Occupational Safety Training for Lighter Manufacturing

99,000 ₫

Note: The above price is calculated for one person, and the price may fluctuate depending on the number of trainees participating in the course and market movements. For more accurate pricing support, please refer to the pricing table or contact our consulting staff directly.

Occupational safety is an important issue in factories manufacturing lighters and must be addressed promptly to ensure the health and safety of workers while enhancing the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to increase awareness of how to prevent workplace accidents for workers involved in lighter manufacturing.

Table of Contents

Toggle1. Overview of Lighters

a. What is a Lighter?

- A lighter, also known as a fire starter, is a device used to create a flame for igniting materials such as cigarettes, candles, incense, or other items.

- Lighters are usually made of metal, containing a flint encased in a metal shell. Striking the flint against a suitable friction material such as wool or cotton generates a flame.

- Lighters are compact and convenient to carry, commonly used for outdoor activities, indoor use, or during meetings and parties.

b. Types of Machinery in Lighter Manufacturing

Machinery for lighter manufacturing is generally divided into two main types: flint lighter machines and gas lighter machines.

- Machines for producing fuel lighters:

- Metal sheet cutting machines: used to cut metal sheets into the shape of the lighter body and to cut holes for the flint, spring, and locking mechanism.

- Box closing machines: used to assemble the two halves of the lighter while inserting the flint, spring, and locking mechanism inside.

- Printing machines: used to print logos or images on the surface of the lighter.

- Inspection and packaging machines: used to check the quality of lighters and then package them into suitable packaging.

- Machines for producing gas lighters:

- Metal sheet cutting machines: similar to flint lighter machines, but cut into shapes suitable for holding gas.

- Gas filling machines: used to pump gas into the lighter.

- Box closing machines: used to assemble the two halves of the lighter and seal the gas filling holes.

- Printing and inspection machines: similar to flint lighter machines but designed to print logos or images on the surface of gas lighters and inspect their quality.

- Packing machines: used to package gas lighters into appropriate packaging.

c. Lighter Manufacturing Companies in Vietnam

In Vietnam, several companies manufacture lighters, including:

- Doga Vina Co., Ltd.: a 100% foreign-invested company specializing in the production and export of gas lighters.

- Suc Song Viet Nam Co., Ltd.: specializes in manufacturing flint lighters, gas lighters, and related products in Tan Tao Industrial Park, Ho Chi Minh City.

- Dai Dong Thanh Co., Ltd.: produces gas lighters and promotional metal gift products in Tan Phu Trung Industrial Park, Ho Chi Minh City.

- Thang Long Co., Ltd.: specializes in producing flint lighters and gas lighters, as well as promotional metal gift products in Van Trung Industrial Park, Hung Yen Province.

- Thanh Dat Manufacturing and Trading Development Joint Stock Company: produces flint and gas lighters, along with metal gift and promotional products in Tan Binh Industrial Park, Ho Chi Minh City.

There are also many smaller companies producing lighters in Vietnam.

d. Specific Jobs in a Lighter Manufacturing Factory

Group 1

- Executive Director, Deputy Executive Director, and Department Heads in the lighter manufacturing factory.

Group 2

- Safety Officers: manage safety in the factory, design safety procedures, supervise and ensure employees follow safe work procedures.

Group 3

- Material Receiving: includes checking and organizing materials such as metal, flint, gas, packaging, and other components.

- Metal Cutting and Processing: metals are cut and processed into small parts, including the lighter body, cap, and other components.

- Polishing and Plating: metal parts are polished to create a shiny surface and then plated with metals like copper, nickel, gold, or silver.

- Assembly: parts are assembled using machinery or manually to produce the final product.

- Quality Control: products are checked to ensure they meet quality and safety standards.

- Packing and Transport: products are packaged and prepared for delivery to distributors or end customers.

Group 4

- Office, service, sales, and marketing roles.

- Production management, quality management, human resources management, material management, financial and accounting management.

- Research and development of new products, packaging design.

2. Overview of Occupational Safety Training for Lighter Manufacturing

This article focuses on Group 3 because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. Refer to other groups here.

a. What is Group 3 Occupational Safety Training?

- Group 3 occupational safety training equips workers with awareness on preventing workplace accidents.

- The training helps workers identify and avoid hazards, reducing risks of occupational accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial Safety Training

- Total training time is at least 24 hours, including examination time.

- 8 hours of theoretical lessons on policies, laws, and occupational safety and hygiene

- 8 hours of theoretical lessons on basic occupational safety and hygiene knowledge

- 4 hours of theoretical lessons on specialized training content

- 2 hours of practical lessons on specialized training content

- 2 hours of final theoretical examination

The safety training center can schedule sessions flexibly depending on worker availability. Typically, training consists of 6 sessions over 3 days, provided the company arranges continuous learning time.

Periodic Safety Training

- Before the occupational safety card expires, workers needing renewal must complete periodic safety training with a duration of at least 50% of the initial safety training duration.

Explanation: total periodic safety training is at least 12 hours, including examination time. Upon completion and passing the test, workers are reissued and have their occupational safety card renewed.

c. Training Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Examination | |||

| I | Policies and Laws on Occupational Safety and Hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | Standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations by state management authorities on occupational safety and hygiene when constructing, expanding, or renovating facilities, and handling machines, equipment, materials, and substances with strict safety requirements. | 1 | 1 | ||

| II | Basic Knowledge of Occupational Safety and Hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; occupational safety policies; roles of safety officers. | 1 | 1 | ||

| 5 | Occupational safety rules, signage, use of safety devices and personal protective equipment; first aid skills, and occupational disease prevention. | 1 | 1 | ||

| III | Specialized Training Content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, hazardous substances; risk analysis and management; safe working procedures with machines and hazardous materials. | 6 | 4 | 2 | ||

| IV | Final Safety Training Examination | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

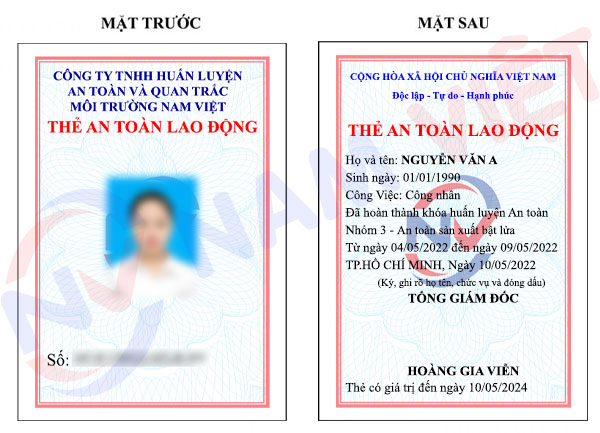

d. Occupational Safety Card

After completing the occupational safety training and passing the exam, workers will be issued a Group 3 Occupational Safety Card (commonly called a Group 3 Safety Certificate).

The Group 3 card displays information such as name, date of birth, job, and specific work environment, along with training duration, official stamp, and signature confirming course completion.

According to Clause 2 of Article 24 of Decree 44/2016/NĐ-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign and stamp the safety card for the Group 3 worker after they complete training and pass the exam.

- If the worker is freelance or temporary without a labor contract, the training unit must sign and stamp the safety card after training and passing the exam.

3. Identifying Hazards Affecting Workers During Manufacturing of Lighters

Potential hazards for workers during the manufacturing of lighters include:

- Fire and explosion hazards: Manufacturing lighters involves flammable materials such as gas, oil, or stones, which can pose a risk of fire and explosion.

- Heat hazards: The manufacturing processes for lighters involve machinery that can generate high temperatures.

- Injury hazards: Materials like metal can cause serious injuries to workers if not handled properly.

- Poisoning risks: The use of chemicals and toxic gases in manufacturing exposes employees to potential poisoning if proper protection is not used.

- Occupational accident risks: Machinery in the factory can cause accidents if not operated or maintained properly.

- Electrical hazards: If electrical equipment in the factory is not regularly maintained or properly insulated and waterproofed, workers are at risk of electric shock during manufacturing.

4. Common Occupational Accidents for Workers During Manufacturing of Lighters

Common occupational accidents for workers during lighter manufacturing include:

-

- Fire and explosion: Due to gas compounds and flammable chemicals used in production, the factory has a risk of fire or explosion. The most severe accidents usually occur during gas production.

- Burns or scalds: Machinery in the factory can generate high temperatures, posing a risk of burns to employees.

- Machine jams: Machinery may get clogged with grease or metal materials, causing accidents if not handled properly.

- Ear pain and difficulty breathing: Employees working in lighter manufacturing environments may experience ear pain and respiratory issues due to noise and toxic gases such as CO2 or CO.

- Injury from collisions: During production, workers may suffer from impacts or injuries caused by metal materials or production equipment.

5. Safety Measures for Participation in Lighter Manufacturing

Safety measures in lighter manufacturing include:

- Ensure good ventilation in the factory: Lighter manufacturing often produces smoke and dust; sufficient ventilation is needed to minimize harmful effects on workers’ health.

- Use personal protective equipment (PPE): Workers should wear PPE such as respirators, safety glasses, gloves, fire-resistant jackets, and safety shoes to minimize injury risks and exposure to harmful agents.

- Occupational safety training: Factories should train workers on machinery operation and PPE usage to ensure safety during work.

- Inspect and maintain machinery: Regular inspection and maintenance of machinery is required to reduce the risk of accidents. Any technical faults must be repaired or replaced immediately.

- Manage materials and supplies: Materials used in lighter manufacturing must be properly stored and monitored. Quality checks should be conducted before use to minimize production risks.

- Adjust gas pressure: Gas is flammable, so the pressure must be regulated before use to ensure safety during production.

- Fire prevention: Factories must have fire prevention systems to minimize damage to property and health in case of fire.

- Periodically conduct workplace environment monitoring to collect and analyze harmful factors, and adjust to reduce risks, preventing occupational diseases.

6. Benefits of Occupational Safety Training in Lighter Manufacturing

An Toan Nam Viet provides the following benefits to enterprises after completing occupational safety training in accordance with Decree 44/2016/NĐ – CP on occupational safety and hygiene:

- Workers can recognize potential hazards and take preventive measures to avoid occupational accidents.

- Enterprises can establish risk prevention measures in production, operation, and maintenance processes.

- Minimize costs associated with workplace safety risks.

- Continuous production improves labor productivity and product quality.

- Compliance with labor safety laws, reducing legal risks.

- Enhance professionalism and reputation, elevating the enterprise’s brand.

Nam Viet’s training programs help individuals prevent external hazards that could lead to injury or even death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

7. Customer Feedback After Completing Occupational Safety Training in Lighter Manufacturing

An Toan Nam Viet has years of experience supporting many enterprises in Vietnam, particularly in southern provinces. This responsibility is highly valued, so our occupational safety training is increasingly professional. Positive feedback and suggestions from partners have driven our growth. Below are testimonials from partners we have served.

See more customer interviews after using An Toan Nam Viet services

8. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam. Training sessions are held continuously at factories, manufacturing plants, or construction sites across all 63 provinces.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Safety under the Ministry of Labor – Invalids and Social Affairs, granting certification for occupational safety and hygiene training. This further strengthens our training capacity.

Training Materials and Lectures

- Training materials are reviewed and approved to ensure accuracy and effectiveness before inclusion in ATLĐ courses.

- Lecturing methods follow An Toan Nam Viet standards, developed by experts in occupational safety training to maximize knowledge absorption.

Facilities

- Controlling classroom factors improves teaching efficiency and learner comprehension.

- Our training facilities are spacious and meet standards for area, lighting, and equipment.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, we prioritize professional occupational safety training. We carefully prepare all aspects of training, from tools, teaching equipment, curricula, materials, to audio and lighting.

Our instructors are experienced specialists, with research on hazard identification across industries and prevention methods. Lectures are practical, vivid, and easily understandable, aligned with Decree 44/2016/NĐ-CP.

Through this, workers learn hazard prevention and self-protection measures applicable in real work scenarios.

Our safety training center is proud to offer professional occupational safety training with advantages:

- Competitive training costs with guaranteed quality.

- Flexible training schedules according to enterprise production.

- Fast and lawful certification procedures.

- Experienced instructors.

- Controlled classroom environment to enhance learning efficiency.

- Lectures tailored for enterprise occupational safety.

- Dedicated and professional service for accurate and prompt support.

10. Additional Reference Materials for Occupational Safety Training in Lighter Manufacturing

- Occupational safety materials for lighter manufacturing

- Occupational safety training materials set

- Occupational safety training test set

- Occupational safety multiple-choice test for lighter manufacturing

- Training slides for lighter manufacturing occupational safety

1 review for Occupational Safety Training for Lighter Manufacturing

No comments yet

namchinh.haiphong341

Bài giảng rất sinh động!