Occupational Safety Training in Ice Cream Manufacturing Factory

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the movement of the market. For more accurate pricing support, please refer to the quotation table or contact our consulting staff directly.

Occupational safety is an important issue in ice cream manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of enterprises. The Occupational Safety Training course is one of the effective solutions to raise awareness about preventing occupational accidents for workers when participating in ice cream manufacturing.

Table of Contents

Toggle1. Overview of Ice Cream

a. What is Ice Cream?

- Ice cream is a type of food made from milk, sugar and other ingredients such as fruit, nuts, chocolate, or coffee, which is frozen or solidified to create a cream-like structure. Ice cream comes in many different flavors and textures, from traditional vanilla ice cream to chocolate, strawberry, mango, cappuccino ice cream and many more. It is often used as a dessert at parties or as a refreshing cold drink in the summer.

- Vietnam has many ice cream manufacturing locations, meeting the increasing demand of consumers. In addition to large ice cream companies, there are also many small and medium-sized manufacturers, especially ice cream shops in Ho Chi Minh City and neighboring provinces.

- According to a report by the Vietnam General Confederation of Labor, the food and beverage processing industry, including the ice cream manufacturing industry, has grown significantly recently, contributing significantly to Vietnam’s economy.

- Vietnam has also manufactured some types of ice cream for export to many markets around the world, but there are still no famous brands in the ice cream manufacturing industry.

b. Types of ice cream manufacturing machinery

Types of ice cream manufacturing machinery include:

- Cream mixer: used to mix the cream, milk and sugar mixture during the ice cream manufacturing process.

- Cream sprayer: used to shape and texturize the ice cream, pushing the ice cream out of the nozzle through a control unit.

- Freezing machine: used to freeze the ice cream during the manufacturing process, to create the structure and consistency of the ice cream.

- Ice cream packaging machine: used to pack ice cream into boxes, refrigerators or ice cream bags for preservation and transportation.

In addition, there are other equipment and accessories such as cream vaporizers, ice crushers, blenders, cake makers, mixing tanks, cold cabinets, freezers, various ice cream molds, cream spray nozzles and other tools.

c. Typical ice cream manufacturing companies

Some typical ice cream manufacturing companies in Vietnam include:

- Kido Group: A group specializing in manufacturing and trading frozen food products, of which ice cream is the main product. Kido Group owns the Givral ice cream brand and has large ice cream factories in Ha Noi, Hai Phong, Ho Chi Minh and Dong Nai.

- Vinamilk: The largest milk group in Vietnam, Vinamilk not only manufactures milk products but also has an ice cream product line. Vinamilk has ice cream factories in Binh Duong and Long An.

- FrieslandCampina: One of the largest dairy companies in the world, FrieslandCampina also manufactures ice cream products and has a factory in Tay Ninh.

- Unilever: A multinational corporation operating in the field of manufacturing and trading consumer products, including ice cream products. Unilever has famous ice cream brands such as Wall’s, Paddle Pop and has a factory in Hai Phong.

- Th True Milk: A group specializing in manufacturing milk and dairy products, Th True Milk also has an ice cream product line and a factory in Nghe An.

d. Specific jobs in an ice cream factory

Group 1

- Executive director, deputy executive director, department head in an ice cream factory.

Group 2

- Safety officer: manages safety in the factory, designs safety procedures, supervises and urges employees to comply with safe working procedures.

Group 3

- Ingredient mixing: Ingredients such as fresh milk, sugar, fresh cream and flavorings are mixed according to a preset formula to create the ice cream mixture.

- Distillation: The ice cream mixture is distilled in special equipment to remove impurities and increase product consistency.

- Cooling: After distillation, the ice cream mixture is cooled to a suitable temperature to form ice cream.

- Packaging: Ice cream is packaged in containers such as paper boxes or plastic shells, then packed into cartons for transport to stores and supermarkets.

- Quality control: During the manufacturing process, ice cream is checked for quality to ensure that the product meets food safety and freshness standards.

- Hygiene and maintenance: Machinery and ice cream manufacturing areas are regularly cleaned and maintained to ensure that products are manufactured in a clean and safe environment.

Group 4

- Office jobs, serving, sales, marketing.

- Production management, quality management, human resource management, material management, financial accounting management.

- Research and develop new products, design product packaging.

2. Overview of ice cream manufacturing occupational safety training course

Within the scope of this article, we focus on the issues surrounding group 3, because group 3 is the group directly involved in the manufacturing process, bearing the highest risk of occupational safety. Refer to other groups here

a. What is group 3 occupational safety training?

- Occupational safety training for group 3 are classes that equip workers with awareness of how to prevent occupational accidents.

- The occupational safety training course will help workers identify and avoid dangers and limit the risks of occupational accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

b. Training time

First-time safety training time

- Total training time is at least 24 hours, including inspection time.

- 8 hours of theoretical study on the policy system, law on occupational safety and health

- 8 hours of theoretical study on basic knowledge of occupational safety and health

- 4 hours of theoretical study on specialized training content

- 2 hours of practical study on specialized training content

- 2 hours of theoretical review at the end of the training course

The safety training center will allocate the time into many training sessions depending on the work schedule of the employees. But usually, there will be 6 training sessions, the course will last 3 days, on the condition that the manufacturing company can arrange continuous study time.

Periodic safety training time

- Before the occupational safety card expires, if an employee wants to renew it, they must undergo a periodic occupational safety training course, with the periodic safety training time being at least 50% of the first-time safety training time.

Explanation: The total periodic occupational safety training time is at least 12 hours, including the inspection time. After completing the periodic training course and passing the required test, the employee will be re-issued, and the occupational safety card will be extended.

c. Content of the training course

| STT | TRAINING CONTENT | TRAINING TIME (HOURS) | |||

| Total number | Of which | ||||

| Theory | Practice | Inspection | |||

| I | System of policies and laws on occupational safety and health | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and health. | 6 | 6 | ||

| 2 | System of occupational safety and health technical standards and regulations. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and health when newly constructing, expanding or renovating works, facilities for manufacturing, using, preserving, storing and inspecting types of machinery, equipment, materials, and substances with strict requirements for occupational safety and health. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and health | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of dangerous and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers, employees; policies and regimes on occupational safety and health for employees; functions and duties of the network of occupational safety and health officers. | 1 | 1 | ||

| 5 | Occupational safety and health rules, signs, safety and health signs and use of safety equipment, personal protective equipment; professional skills, first aid skills for occupational accidents, prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| General knowledge about types of machinery, equipment, substances that generate dangerous and harmful factors; analyzing, assessing, and managing risks related to occupational safety and health, and safe working procedures with machinery, equipment, and substances with strict requirements for occupational safety and health. | 6 | 4 | 2 | ||

| IV | Checking safety training content at the end of the training course | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

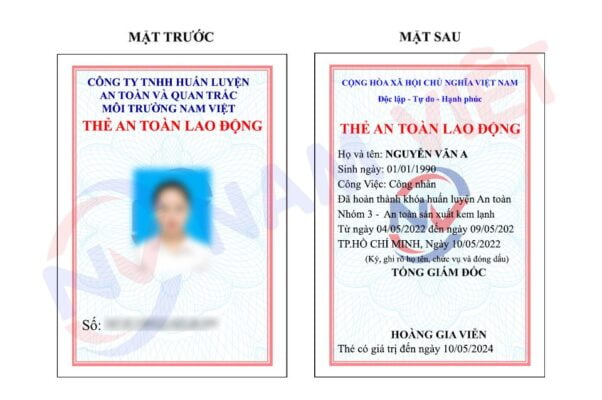

d. Occupational safety card

After completing the occupational safety training course and passing the test, the employee will be granted an occupational safety card (in practice, also called occupational safety certificate for group 3).

Specifically, the group 3 safety card will clearly show information such as: full name, date of birth, specific job and working environment. At the same time, it also has the training time, red stamp and signature confirming completion of the training course.

According to the regulations on issuing safety cards stated in Clause 2 of Article 24 of Decree 44/2016/ND-CP, it is divided into 2 cases:

- In the case that the employer and the employee have a labor contract, the employer must sign, stamp and seal the safety card for the trained person in group 3 after completing the training course from the occupational safety training unit and passing the test.

- In the case that the employee is a freelancer, seasonal worker, or does not have a labor contract, the training unit must sign, stamp and seal the safety card for the employee after completing the training course from the occupational safety training unit and passing the test.

3. Identifying hazards when manufacturing ice cream

Some of the hazards that can be encountered when manufacturing ice cream include:

- Ice cream needs to be manufactured and preserved in a clean and safe environment to prevent bacteria and mold from growing, posing a risk of infection and harming consumer health.

- The ice cream manufacturing process often involves the use of hot liquids and high temperatures, so there is a risk of burns if safety measures are not taken while working.

- Some ice cream manufacturing machinery can use high power and pose a risk of fire and explosion if not used correctly.

- Ice cream manufacturing may use chemicals such as thickeners, food colorings and flavorings, and if not used correctly, these chemicals can be harmful to consumer health.

- Ice cream manufacturing involves the use of machinery and engine equipment, various knives and cutting blades, and the movement of heavy materials. Employees may be at risk of occupational accidents if they do not take safety measures while working.

- The environment of an ice cream factory is a place with low temperatures to keep the product at a good quality, which is why the cold air can affect workers, causing bronchitis.

4. Common occupational accidents when manufacturing ice cream

The types of occupational accidents that often occur when manufacturing ice cream include:

- Fire and explosion accidents: When manufacturing ice cream, the use of liquids and cold gases can cause fires and explosions if not operated correctly or if an incident occurs.

- Vibration accidents: Ice cream manufacturing employees must work with machinery that has strong vibrations. If they do not wear full protective equipment and do not comply with safety regulations, employees may be at risk from the vibration of these devices.

- Injury accidents: Ice cream manufacturing requires employees to work with cutting, touching, and mixing equipment. If they do not wear full protective equipment or do not comply with safety regulations, employees may be injured or harmed.

- Poisoning accidents: The use of chemicals and toxic substances in the ice cream manufacturing process can be harmful to the health of employees. If not properly trained or if they do not comply with safety regulations, employees may be at risk from these toxic substances.

- Temperature accidents: Ice cream manufacturing requires working at very low temperatures, which can cause health problems such as blood clots, loss of sensation, or cold pain for employees. If not properly trained and equipped, employees may be at risk from temperature-related problems.

5. Safety measures when participating in ice cream manufacturing

To ensure safety during the ice cream manufacturing process, the following safety measures can be applied:

- Ice cream manufacturing employees need to be trained in occupational safety about manufacturing procedures, equipment, machinery, chemicals used, and how to deal with emergency situations.

- Personal protective equipment such as helmets, safety glasses, protective sleeves, safety shoes, and masks should be used to protect employees from harmful agents such as chemicals, temperature or humidity.

- Tools, equipment, workbenches and work areas need to be cleaned periodically to ensure food safety and hygiene and prevent infectious diseases.

- Equipment and machinery need to be checked periodically to ensure that they are working well and are safe.

- Ice cream manufacturing ingredients need to be stored properly, checked for quality periodically and preserved correctly to avoid health and food safety problems.

- The materials used to manufacture ice cream need to be used correctly to avoid dangerous situations that are harmful to the health of consumers.

- Ice cream needs to be preserved correctly to avoid being infected with bacteria or contaminated.

- Safety measures need to be clearly warned so that employees can perform them accurately and correctly.

- Periodically organize work environment monitoring in factories and enterprises, collect and analyze factors harmful to workers, thereby adjusting to reduce the level of harm to prevent occupational diseases for them.

6. Benefits of ice cream manufacturing occupational safety training

An Toan Nam Viet provides businesses with great benefits after completing occupational safety training courses according to the regulations in Decree 44/2016/ND – CP on occupational safety and health work, Companies, factories, enterprises.

- Employees can identify the potential risks of occupational accidents, thereby having preventive measures to avoid occupational accidents.

- Your Business can establish risk prevention measures in the manufacturing, operation and maintenance processes.

- Minimize costs when there is a risk of losing occupational safety.

- The uninterrupted manufacturing process will help increase labor productivity and product quality.

- Comply with occupational safety laws, avoiding legal risks.

- Create prestige and professionalism in all aspects, thereby elevating your business brand.

Nam Viet’s training courses are the solution to prevent and combat external factors that affect each individual so that they can avoid danger that can lead to injury or, more seriously, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

7. Customer feedback after completing the ice cream manufacturing occupational safety training course

An Toan Nam Viet has many years of experience in the mission of accompanying many businesses in Vietnam in general and in the southern provinces in particular. And that responsibility is something very valuable to Nam Viet, which is why Nam Viet’s Occupational Safety Training is increasingly focused on becoming more professional. The motivation for An Toan Nam Viet to grow strong to this day comes from the positive feedback and suggestions from businesses. Below are the feedbacks from our partners we have served.

Bac Nam E&C Investment and Construction Joint Stock Company

“The first time I used An Toan Nam Viet’s service, I was very surprised by the enthusiastic 24/7 support of the consulting team. The class organization was very fast and convenient for our company, thank you very much for Nam Viet’s service!”

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service has helped us a lot in simplifying occupational safety and completing safety records for the work process. The consulting team is enthusiastic and timely in answering our questions. 5 stars for Nam Viet”

See more customer interviews after using An Toan Nam Viet’s service

8. An Toan Nam Viet’s Occupational Safety Training capacity

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam today. With occupational safety training sessions held continuously at manufacturing workshops, factories or construction sites across the country (63 provinces and cities in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected by the Department of Labor – Invalids and Social Affairs and granted a certificate of eligibility to operate occupational safety and health training. This further strengthens our occupational safety training capacity.

Materials and lectures

- Before occupational safety training materials are put into occupational safety training courses, they have been reviewed and censored to ensure that the lecture is always correct in terms of knowledge and effective when applied.

- The teaching method of the lecturers is synchronized according to the teaching standards of An Toan Nam Viet, which is a method that experts on occupational safety and health training have researched and drawn from the teaching process to bring the highest knowledge acquisition efficiency for students.

Facilities

- Controlling factors in the classroom that affect the training process will increase teaching performance and the effectiveness of students’ knowledge acquisition.

- The facilities supporting our training course always have spacious classrooms that meet standards for area, lighting, training equipment … etc…

9. Reputable and quality safety training center nationwide

At An Toan Nam Viet, we always prioritize our professional dedication to occupational safety training. For us, imparting knowledge on how to protect oneself to workers so they can have a safe luggage on their journey to make a living is contributing to building the country.

To ensure the effectiveness of the training, we carefully and meticulously prepare every little thing, even the smallest. From preparing tools, utensils, and teaching equipment to textbooks, documents, sound, and lighting.

Our occupational safety training lecturers are experts with many years of experience in the field. They even have research projects to identify hazards in all occupations and how to prevent them.

The lecturer’s lectures are drawn from practice and conveyed in the most vivid and easy-to-visualize way to workers. These factors help workers feel comfortable during their study time and absorb our teaching knowledge well. Of course, the knowledge conveyed always closely follows Decree 44/2016/ND-CP.

From there, they grasp many measures to prevent danger and how to protect themselves. At the same time, they also apply it in the most appropriate way in their actual work.

Our safety training center is proud to be a reputable and professional provider of occupational safety training services with the following advantages:

- Competitive training costs but training quality is still guaranteed.

- Flexible training schedule with the manufacturing situation of the Company business.

- Procedures for granting occupational safety training certificates are fast and in accordance with the provisions of the law.

- The training lecturers are people with many years of experience in the profession.

- The classroom is controlled for factors affecting the training process, increasing teaching performance and the effectiveness of students’ knowledge acquisition.

- The lectures are compiled to be suitable for occupational safety work in Businesses.

- An Toan Nam Viet works with dedication and professionalism to support customers accurately and quickly.

10. Refer to more ice cream manufacturing occupational safety training materials

- Ice cream manufacturing occupational safety materials

- Occupational safety training materials

- Set of occupational safety training test questions

- Ice cream manufacturing occupational safety multiple-choice test

- Slides of occupational safety training lectures for ice cream manufacturing

1 review for Occupational Safety Training in Ice Cream Manufacturing Factory

No comments yet

namchinh.haiphong341

Bài giảng rất sinh động!