.

8. Surface Finishing Machine

- Function: Finishes the ball’s surface for smoothness and uniformity.

- Process: Removes minor defects and produces a glossy, even surface.

9. Flight Testing Machine

- Function: Tests the golf ball’s flight performance to ensure it meets performance requirements.

- Process: Uses testing devices to measure distance, stability, and other flight characteristics.

c. Famous Golf Ball Brands

1. Titleist

- Notable products: Pro V1, Pro V1x, AVX

- Features: One of the leading golf brands, known for high quality and performance. Popular among professionals and avid golfers.

2. Callaway

- Notable products: Chrome Soft, Supersoft, ERC Soft

- Features: Known for advanced technology and consistent quality. Offers a good balance of distance and control.

3. TaylorMade

- Notable products: TP5, TP5x, Tour Response

- Features: Renowned for advanced technology and innovative designs that enhance performance and feel.

4. Srixon

- Notable products: Z-Star, Q-Star, Soft Feel

- Features: Known for high quality and affordable pricing. Offers a variety for golfers of all skill levels.

5. Bridgestone

- Notable products: Tour B, e6, e12

- Features: Focuses on durable, high-performance golf balls with proprietary technology for improved distance and feel.

6. Wilson Staff

- Notable products: Staff Model, Duo, Fifty Elite

- Features: Offers quality golf balls at reasonable prices, suitable for players of various skill levels.

7. Mizuno

- Notable products: MP-S, MP-X

- Features: Famous for quality and refined design, appealing to golfers seeking superior feel and control.

8. Nike Golf

- Notable products: Nike One, Nike RZN

- Features: Although Nike has exited the golf ball market, its products remain known for advanced technology and high performance.

9. Snell Golf

- Notable products: MTB-X, MTB Black

- Features: Offers high-quality golf balls with advanced technology at competitive prices, aiming to match big-brand performance for less.

10. Volvik

- Notable products: Vivid, Crystal

- Features: Stands out with brightly colored golf balls and proprietary technology, delivering performance and easy identification on the course.

d. Specific Jobs in a Golf Ball Manufacturing Plant

Group 1

- CEO, deputy CEO, department heads in the golf ball manufacturing plant.

Group 2

- Safety officers: manage safety in the plant, design safety procedures, supervise and ensure staff compliance with safe work procedures.

Group 3

- Core Molding Operation: Operate machines to mold golf ball cores to specified size and shape.

- Injection Molding Operation: Operate machines to create the mantle layer around the core.

- Cover Molding Operation: Mold the outer cover onto the mantled core.

- Dimple Mold Preparation: Set up molds to create dimples on the ball’s surface.

- Dimple Punching Operation: Use punching machines to form dimples on the golf ball.

- Surface Finishing: Process the ball’s surface to remove minor defects and ensure smoothness.

- Size and Weight Inspection: Measure to ensure compliance with size and weight standards.

- Flight Testing: Test ball flight and distance.

- Performance Testing: Evaluate performance under various conditions to meet standards.

- Product Packaging: Pack golf balls into boxes or packaging per regulations.

- Labeling and Final Inspection: Label and inspect packaging to ensure readiness for distribution.

Group 4

- Office work, service, sales, marketing.

- Production management, quality control, HR management, materials management, finance, and accounting.

- R&D for new products, packaging design.

2. Overview of Occupational Safety Training for Golf Ball Manufacturing

Within this article, we focus on Group 3, as Group 3 is directly involved in the production process and faces the highest occupational safety risks. See other groups here.

a. What is Group 3 Occupational Safety Training?

- Group 3 occupational safety training consists of sessions that provide awareness on preventing workplace accidents for workers.

- The course helps workers recognize and avoid hazards, reducing risks of accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial safety training duration

- Total training duration is at least 24 hours, including testing time.

- 8 hours of theory on the system of policies and laws on occupational safety and hygiene.

- 8 hours of theory on basic occupational safety and hygiene knowledge.

- 4 hours of theory on specialized training content.

- 2 hours of practical specialized training.

- 2 hours of final theory examination.

The safety training center will arrange the schedule into several sessions depending on the company’s availability. Typically, there are 6 sessions over 3 days if continuous learning is possible.

Periodic safety training duration

- Before the occupational safety card expires, workers must undergo periodic occupational safety training to renew it. The periodic training duration must be at least 50% of the initial training duration.

Explanation: Total periodic safety training is at least 12 hours, including testing. Upon completion and passing the test, the occupational safety card will be renewed.

c. Training Content

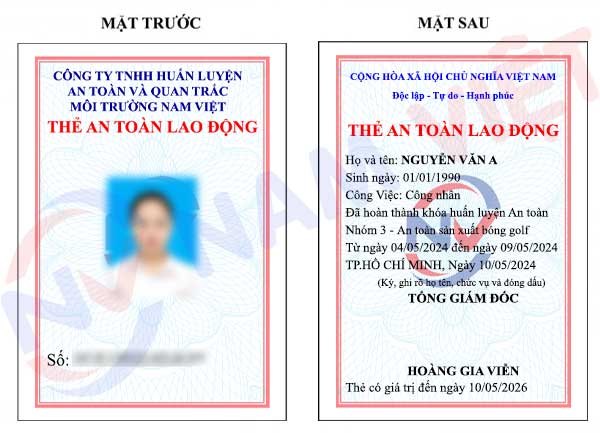

d. Occupational Safety Card

After completing the occupational safety training and passing the test, the worker will be issued an occupational safety card (commonly called Group 3 occupational safety certificate).

The Group 3 safety card clearly shows information such as: full name, date of birth, job and specific work environment, training duration, red stamp, and signature confirming course completion.

As per Clause 2, Article 24 of Decree 44/2016/NĐ-CP, there are two cases:

- If the employer and the worker have a labor contract, the employer must sign, stamp, and seal the safety card for Group 3 workers after completing training and passing the test.

- If the worker is freelance, seasonal, or without a labor contract, the training provider must sign, stamp, and seal the safety card after the worker completes training and passes the test.

3. Identifying Hazards Affecting Workers in Golf Ball Production

Mechanical Hazards

- Machinery and Equipment: Using heavy machinery and mechanical equipment can cause accidents such as pinching or cutting.

- Material Handling: Moving heavy materials can cause muscle and spinal injuries.

Chemical Hazards

- Chemicals: Chemicals such as urethane, rubber, and solvents can cause skin irritation, respiratory issues, or poisoning.

Noise Hazards

- Noise from Machinery: Machines and equipment may generate loud noise, affecting hearing.

Temperature Hazards

- High Temperatures: Some production processes, like molding pads and covers, require high temperatures, which can cause burns or heat-related health issues.

Electrical Hazards

- Electric Shock: Electrical devices and wiring systems pose the risk of electric shock.

Air Quality Hazards

- Air Pollution: Production processes may produce dust, fumes, or other pollutants.

Lighting Hazards

- Insufficient or Excessive Lighting: Insufficient lighting can cause eye strain, while excessive lighting may lead to eye fatigue or headaches.

Psychological Health Hazards

- Work Stress and Pressure: High work pressure and stressful environments can cause mental health issues.

Accident Hazards

- Incidents and Accidents: Incidents such as chemical leaks, fires, explosions, or unforeseen accidents may occur.

4. Safety Measures When Participating in Golf Ball Production

Training and Education

- Employee Training: Provide thorough training for employees on safe work procedures, proper use of machinery and equipment, and factory safety rules.

- Regular Safety Drills: Conduct regular occupational safety and emergency response drills to update employee skills and knowledge.

Personal Protective Equipment (PPE)

- Providing PPE: Supply and require the use of full personal protective equipment, including gloves, masks, safety glasses, earplugs, and protective clothing.

- Ensuring Proper PPE Use: Maintain and periodically replace PPE to ensure effective protection.

Chemical Management

- Safe Chemical Storage: Store chemicals in specially designed areas with clear labels and safety instructions.

- Proper Chemical Use: Ensure employees are trained in the safe use, transport, and handling of chemicals.

Machinery Maintenance and Inspection

- Regular Maintenance: Perform regular maintenance on all machinery and equipment to ensure safe and efficient operation.

- Inspection and Repair: Immediately inspect and repair any faulty or damaged equipment.

Risk Management

- Risk Assessment: Conduct regular risk assessments to identify and control potential hazards in production.

- Updating Safety Measures: Update and improve safety measures based on assessment results and incidents.

Electrical Safety

- Electrical System Checks: Ensure all electrical systems are regularly inspected and maintained to prevent electric shock risks.

- Electrical Safety Training: Train employees on handling electrical situations and electrical safety rules.

Temperature Management

- Temperature Control: Ensure proper cooling and ventilation systems to control temperature in high-heat work areas.

- Provide Water and Breaks: Provide drinking water and sufficient rest time for employees working in hot environments.

Noise Control

- Use Noise Reduction Devices: Provide hearing protection such as earplugs or noise-cancelling headphones.

- Design Work Areas: Design work areas to minimize noise and use noise reduction measures like soundproof partitions.

Air Quality Control

- Ventilation and Air Filtration: Ensure effective ventilation and air filtration systems to reduce dust and airborne pollutants.

- Use Respiratory Protection Systems: Provide and require respiratory protection equipment when necessary.

- Periodically conduct occupational environmental monitoring in factories to collect and analyze harmful factors affecting workers, then adjust to reduce hazards and prevent occupational diseases.

Mental Health Management

- Mental Health Support Programs: Provide mental health support programs and create a positive work environment.

- Reduce Work Pressure: Ensure reasonable workloads and provide rest time to reduce stress and fatigue.

Emergency Response

- Emergency Response Plan: Develop and implement emergency plans for situations like fires, chemical leaks, and accidents.

- Training and Drills: Conduct training sessions and drills on emergency responses to ensure employees know how to handle emergencies.

Creating a Safe Work Environment

- Cleaning and Maintaining Work Areas: Keep work areas clean and organized to avoid accident risks.

- Evaluation and Improvement: Regularly evaluate safety measures and make necessary improvements.

5. Benefits of Occupational Safety Training for Golf Ball Production

An Toàn Nam Việt offers your business great benefits after completing occupational safety training courses as regulated by Decree 44/2016/ND-CP on Occupational Safety and Hygiene. Companies, factories, and enterprises will:

- Enable workers to recognize potential occupational hazards and take preventive measures to avoid accidents.

- Help your business establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs related to occupational safety risks.

- Prevent production disruptions, increasing labor productivity and product quality.

- Comply with occupational safety laws, avoiding legal risks.

- Enhance reputation and professionalism in all aspects, thereby elevating your business brand.

Nam Việt’s training courses are solutions to prevent and combat external hazards impacting individuals, helping them avoid dangers that can lead to injury or, worse, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

6. Customer Feedback After Completing Golf Ball Production Safety Training

An Toàn Nam Việt has many years of experience accompanying numerous enterprises across Vietnam in general and in the southern provinces in particular. This responsibility is precious to Nam Việt, which is why its Occupational Safety Training is increasingly professional. The motivation for An Toàn Nam Việt’s growth comes from positive feedback and suggestions from businesses. Below are some testimonials from partners we have served.

Bắc Nam E&C Investment and Construction Joint Stock Company

“My first experience with An Toàn Nam Việt’s service surprised me by their 24/7 enthusiastic support from the consulting team. The organization of the class was quick and convenient for our company. Thank you very much, Nam Việt!”

Hoa Đất Construction and Trading Joint Stock Company

“Nam Việt’s service greatly helped us simplify occupational safety and complete safety documentation for our work process. The consulting team was enthusiastic and timely in addressing our questions. 5 stars for Nam Việt.”

See more customer interviews after using An Toàn Nam Việt’s services

7. Occupational Safety Training Capability of An Toàn Nam Việt

An Toàn Nam Việt is a reputable and quality occupational safety training center in Vietnam today. Safety training sessions are continuously held at manufacturing workshops, factories, or construction sites across the country (all 63 provinces of Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toàn Nam Việt has been inspected and certified by the Safety Department of the Ministry of Labor – Invalids and Social Affairs, granting a certificate of eligibility for occupational safety and hygiene training activities. This further strengthens our training capacity.

Materials and Lectures

- Before the occupational safety training materials are used in ATLĐ courses, they are reviewed and approved to ensure the lectures are accurate and effective.

- The teaching methods of instructors are standardized according to An Toàn Nam Việt’s teaching standards, developed by experts in occupational safety and hygiene training to maximize learner knowledge absorption.

Facilities

- Controlling factors in the classroom that affect training enhances teaching performance and knowledge absorption.

- Our training support facilities include spacious classrooms meeting standards for area, lighting, training equipment, etc.

8. Nationwide Reputable and Quality Safety Training Center

At An Toàn Nam Việt, we always prioritize occupational safety training professionalism. For us, imparting knowledge for workers to protect themselves is part of nation-building.

To ensure training effectiveness, we meticulously prepare every detail, from tools, teaching devices to curricula, documents, sound, and lighting.

Our occupational safety instructors are experts with many years of experience, some having research projects identifying hazards in all industries and prevention methods.

Lectures are practical and delivered in a vivid, easy-to-understand manner for workers. This helps them feel comfortable during learning and absorb knowledge effectively. Of course, the content strictly follows Decree 44/2016/ND-CP.

Thus, workers learn many hazard prevention measures and how to protect themselves, applying them appropriately in real work.

Our training center is proud to be a professional, reputable occupational safety training provider with advantages such as:

- Competitive training costs while maintaining quality.

- Flexible training schedules suited to company production.

- Quick, legal-compliant certification issuance procedures.

- Experienced instructors with many years in the field.

- Classrooms controlled for factors improving teaching efficiency and knowledge absorption.

- Lectures tailored for occupational safety in enterprises.

- An Toàn Nam Việt works dedicatedly and professionally to provide accurate and quick support.

9. Additional References for Golf Ball Production Occupational Safety Training Materials

- Golf Ball Production Occupational Safety Materials

- Occupational Safety Training Material Set

- Occupational Safety Training Test Set

- Golf Ball Production Occupational Safety Training Curriculum

- Golf Ball Production Occupational Safety Multiple Choice Test

No comments yet

Review Occupational Safety Training for Golf Ball Manufacturing

There are no reviews yet.