Occupational Safety Training for Foam Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the market movement. For more accurate price support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in foam factories and needs to be addressed promptly to ensure the health and safety of workers and to enhance the reputation of enterprises. The Occupational Safety Training course is one of the effective solutions to raise awareness about how to prevent occupational accidents for workers when participating in foam manufacturing.

Table of Contents

Toggle1. Overview of Foam

a. What is foam?

- Foam is a type of lightweight and soft material made from polymer foam or various additives. Foam is widely used in household products, such as mattresses, chairs, cushions, blankets, pillows, footwear, padding sheets, sunshade panels, curtains, protective casings, and other industrial products. Foam has soundproofing, heat insulation, shock resistance, elasticity, is easy to fabricate and install, and can protect products from impact, scratches, and damage.

- The foam manufacturing industry is an industrial sector producing products with shockproof, impact-resistant, heat-insulating, and soundproofing properties, and it is widely applied in shipbuilding, automobile manufacturing, household appliances, medical equipment, electronics, toys, and many other industries.

- In Vietnam, the foam manufacturing industry is developing, with many enterprises producing and supplying high-quality foam products to domestic and international customers. Many businesses in this sector have invested in modern manufacturing technologies, improved production processes, and enhanced product quality to meet the increasing market demand.

- Common foam products in Vietnam include EVA foam, PE foam, PU foam, synthetic rubber foam, spiral foam, shoe padding foam, decorative foam, heat-insulating and soundproof foam, etc. The demand for these foam products is steadily increasing, especially in shipbuilding, automobile manufacturing, electronics, and household appliance industries.

b. Machinery used in foam manufacturing

Foam is a material widely used across many industries, from household manufacturing to automobile and aircraft manufacturing. The foam manufacturing process involves using specialized machinery and equipment to produce products with specific properties.

The main types of machinery used in foam manufacturing include:

- Foam compression machines: These are the primary machines used to create foam, including pressing and compressing the material to produce foam sheets with the required thickness and durability.

- Foam cutting machines: These machines are used to cut foam sheets into different sizes and shapes for use in various products.

- Foam trimming machines: These machines trim foam sheets into different shapes for manufacturing toys, pillows, cushions, and other products.

- Foam spraying machines: These machines are used to spray material into molds to create foam products with special shapes, for example, foam for swimsuits or footwear manufacturing.

- Foam extrusion machines: These machines are used to extrude foam sheets together to create thicker or more durable foam products.

All these machines are computer-controlled and use advanced technology to produce foam products with high precision and optimal manufacturing efficiency.

c. Prominent foam manufacturing enterprises

Currently, in Vietnam, there are many enterprises producing foam with various scales and specializations. Some prominent foam manufacturing enterprises include:

- Ha Noi Foam Company Limited – Address: Quang Minh Industrial Park, Me Linh, Ha Noi.

- Tam Thai Manufacturing, Trading, and Services Company Limited – Address: Lot E16-CN2, Dong Van III Industrial Park, Duy Tien District, Ha Nam Province.

- Thanh Phat Manufacturing and Trading Company Limited – Address: Thuan Dao Industrial Park, Long Hoa Commune, Chau Thanh District, Ben Tre Province.

- Asia Manufacturing and Trading Company Limited – Address: Lot B1-1, Dong Van II Industrial Park, Dong Tam Commune, My Duc District, Ha Noi.

- Tan Tao Industrial Joint Stock Company – Address: 10-12 Street No.4, Tan Tao Industrial Park, Binh Tan District, Ho Chi Minh City.

- Hung Phuc Rubber Company Limited – Address: 25 Street No.3A, Tan Tao Industrial Park, Binh Tan, Ho Chi Minh City.

These are only some representative foam manufacturing enterprises; however, the foam manufacturing industry in Vietnam is rapidly growing, with many other enterprises producing and supplying foam products in the market.

d. Specific jobs in a foam manufacturing factory

Group 1

- Executive director, deputy executive director, department heads in the foam manufacturing factory.

Group 2

- Safety officer: managing safety in the factory, designing safety procedures, supervising and ensuring employees follow safe working procedures.

Group 3

- Material preparation: preparing necessary materials for foam manufacturing such as chemicals, foaming agents, bonding agents, and adhesives.

- Mixing and foaming: mixing materials together to create a foam mixture and whipping it to increase foam porosity.

- Foam blowing: using machinery to blow the foam mixture into sheets, which can be cut into various sizes and shapes depending on use.

- Quality control: inspecting products by testing foam elasticity, durability, and thickness.

- Packing and transporting: packing foam products and preparing them for delivery to partners or customers.

- Equipment maintenance and repair: maintaining and repairing factory equipment to ensure smooth and safe manufacturing.

- Warehouse management: managing inventory including receiving, issuing, stock-taking, storage, and handling of materials.

Group 4

- Office, service, sales, and marketing jobs.

- Production management, quality management, human resources management, material management, financial accounting management.

- Research and development of new products, designing packaging and product samples.

2. Overview of foam manufacturing occupational safety training course

In this article, we focus on Group 3 because Group 3 directly participates in the manufacturing process and faces the highest occupational safety risks. For other groups, refer here.

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training consists of sessions equipping workers with knowledge on preventing workplace accidents.

- The training helps workers recognize and avoid hazards, reducing the risks of workplace accidents during manufacturing.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial occupational safety training

- Total training duration is at least 24 hours, including assessment time.

- 8 hours of theory on policies, laws on occupational safety and hygiene

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized occupational safety training

- 2 hours of practical training on specialized content

- 2 hours of final theory test

The occupational safety training center will schedule multiple sessions depending on employee availability. Typically, there are 6 sessions over 3 days, assuming the manufacturing enterprise arranges continuous training time.

Periodic occupational safety training

- Before the occupational safety card expires, employees must undergo periodic occupational safety training if they wish to renew, with a periodic training duration of at least 50% of the initial training duration.

Explanation: total periodic occupational safety training lasts at least 12 hours, including assessment time. Upon completion of the course and passing the test, employees will be issued or renewed their occupational safety card.

c. Training content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Assessment | |||

| I | Policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of legal documents system on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of occupational safety and hygiene standards and technical regulations. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when constructing, expanding, or renovating factories, facilities, machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors at the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; policies on occupational safety and hygiene; functions and duties of safety network officers. | 1 | 1 | ||

| 5 | Rules on occupational safety and hygiene, safety signs, instructions, use of safety equipment, personal protective gear; skills in first aid and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, substances generating hazardous factors; analyzing, evaluating, managing risks; safe working procedures for machines, equipment, and substances with strict occupational safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Final assessment of occupational safety training | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

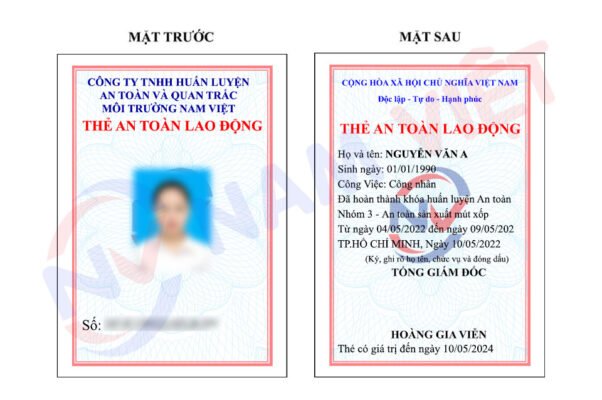

d. Occupational safety card

After completing the occupational safety training and passing the assessment, employees will be issued a Group 3 occupational safety card (commonly called Group 3 safety certificate).

The Group 3 card clearly shows information such as name, date of birth, specific job and working environment, training duration, red stamp, and signature confirming course completion.

According to the issuance regulations in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and seal the occupational safety card for the Group 3 trainee after completing the course from the occupational safety training unit and passing the test.

- If the employee is freelance or temporary without a labor contract, the training unit must sign, stamp, and seal the occupational safety card after the employee completes the course and passes the test.

3. Identifying hazards in foam manufacturing

During foam manufacturing, several hazards may occur. Some common hazards and ways to identify them include:

- Chemicals used in foam manufacturing can be harmful if not used properly. Workers must wear full protective gear, such as masks, safety goggles, reflective jackets, and gloves when handling chemicals.

- Foam is flammable, posing fire and explosion risks during manufacturing. Workers must ensure no ignition sources are near the foam manufacturing area.

- Foam manufacturing requires extensive use of machinery and equipment. Workers must be trained in safely operating equipment to prevent workplace accidents.

- The foam manufacturing process often involves high temperatures and pressures. Workers must ensure equipment is designed to withstand these conditions.

- Some types of foam can be very heavy, making transportation and handling difficult. Workers must use supporting equipment such as cranes and forklifts to move materials safely.

4. Common Occupational Accidents in Foam Manufacturing

The types of occupational accidents that often occur in foam manufacturing can include:

- Poisoning: During foam manufacturing, catalysts and fillers used to create the foam can cause poisoning if not used properly or if adequate protective equipment is not worn. Poisoning may result in symptoms such as headache, nausea, difficulty breathing, or even death.

- Fire and explosion: The foam manufacturing process often involves the use of flammable substances, which can pose fire and explosion hazards. If safety regulations are not fully followed during production, accidents related to fire and explosions may occur, causing serious damage to the factory and employees.

- Respiratory obstruction: During production, small foam particles can be dispersed into the air and cause respiratory obstruction for employees. This can happen if protective equipment is not used properly or if there is no proper ventilation system to ensure clean and safe air for workers.

- Physical accidents: Machines in the foam manufacturing factory can cause physical accidents if not operated correctly or maintained regularly. Accidents can include entanglement, being trapped, crushing, and other injuries.

5. Safety Measures for Participating in Foam Manufacturing

Safety measures when participating in foam manufacturing include:

- Ensure full protective equipment: such as masks, safety goggles, respirators, gloves, protective clothing, safety shoes, etc.

- Machines and equipment must be used correctly according to manufacturer instructions. In case of any malfunction, employees should stop using it immediately and notify the supervisor.

- Safety devices such as air filters, safety sensors, safety valves, etc., need to be inspected regularly to ensure effective operation.

- Employees must receive occupational safety training on safe procedures, proper use of safety equipment, and emergency measures in case of incidents.

- Production activities should be monitored and inspected regularly to detect potential incidents early and take timely corrective actions.

- Factory safety regulations must be strictly enforced to ensure the safety of employees and products.

- Regularly conduct occupational environment monitoring in factories, collect and analyze harmful factors for employees, and adjust to reduce risks to prevent occupational diseases.

6. Benefits of Foam Manufacturing Occupational Safety Training

An Toan Nam Viet provides businesses with the following benefits after completing occupational safety training courses in accordance with Decree 44/2016/ND-CP on occupational safety and hygiene for companies and factories:

- Employees can recognize potential occupational hazards and take preventive measures to avoid accidents.

- Your business can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs related to occupational safety incidents.

- Uninterrupted production increases labor productivity and product quality.

- Compliance with occupational safety laws to avoid legal risks.

- Enhances credibility and professionalism in all aspects, thereby elevating your company’s brand.

Nam Viet’s training courses are a solution to prevent external factors from affecting individuals, helping them avoid dangers that could lead to injury or, in severe cases, death.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback After Completing Foam Manufacturing Safety Training

An Toan Nam Viet has many years of experience in accompanying businesses in Vietnam in general and in southern provinces in particular. This responsibility is extremely valuable to Nam Viet, which is why our Occupational Safety Training is increasingly professional. The motivation for An Toan Nam Viet’s growth comes from positive feedback and suggestions from businesses. Below are testimonials from partners we have served.

Bac Nam E&C Construction Investment Joint Stock Company

“My first experience with An Toan Nam Viet was surprising due to the 24/7 enthusiastic support from the consulting team. The class organization was fast and convenient for our company. Thank you very much for Nam Viet’s service!”

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service helped us greatly in simplifying occupational safety and completing safety records for our operations. The consulting team was enthusiastic and timely in answering our questions. Five stars for Nam Viet.”

See more customer interview sessions after using the service from An Toan Nam Viet

8. An Toan Nam Viet’s Occupational Safety Training Capacity

An Toan Nam Viet is a prestigious and high-quality occupational safety training center in Vietnam. Training sessions are continuously conducted at factories, manufacturing facilities, or construction sites across the country (all 63 provinces of Vietnam).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Safety under the Ministry of Labor – Invalids and Social Affairs, granting certification for occupational safety and hygiene training activities. This further strengthens our capability in occupational safety training.

Training Materials and Lectures

- Before being applied to occupational safety training courses, materials are reviewed to ensure accuracy and effectiveness.

- Lecturers follow standardized teaching methods of An Toan Nam Viet, developed by experts in occupational safety and hygiene training to ensure the highest knowledge retention for trainees.

Facilities

- Controlling classroom factors affecting training increases teaching efficiency and trainee comprehension.

- Our training facilities provide spacious classrooms meeting standards for area, lighting, and training equipment, etc.

9. Nationwide Prestigious Occupational Safety Training Center

At An Toan Nam Viet, we prioritize occupational safety training. Teaching workers to protect themselves is a contribution to nation-building.

To ensure effective training, we carefully prepare every detail, from tools, teaching equipment to curricula, materials, audio, and lighting.

Our occupational safety trainers are experts with years of experience and research on hazard identification across industries and prevention methods.

Lectures are based on practical experience and delivered in a vivid, easy-to-understand manner. This helps trainees feel comfortable and absorb knowledge effectively, always aligned with Decree 44/2016/ND-CP.

This helps workers learn prevention methods and how to protect themselves, applying them appropriately in real work situations.

Our training center proudly provides professional and reputable occupational safety training services with advantages:

- Competitive training costs without compromising quality.

- Flexible training schedules according to company operations.

- Quick and lawful certification procedures.

- Experienced and skilled trainers.

- Classroom conditions controlled to enhance teaching efficiency and knowledge retention.

- Lectures tailored to occupational safety requirements in companies.

- An Toan Nam Viet works professionally and dedicatedly to provide fast and accurate support for clients.

10. Additional References for Foam Manufacturing Occupational Safety Training Materials

- Foam (Styrofoam) Manufacturing Occupational Safety Materials

- Occupational Safety Training Materials

- Occupational Safety Training Test Sets

- Foam (Styrofoam) Manufacturing Occupational Safety Quiz

- Foam Manufacturing Occupational Safety Training Slides

1 review for Occupational Safety Training for Foam Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ ở đây tốt nhé!