Occupational Safety Training for Drone Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the market movement. For more accurate price support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in factory manufacturing drone (flycam) and needs to be addressed promptly to ensure the health and safety of workers, enhancing the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness of how to prevent occupational accidents for workers participating in drone (flycam) manufacturing.

Table of Contents

Toggle1. Overview of Drone

a. What is drone?

- Drone is an unmanned aerial vehicle (Flycam) used for filming and photographing from the sky. Flycam is equipped with sensors and an automatic control system to keep it stable during flight. Flycam can be controlled remotely through a controller or from a mobile phone or tablet application. Flycam is widely used in advertising, filmmaking, sports, and environmental monitoring.

- The flycam manufacturing industry in Vietnam has been developing rapidly in recent years, especially after the Noise Prevention Law of Vietnam came into effect in 2018, allowing the use of flycam in manufacturing, trade, and services. According to the Vietnam Drones Association, in 2020, the number of flycams registered and licensed in Vietnam doubled compared to 2019.

- Flycam manufacturing enterprises in Vietnam today are not few, including both large and small businesses. However, most of these enterprises are focusing on manufacturing simple flycams with basic photography and filming functions, with not many high-end products or applications of new technology.

b. Types of machines for flycam manufacturing

Types of machines for flycam manufacturing include:

- Laser cutting machine: Used to cut case parts, propellers, and other components of the flycam. The laser cutting machine helps save time and manufacturing costs while ensuring high precision in the cutting process.

- CNC lathe: Used to process metal components of the flycam. With CNC technology, the lathe can produce precise parts with high durability and minimize manufacturing errors.

- Molding machine: Used to create molds from plastic or metal materials to shape the case, components, and propellers of the flycam.

- Welding machine: Used to weld the metal parts of the flycam together. The welding machine increases the durability of the flycam and minimizes failures caused by welding errors.

- Filming machine: Used to film the flycam during testing and quality inspection before launching to the market.

- Quality inspection machine: Used to check technical specifications of the flycam, ensuring the product meets quality and safety standards.

c. Typical flycam manufacturing enterprises

In Vietnam, there are many flycam manufacturing enterprises with different brands. Here are some typical flycam manufacturing enterprises in Vietnam:

- DJI – The Chinese company DJI has established a branch in Vietnam and manufactures flycams here. DJI is considered the world’s leading flycam brand.

- Skytech – One of the pioneering enterprises in flycam manufacturing in Vietnam, Skytech has many flycam products popular in the market.

- Hovership – This enterprise specializes in manufacturing flycams for entertainment and filming, with many high-quality products.

- Flycam Viet – One of the first flycam brands in Vietnam, Flycam Viet manufactures many quality flycam products suitable for user needs.

- Energen – This is a flycam manufacturing enterprise in Vietnam with many high-quality products popular in the market.

d. Specific jobs in a flycam manufacturing factory

Group 1

- Chief executive officer, deputy chief executive officer, department heads in a flycam manufacturing factory.

Group 2

- Safety officer: managing safety in the factory, designing safety procedures, supervising and urging employees to comply with safe working procedures.

Group 3

- Component manufacturing: Flycam factories need to manufacture components including electronic parts, motors, propellers, and airframes.

- Assembly: After manufacturing components, workers assemble flycams by joining parts and installing electronic devices.

- Quality inspection: Flycams must undergo quality inspection to ensure stability, safety, and good operation.

- Packing and transportation: After quality inspection, flycams will be packed and transported to sales points or delivered directly to customers.

- After-sales service: Flycam manufacturing factories also provide after-sales services such as maintenance, repair, and software updates for customers’ flycams.

Group 4

- Office work, service, sales, marketing.

- Production management, quality management, human resources management, material management, financial and accounting management.

- Research and development of new products, design of product packaging.

2. Overview of occupational safety training in drone manufacturing

In this article, we focus on issues surrounding group 3, because group 3 is the group directly involved in the manufacturing process, facing the highest occupational safety risks. Refer to other groups here

a. What is group 3 occupational safety training?

- Group 3 occupational safety training are lessons equipping workers with awareness of how to prevent occupational accidents.

- The occupational safety training course will help workers recognize and avoid hazards, reducing risks of occupational accidents while working.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

First-time safety training duration

- Total training duration is at least 24 hours, including examination time.

- 8 hours of theory on the system of policies, laws on occupational safety and hygiene

- 8 hours of theory on basic knowledge of occupational safety and hygiene

- 4 hours of theory on specialized training content

- 2 hours of practice on specialized training content

- 2 hours of theoretical test at the end of the training course

The occupational safety training center will arrange the training duration into several sessions depending on the scheduling of workers. Normally, there will be 6 training sessions, the course will take place over 3 days, provided that the manufacturing enterprise arranges continuous study time.

Periodic safety training duration

- Before the occupational safety card expires, workers who want reissuance must undergo a periodic occupational safety training course, with the periodic safety training duration being at least 50% of the first-time safety training duration.

Explanation: the total periodic occupational safety training duration is at least 12 hours, including examination time. After completing the periodic training course and passing the test, workers will be reissued and have their occupational safety card renewed.

c. Training course content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | System of policies, laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards, technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when building new, expanding, or renovating works, facilities for manufacturing, using, storing, and inspecting machinery, equipment, materials, substances with strict occupational safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods of improving working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers, employees; policies and regimes on occupational safety and hygiene for employees; functions and duties of the occupational safety and hygiene network. | 1 | 1 | ||

| 5 | Rules of occupational safety and hygiene, safety signs, instructions, and use of safety equipment, personal protective equipment; skills in first aid for occupational accidents, prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| General knowledge about machines, equipment, substances generating hazardous and harmful factors; analysis, assessment, risk management of occupational safety and hygiene; safe working procedures with machines, equipment, substances with strict occupational safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Final test of occupational safety training content | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

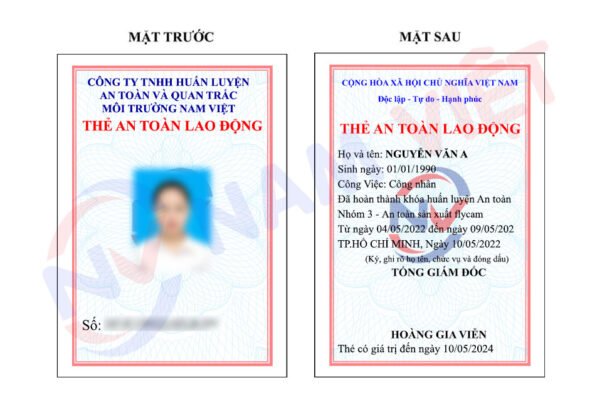

d. Occupational safety card

After completing the occupational safety training course and passing the test, workers will be issued an occupational safety card (commonly called Group 3 safety certificate).

The Group 3 safety card will clearly show information such as: full name, date of birth, job, and specific working environment. It also includes training duration, red stamp, and signature confirming completion of the training course.

According to the regulations on issuing safety cards stated in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must stamp and sign the safety card for the worker trained in group 3 after completing training from the occupational safety training unit and passing the test.

- If the worker is freelance or seasonal and does not have a labor contract, the training unit must stamp and sign the safety card for the worker after completing training from the occupational safety training unit and passing the test.

3. Identifying Hazards in Flycams Manufacturing

The hazards in flycam manufacturing may include:

- Flycams may be equipped with many electronic components such as batteries, motors, circuits, etc. If not handled properly, these components may cause fire, explosion, or generate abnormal signals, leading to risks for workers.

- The assembly processes of flycams require carefulness and special skills. If these processes are not performed correctly, the flycam may not operate properly or may encounter safety issues.

- Flycams are often made from materials such as metal, plastic, fabric, and other substances. If these materials are not processed properly or do not meet standards, they may pose hazards to workers, such as toxicity, fire, explosion, or bursting.

- The inspection and operation processes of flycams may also pose dangers to workers. For example, flycams require battery and control checks to ensure they function correctly and do not cause safety issues.

4. Common Occupational Accidents in Flycam Manufacturing

Flycam manufacturing is a job with a high risk of occupational accidents. Common accidents during flycam manufacturing may include:

- Electric shock: When working with electronic devices and high voltage, even small mistakes can lead to the risk of electric shock.

- Puncture injuries, fire, explosion: When using materials and chemical liquids in production, there is a risk of puncture injuries, fire, or explosion if safety procedures and measures are not followed properly.

- Scratches and injuries: Moving, assembling, maintaining, or repairing flycams may cause scratches or injuries if workers do not wear protective equipment or follow safety procedures.

- Hazards during flycam testing: Testing processes may cause accidents due to loss of control or flycams falling.

- Hazards during flycam flight: Operating flycams in open space may cause accidents if safety rules are not followed, or if the flycam loses control and collides with objects or people.

5. Safety Measures in Flycam Manufacturing

To ensure safety for employees participating in flycam manufacturing, several measures must be implemented:

- Employees must be equipped with full personal protective equipment, including helmets, special shoes, gloves, safety glasses, and protective clothing.

- Devices and machinery must be regularly inspected to ensure they operate safely and do not pose hazards to employees.

- All employees involved in flycam manufacturing must be trained in occupational safety, including safety procedures, accident prevention measures, and how to use protective equipment.

- Chemicals must be used properly to avoid hazards to employees.

- Materials and equipment must be well managed to avoid falling or causing hazards to employees.

- The factory must have a modern fire protection system, regularly inspected to ensure readiness in emergencies.

- Machines must be maintained periodically to ensure safe operation without posing hazards to employees.

- All employees must comply with occupational safety regulations and act accordingly to ensure their own safety and that of colleagues.

- Regularly conduct occupational environment monitoring in factories and enterprises, collecting and analyzing harmful factors for workers to adjust and reduce hazards, thereby preventing occupational diseases.

6. Benefits of Occupational Safety Training in Flycam Manufacturing

An Toan Nam Viet provides your business with the following outstanding benefits after completing occupational safety training courses in accordance with Decree 44/2016/ND – CP on occupational safety and hygiene for companies, factories, and enterprises.

- Workers can identify potential occupational accident risks and take preventive measures to avoid accidents.

- Your business can establish risk prevention measures in manufacturing, operation, and maintenance processes.

- Minimize costs arising from occupational safety incidents.

- Uninterrupted manufacturing processes help increase productivity and product quality.

- Compliance with occupational safety laws, avoiding legal risks.

- Create credibility and professionalism, thereby enhancing your company’s brand.

Nam Viet’s training courses are solutions to prevent and counter external risk factors that may affect individuals, helping them avoid hazards that may cause injuries or, in severe cases, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback After Completing Occupational Safety Training in Flycam Manufacturing

An Toan Nam Viet has many years of experience in the mission of accompanying businesses across Vietnam in general and in southern provinces in particular. This responsibility is invaluable to us, which is why our Occupational Safety Training work is increasingly professional. The motivation for An Toan Nam Viet’s growth comes from positive feedback as well as constructive suggestions from enterprises. Below are some testimonials from our partners we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“My first experience with An Toan Nam Viet was surprisingly positive due to the 24/7 support from the consulting team. The class organization was quick and convenient for our company. Many thanks for Nam Viet’s service!”

See more customer interviews after using An Toan Nam Viet’s services

8. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. Training sessions are continuously held at manufacturing workshops, factories, or construction sites nationwide (63 provinces in Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Safety under the Ministry of Labor, Invalids and Social Affairs, confirming eligibility to conduct occupational safety and hygiene training. This further strengthens our capacity in occupational safety training.

Training Materials and Lectures

- Before occupational safety training materials are used in training courses, they are reviewed and approved to ensure accuracy and effectiveness.

- Instructor teaching methods are standardized according to An Toan Nam Viet standards, researched and developed by occupational safety experts to maximize knowledge retention for trainees.

Facilities

- Controlling classroom factors affecting training will increase teaching efficiency and knowledge absorption of trainees.

- Our training facilities always provide spacious classrooms meeting standards for area, lighting, training equipment, etc.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, we always place professional dedication to occupational safety training as the top priority. To us, imparting knowledge that helps workers protect themselves provides them with safety on their livelihood journey and contributes to building the nation.

To ensure training effectiveness, we carefully and meticulously prepare even the smallest details—from tools, teaching devices, lesson plans, and materials to sound and lighting.

Our occupational safety trainers are experts with many years of experience, even with research projects on hazard identification across industries and preventive measures.

Lectures are practical and delivered vividly and understandably to workers. These elements help workers feel comfortable and absorb knowledge effectively. The content always adheres to Decree 44/2016/ND-CP.

From there, workers can learn preventive measures and self-protection methods and apply them appropriately in real work situations.

Our training center proudly provides reputable and professional occupational safety training with the following advantages:

- Competitive training fees while maintaining quality.

- Flexible training schedules tailored to enterprise manufacturing operations.

- Fast occupational safety certification procedures in compliance with laws.

- Experienced instructors with many years of expertise.

- Classrooms controlled to optimize teaching efficiency and learning outcomes.

- Lectures designed to suit occupational safety practices in enterprises.

- An Toan Nam Viet works diligently and professionally to provide clients with accurate and fast support.

10. Additional References for Occupational Safety Training in Flycam Manufacturing

- Occupational Safety Documents for Flycam Manufacturing

- Occupational Safety Training Materials

- Occupational Safety Training Tests

- Multiple-choice Occupational Safety Test for Flycam Manufacturing

- Slide Lectures on Occupational Safety Training in Flycam Manufacturing

1 review for Occupational Safety Training for Drone Manufacturing

No comments yet

namchinh.haiphong341

Cảm ơn trung tâm! tôi rất hài lòng với dịch vụ