Occupational Safety Training for Plasma Cutting Machine Operation

99,000 ₫

Note: The above price is calculated for one person and may fluctuate depending on the number of course participants and market movements. For more accurate pricing support, please refer to the pricing table or contact our consulting staff directly.

Occupational safety is an important issue when operating Plasma cutting machines and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses here. The Occupational Safety Training course is one of the effective solutions to raise awareness about accident prevention for workers operating Plasma cutting machines.

Table of Contents

Toggle1. Overview of Plasma Cutting Machines

a. What is a Plasma Cutting Machine?

A Plasma Cutting Machine is an industrial device used to cut ductile materials such as steel, stainless steel, aluminum, and other metals using the high thermal intensity of plasma. Plasma is a state of matter, usually in the gaseous state, created by heating compressed or supplied gas in an electrically insulated tube.

The plasma cutting process occurs when a high-frequency electric current is used to ionize and heat the plasma, generating a powerful form of thermal energy. When the plasma is hot enough, it can cut through ductile materials by melting them and blowing them away from the cutting area. This process allows for high-precision cuts and sharp cutting edges.

Plasma cutting machines are commonly used in industrial applications such as metal fabrication, construction, mechanical engineering, and metal manufacturing. They are also used to create custom patterns and designs. Plasma cutting machines can be computer-controlled to ensure high accuracy and easily produce complex cut products.

b. Applications of Plasma Cutting Machines in Manufacturing

Plasma cutting machines have many important applications in the manufacturing industry due to their cutting precision and efficiency. Below are some common applications of plasma cutting machines in production:

- Metal Fabrication: Plasma cutting machines are widely used in the metal fabrication industry to cut and process metal sheets such as carbon steel, stainless steel, aluminum, copper, and titanium. They help produce high-precision metal components for applications such as frames, assembly surfaces, and machinery parts.

- Construction: In construction, plasma cutting machines are used to cut metal sheets and other metal components to create steel structures, columns, and other parts for projects like bridges, high-rise buildings, and factories.

- Aerospace Industry: Plasma cutting machines are used to process airplane and spacecraft components, where precision and high-quality metal parts are required.

- Automobile Manufacturing: In the automotive industry, plasma cutting machines are used to cut and process metal parts such as vehicle frames, car surfaces, and other components during production.

- Advertising and Signage: Plasma cutting machines are used to cut signs and complex graphics in the advertising and printing industry.

- Energy Manufacturing: In energy production, plasma cutting machines can be used to cut and process components of renewable energy systems such as solar panels and wind turbine blades.

- Unmanned Aviation Manufacturing: Plasma cutting machines can also be used in the production of unmanned aviation components, including cutting and processing parts for drones and other unmanned systems.

c. Industries Using Plasma Cutting Machines

Plasma cutting machines are used in many industries to cut and process ductile metal materials. Below are the main industries that use plasma cutting machines:

- Metal Industry: Plasma cutting machines are essential tools in metal production. They are used to cut carbon steel, stainless steel, aluminum, copper, titanium, and other metals to produce a wide range of metal products and components.

- Construction Industry: Plasma cutting machines are used in construction to cut and process metal sheets and components. They help create steel structures, columns, and other parts for buildings such as bridges, high-rises, and factories.

- Aerospace Industry: For manufacturing airplane, spacecraft, and UAV (Unmanned Aerial Vehicle) components, plasma cutting machines are used for high-precision metal cutting and processing.

- Automotive Industry: Plasma cutting machines play an important role in producing metal parts for cars, including frames, car surfaces, and other components.

- Renewable Energy Manufacturing: In producing components for renewable energy systems such as solar panels, plasma cutting machines are also used to ensure high-quality parts.

- Unmanned Aviation Manufacturing: Plasma cutting machines can be used to produce components for drones and other unmanned systems.

- Signage and Advertising Production: Plasma cutting machines are used to cut advertising signs and complex graphics in printing and advertising.

Thus, plasma cutting machines have wide applications in various industries and help produce diverse metal products with high precision.

2. Overview of Occupational Safety Training for Operating Plasma Cutting Machines

a. What is Occupational Safety Training?

- Occupational safety training for operating plasma cutting machines consists of sessions that equip workers with awareness of how to prevent workplace accidents. Workers directly operating plasma cutting machines belong to Group 3.

- The occupational safety training course helps workers recognize and avoid hazards, reducing the risk of workplace accidents during work.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training Duration

Initial Occupational Safety Training Duration

- Total training duration is at least 24 hours, including assessment time.

- 8 hours of theory on the system of policies and laws on occupational safety and hygiene

- 8 hours of theory on basic knowledge of occupational safety and hygiene

- 4 hours of theory on specialized training content

- 2 hours of practice on specialized training content

- 2 hours of theory assessment at the end of the course

The safety training center will distribute the course into multiple sessions depending on the worker schedule. Typically, there are 6 training sessions over 3 days, provided the company arranges continuous learning time.

Periodic Occupational Safety Training Duration

- Before the occupational safety card expires, employees seeking renewal must complete a periodic occupational safety training course with a duration of at least 50% of the initial training duration.

Explanation: The total duration of periodic occupational safety training is at least 12 hours, including assessment time. Upon completion and passing the assessment, employees will have their occupational safety card renewed.

c. Training Course Content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Assessment | |||

| I | System of policies and laws on occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Overview of the system of legal documents on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations from state agencies regarding occupational safety and hygiene when constructing, expanding, or renovating facilities for production, usage, storage, and inspection of machinery, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies and regimes on occupational safety and hygiene; roles and duties of safety personnel. | 1 | 1 | ||

| 5 | Occupational safety rules, safety signs, guidance signs, use of safety equipment and personal protective equipment; first aid skills for work accidents and occupational disease prevention. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machinery, equipment, substances causing hazards; analysis, evaluation, and risk management for occupational safety; safe working procedures with machines, equipment, and substances with strict safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Assessment at the end of the training course | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of 6 groups

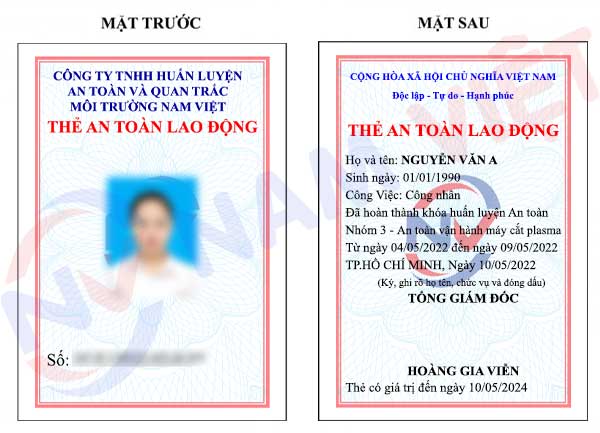

d. Occupational Safety Card

After completing the occupational safety training course and passing the assessment, employees will be issued a safety card (commonly called a Group 3 safety certificate).

The Group 3 card shows full name, date of birth, specific job and working environment. It also contains training duration, red stamp, and signature confirming course completion.

According to regulations in Clause 2 of Article 24, Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and endorse the safety card for Group 3 employees after they complete the training and pass the assessment.

- If the employee is freelance or temporary without a labor contract, the training unit must sign, stamp, and endorse the safety card after the employee completes the training and passes the assessment.

3. Hazards When Operating a Plasma Cutting Machine

Operating a plasma cutting machine can pose several hazards to both users and the work environment. Below are the main hazards that should be considered when working with a plasma cutter:

- Risk of fire and explosion: Plasma can reach extremely high temperatures, and working near it may cause a fire or explosion, especially with flammable materials. Safety rules for fire prevention should be followed, and personal protective equipment such as protective clothing, safety goggles, and heat-resistant gloves should be used.

- Emission of toxic gases: Plasma cutting may produce harmful gases such as metal fumes and flux fumes. These can be hazardous to health if proper ventilation systems are not used and safety regulations for toxic gases are ignored.

- UV and X-ray radiation: Plasma cutting can emit UV and X-ray radiation, which can harm the eyes and skin. Operators should wear UV-protective goggles and protective clothing when exposed to plasma.

- High voltage: Plasma cutting machines usually operate at high voltage to generate plasma. Users must follow electrical safety rules and avoid contact with high-voltage parts of the machine.

- Heavy metal contamination: Fumes and dust generated during plasma cutting may contain toxic heavy metals such as lead and cadmium. Protective equipment and appropriate air filtration systems are essential to prevent poisoning.

- Bodily injury from cutting: Due to the sharp nature of plasma, failing to follow safety rules can result in severe injuries. Users must be trained in safe plasma cutter operation and comply with safety procedures.

To ensure safety when operating a plasma cutting machine, users must adhere to safety regulations, particularly regarding personal protective equipment and safe handling of materials and toxic gases. This helps minimize potential hazards and ensures a safe working environment for all employees.

4. Accident Prevention Measures When Operating a Plasma Cutting Machine

To control occupational accidents when operating a plasma cutting machine and ensure employee safety, the following measures should be implemented:

- Employee training: Provide safety training to all employees working with plasma cutters. Ensure they fully understand the hazards and safety measures required, as well as machine operation rules.

- Use of personal protective equipment: Require employees to wear complete personal protective equipment, including safety goggles, protective clothing, heat-resistant gloves, and safety shoes. Ensure protective equipment is inspected and maintained regularly.

- Machine inspection and maintenance: Conduct regular inspections and maintenance to ensure the plasma cutting machine operates safely and correctly. Repair or replace any defective parts immediately.

- Smoke extraction system: Install a smoke and air filtration system to remove toxic gases and harmful dust from the workplace.

- Electrical safety: Ensure the plasma cutter is connected properly and electrical safety regulations are followed. Minimize contact with high-voltage parts of the machine.

- Workplace management: Keep the workspace clean and well-ventilated to prevent fire risks and enhance toxic gas management.

- Work environment inspection: Regularly inspect the workplace to ensure there is no flooding, subsidence, or other hazards that may cause accidents.

- Machine usage regulations: Ensure employees use the plasma cutter only if trained and experienced. Strictly enforce machine usage rules and limit access to untrained personnel.

- Risk management: Conduct risk assessments to identify potential hazards and develop control plans, including identifying dangerous areas and implementing preventive measures.

- Warning and alarm systems: Install alert and alarm systems to warn employees in case of risk or incidents.

- Periodic inspection of plasma cutting machines to detect early safety issues such as mechanical wear or damage, thereby reducing occupational accident risks.

5. Benefits of Occupational Safety Training

An Toàn Nam Việt provides your business with the following benefits after completing occupational safety training courses as stipulated in Decree 44/2016/ND-CP on Occupational Safety and Health:

- Workers can recognize potential occupational hazards and take preventive measures to avoid accidents.

- Your business can establish preventive measures for risks in production, operation, and maintenance processes.

- Reduce costs associated with potential safety incidents.

- Uninterrupted production increases labor productivity and product quality.

- Ensure compliance with occupational safety laws, avoiding legal risks.

- Enhance corporate reputation and professionalism, elevating your business brand.

Nam Việt’s training courses are a solution to protect individuals from external hazards, helping them avoid injuries or, in severe cases, fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

6. Customer Feedback After Completing Training

An Toàn Nam Việt has many years of experience accompanying numerous businesses across Vietnam, particularly in the southern provinces. This responsibility is invaluable, which is why our Occupational Safety Training is increasingly professional. The motivation for our growth comes from positive feedback and constructive suggestions from partner businesses. Below are some testimonials from our clients:

See more customer interviews after using our services from An Toàn Nam Việt

7. Occupational Safety Training Capabilities of An Toàn Nam Việt

An Toàn Nam Việt is a reputable and high-quality occupational safety training center in Vietnam. Training sessions are conducted continuously at production workshops, factories, or construction sites nationwide (across all 63 provinces).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational Safety Training License

- An Toàn Nam Việt has been inspected and certified by the Department of Occupational Safety, Ministry of Labor – Invalids and Social Affairs, certifying that we meet the conditions for occupational safety and hygiene training. This strengthens our training capabilities.

Materials and Lectures

- Before being used in safety training courses, training materials are reviewed to ensure accuracy and practical effectiveness.

- Our instructors use standardized teaching methods developed by An Toàn Nam Việt, based on expert research and practical experience in occupational safety and hygiene training, ensuring optimal knowledge transfer to trainees.

Facilities

- Controlling environmental factors in classrooms enhances teaching efficiency and knowledge retention.

- Our training facilities include spacious classrooms meeting standard requirements for area, lighting, and training equipment.

8. Nationwide Reputable Occupational Safety Training Center

At An Toàn Nam Việt, occupational safety training is our top priority. Our mission is to equip workers with the knowledge to protect themselves, contributing to national development.

We carefully prepare every aspect, from tools and teaching equipment to curricula, materials, audio, and lighting, ensuring effective training.

Our instructors are experts with years of experience, including research on hazard identification across industries and prevention methods.

Lessons are delivered vividly and practically, making it easy for workers to understand and retain information. Our training strictly follows Decree 44/2016/ND-CP.

Trainees learn hazard prevention measures and how to protect themselves, applying them effectively in real work situations.

Our training center proudly offers professional and reliable occupational safety training with the following advantages:

- Competitive training costs without compromising quality.

- Flexible training schedule to fit company production timelines.

- Quick and compliant certification procedures.

- Experienced instructors with extensive industry knowledge.

- Classrooms optimized for effective teaching and learning.

- Curricula tailored to occupational safety in enterprises.

- Dedicated and professional service for prompt client support.

9. Additional Occupational Safety Training Materials

- Occupational safety materials for plasma cutter operation

- Complete occupational safety training materials

- Occupational safety training test materials

- Occupational safety multiple-choice test for plasma cutter operation

- Slides for occupational safety training on plasma cutter operation

1 review for Occupational Safety Training for Plasma Cutting Machine Operation

No comments yet

phanminhhang341

Giảng viên dạy rất sinh động dễ hiểu!