Occupational Safety Training for Tire Manufacturing

99,000 ₫

Note: The above price is calculated per person and may vary depending on the number of participants in the course and market fluctuations. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in tire manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness of accident prevention for workers involved in tire manufacturing.

Table of Contents

Toggle1. Overview of Tires

a. What is a tire?

- A tire is a component fitted on motorcycles, cars, trucks, buses, excavators, tractors, etc. Tires allow vehicles to move across all types of terrain and help absorb shocks during movement, while also playing a key role in ensuring the safety of drivers and passengers. Tires consist of main components such as the inner liner, carcass, tread, and sidewall. Common types of tires today include slick tires, grooved tires, off-road tires, rain tires, and reinforced tires.

- The tire manufacturing industry in Vietnam has developed in recent years, with many companies being established and invested in. Currently, tire manufacturing companies are mainly concentrated in industrial parks in Binh Duong, Dong Nai, Hai Phong, Ha Noi, Thai Nguyen, and Ho Chi Minh City. Major tire manufacturers in Vietnam include Bridgestone, Michelin, Kumho Tire, Hankook Tire, Goodyear, Yokohama, Continental, etc.

- The tire manufacturing industry in Vietnam is still developing and has not yet reached a production level sufficient to meet domestic demand. Therefore, tire manufacturers still import tires from abroad to supplement supply. However, the Vietnamese government has introduced policies to support and encourage domestic companies to invest in and manufacture tires to reduce dependence on imports and meet domestic demand.

b. Machinery used in tire manufacturing

The main types of machinery used in tire manufacturing include:

- Tire press machines: Used to press the inner liner and tread together to form a tire.

- Conveyor cutting machines: Used to cut the inner liner and tread layers of the tire to the required size and shape.

- Carcass processing machines: Used to process details on the tire carcass, including steel cords, cables, and grinding particles.

- Abrasion coating machines: Used to apply anti-wear rubber layers on the tire surface.

- Tire packaging machines: Used to package and seal finished tires for transport and sale.

Other machines such as round tire presses, valve making machines, polishing machines, and quality inspection machines are also used during tire manufacturing.

c. Prominent tire manufacturing enterprises in Vietnam

Currently, notable tire manufacturers in Vietnam include:

- Vietnam Tire Joint Stock Company (CASUMINA): The largest enterprise in the tire manufacturing industry in Vietnam, established in 1976. CASUMINA produces tires for cars, motorcycles, trucks, and buses.

- Sao Mai Tire Joint Stock Company (SMA): Established in 2007, SMA is one of the leading tire manufacturers in Vietnam, producing tires for motorcycles and scooters.

- Bridgestone Vietnam Joint Stock Company: A subsidiary of Bridgestone Corporation, one of the largest tire manufacturers in the world. Bridgestone Vietnam produces tires for cars and trucks.

- Michelin Saigon Co., Ltd. (Michelin Vietnam): A subsidiary of Michelin Group, also one of the largest tire manufacturers in the world. Michelin Vietnam produces tires for cars, trucks, and buses.

- Kumho Tire Vietnam Co., Ltd.: Established in 2008, a subsidiary of Kumho Tire Group, a leading tire manufacturer in South Korea. Kumho Tire Vietnam produces tires for cars and trucks.

d. Specific jobs in a tire manufacturing factory

Group 1

- Executive director, deputy executive director, department heads in the tire manufacturing factory.

Group 2

- Safety officer: managing safety in the factory, designing safety procedures, supervising and ensuring employees follow safe working procedures.

Group 3

- Cleaning and preparing materials: Materials such as rubber, steel cords, and chemicals for tire manufacturing are prepared and stored at the factory. Cleaning and preparing these materials is crucial to ensure the quality of the final product.

- Rubber mixing: Rubber materials are mixed to create the compound for tire molding. The mixing process must be precise to ensure rubber quality.

- Tire molding: The molding process is the most important step in tire manufacturing. Rubber is molded into the tire mold, then steel and fabric layers are placed over the rubber to form the tire structure.

- Pressing and heating: After rubber, steel, and fabric layers are assembled, the tire is pressed and heated to ensure tight bonding and high durability.

- Cutting and finishing: Tires are cut into different shapes according to their use. Then, they are finished by polishing and painting.

- Quality inspection: Finally, tires are inspected before leaving the factory to ensure they meet quality and safety standards.

Group 4

- Office, service, sales, and marketing work.

- Production management, quality management, human resources management, material management, financial accounting management.

- Research and development of new products, designing product packaging and samples.

2. Overview of tire manufacturing occupational safety training course

In this article, we focus on Group 3 because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. For other groups, refer here.

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training consists of sessions equipping workers with awareness on preventing workplace accidents.

- The training helps workers recognize and avoid hazards, reducing the risk of workplace accidents during production.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial occupational safety training

- Total training duration is at least 24 hours, including assessment time.

- 8 hours of theory on policies and laws on occupational safety and hygiene

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized occupational safety training

- 2 hours of practical training on specialized content

- 2 hours of final theory test

The training center will schedule multiple sessions depending on employee availability. Typically, there are 6 sessions over 3 days, assuming the manufacturing company arranges continuous training time.

Periodic occupational safety training

- Before the occupational safety card expires, employees must undergo periodic occupational safety training if they want to renew it, with a periodic training duration of at least 50% of the initial training duration.

Explanation: total periodic occupational safety training lasts at least 12 hours, including assessment time. After completing the periodic course and passing the test, employees will be issued or renewed their occupational safety card.

c. Training content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Assessment | |||

| I | Policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of occupational safety and hygiene standards and technical regulations. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when constructing, expanding, or renovating factories, facilities, machinery, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; occupational safety and hygiene policies; roles and duties of safety network officers. | 1 | 1 | ||

| 5 | Occupational safety rules, safety signs, instructions, use of safety equipment and personal protective gear; first aid and occupational disease prevention skills. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, substances generating hazards; analyzing, evaluating, managing occupational safety risks; safe working procedures for machinery, equipment, and substances with strict safety requirements. | 6 | 4 | 2 | ||

| IV | Final assessment of occupational safety training | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

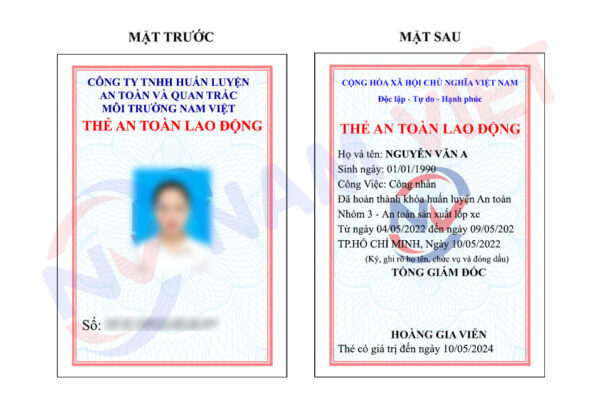

d. Occupational safety card

After completing the occupational safety training and passing the assessment, employees will be issued a Group 3 occupational safety card (commonly called Group 3 safety certificate).

The Group 3 card clearly shows information such as name, date of birth, specific job and working environment, training duration, red stamp, and signature confirming course completion.

According to the issuance regulations in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and seal the occupational safety card for the Group 3 trainee after completing the course from the occupational safety training unit and passing the test.

- If the employee is freelance or temporary without a labor contract, the training unit must sign, stamp, and seal the occupational safety card after the employee completes the course and passes the test.

3. Recognizing Hazards Affecting Workers in Tire Manufacturing

Some hazards affecting workers in tire manufacturing may include:

- During the manufacturing process, there is a risk of fire and explosions as well as incidents related to liquids, gases, or chemicals. This is especially true in rubber and tire factories, where flammable and explosive chemicals are used and stored.

- Tire factories often have large machinery and use various technologies. Occupational accidents can occur due to working with machinery, handling materials, or transporting products.

- Tire factories use many chemicals in the production process, including toxic and irritating substances. Workers in tire factories may be exposed to these chemicals through skin contact or inhalation of harmful vapors.

- Tire factories use many sharp materials such as metals, saws, and knives for cutting and processing tires. This can lead to cuts, injuries, or other harm if workers do not wear full protective equipment.

- Tire factories can generate high noise levels during production, especially when using large machinery. Continuous exposure to high noise levels can lead to health issues, including hearing loss and stress.

4. Common Occupational Accidents in Tire Manufacturing

Common occupational accidents during tire manufacturing include:

- Machinery accidents: During tire manufacturing, workers may encounter accidents such as getting caught between machine parts, being struck, or having limbs cut off.

- Material-related accidents: Producing tires requires various materials, some of which are hazardous, such as asbestos, benzene, manganese, gypsum, and sulfur compounds. Improper use or lack of protective equipment can lead to exposure or inhalation of these hazardous substances.

- Natural force accidents: Tire factories are often located in industrial parks in suburban areas where weather changes such as rain, wind, tornadoes, or lightning may occur. These natural force incidents can affect worker safety.

- Human-related accidents: Workers may experience accidents due to negligence or violations of safety procedures, such as improper equipment use, not wearing protective gear, or performing tasks incorrectly.

5. Safety Measures for Participating in Tire Manufacturing

Safety measures for participating in tire manufacturing include:

- Workers must wear protective glasses, helmets, safety shoes, long sleeves, and masks to protect themselves while working in a tire manufacturing environment.

- Workers must fully comply with the production procedures established in the factory to minimize occupational accident risks.

- Workers must use tire manufacturing machinery correctly and safely. If machinery is damaged or unsafe, workers must report to supervisors and stop using it immediately.

- Safety equipment in the tire factory must be regularly inspected to ensure proper and safe operation.

- The tire factory must provide comprehensive occupational safety training for new workers so they understand safety procedures, equipment, regulations, and safe work instructions.

- Tire manufacturing equipment and machinery must be maintained regularly to ensure proper and safe operation.

- Equipment and machinery must be thoroughly checked before operation to ensure worker safety.

- Supplies and chemicals must be managed correctly to avoid accidents due to poor-quality materials or improper use.

- Regularly conduct workplace environmental monitoring in the factory, collect and analyze harmful factors affecting workers, and adjust to reduce hazards to prevent occupational diseases.

6. Benefits of Occupational Safety Training in Tire Manufacturing

An Toan Nam Viet provides enterprises with the following benefits upon completing occupational safety training courses in accordance with Decree 44/2016/NĐ – CP on occupational safety and hygiene for companies and factories:

- Workers can recognize potential occupational hazards and take preventive measures to avoid accidents.

- Enterprises can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs related to occupational safety incidents.

- Continuous production increases labor productivity and product quality.

- Compliance with occupational safety laws to avoid legal risks.

- Enhances credibility and professionalism, thereby improving the enterprise’s brand.

Nam Viet’s training courses provide solutions to protect individuals from external hazards that could lead to injury or even death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

7. Customer Feedback After Completing Tire Manufacturing Safety Training

An Toan Nam Viet has many years of experience accompanying enterprises in Vietnam, particularly in southern provinces. This responsibility is highly valued by Nam Viet, so our Occupational Safety Training is increasingly professional. The growth and development of An Toan Nam Viet are fueled by positive feedback and suggestions from enterprises. Below are some feedback from partners we have served.

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service greatly helped us simplify occupational safety and complete safety documentation for work processes. The consulting team was attentive and timely in addressing our questions. Five stars for Nam Viet.”

See more customer interviews after using our services from An Toan Nam Viet

8. An Toan Nam Viet’s Occupational Safety Training Capacity

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam. Training sessions are continuously conducted at factories, workshops, and construction sites across the country (63 provinces).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICES

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety of the Ministry of Labor – Invalids and Social Affairs, confirming our eligibility to conduct occupational safety and hygiene training. This further strengthens our occupational safety training capabilities.

Training Materials and Lectures

- Before being included in occupational safety courses, training materials are reviewed to ensure content accuracy and effectiveness.

- Our instructors’ teaching methods follow the standards of An Toan Nam Viet, based on expert research and practice in occupational safety and hygiene training, ensuring maximum knowledge absorption for learners.

Facilities

- Controlling factors in the classroom that affect training increases teaching efficiency and learners’ knowledge absorption.

- Our training support facilities include spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, we prioritize professional dedication in occupational safety training. Educating workers to protect themselves contributes to national development.

To ensure training effectiveness, we meticulously prepare all materials, tools, equipment, curriculum, documents, sound, and lighting.

Our occupational safety instructors are experienced professionals, with research on hazard identification in all industries and prevention methods.

Lectures are practical, lively, and easy to understand, allowing workers to absorb knowledge effectively, always aligned with Decree 44/2016/NĐ-CP.

Workers learn preventive measures and self-protection techniques, applying them effectively in their work.

Our training center proudly provides professional, reliable occupational safety training with the following advantages:

- Competitive training costs while maintaining quality.

- Flexible training schedules tailored to company production.

- Fast and compliant occupational safety certification procedures.

- Instructors with many years of experience.

- Classrooms controlled to optimize training efficiency and knowledge absorption.

- Lectures designed specifically for enterprise occupational safety needs.

- An Toan Nam Viet works professionally and diligently to provide accurate and fast support to clients.

10. Additional References for Tire Manufacturing Occupational Safety Training

- Tire Manufacturing Occupational Safety Materials

- Complete Occupational Safety Training Materials

- Occupational Safety Training Test Set

- Tire Manufacturing Occupational Safety Quiz

- Tire Manufacturing Occupational Safety Training Slides

1 review for Occupational Safety Training for Tire Manufacturing

No comments yet

namchinh.haiphong341

Giảng viên dạy rất sinh động dễ hiểu!