Occupational Safety Training For Rice Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the movement of the market. For more accurate pricing support, please refer to the quotation or contact directly with our consultants.

Occupational safety is an important issue in rice manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of enterprises. The Occupational Safety Training course is one of the effective solutions to raise awareness about preventing occupational accidents for workers participating in rice manufacturing.

Table of Contents

Toggle1. Overview of Rice

a. What is rice?

Rice is the seed of the rice plant (Oryza sativa) after harvesting, dehusking, and drying. It is an important source of nutrition and a staple food in most Southeast Asian, East Asian, and South Asian countries. Rice is a good source of carbohydrates, protein, B vitamins, folic acid, and minerals such as iron and zinc.

Rice is one of the basic food sources for humans, cultivated on fields around the world. Rice provides a significant amount of carbohydrates and is essential for daily energy needs. In addition, rice contains many vitamins and minerals such as vitamin B, vitamin E, iron, zinc, magnesium, potassium, and manganese.

Rice grains are used to prepare various dishes, from simple meals like plain rice to more complex dishes such as sushi, pho, or risotto. In many cultures worldwide, rice is also considered an important food for festivals and religious ceremonies.

b. Machinery used in rice manufacturing

There are many types of machinery used in rice manufacturing, depending on the manufacturing scale and technology applied. Below are some commonly used machines in rice manufacturing:

- Plowing machine: used to till and turn the soil before sowing seeds.

- Seed drill: used to sow rice seeds.

- Rice plow: used to plow the land and prepare it for rice cultivation.

- Rice harvester: used to harvest rice.

- Rice milling machine: used to remove the husk and bran from rice grains to obtain white rice.

- Rice sorting machine: used to separate rice grains by size and quality.

- Rice packaging machine: used to pack rice into standard packages and seal them.

Additionally, rice manufacturing involves other supporting equipment such as feed grinders, irrigation machines, water pumps, dryers, bran mills, packaging machines, etc.

c. Rice manufacturing companies in Vietnam

Vietnam is one of the world’s leading rice producers, so there are many rice manufacturing companies here. Some notable rice companies in Vietnam include:

- Vietnam Food Corporation (VINAFOOD): VINAFOOD is considered the largest food corporation in Vietnam with many branches and rice manufacturing factories nationwide.

- Thanh Cong Group Joint Stock Company: Thanh Cong is also one of the major food corporations in Vietnam, with multiple rice factories across the country.

- Cuong Thuan Group Joint Stock Company: One of the leading rice producers in Vietnam, with famous rice brands such as “Nam Huong” and “Thien Loc”.

- Southern Food Joint Stock Company: A major rice producer in Southern Vietnam, with many manufacturing and packaging plants across provinces in the region.

- Loc Troi Group Joint Stock Company: Loc Troi not only produces and trades other agricultural products like vegetables, tubers, and fruits but also engages in rice manufacturing and trading.

There are many other rice manufacturing and trading companies in Vietnam.

d. Specific tasks in a rice manufacturing factory

Group 1

- Executive director, deputy director, department heads in the rice manufacturing factory.

Group 2

- Safety officers: manage safety in the factory, design safety procedures, monitor and enforce compliance with safe working practices.

Group 3

- Raw material pre-treatment: this process involves removing weeds and other impurities from rice grains using machines such as sieves, washing machines, and grain separators.

- Drying: after pre-treatment, rice grains are dried using dryers to maintain low moisture content.

- Surface treatment: rice surfaces are treated using water sprays or chemicals to remove dirt, impurities, and mold.

- Sorting: processed rice grains are sorted by size and quality using automatic sorting machines.

- Packaging: rice grains are packed into bags or boxes using automatic packaging machines and then stored in the warehouse ready for distribution.

- Quality control: during manufacturing, the factory conducts quality checks to ensure rice meets food safety standards and customer requirements.

Group 4

- Office, service, sales, and marketing tasks.

- Manufacturing management, quality management, human resources management, material management, financial accounting management.

2. Overview of Rice Manufacturing Occupational Safety Training

In this article, we focus on issues related to Group 3 because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. For other groups, refer here.

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training are sessions designed to raise awareness and teach workers how to prevent occupational accidents.

- The training course helps workers recognize and avoid hazards, reducing the risk of accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial occupational safety training

- Total training time is at least 24 hours, including examination time.

- 8 hours of theory on safety and labor hygiene policies and laws

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical exam at the end of the course

The safety training center schedules multiple sessions depending on workers’ availability. Typically, there are 6 sessions over 3 days if the company can arrange continuous training.

Periodic occupational safety training

- Before the occupational safety card expires, workers must undergo periodic occupational safety training, with the periodic training duration being at least 50% of the initial training duration.

Explanation: the total periodic occupational safety training duration is at least 12 hours, including examination time. After completing the periodic training and passing the exam, workers are reissued and have their occupational safety card renewed.

c. Training content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practical | Exam | |||

| I | Safety and labor hygiene policies and laws | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents on safety and labor hygiene. | 6 | 6 | ||

| 2 | System of safety and labor hygiene standards and regulations. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on safety and labor hygiene when constructing, expanding, or renovating facilities, producing, using, storing, and inspecting machines, equipment, materials, and substances requiring strict safety and labor hygiene control. | 1 | 1 | ||

| II | Basic occupational safety and hygiene knowledge | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies on occupational safety and hygiene; roles and responsibilities of safety network members. | 1 | 1 | ||

| 5 | Safety rules, signage, use of safety equipment and personal protective equipment; skills in first aid for occupational accidents and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, substances causing hazards; risk assessment and management in occupational safety and hygiene; safe working procedures for machines, equipment, and substances requiring strict safety and hygiene standards. | 6 | 4 | 2 | ||

| IV | End-of-course occupational safety examination | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

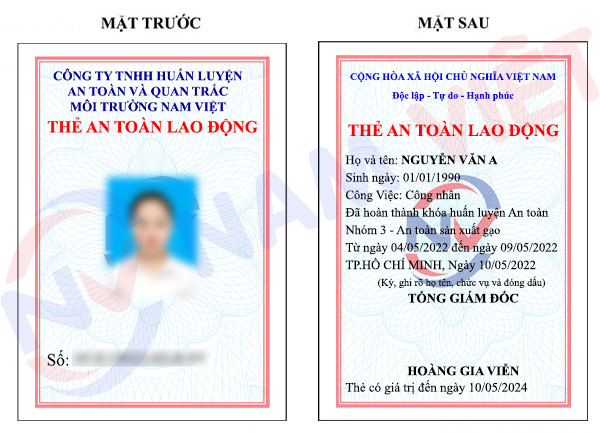

d. Occupational Safety Card

After completing the occupational safety training and passing the examination, workers will be issued an Occupational Safety Card (commonly called Occupational Safety Certificate for Group 3).

The Group 3 safety card clearly shows information such as full name, date of birth, job, and specific work environment. It also includes training duration, red stamp, and signature confirming course completion.

According to the regulations specified in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and seal the safety card for Group 3 workers after completing the occupational safety training from the training unit and passing the examination.

- If the worker is freelance, seasonal, or does not have a labor contract, the training unit must sign, stamp, and seal the safety card for the worker after completing the training and passing the exam.

3. Identifying Hazards Affecting Workers in Rice Manufacturing

During rice manufacturing, workers may face the following hazards:

- Hazards related to machinery and equipment: Machines in rice manufacturing factories, such as grinders, sieves, presses, and wastewater treatment machines, can pose dangers to operators if safety procedures are not followed.

- Hazards related to chemicals: During rice manufacturing, chemicals such as fertilizers, pesticides, herbicides, water treatment chemicals, and preservatives can harm workers’ health if not used correctly with proper protective equipment.

- Electrical hazards: Rice manufacturing factories use electrical and electronic equipment, such as motors, transformers, and generators, which can cause accidents if not properly maintained and operated.

- Hazards related to toxic gases: During rice manufacturing, toxic gases such as steam from cooking machines or gases from wastewater treatment can harm workers’ health if proper safety measures are not taken.

- Hazards related to transport loads: Workers operating machinery to transport rice from the factory to consumption points may be at risk of accidents if safety procedures and protective equipment are not followed.

- Hazards related to the working environment: Temperature and humidity in rice manufacturing factories can affect workers’ health if the working environment is not properly managed.

4. Common Occupational Accidents in Rice Manufacturing

Common occupational accidents during rice manufacturing include:

- Accidents with machinery: Machines in rice manufacturing often operate at high speeds with many moving parts, so workers may get trapped, crushed, cut, pierced, or suffer fractures from collisions with machinery.

- Electrical accidents: Electrical equipment in rice manufacturing factories may cause electric shocks, fires, or burn hazards.

- Chemical poisoning: Chemicals such as pesticides, herbicides, fertilizers, and cleaning agents are used to maintain product quality and safety standards. Improper use or lack of personal protective equipment can lead to chemical poisoning.

- Hot liquid accidents: Devices like rice cookers, microwaves, or other rice processing equipment can pose hazards if used incorrectly.

- Accidents from falling heavy objects: When moving sacks of rice or other rice products, improper handling or lack of protective equipment may cause injuries from falling objects.

- Accidents due to poor posture: Rice manufacturing work often requires bending or stretching for extended periods, which may lead to back pain, cervical spine degeneration, or joint issues.

5. Safety Measures for Rice Manufacturing

Safety measures in rice manufacturing include:

- Wearing full personal protective equipment: Employees should wear masks, helmets, safety glasses, aprons, gloves, and safety shoes when operating rice manufacturing machines to protect eyes, skin, and respiratory system from dust and toxic fumes.

- Occupational Safety Training: Employees must be trained in safety techniques, proper machine use, safe work procedures, and emergency response.

- Regular inspection and maintenance of machinery: Rice manufacturing machinery must be inspected and maintained regularly to ensure safe and efficient operation. Machine parts should be lubricated and replaced as needed.

- Follow safety regulations at work: Safety rules such as no smoking in manufacturing areas, avoiding damaged or misused tools, keeping objects off power lines, and storing sharp tools safely must be followed.

- Check rice quality: Rice products must be inspected for quality before packaging and shipping. Manufacturing units should ensure rice meets standards for moisture, dust content, grain length, size, and color.

- Fire and explosion prevention: Potential fire and explosion hazards may occur during rice manufacturing. Factories must implement measures such as fire alarm systems, isolating flammable materials, and prohibiting smoking in manufacturing areas.

- Regular work environment monitoring in factories to collect and analyze harmful factors, then adjust and reduce risks to prevent occupational diseases.

6. Benefits of Occupational Safety Training in Rice Manufacturing

An Toan Nam Viet provides businesses with the following benefits after completing occupational safety training courses according to Decree 44/2016/ND – CP regarding occupational safety and hygiene:

- Workers can identify potential accident risks and take preventive measures to avoid occupational accidents.

- Businesses can establish risk prevention measures in manufacturing, operation, and maintenance processes.

- Reduce costs associated with occupational safety hazards.

- Uninterrupted manufacturing increases labor productivity and product quality.

- Compliance with labor safety laws avoids legal risks.

- Enhances credibility and professionalism, elevating the company’s brand image.

Training courses by An Toan Nam Viet help individuals prevent external hazards that could cause injuries or fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

7. Customer Feedback After Completing Rice Manufacturing Safety Training

An Toan Nam Viet has years of experience supporting businesses in Vietnam, especially in southern provinces. Our dedication to occupational safety training is highly valued, and our growth is driven by positive feedback and suggestions from our partners. Below are some testimonials from our clients.

See more customer interviews after using services by An Toan Nam Viet

8. An Toan Nam Viet Occupational Safety Training Capabilities

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam. Our training sessions are conducted continuously at manufacturing factories, workshops, and construction sites across all 63 provinces in Vietnam.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Labor Safety under the Ministry of Labor – Invalids and Social Affairs, confirming our qualification to provide occupational safety and hygiene training.

Training Materials and Lectures

- Before being used in Occupational Safety Training Courses, all training materials are reviewed to ensure knowledge accuracy and applicability.

- Teaching methods of instructors are standardized according to An Toan Nam Viet guidelines, designed by occupational safety experts to maximize knowledge retention for trainees.

Facilities

- Control of classroom factors affects training efficiency and trainees’ knowledge absorption.

- Our training facilities are spacious, meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, occupational safety training is our top priority. Teaching workers to protect themselves contributes to national development.

We carefully prepare every detail: tools, teaching equipment, curriculum, documents, sound, and lighting.

Our instructors are experts with years of experience, including research on hazard identification in all sectors and prevention methods.

Lectures are practical, engaging, and easy to understand, helping trainees absorb knowledge efficiently while complying with Decree 44/2016/ND-CP.

Our training center offers:

- Competitive training costs without compromising quality.

- Flexible training schedule based on company operations.

- Quick certification process in accordance with the law.

- Experienced instructors with many years in the field.

- Classroom factor control enhances teaching efficiency and knowledge absorption.

- Lectures tailored to occupational safety in businesses.

- Professional and dedicated service for accurate and fast client support.

10. Additional Rice Manufacturing Occupational Safety Training Materials

- Occupational Safety Training Materials Collection

- Rice Manufacturing Safety Training Materials

- Occupational Safety Training Test Set

- Rice Manufacturing Safety Training Curriculum

- Rice Manufacturing Occupational Safety Quiz

1 review for Occupational Safety Training For Rice Manufacturing

No comments yet

namchinh.haiphong341

Cảm ơn trung tâm! tôi rất hài lòng với dịch vụ