Occupational Safety Training in Hammock Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and the dynamics of the market. For more accurate price support, please refer to the quotation table or contact our consulting staff directly.

Occupational safety is an important issue in hammock manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, as well as to enhance the reputation of businesses. The Occupational safety training course is one of the effective solutions to raise awareness of accident prevention for workers participating in hammock production.

Table of Contents

Toggle1. Overview of Hammocks

a. What is a hammock?

- A hammock is a piece of furniture used for resting or relaxing, consisting of a bamboo or metal frame and a piece of fabric or rope suspended from the frame. Hammocks can be hung indoors or outdoors, often used in gardens, yards, or on the beach to enjoy a cool and comfortable space. There are many types of hammocks, from classic hammocks to cushioned hammock chairs, two-person hammocks, double hammocks, hanging hammocks, and even hammocks with canopies to protect from sunlight and mosquitoes.

- Hammock manufacturing is one of the small-scale industries in Vietnam and is mainly concentrated in traditional craft villages such as Nga Son, Ninh Xuan in Thanh Hoa province and some other regions across the country. Hammock production in Vietnam faces challenges due to competition from imported products and domestic production costs that cannot compete with imported goods.

- However, with the trend of returning to traditional, high-quality products and the interest in handicrafts, the market for handmade hammocks is growing and is considered potential for Vietnam’s handicraft industry. Enterprises and hammock brands such as Lang Nghe Nga Son, Ninh Xuan Handicraft, Hong Minh Handicraft, and Gia Huy Handicraft are regarded as typical representatives in hammock manufacturing in Vietnam.

b. Machinery for hammock manufacturing

The machinery and equipment commonly used in hammock factories include:

- Industrial sewing machines: Single-needle, double-needle, 4-needle, or 5-needle machines to sew hammock components such as the body, handles, edges, folds, diagonal stitching, and other details.

- Automatic cutting machines: Machines used to cut hammock parts from large rolls of fabric according to specific sizes.

- Heat press machines: Heat press machines used to print patterns or images on the hammock surface through heat pressing.

- Automatic thread cutting machines: Machines to cut threads to the required length and quantity for sewing products.

- Laser cutting machines: Laser machines to cut special shapes or extremely precise details.

- Pressing tables: Used to fold hammock components before sewing to ensure product accuracy.

- Heat transfer printing machines: Machines to print images or patterns onto the hammock surface.

- Rope cutting machines: Machines to cut rope strands needed for hammock components.

c. Typical hammock manufacturing enterprises in Vietnam

Some typical hammock manufacturing enterprises in Vietnam are:

- Viet Thai International Manufacturing and Trading Co., Ltd: One of the leading units producing and supplying hammocks in Vietnam.

- Tam Lam Hung Co., Ltd: Specializes in handmade hammocks made from natural bamboo ropes.

- Xuan Hoa Manufacturing and Trading Co., Ltd: Specializes in producing and supplying hammocks, hammock chairs, floor mats, bamboo mats, table mats, bed mats, and other interior accessories.

- Truong Phat Manufacturing Trading and Export Co., Ltd: Produces various types of handmade hammocks from natural bamboo ropes, crafted by artisans from traditional craft villages in Vietnam.

- Nhat Minh Manufacturing and Trading Co., Ltd: Produces hammock-related products such as hammocks, hammock chairs, accessories, bamboo ropes, and other interior items.

Above are some typical hammock manufacturing enterprises in Vietnam, but there are many other enterprises operating in this field.

d. Specific jobs in a hammock manufacturing factory

Group 1

- Chief Executive Officer, Deputy CEO, department heads in a hammock manufacturing factory.

Group 2

- Safety officer: manages safety in the factory, designs safety procedures, supervises and ensures employees comply with safe working processes.

Group 3

- Fabric selection: Workers select suitable fabrics to manufacture different types of hammocks.

- Fabric cutting: Workers use fabric cutting tools to cut pieces of fabric into different sizes according to production requirements.

- Weaving hammocks: Workers weave fabric strands through the frame to form a complete hammock.

- Quality control: After production, workers inspect product quality to ensure all details are finished and free of defects.

- Packing: After quality inspection, workers pack the product and prepare it for shipment.

Group 4

- Office, service, sales, marketing jobs.

- Production management, quality management, human resources management, material management, finance and accounting management.

- Research and development of new products, design of product packaging.

2. Overview of occupational safety training for hammock manufacturing

In this article, we focus on issues related to Group 3, because Group 3 directly participates in the production process and faces the highest occupational safety risks. Refer to other groups here

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training consists of sessions that equip workers with awareness of how to prevent workplace accidents.

- The training course helps workers recognize and avoid hazards, reducing the risk of accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial safety training duration

- Total training duration is at least 24 hours, including assessment time.

- 8 hours of theory on safety and labor hygiene policies and laws

- 8 hours of theory on basic knowledge of occupational safety and hygiene

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical assessment at the end of the training course

The safety training center will divide the time into multiple sessions depending on the worker schedule. Usually, there are 6 training sessions over 3 days, provided the enterprise arranges continuous study time.

Periodic safety training duration

- Before the occupational safety card expires, workers who want to renew must undergo periodic occupational safety training, with a periodic training duration of at least 50% of the initial training duration.

Explanation: total periodic occupational safety training duration is at least 12 hours, including assessment time. After completing the periodic course and passing the test, workers will have their occupational safety cards reissued or extended.

c. Training content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Assessment | |||

| I | System of policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when building, expanding, or renovating facilities for manufacturing, using, preserving, storing, and inspecting machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in manufacturing and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; safety and hygiene policies for workers; functions and duties of safety network personnel. | 1 | 1 | ||

| 5 | Safety and hygiene regulations, signage, safety instructions, use of safety equipment and personal protective equipment; first aid skills, occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, substances causing hazards, risk analysis, occupational safety and hygiene management, safe working procedures with machines, equipment, and substances with strict safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | End-of-course safety assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

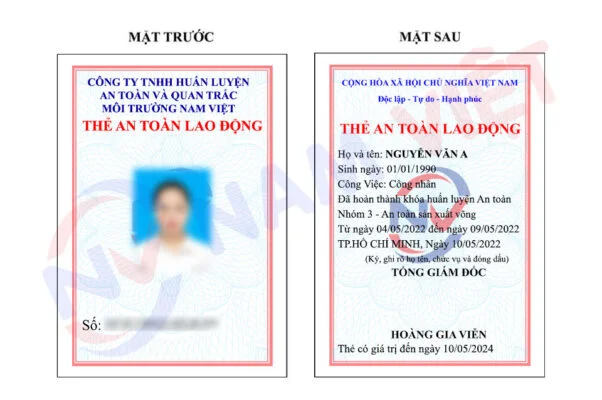

d. Occupational safety card

After completing the occupational safety training and passing the assessment, workers will be issued a occupational safety card (commonly referred to as Group 3 occupational safety certificate).

The Group 3 safety card clearly shows information such as name, date of birth, job, and specific work environment. It also includes training duration, official stamp, and signature confirming course completion.

According to the regulations for issuing safety cards specified in Clause 2 of Article 24 Decree 44/2016/ND-CP, there are 2 cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and endorse the Group 3 safety card after the worker completes the training and passes the assessment from the occupational safety training unit.

- If the worker is freelance or temporary and does not have a labor contract, the training unit must sign, stamp, and endorse the safety card after the worker completes the training and passes the assessment.

3. Identifying Hazards Affecting Workers in Hammock Manufacturing

Potential hazards in hammock manufacturing may include:

- During the manufacturing process, machines use electricity to operate. If not operated properly, exposure to high voltage can cause electrical accidents.

- During production and transportation, materials and products may fall from heights and cause injuries to workers.

- Machines in hammock factories often generate high noise levels; without proper noise protection, workers may face risks to their hearing health.

- Chemicals such as softeners, surface coatings, and cleaning agents may be used to make products more attractive and durable. However, improper use or lack of chemical pollution prevention measures can affect workers’ health.

- During manufacturing, liquids, gases, and vapors may be used and handled. Failure to follow proper safety procedures can result in fire or explosion risks, causing serious workplace accidents.

4. Common Workplace Accidents for Workers in Hammock Manufacturing

During hammock manufacturing, staff may face various hazards and workplace accidents such as:

- Fire and explosion hazards: Due to equipment using fuels such as sewing machines, cutting machines, and pressing machines using oil, electricity, compressed air, etc. Improper use can cause fire or explosions and seriously affect workers’ health.

- Electrical hazards: Electrical equipment such as sewing machines, cutting machines, pressing machines, welding machines, and lighting devices can pose electrical dangers if not used correctly or if damaged.

- Material hazards: Materials such as fibers, metals, plastics, etc., can cause injuries, cuts, punctures, or burns if not used properly or without safety measures.

- Equipment hazards: Hammock manufacturing equipment such as sewing machines, cutting machines, pressing machines, welding machines, etc., can cause workplace accidents if not used properly or if malfunctioning.

- Environmental impact hazards: Workers may have to work in wet, dusty, hot, or poorly lit environments. Without proper protection, they may develop respiratory, skin, eye, or ear problems.

5. Safety Measures When Participating in Hammock Manufacturing

To ensure workers’ safety during hammock manufacturing, the following safety measures should be applied:

- Use protective equipment: Ensure workers are provided with complete protective gear such as helmets, safety shoes, gloves, masks, safety glasses, aprons, etc.

- Staff training: All staff must be trained in workplace safety before starting work. Training should include knowledge of work procedures, equipment use, accident prevention measures, and emergency handling.

- Regular equipment inspections: Manufacturing and safety equipment must be checked regularly to ensure proper operation and worker safety.

- Production supervision: Supervisors should monitor the implementation of safety measures and ensure production processes are followed correctly. Any incidents or safety violations must result in immediate production stoppage for rectification.

- Material and chemical management: Materials and chemicals used in hammock manufacturing must be strictly managed to ensure worker safety. They should be stored in dry, ventilated areas, away from flames and flammable substances.

- Workplace hygiene: The workplace must be kept clean to avoid microbial risks and other infectious diseases.

- Fire prevention and firefighting training: Staff should be trained on how to use firefighting equipment and apply it during fire emergencies.

- Periodically conduct workplace environmental monitoring in factories, collect and analyze harmful factors, and adjust to reduce hazards to prevent occupational diseases.

6. Benefits of Hammock Manufacturing Safety Training

An Toan Nam Viet provides enterprises with the following benefits after completing mandatory occupational safety training according to Decree 44/2016/ND – CP on Occupational Safety and Hygiene:

- Workers can identify potential accident risks and take preventive measures to avoid workplace accidents.

- Enterprises can establish risk prevention measures in production, operation, and maintenance processes.

- Minimize costs associated with workplace safety hazards.

- Continuous production improves labor productivity and product quality.

- Ensure compliance with labor safety laws and avoid legal risks.

- Enhance enterprise reputation and professionalism, improving brand value.

Nam Viet training courses are a solution to prevent external hazards, helping individuals avoid injuries or, in severe cases, fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

7. Customer Feedback After Completing Hammock Manufacturing Safety Training

An Toan Nam Viet has many years of experience accompanying enterprises in Vietnam in general and southern provinces in particular. This responsibility is highly valued, which is why Nam Viet’s Occupational Safety Training is increasingly professional. The motivation for An Toan Nam Viet’s growth comes from positive feedback and suggestions from enterprises. Below are feedbacks from partners we have served.

Hoa Dat Construction and Trading Joint Stock Company

“Nam Viet’s service greatly helped us simplify occupational safety and complete safety documentation for our work process. The consulting team responded promptly to our inquiries. Five stars for Nam Viet.”

See more customer interviews after using Nam Viet’s services

8. Occupational Safety Training Capability of An Toan Nam Viet

An Toan Nam Viet is a reputable and quality occupational safety training center in Vietnam. Continuous safety training sessions are held at factories, manufacturing plants, and construction sites across all 63 provinces in Vietnam.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational safety training license

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety under the Ministry of Labor, War Invalids, and Social Affairs, certifying eligibility for occupational safety and hygiene training. This reinforces our occupational safety training capability.

Materials and lectures

- Before being included in Occupational Safety Training Courses, materials are reviewed to ensure knowledge accuracy and effective application.

- Teaching methods of instructors follow An Toan Nam Viet standards, developed by occupational safety experts to maximize learning efficiency.

Facilities

- Control of classroom factors affecting training increases teaching efficiency and student learning outcomes.

- Our training facilities provide spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Safety Training Center

At An Toan Nam Viet, occupational safety training is our top priority. We aim to equip workers with self-protection knowledge, contributing to national development.

To ensure effective training, we meticulously prepare everything, from tools and teaching aids to manuals, documents, sound, and lighting.

Our occupational safety instructors are experienced experts, some with research on hazard identification across industries and preventive measures.

Lectures are practical and clearly conveyed to help workers comfortably absorb knowledge. Training content strictly follows Decree 44/2016/ND-CP.

Participants learn preventive measures and self-protection techniques, applying them effectively in the workplace.

Our safety training center is proud to offer professional and reputable occupational safety training with the following advantages:

- Competitive training costs with ensured quality.

- Flexible training schedules aligned with company operations.

- Fast certification procedures compliant with legal regulations.

- Experienced instructors with years in the field.

- Classrooms are controlled to optimize teaching efficiency and learning outcomes.

- Lectures are tailored to occupational safety requirements of enterprises.

- An Toan Nam Viet provides dedicated, professional, and fast support to customers.

10. Additional Hammock Manufacturing Safety Training Materials

- Hammock Manufacturing Safety Training Materials

- Occupational Safety Training Material Set

- Occupational Safety Training Test Set

- Hammock Manufacturing Safety Multiple Choice Test

- Hammock Manufacturing Safety Training Slides

1 review for Occupational Safety Training in Hammock Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ tốt nhé! triển khai nhanh chóng và chu toàn