Occupational Safety Training for Candle Wax Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees attending the course and market movements. For more accurate pricing support, please refer to the price list or contact our consulting staff directly.

Occupational safety is an important issue in factory manufacturing candle wax and needs to be addressed promptly to ensure the health and safety of workers, as well as enhance the reputation of businesses. The Occupational Safety Training course is one of the effective solutions to raise awareness of how to prevent workplace accidents for employees participating in candle wax manufacturing.

Table of Contents

Toggle1. Overview of Candle Wax

a. What is Candle Wax?

- Candle wax is a type of wax made from natural or synthetic waxes. Candle wax can come in various shapes, colors, and scents depending on the type of wax and additives used during manufacturing.

- Candle wax can be used for multiple purposes, from decoration to providing light and fragrance. It is commonly used in parties, festivals, outdoor sports activities, and art performances. Additionally, candle wax is used to create relaxing environments and add fragrance in living and working spaces.

- Depending on the type of wax and additives used, candle wax can be manufactured with different properties, including burn time, fragrance, brightness, and durability.

- In the domestic market, candle wax is widely used in festivals, birthdays, weddings, and other events. It is also used for interior decoration and fragrance purposes.

- Some candle wax manufacturing companies in Vietnam have invested in modern production technology and equipment to improve product quality. However, the candle wax manufacturing industry in Vietnam still faces challenges such as competition from foreign manufacturers and difficulties in accessing large distribution channels.

b. Types of Candle Wax Manufacturing Machinery

The types of machinery and equipment used in candle wax manufacturing include:

- Candle pouring machine: Used to pour wax into molds to form the shape of the candle.

- Candle cutting machine: Used to cut candle wax into shorter segments of desired length.

- Wax mixing machine: Used to mix ingredients to create candle wax, including wax, colorants, fragrances, and other additives.

- Candle pressing machine: Used to press mixed components together to form the candle.

- Cooling machine: Used to cool the candle after molding or pressing to achieve the required hardness.

- Coloring equipment: Used to add color to candle wax.

- Fragrance equipment: Used to add scents to candle wax.

- Candle molds: Molds are used to create the shape and size of the candles.

These machines and equipment are designed to minimize losses and increase production efficiency, making the candle wax manufacturing process easier and more effective.

c. Notable Candle Wax Manufacturing Companies in Vietnam

Currently, there are many candle wax manufacturing companies in Vietnam. Some notable companies include:

- Tay Do Interior Decoration Trading and Services One Member Limited Company: A leading candle wax manufacturer in Vietnam with a nationwide product distribution system.

- Duc Hanh One Member Limited Company: A reputable candle wax manufacturer in Vietnam offering a range of popular products.

- Hung Thinh Candle Wax Company Limited: Provides high-quality candle wax products at affordable prices.

- Minh Long Art Ceramics One Member Limited Company: Besides producing art ceramics, Minh Long also manufactures and distributes candle wax in diverse designs.

- Thang Long Candle Wax Company Limited: Specializes in manufacturing and supplying premium candle wax to meet domestic and international customer demands.

These companies are committed to delivering high-quality candle wax products, ensuring safety for health, and fully complying with quality regulations and standards.

d. Specific Jobs in a Candle Wax Factory

Group 1

- Chief Executive Officer, Deputy CEO, and department heads in a candle wax factory.

Group 2

- Safety officers: Manage safety in the factory, design safety procedures, monitor and enforce staff compliance with safe working practices.

Group 3

- Raw material preparation: The main ingredients for candle wax manufacturing are wax, fragrance oils, and colorants. These materials are prepared and mixed according to predefined ratios and processes.

- Temperature and time control: During candle wax manufacturing, temperature and timing are crucial to ensure product quality. Staff must monitor temperature and production time to produce candles with optimal hardness, shine, and color.

- Mold making and wax pouring: Candle molds are prepared to pour wax into. Staff make the molds and pour the wax to form the desired candle shapes.

- Coloring and fragrance addition: After shaping, staff add colorants and fragrance oils to produce colored and scented candles.

- Cutting, packaging, and quality inspection: After shaping, coloring, and adding fragrance, staff cut, package, and inspect product quality to ensure compliance with required standards.

Group 4

- Office work, service, sales, and marketing roles.

- Production management, quality management, human resource management, material management, financial and accounting management.

- Research and development of new products, designing product packaging.

2. Overview of Occupational Safety Training for Candle Wax Manufacturing

In this article, we focus on issues related to Group 3 because Group 3 directly participates in the manufacturing process and bears the highest occupational safety risks. For reference to other groups, see here.

a. What is Group 3 Occupational Safety Training?

- Group 3 occupational safety training consists of sessions that provide workers with awareness on preventing occupational accidents.

- The training helps workers identify hazards and prevent risks, minimizing the occurrence of occupational accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial occupational safety training:

- Total training time is at least 24 hours, including examination time.

- 8 hours of theory on occupational safety and hygiene policies and legislation

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized training content

- 2 hours of practice on specialized training content

- 2 hours of theoretical examination at the end of the training course

The safety training center will divide the time into multiple sessions depending on workers’ schedules. Usually, there are 6 training sessions over 3 days, provided the factory can arrange continuous training.

Periodic occupational safety training:

- Before the occupational safety card expires, workers who want a renewal must undergo periodic occupational safety training, with training time of at least 50% of the initial training duration.

Explanation: The total duration of periodic occupational safety training is at least 12 hours, including examination time. Upon completion and passing the test, the worker will be reissued and have the occupational safety card extended.

c. Training Content

| No. | TRAINING CONTENT | TRAINING TIME (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Policies and legislation on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations by state management agencies on occupational safety and hygiene for newly constructed, expanded, or renovated works and facilities for manufacturing, using, storing, and inspecting machinery, equipment, materials, and substances with strict safety requirements. | 1 | 1 | ||

| II | Basic knowledge on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; occupational safety policies; functions of safety and hygiene networks. | 1 | 1 | ||

| 5 | Occupational safety rules, signs, instructions, use of safety equipment and personal protective equipment; first aid skills, and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, substances causing hazards; risk analysis and management in occupational safety; safe working procedures for machinery, equipment, and substances with strict safety requirements. | 6 | 4 | 2 | ||

| IV | Final occupational safety assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

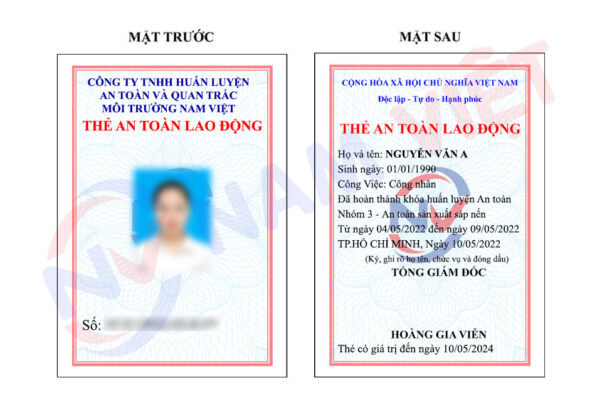

d. Occupational Safety Card

After completing the occupational safety training and passing the test, workers will be issued a Group 3 occupational safety card (commonly called Group 3 safety certificate).

The Group 3 safety card contains information such as full name, date of birth, job, and specific work environment. It also shows training duration, red stamp, and signature confirming completion of training.

According to regulations on issuing safety cards in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are 2 cases:

- If there is an employment contract between the employer and employee, the employer must sign, stamp, and validate the safety card for the trained Group 3 worker after completing training and passing the test.

- If the worker is freelance or temporary without an employment contract, the training unit must sign, stamp, and validate the safety card after the worker completes the training and passes the test.

3. Recognizing Hazards Affecting Workers in Candle Wax Manufacturing

The candle wax manufacturing process can contain many hazards that affect workers’ health. Below are some hazards that need to be recognized and addressed during the candle wax manufacturing process:

- Candle wax is flammable, so the manufacturing process requires using fireproof equipment and ensuring fire safety measures when handling candle wax.

- During candle wax manufacturing, the use of chemicals and fragrances can release toxic fumes. Production workers must wear masks and be trained to use respiratory protection devices such as air purifiers, gas extractors, and fume hoods.

- The process of pouring wax into molds, adjusting temperature, and production timing can cause burns and explosion risks. Production workers must ensure their safety by using personal protective equipment such as gloves, fireproof jackets, and safety goggles.

- Candle wax manufacturing requires the use of various machinery and equipment, which can pose collision and injury risks to workers. Workers need to be trained and use protective gear such as helmets, safety shoes, and fireproof jackets to ensure workplace safety.

- The candle wax manufacturing process may produce smoke and dust, causing air pollution in the factory. Production workers need to be trained to use protective equipment such as masks and safety glasses to safeguard their health.

4. Common Workplace Accidents for Workers in Candle Wax Manufacturing

Common workplace accidents during candle wax manufacturing include:

- Fire and explosion: Candle wax is flammable, creating risks of fire and explosion during manufacturing and pouring wax into molds. This can cause serious injuries or fatalities.

- Burns: Workers may suffer burns from hot wax, manufacturing machines, wax-heating equipment, and chemicals used in the manufacturing process.

- Injuries: Accidents may occur while operating machinery, equipment, or tools used in candle wax manufacturing. Production workers may be injured when handling wax materials and mechanical equipment.

- Toxic exposure: Chemicals used in candle wax manufacturing can harm workers’ health. Workers may be exposed to toxic substances through inhalation, direct contact, or accidental ingestion.

- Hearing loss: Loud noise from machines and equipment may reduce workers’ hearing. Without proper protective measures, production workers may develop hearing issues.

Therefore, candle wax production workers must be trained in occupational safety and use full protective equipment to minimize workplace accidents.

5. Safety Measures in Candle Wax Manufacturing

To minimize workplace accident risks during candle wax manufacturing, the following safety measures should be applied:

- Staff training: Candle wax production workers must be trained in occupational safety and the use of protective equipment to avoid hazards at work.

- Use of protective equipment: Production workers must use full protective gear such as masks, safety goggles, gloves, protective jackets, and safety shoes to reduce risks of fire, burns, injuries, and toxic exposure.

- Use of safety equipment: Production staff should utilize fire extinguishers, rescue equipment, ventilation systems, and other safety devices to address potential hazardous situations.

- Conduct safety inspections: Machines and equipment in candle wax manufacturing should be regularly inspected to ensure safety and prevent accidents.

- Adjust the working environment: Proper lighting, humidity, temperature, and ventilation are simple yet essential measures to improve the working environment, reduce accident risks, and enhance productivity.

- Use chemicals safely: Chemicals used in candle wax manufacturing should be stored, used, and transported correctly to reduce risks of toxic exposure and fire.

- Designated wax storage areas: The manufacturing area should have designated wax storage away from heat sources and flammable materials to minimize fire risks.

- Regularly conduct occupational environment monitoring in factories, collect and analyze harmful factors, and adjust measures to reduce hazards and prevent occupational diseases.

6. Benefits of Occupational Safety Training in Candle Wax Manufacturing

An Toan Nam Viet provides businesses with the following benefits after completing occupational safety training courses in accordance with Decree 44/2016/NĐ – CP regarding Occupational Safety and Health:

- Workers can recognize potential accident hazards and take preventive measures to avoid workplace accidents.

- Businesses can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs associated with safety incidents.

- Uninterrupted production increases labor productivity and product quality.

- Comply with occupational safety laws and reduce legal risks.

- Enhance professionalism and reputation, improving the company’s brand.

An Toan Nam Viet’s training courses are designed to help individuals avoid dangers that could lead to injuries or fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback after Completing Candle Wax Manufacturing Safety Training

An Toan Nam Viet has many years of experience supporting businesses in Vietnam, especially in southern provinces. This responsibility is highly valuable, so our Occupational Safety Training is increasingly professional. The motivation for our growth comes from positive feedback and suggestions from our business partners. Below are feedback excerpts from partners we have served.

Hoa Dat Construction and Trading Joint Stock Company

“An Toan Nam Viet’s service greatly helped us simplify occupational safety and complete safety documentation efficiently. The consulting team responded promptly to our questions. Five stars for An Toan Nam Viet.”

See more customer interviews after using the service of An Toan Nam Viet

8. Occupational Safety Training Capacity of An Toan Nam Viet

An Toan Nam Viet is a reputable occupational safety training center in Vietnam. Safety training courses are continuously held at factories, workshops, and construction sites across all 63 provinces of Vietnam.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety under the Ministry of Labor, Invalids and Social Affairs, which reinforces our training capabilities.

Training Materials and Lectures

- Before being applied in safety training courses, all training materials are reviewed to ensure accuracy and effectiveness.

- Teaching methods follow An Toan Nam Viet standards, based on research and experience in occupational safety training to maximize knowledge absorption.

Facilities

- Controlling classroom factors enhances teaching efficiency and knowledge absorption.

- Our facilities provide spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, we prioritize occupational safety training passionately. We aim to equip workers with knowledge to protect themselves while contributing to national development.

We meticulously prepare all teaching tools, materials, audio, and lighting to ensure training effectiveness.

Our trainers are experts with years of experience, including research on hazard recognition across various industries and preventive measures.

Lectures are practical, engaging, and aligned with Decree 44/2016/NĐ-CP, allowing workers to understand safety measures and apply them appropriately.

Our training center is proud to provide professional, reputable safety training with the following advantages:

- Competitive training costs while ensuring quality.

- Flexible training schedules according to company production.

- Quick and compliant certification procedures.

- Experienced trainers.

- Classroom conditions optimized for learning efficiency.

- Lectures tailored to occupational safety requirements.

- An Toan Nam Viet provides dedicated and professional support to clients.

10. Additional Reference Materials for Candle Wax Manufacturing Safety Training

- Candle Wax Manufacturing Occupational Safety Materials

- Occupational Safety Training Materials Set

- Occupational Safety Test Set

- Candle Wax Manufacturing Occupational Safety Quiz

- Candle Wax Manufacturing Safety Training Slides

1 review for Occupational Safety Training for Candle Wax Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ huấn luyện an toàn lao động rất tốt nhé, giảng viên dạy rất sinh động dễ hiểu!