Occupational Safety Training in Bedding Manufacturing (Blankets, Sheets, Pillows, and Mattresses)

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the dynamics of the market. For more accurate price support, please refer to the quotation table or contact our consulting staff directly.

Occupational safety is an important issue in bedding manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of businesses. The Occupational safety training course is one of the effective solutions to raise awareness of accident prevention for workers when participating in manufacturing.

Table of Contents

Toggle1. Overview of bedding products

a. What are bedding products?

- Bedding products include blankets, sheets, pillows, and mattresses used for bed making and sleeping. They are usually made from materials such as cotton, wool, linen, or other fabrics depending on the purpose of use and design style. Bedding products are often sold in household goods stores, supermarkets, and department stores, with various price ranges depending on material and brand.

- Currently, the bedding manufacturing industry is a major business sector in Vietnam. Many enterprises operate in this field, from large corporations to small facilities. Bedding products are manufactured in diverse types, sizes, colors, materials, and prices to meet consumer needs, from premium to budget products. According to the market report of Euromonitor International, the bedding manufacturing industry in Vietnam generated revenue of over 4.2 billion USD in 2021.

b. Types of machinery in bedding manufacturing

Types of machinery in bedding manufacturing include:

- Automatic fabric cutting machine: This machine is used to cut fabric pieces into required sizes to form bedding products.

- Automatic sewing machine: This machine stitches fabric pieces together to create bedding products. Sewing machines can be used for fabrics or other materials such as leather or vinyl.

- Packing machine: This machine is used to pack bedding products. It can automatically pack and seal products or be operated manually.

- Compressing machine: This machine compresses bedding products to keep them uniform in shape and prevent peeling.

- Material processing machine: This machine is used to process materials such as cotton, feathers, or other fillers for bedding manufacturing. It can process materials into different sizes and thicknesses to meet final product requirements.

c. Bedding manufacturing enterprises in Vietnam

Some bedding manufacturing enterprises in Vietnam include:

- Hoa Thanh Holdings (HTP): One of Vietnam’s leading corporations in bedding manufacturing and trading, with well-known brands such as Everon, Song Hong, Lavenza, Comforta, Fazz, etc.

- TNG Investment and Trading Joint Stock Company: A company specializing in premium bedding manufacturing with well-known brands such as TNG, Gavi, Hometex, etc.

- Van Thanh: A company specializing in bedding manufacturing with well-known brands such as Van Thanh, Bim Son, AK Home, etc.

- Everpia: A company with 100% Korean investment, specializing in bedding manufacturing with well-known brands such as Everon, Alodiamond, etc.

- Kymdan: A company specializing in natural rubber bedding manufacturing with the Kymdan brand.

- Kim Cuong: A company specializing in bedding manufacturing and trading with well-known brands such as Kim Cuong, Song Hong, Château d’Ax, etc.

d. Specific jobs in bedding manufacturing factories

Group 1

- Chief executive officer, deputy chief executive officer, department managers in bedding manufacturing factories.

Group 2

- Safety officer: managing safety in the factory, designing safety procedures, supervising, and urging employees to comply with safe working procedures.

Group 3

- Preparing raw materials: Raw materials required for bedding manufacturing include fabrics, felt, cotton, feathers, synthetic fibers, natural fibers, lining materials, and accessories. This work includes selecting, inspecting, arranging, and storing materials.

- Cutting and sewing fabric: Fabric is the main raw material for bedding manufacturing. After selecting fabrics, workers cut and sew them into pieces to make bedding products.

- Filling cotton and processing feathers: Cotton and feathers are materials used to create softness and warmth for bedding. This work includes filling cotton and feathers into bedding and processing them to ensure purity and safety for users.

- Packing and transportation: After manufacturing, bedding products are packed and transported to distributors, retail stores, or end customers.

- Quality inspection: This is the final stage in bedding manufacturing. Workers inspect product quality before launching to the market.

Group 4

- Office work, services, sales, marketing.

- Production planning: This is the first important step in bedding manufacturing. The plan includes calculating the number of products to be manufactured within a certain period, allocating resources, and determining the product line.

- Research and development of new products, designing product packaging models.

2. Overview of occupational safety training in bedding manufacturing

In this article, we focus on issues related to group 3, because group 3 directly participates in the manufacturing process and is exposed to the highest occupational safety risks. Refer to other groups here

a. What is occupational safety training for group 3?

- Occupational safety training for group 3 are sessions that provide awareness about accident prevention for workers.

- The occupational safety training course helps workers identify and avoid hazards, reducing risks of occupational accidents at work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial occupational safety training duration

- Total training duration is at least 24 hours, including examination time.

- 8 hours of theoretical study on occupational safety and hygiene policies and laws

- 8 hours of theoretical study on basic occupational safety and hygiene knowledge

- 4 hours of theoretical study on specialized training content

- 2 hours of practical study on specialized training content

- 2 hours of theoretical examination at the end of the course

The occupational safety training center will divide the schedule into multiple sessions depending on the arrangement of employees’ learning time. Normally, there are 6 sessions, and the course lasts 3 days, provided that the manufacturing enterprise arranges continuous training time.

Periodic occupational safety training duration

- Before the occupational safety card expires, workers must take a periodic occupational safety training course, with training duration of at least 50% of the initial occupational safety training duration.

Explanation: the total periodic occupational safety training duration is at least 12 hours, including examination time. After completing the periodic training and passing the examination, workers will be reissued or have their occupational safety card renewed.

c. Training course content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Examination | |||

| I | System of occupational safety and hygiene policies and laws | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of occupational safety and hygiene technical standards and regulations. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when constructing, expanding, or renovating facilities for manufacturing, using, storing, preserving, and inspecting machines, equipment, supplies, and substances with strict requirements on occupational safety and hygiene. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and workers; occupational safety and hygiene policies and regimes for workers; functions and duties of the occupational safety and hygiene network. | 1 | 1 | ||

| 5 | Occupational safety and hygiene rules, safety signs and instructions, use of safety equipment and personal protective equipment; professional skills in first aid for occupational accidents and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, substances generating hazardous and harmful factors; analysis, evaluation, and risk management of occupational safety and hygiene; safe working procedures with machinery, equipment, and substances with strict occupational safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Final occupational safety training examination | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

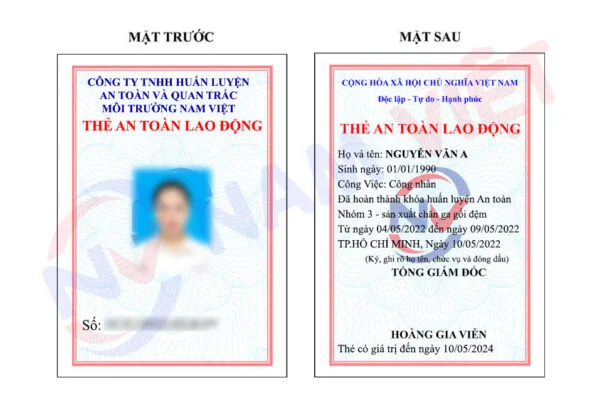

d. Occupational safety card

After completing occupational safety training and passing the examination, workers will be issued an occupational safety card (commonly referred to as an occupational safety certificate for group 3).

The group 3 safety card clearly states information such as full name, date of birth, job, and specific working environment. It also shows the training duration, red seal, and signature confirming training completion.

According to the regulations on issuing safety cards specified in clause 2 of article 24 of decree 44/2016/ND-CP, there are 2 cases:

- If the employer and worker have a labor contract, the employer must sign, stamp, and affix the occupational safety card for group 3 workers after completing training and passing the examination from the occupational safety training unit.

- If the worker is a freelancer or seasonal worker without a labor contract, the training unit must sign, stamp, and affix the occupational safety card after the worker completes training and passes the examination.

3. Identifying hazards affecting workers in bedding manufacturing

During the bedding manufacturing process, employees may encounter the following hazards:

- Because the manufacturing process involves the use of chemicals and flammable materials, there may be risks of fire and explosion in the factory.

- Tasks such as cutting, sewing, and packaging can cause accidents such as cuts, injuries, or punctures to the hands.

- During the manufacturing process, employees may be exposed to dust particles and toxic gases that can cause respiratory diseases.

- Production employees may be exposed to chemicals, cleaning agents, and odorants that can cause irritation and skin-related illnesses.

- When using manufacturing equipment and machinery, employees may encounter accidents caused by broken equipment, misuse, or lack of periodic maintenance.

- Employees in bedding manufacturing may have to work in environments with high light, temperature, and humidity, which can lead to health issues such as headaches, fatigue, and discomfort.

- If electrical equipment in the factory is not regularly maintained, insufficiently insulated, or waterproofed, it will pose an electric shock hazard to workers during the manufacturing process.

4. Common occupational accidents occurring to workers in bedding manufacturing

Common occupational accidents that may occur in bedding manufacturing include:

- Injuries from knives, scissors, cutting tools, stamping: Cutting, stamping, buttoning, and sewing operations in the bedding manufacturing process all pose a risk of injury if not performed correctly and without the proper use of protective equipment.

- Burns from touching the heat press: Heat presses are used to bond layers of materials together to form bedding products. However, during machine operation, workers may accidentally touch the machine surface and suffer burns.

- Chemical poisoning: Chemicals used for bleaching, coloring, or disinfecting bedding products can cause poisoning if not used properly or if protective equipment such as masks, gloves, and coats are not worn.

- Falls: During machine operation or moving manufacturing materials, workers may fall and sustain injuries or even life-threatening harm.

- Bruises, back and spine injuries: Workers in bedding manufacturing factories often have to lift, pull, and transport heavy materials, which can cause injuries to body parts such as the back, spine, shoulders, and arms.

5. Safety measures when participating in bedding manufacturing

Safety measures when participating in bedding manufacturing include:

- Use protective equipment: Employees must fully use protective equipment such as helmets, protective glasses, masks, gloves, etc. to avoid injury when working with machinery in bedding manufacturing factories.

- Proper use of equipment and tools: Employees must use equipment and tools correctly to avoid causing danger to themselves and others. At the same time, equipment and tools must be regularly inspected to ensure safety during use.

- Training and instruction: New employees must be trained and instructed in safe work procedures, proper equipment and tool usage skills, and other safety measures to avoid occupational accidents.

- Risk reduction: Bedding manufacturing factories must implement risk reduction measures such as periodic equipment inspections, proper repair and maintenance, and installation of safety warnings.

- Safety organization: Bedding manufacturing factories must establish strict safety management systems and clear regulations to ensure worker safety during work. Fire prevention, explosion control, and emergency evacuation plans must be in place.

- Hygiene compliance: Bedding manufacturing factories must comply with hygiene regulations, ensuring a safe and hygienic working environment to prevent illness and protect employees’ health.

- Regularly conduct occupational environment monitoring in factories, collect and analyze harmful factors for workers, and adjust to reduce hazards to prevent occupational diseases for them.

6. Benefits of occupational safety training in bedding manufacturing

An Toan Nam Viet provides businesses with the following outstanding benefits after completing occupational safety training courses according to Decree 44/2016/ND – CP on occupational safety and hygiene work for companies, factories, and enterprises.

- Workers can identify potential risks of occupational accidents and take preventive measures to avoid accidents.

- Businesses can establish risk prevention measures in the production, operation, and maintenance process.

- Minimize costs when occupational safety risks occur.

- Uninterrupted production helps increase labor productivity and product quality.

- Comply with occupational safety laws and avoid legal risks.

- Create prestige and professionalism in all aspects, thereby enhancing the brand for businesses.

Nam Viet’s training courses are solutions to prevent and protect against external factors that may endanger individuals, helping them avoid injuries or even death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer feedback after completing occupational safety training in bedding manufacturing

An Toan Nam Viet has accumulated many years of experience in the mission of accompanying businesses across Vietnam in general and the southern provinces in particular. That responsibility for Nam Viet is extremely valuable, which is why Nam Viet’s Occupational Safety Training work is always increasingly professional. The motivation for An Toan Nam Viet’s strong development today comes from both positive feedback and constructive suggestions from enterprises. Below are feedback from our partners that we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“This was the first time using services at An Toan Nam Viet and I was very surprised by the enthusiastic 24/7 support of the consulting team. The class organization was very quick and convenient for our company, thank you very much Nam Viet for your service!”

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service has helped us a lot in simplifying occupational safety and completing safety documentation for the work process. The consulting team was enthusiastic and timely in answering our questions. 5 stars for Nam Viet”

See more customer interviews after using the service of An Toan Nam Viet

8. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. With continuous occupational safety training sessions held at factories, plants, or construction sites across the country (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

License for occupational safety training

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety of the Ministry of Labor – Invalids and Social Affairs to be qualified to conduct occupational safety and hygiene training activities. This further strengthens our occupational safety training capacity.

Documents and lectures

- Before occupational safety training documents are introduced into occupational safety training courses, they are reviewed and approved to ensure the lectures are accurate and effective when applied.

- The teaching methods of the instructors are standardized according to An Toan Nam Viet teaching standards, developed by experts in occupational safety and hygiene training to achieve the highest learning efficiency for trainees.

Facilities

- Controlling classroom factors that affect training will improve teaching efficiency and student knowledge absorption.

- Our training facilities always arrange spacious classrooms that meet standards in terms of area, lighting, and training equipment, etc.

9. Reputable and high-quality national occupational safety training center

At An Toan Nam Viet, we always put our dedication to occupational safety training as a top priority. For us, imparting self-protection knowledge to workers so they can have safety as their foundation in their livelihood is part of building the country.

To ensure effective training, we carefully and meticulously prepare every detail, no matter how small. From preparing tools, teaching equipment, curriculum, and documents to sound and lighting.

Our occupational safety training instructors are experts with many years of experience in the field. They even have research projects identifying hazards in all industries and ways to prevent them.

The lectures are drawn from practice and conveyed in a lively and easy-to-understand way to workers. These factors help workers feel comfortable during learning and absorb our teaching well. Of course, the knowledge conveyed always follows Decree 44/2016/ND-CP.

From there, they can grasp many preventive measures against hazards and how to protect themselves. At the same time, they can apply them appropriately in real work.

Our training center is proud to be a provider of reputable and professional occupational safety training services with the following advantages:

- Competitive training costs but training quality is still guaranteed.

- Flexible training schedules in line with the company’s production situation.

- Quick processing of occupational safety training certification documents, in compliance with the law.

- Instructors with many years of professional experience.

- Classrooms are controlled for factors affecting training, improving teaching efficiency and knowledge absorption.

- Lectures are designed to suit occupational safety work at enterprises.

- An Toan Nam Viet works dedicatedly and professionally to support customers accurately and quickly.

10. Additional references for occupational safety training in bedding manufacturing

- Occupational safety documents for bedding manufacturing

- Occupational safety training document set

- Occupational safety training test set

- Occupational safety multiple-choice test for bedding manufacturing

- Slides of occupational safety training lectures in bedding manufacturing

1 review for Occupational Safety Training in Bedding Manufacturing (Blankets, Sheets, Pillows, and Mattresses)

No comments yet

namchinh.haiphong341

OK tốt!!!!!