Occupational Safety Training in Ceramic Manufacturing Factory

99,000 ₫

Note: The above price is calculated for one person and may fluctuate depending on the number of trainees participating in the course and market movements. For more accurate pricing support, please refer to the quotation table or contact our consulting staff directly.

Occupational safety is a critical issue in ceramic manufacturing factories and must be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses. The Occupational Safety Training course is an effective solution to raise awareness among workers on accident prevention during ceramic manufacturing.

Table of Contents

Toggle1. Overview of ceramics

a. What are ceramics?

- Ceramics are a type of product made from clay that is fired at high temperatures. Ceramics are usually made from clay mixed with water and shaped as desired before being fired. When clay is fired at high temperatures, it becomes hard and durable.

- Ceramics are divided into many types, including porcelain, white porcelain, raku fired pottery, earthenware, glazed ceramics, and many other types of ceramics.

- Ceramics are also considered a traditional art of many countries and are still maintained and developed to this day. In different cultures, ceramics show the diversity and uniqueness of each country and region, and are also an indispensable part of decorative art and items in daily life.

- The ceramic manufacturing industry in Vietnam has a long and diverse history, with many products being manufactured and developed across the country. However, the ceramic manufacturing industry in Vietnam is currently still facing many challenges and difficulties.

- According to statistics from the Ministry of Industry and Trade, the domestic ceramics output currently only meets about 70% of the domestic demand. Vietnamese ceramic products are mainly consumed in the domestic market and exported to some Asian markets such as Japan, Korea, and China. However, with fierce competition from ceramic products of other countries in the region, especially China, many Vietnamese ceramic enterprises are facing difficulties in accessing the market and customers.

- Some other problems affecting the ceramic manufacturing industry in Vietnam include raw material supply, poor manufacturing capacity, outdated manufacturing technology, unsecured product quality, high manufacturing costs and requiring large investment capital.

- However, Vietnamese ceramic manufacturing enterprises are still making efforts to improve product quality, innovate manufacturing technology, expand the market and reach new customers. Many enterprises are also looking for cooperation opportunities with domestic and foreign partners to enhance manufacturing capacity and access a larger market.

b. Types of machinery for ceramic manufacturing

The types of machinery for ceramic manufacturing include:

- Shaping machine: used to press and compress clay into the shape of the ceramic product.

- Clay rolling machine: used to roll clay into thin sheets for the convenience of making ceramic products.

- Stamping machine: used to stamp and compress clay into the required shape.

- Spraying machine: used to spray a layer of paint on the surface of the ceramic product.

- Kiln: used to fire the ceramic product in a specific temperature and humidity environment so that the product can become hard and durable.

- Printing machine: used to print patterns and images on the surface of the ceramic product.

- Molding machine: used to create molds to manufacture ceramic products in specific shapes.

The types of machinery for ceramic manufacturing must be used correctly and maintained periodically to ensure the safety of workers as well as ensure product quality.

c. Typical ceramic manufacturing enterprises

Typical ceramic manufacturing enterprises in Vietnam include:

- Minh Long I Co., Ltd: This is one of the largest ceramic manufacturing companies in Vietnam, with more than 800 employees and 7 manufacturing factories spread across the country. The company manufactures high-end ceramic products, which are exported to different markets around the world.

- Bat Trang Ceramic Joint Stock Company: This is one of the most famous traditional ceramic manufacturing enterprises in Vietnam, with more than 200 years of ceramic manufacturing history. The company specializes in manufacturing decorative ceramic products, household items and gifts.

- Huu Nhat Ceramic Company Limited: The company was established in 2008 and has become one of the leading ceramic manufacturing units in Vietnam. The company specializes in manufacturing high-end ceramic products such as plates, bowls, cups, teapots, etc.

- Thanh Ha Pottery Village: This is one of the most famous traditional pottery villages in Vietnam, located in Hoi An, Quang Nam. This pottery village was established in the 16th century and still maintains ceramic manufacturing activities to this day, with many decorative ceramic products, household items and gifts.

In addition, there are many other ceramic manufacturing enterprises such as Van Hanh, Dieu Khac My Nghe, Thanh Tam, Binh An, etc. which are also developing and contributing to the development of the ceramic manufacturing industry in Vietnam.

d. Specific jobs in a ceramic manufacturing factory

Group 1

- CEO, Deputy CEO, department manager in a ceramic manufacturing factory.

Group 2

- Safety officer: manages safety in the factory, designs safety procedures, supervises and urges employees to comply with safe work procedures.

Group 3

- Ceramic manufacturing: The ceramic manufacturing process includes many steps such as mixing clay, shaping products, drying, firing products at high temperatures, painting and decorating products.

- Operating manufacturing machinery: Employees who operate manufacturing machinery need to have knowledge of operating the equipment, ensuring that the manufacturing process takes place effectively and safely.

- Quality control: Quality control staff will check ceramic products before putting them into the next manufacturing process. Products that do not meet quality requirements will be discarded or repaired.

- Warehouse management: Warehouse management staff need to store, package and transport ceramic products to send to dealers or customers.

- Manufacturing management: Manufacturing management staff are responsible for supervising the manufacturing process, ensuring that products are manufactured on time and with the best quality.

Group 4

- Office jobs, services, sales, marketing.

- Manufacturing management, quality management, human resource management, material management, financial accounting management.

- Research and development of new products.

- Product design: Design staff will create technical drawings and models for ceramic products.

e. Some common products made from ceramics

Ceramics are a common material in the manufacturing of household items and decorations. Some common products made from ceramics include:

- Tea sets: Used for brewing and enjoying tea at parties or for family use.

- Plant pots: Products used for growing decorative plants indoors, on balconies or in gardens.

- Vases: Products for decorating party tables, living rooms, bedrooms and even outdoors.

- Clock statues: This product is made from clay, which can be painted and decorated with unique colors.

- Wash basins and bathtubs: Used in bathrooms for personal hygiene.

- Decorative lamps: Used for lighting, creating a warm space indoors or outdoors.

- Bowls, plates, fruit plates, table mats: These are products used for family meals or parties.

- Cups, tea plates, drinking glasses: These are products used for drinking water, coffee, tea, etc.

- Paintings, home decorations: There are many different types of items made from ceramics such as wrist bracelets, rings, picture frames, jewelry boxes, perfume sprayers, plant seeds, etc.

With high aesthetics, products made from ceramics have become an indispensable part of people’s daily lives.

2. Overview of occupational safety training course for ceramic manufacturing

In the scope of this article, we focus on issues related to group 3, because group 3 is the group that directly participates in the manufacturing process and bears the highest risk of occupational safety. Refer to other groups here

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training are training sessions to equip workers with awareness of how to prevent workplace accidents.

- The occupational safety training course will help workers recognize and prevent dangers, and limit the risks of workplace accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

b. Training duration

Initial safety training duration

- The total training duration is at least 24 hours, including the exam time.

- 8 hours of theoretical study on the system of policies and laws on occupational safety and health.

- 8 hours of theoretical study on basic knowledge of occupational safety and health.

- 4 hours of theoretical study on specialized training content.

- 2 hours of practical training on specialized training content.

- 2 hours of theoretical exam at the end of the training course.

The safety training center will allocate the time into many training sessions depending on the time arrangement for the staff. But normally, there will be 6 training sessions, the course will last 3 days, on the condition that the manufacturing enterprise can arrange continuous study time.

Periodic safety training duration

- Before the occupational safety card expires, if workers want to renew it, they must undergo a periodic occupational safety training course, with the periodic safety training duration being at least 50% of the initial safety training duration.

Explanation: The total periodic occupational safety training duration is at least 12 hours, including the exam time. After completing the periodic training course and passing the exam, workers will have their occupational safety card renewed or extended.

c. Content of the training course

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Of which | ||||

| Theory | Practice | Exam | |||

| I | System of policies and laws on occupational safety and health | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and health. | 6 | 6 | ||

| 2 | System of technical standards and regulations on occupational safety and health. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and health when building new, expanding or renovating works, facilities for manufacturing, using, preserving, storing and inspecting types of machinery, equipment, materials, and substances with strict requirements on occupational safety and health. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and health | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of dangerous and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods of improving working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies and regimes on occupational safety and health for employees; functions and duties of the occupational safety and health network. | 1 | 1 | ||

| 5 | Occupational safety and health regulations, signs, occupational safety and health signs and use of safety equipment, personal protective equipment; professional skills, first aid for workplace accidents, and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| General knowledge about types of machinery, equipment, and substances that generate dangerous and harmful factors; analyzing, assessing, and managing risks related to occupational safety and health, safe work procedures with machinery, equipment, and substances with strict requirements on occupational safety and health. | 6 | 4 | 2 | ||

| IV | Occupational safety training exam at the end of the training course | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

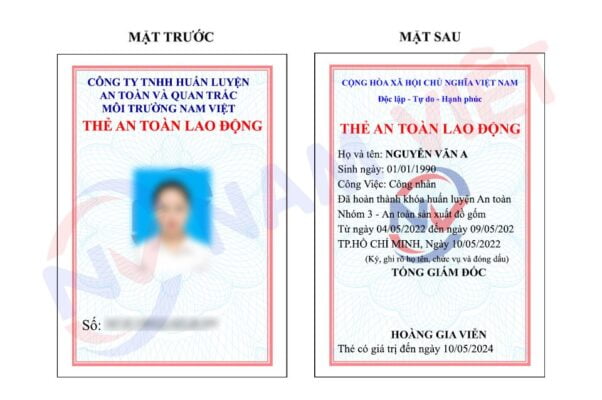

d. Occupational safety card

After completing the occupational safety training course and passing the exam, the worker will be issued an occupational safety card (in practice, also called a Group 3 occupational safety certificate).

In which, the Group 3 safety card will clearly show information such as: full name, date of birth, job and specific work environment. At the same time, there will be the training duration, a red seal and a signature confirming the completion of the training course.

According to the regulations on issuing safety cards specified in clause 2 of article 24 of decree 44/2016/ND-CP, there are 2 cases:

- In case the employer and the employee have an employment contract with each other, the employer must sign, seal and initial the safety card for the trained person in Group 3 after undergoing the training course from the occupational safety training unit and passing the exam.

- In case of freelance, seasonal workers, without an employment contract, the training unit must sign, seal and initial the safety card for the worker after undergoing the training course from the occupational safety training unit and passing the exam.

3. Recognizing hazards when manufacturing ceramics

The ceramic manufacturing process can encounter some hazards as follows:

- The pottery making process includes firing at very high temperatures, and the products will then emit very high temperatures. Workers must wear full protective equipment to avoid burns during the work process.

- Clay dust can fly up during the manufacturing process, which when inhaled into the respiratory tract can cause irritation and cause health problems for workers.

- During work, workers have to move and transport ceramic products which can cause collisions and injuries. In addition, heavy objects can cause injuries to workers if not transported safely.

- Ceramic manufacturing requires the use of many types of machinery, so there is a risk of accidents with machinery during the manufacturing process if not used correctly and fully complying with safety regulations.

- The use of kilns to fire ceramic products also has a risk of causing fires and explosions if not done correctly.

4. Workplace accidents that often occur when manufacturing ceramics

Workplace accidents that often occur during the ceramic manufacturing process may include:

- Injuries from collisions: When moving and transporting ceramic products, workers may be at risk of collision with ceramic products or other equipment.

- Burns due to high temperature: The ceramic manufacturing process includes firing products at high temperatures, which can cause a risk of burns to workers.

- Accidents with machinery: The ceramic manufacturing process requires the use of many types of machinery, if not used correctly or not fully complying with safety regulations, it can lead to workplace accidents.

- Chemical poisoning: Ceramic manufacturing may use some chemicals to color or decorate products, if not complying with the regulations on chemical use and storage, it can cause poisoning to workers.

- Inhaling clay dust: During the manufacturing process, ceramic fragments can cause clay dust to fly up into the air, which when inhaled can cause health problems for workers.

5. Safety measures when participating in ceramic manufacturing

To ensure the safety of workers involved in ceramic manufacturing, companies need to apply the following safety measures:

- Occupational safety training for employees on knowledge and skills of occupational safety in the ceramic manufacturing process.

- Provide adequate personal protective equipment for workers such as masks, safety glasses, protective clothing, protective gloves, safety shoes, etc.

- Ensure that items, machinery and equipment are operating in a safe condition and are periodically checked to avoid sudden incidents.

- Ensure good ventilation in the workplace and minimize clay dust and toxic gases in the working environment.

- Store chemicals in a proper storage and monitor them closely to avoid incidents.

- Install an early warning system to detect safety risks early and have a response plan in case of an accident.

- Implement fire and explosion prevention measures, especially during the high-temperature ceramic firing process.

- Periodically check and maintain equipment and machinery to ensure safety during the manufacturing process.

- Conduct periodic health checks for workers to early detect health problems related to working in the ceramic manufacturing environment.

- Periodically organize workplace environment monitoring in the factory, collect and analyze harmful factors to workers, thereby adjusting to reduce the level of harm to prevent occupational diseases for them.

6. Benefits of occupational safety training for ceramic manufacturing

An Toan Nam Viet provides your enterprise with excellent benefits after completing occupational safety training courses as regulated in Decree 44/2016/ND – CP on occupational safety and health work, Companies, manufacturing plants, enterprises.

- Employees can identify potential risks of workplace accidents and thus have preventive measures to avoid workplace accidents.

- Your enterprise can establish risk prevention measures in the manufacturing, operation, and maintenance processes.

- Minimize costs when occupational safety risks occur.

- Uninterrupted manufacturing will help increase labor productivity and product quality.

- Comply with occupational safety laws, avoiding legal risks.

- Build a professional reputation in all aspects, thereby enhancing your brand.

Nam Viet’s training courses are a solution to prevent and combat external factors from affecting each individual so that they can avoid danger that can lead to injury or, more seriously, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

7. Customer feedback after completing the occupational safety training course for ceramic manufacturing

An Toan Nam Viet has many years of experience in the mission of accompanying many enterprises in Vietnam in general and in the southern provinces in particular. And that responsibility is something extremely precious to Nam Viet, which is why Nam Viet’s Occupational Safety Training work is increasingly focused on becoming professional. And the motivation for An Toan Nam Viet to grow strongly to this day comes from the positive feedback and suggestions from enterprises. Below are the feedbacks from our partners we have served.

Bac Nam E&C Investment and Construction Joint Stock Company

“The first time I used An Toan Nam Viet’s service, I was very surprised by the enthusiastic 24/7 support of the consulting team. The class organization was very quick and convenient for our company, thank you very much for Nam Viet’s service!”

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service has helped us a lot in simplifying occupational safety and completing safety records for our work process. The consulting team is enthusiastic and timely in answering our questions. 5 stars for Nam Viet”

See more customer interviews after using An Toan Nam Viet’s service

8. Occupational Safety Training Competence of An Toan Nam Viet

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam today. With occupational safety training sessions taking place continuously at manufacturing workshops, factories or construction sites across the country (63 provinces and cities in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational safety training license

- An Toan Nam Viet has been inspected by the Department of Occupational Safety of the Ministry of Labor – Invalids and Social Affairs and granted a certificate of eligibility to operate occupational safety and health training. This further strengthens our ability to conduct occupational safety training.

Documents and lectures

- Before occupational safety training documents are included in the occupational safety training courses, they are reviewed and censored to ensure that the lectures are always correct in terms of knowledge and effective when applied.

- The teaching method of the lecturers is synchronized according to the teaching standards of An Toan Nam Viet, which is a method that experts in occupational safety and health training have researched and summarized during the teaching process to bring the highest knowledge acquisition efficiency to students.

Facilities

- Controlling the factors in the classroom that affect the training process will increase teaching performance and the effectiveness of knowledge acquisition for students.

- Our facilities to support the training course always arrange spacious classrooms that meet standards for area, lighting, training equipment, etc.

9. Reputable and quality safety training center nationwide

At An Toan Nam Viet, we always put the professional dedication to occupational safety training as our top priority. For us, imparting the knowledge of self-protection to workers so that they can have a safe foundation on their career path is a contribution to building the country.

To ensure effective training, we prepare carefully and meticulously every little detail. From preparing tools, equipment, teaching devices to textbooks, documents, sound, and lighting.

Our occupational safety training lecturers are experts with many years of experience in the field. They even have research projects to identify hazards in all occupations and how to prevent them.

The lecturer’s lectures are summarized from reality and conveyed in the most vivid and easy-to-understand way to the workers. These factors help workers feel comfortable during their study time and absorb our teaching knowledge well. Of course, the knowledge conveyed always closely follows Decree 44/2016/ND-CP.

From there, they grasp many measures to prevent dangers and how to protect themselves. At the same time, they also apply it in the most suitable way in their actual work.

Our safety training center is proud to be a unit that provides reputable and professional occupational safety training services with the following advantages:

- Competitive training costs but training quality is still guaranteed.

- Flexible training schedule with the production situation of the Company or enterprise.

- Quick and legal procedures for issuing occupational safety training certificates.

- Training lecturers are people with many years of experience in the profession.

- The classroom is controlled for factors that affect the training process to increase teaching performance and the effectiveness of knowledge acquisition for students.

- The lectures are compiled to be suitable for occupational safety work at enterprises.

- An Toan Nam Viet works dedicatedly and professionally to support customers accurately and as quickly as possible.

10. Additional References for Occupational Safety Training in Pottery Production

- Occupational Safety Documents for Pottery Production

- Occupational Safety Training Document Set

- Occupational Safety Training Test Set

- Occupational Safety Multiple-Choice Test for Pottery Production

- Slides for Occupational Safety Training in Pottery Production

1 review for Occupational Safety Training in Ceramic Manufacturing Factory

No comments yet

namchinh.haiphong341

Cảm ơn trung tâm! tôi rất hài lòng với dịch vụ