Occupational Safety Training for Operating Ultrasound Machines

99,000 ₫

Note: The above price is calculated per person and may vary depending on the number of trainees participating in the course and market fluctuations. For more accurate pricing support, please refer to the pricing list or contact our consulting staff directly.

Occupational safety is an important issue when operating the ultrasound machine and needs to be addressed promptly to ensure the health and safety of workers and enhance the reputation of businesses here. The Occupational Safety Training is one of the effective solutions to raise awareness on how to prevent occupational accidents for workers operating the ultrasound machine.

Table of Contents

Toggle1. Overview of Ultrasound Machines

a. What is an Ultrasound Machine?

An ultrasound machine in healthcare is an imaging device widely used to create images of the inside of the body using ultrasonic waves. This allows doctors and nurses to view the structure and position of organs, tissues, and blood vessels without performing surgery.

Ultrasound machines are used in many medical applications, including fetal examination, cardiovascular diagnosis, tumor detection, guidance for interventional procedures, and assessment of vascular and internal organ issues. Its convenience and non-invasive nature make ultrasound an important tool in medical diagnosis and treatment.

b. How Ultrasound Machines Work

The operation of ultrasound machines in healthcare is based on the reflection of ultrasonic waves from internal body structures. This complex process can be summarized as follows:

- Emitting Ultrasound Waves: The machine generates ultrasound waves using a transducer, a crucial component that converts electrical energy into sound energy. When activated, the transducer emits high-frequency ultrasound waves.

- Reflection of Ultrasound Waves: When ultrasound waves encounter body structures such as muscles, soft tissues, or fluids, part of the wave is reflected. The level of reflection depends on how the waves are absorbed or reflected by different structures.

- Receiving Reflected Waves: The reflected ultrasound waves are collected by the transducer, which acts as a sensor, converting sound energy into electrical signals.

- Signal Processing and Image Formation: The electrical signals from the transducer are sent to the machine’s central processor (CPU). The CPU analyzes the signals and creates images based on the time and intensity of reflected waves. This information is displayed on a monitor, producing high-quality images for evaluation and diagnosis.

- Adjusting and Storing Data: Ultrasound machines provide adjustment functions so users can optimize images, such as depth or wave frequency. Images and data are stored for future reference or medical records.

c. Industries Using Ultrasound Machines

Ultrasound machines are widely used across various industries, not only in healthcare but also in industrial and scientific applications. Key sectors include:

- Healthcare: Ultrasound is primarily used in medical imaging, such as fetal examinations, tumor detection, cardiovascular assessments, interventional guidance, and other applications.

- Industry: In manufacturing, ultrasound is used for quality inspection, measurement, and production process control. For example, in the automotive sector, it can detect hidden defects in metal components or verify assembly alignment.

- Mechanical Engineering and Shipbuilding: Ultrasound inspects structural integrity and material strength, particularly in metals, to detect potential issues and ensure safety.

- Oil and Gas: Ultrasound is used to inspect pipelines and equipment for cracks, damage, or other operational hazards.

- Scientific Research: Ultrasound supports studies in materials science, biology, and geology, helping to analyze structures, properties, and physical or chemical phenomena.

2. Overview of Occupational Safety Training for Operating Ultrasound Machines

a. What is Occupational Safety Training?

- Occupational safety training for operating ultrasound machines consists of sessions that raise awareness about workplace accident prevention. Workers who directly operate ultrasound machines belong to Group 3.

- The training helps workers recognize and prevent hazards, reducing the risk of workplace accidents.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

b. Training Duration

Initial safety training:

- Total training time is at least 24 hours, including examination time.

- 8 hours of theory on safety policies and labor hygiene laws

- 8 hours of theory on basic occupational safety and hygiene knowledge

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of final theoretical assessment

The training center will divide the time into multiple sessions depending on employee schedules. Typically, there are 6 sessions over 3 days if the employer can arrange continuous training time.

Periodic safety training:

- Before the occupational safety card expires, workers must undergo periodic occupational safety training, with duration at least 50% of the initial training time.

Note: The total periodic safety training time is at least 12 hours, including assessment. After completion and passing the test, workers are reissued and have their occupational safety card renewed.

c. Training Content

| No. | TRAINING CONTENT | TRAINING TIME (HOURS) | |||

| Total | Breakdown | ||||

| Theory | Practice | Exam | |||

| I | Safety Policies and Labor Hygiene Laws | 8 | 8 | 0 | 0 |

| 1 | Overview of occupational safety and hygiene legislation. | 6 | 6 | ||

| 2 | Standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of government authorities regarding occupational safety and hygiene during construction, expansion, or renovation of facilities for production, use, storage, and inspection of machines, equipment, materials, and hazardous substances. | 1 | 1 | ||

| II | Basic Knowledge of Occupational Safety and Hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazards in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and responsibilities of employers and employees; occupational safety policies and programs; roles of safety and hygiene officers. | 1 | 1 | ||

| 5 | Occupational safety rules, signage, use of protective equipment, first aid skills, and prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized Training Content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, and hazardous substances; risk assessment and management; safe working procedures for equipment and hazardous substances. | 6 | 4 | 2 | ||

| IV | Final Safety Training Assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content for all 6 groups

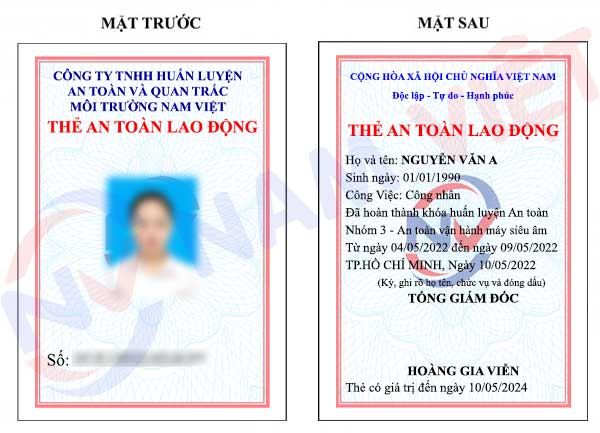

d. Occupational Safety Card

After completing the occupational safety training and passing the exam, workers are issued an occupational safety card (commonly referred to as Group 3 safety certificate).

The Group 3 card displays the worker’s name, date of birth, job, and specific work environment, as well as training duration, red stamp, and signature confirming completion of training.

According to Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and validate the safety card for Group 3 employees after they complete training and pass the assessment.

- If the worker is freelance or seasonal with no labor contract, the training unit must sign, stamp, and validate the safety card after the worker completes training and passes the assessment.

3. Hazards for Workers Operating Ultrasound Machines

Operating ultrasound machines in healthcare can bring many benefits to patients, but there are also several hazards and challenges that workers need to be aware of and manage. Here are the main hazards:

- Exposure to Ultrasound Waves: Healthcare staff may be exposed to ultrasound waves for long periods while performing ultrasound procedures. Although there is no concrete evidence of negative effects on humans, continuous exposure may cause fatigue and stress for staff.

- Posture and Ergonomics: Operating ultrasound machines may require uncomfortable or improper working positions, leading to muscle strain and long-term injuries. Maintaining proper posture and using supportive equipment can help minimize this risk.

- Noise Exposure: Ultrasound machines can generate noise during operation, especially at high levels. Noise can cause stress and fatigue and may damage hearing if proper ear protection is not used.

- Chemical Exposure: Some solutions or gels used during ultrasound procedures may contain chemical compounds that can irritate the skin or cause allergies. Following safety guidelines for using and storing chemicals is crucial.

- Electrical Hazards: As ultrasound machines operate on electricity, workers may face risks such as electric shock. Regular maintenance and inspection of electrical equipment, along with ensuring a safe work environment, are necessary.

- Biological Hazards: Although rare, exposure to blood or other bodily fluids during ultrasound procedures may carry a risk of bacterial or viral infection.

To minimize these hazards, training staff in occupational safety, following personal protection rules, and maintaining a safe and healthy work environment are essential.

4. Accident Prevention Measures When Operating Ultrasound Machines

To prevent occupational accidents when operating ultrasound machines in healthcare, there are several safety measures and rules that staff and medical facilities should follow:

- Training and Education: Provide comprehensive training on ultrasound machine use, including device operation, safety procedures, and accident prevention measures. Ensure that all staff understand potential hazards and safety precautions.

- Compliance with Safety Regulations: Ensure that all local and national safety regulations are followed. This includes using personal protective equipment such as masks, safety glasses, gloves, and protective clothing.

- Inspection and Maintenance: Perform regular inspections and maintenance of ultrasound equipment to ensure it operates correctly and safely. This includes checking the transducer, calibrating technical settings, and performing routine maintenance.

- Safe Workplace Organization: Establish and maintain a clean and safe work environment, keeping workspaces well-ventilated and organized to prevent collisions and accidents.

- Optimized Posture and Ergonomics: Ensure staff maintain comfortable and correct working positions. Use supportive equipment or rotate workstations periodically to reduce muscle strain and injury risk.

- Chemical Management: Ensure that all solutions and chemicals used during ultrasound procedures are stored and used safely. Provide full information and instructions for handling these substances.

- Noise Management: Ensure the work environment does not produce excessive noise. Use ear protection and noise-reducing equipment as necessary.

- Control of Ultrasound Exposure: Limit staff exposure time to ultrasound waves and ensure personal protective measures are used when necessary.

- Periodic Inspection of ultrasound machines to detect safety issues such as wear, mechanical failure, or damage, thereby reducing the risk of occupational accidents.

5. Benefits of Occupational Safety Training

An Toàn Nam Việt provides your business with the following benefits after completing occupational safety training courses according to Decree 44/2016/ND-CP on occupational safety and hygiene for companies, factories, and enterprises:

- Workers can identify potential occupational hazards and take preventive measures to avoid accidents.

- Your business can establish risk prevention measures in production, operation, and maintenance processes.

- Reduce costs associated with safety risks in the workplace.

- Continuous production without interruption increases labor productivity and product quality.

- Ensure compliance with labor safety laws, avoiding legal risks.

- Build credibility and professionalism, thereby enhancing your business brand.

Nam Việt’s training courses are designed to prevent external hazards from affecting individuals, helping them avoid dangers that could cause injuries or even fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

6. Customer Feedback After Completing Training

An Toàn Nam Việt has years of experience collaborating with businesses in Vietnam, especially in the southern provinces. This responsibility is precious, which is why Nam Việt emphasizes professional and high-quality Occupational Safety Training. Our growth is driven by positive feedback and suggestions from our partners. Below are some testimonials from our clients.

See more customer interviews after using our services at An Toàn Nam Việt

7. An Toàn Nam Việt’s Occupational Safety Training Capability

An Toàn Nam Việt is a leading and reputable occupational safety training center in Vietnam. Training sessions are continuously held at factories, production facilities, and construction sites nationwide (all 63 provinces).

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

Occupational Safety Training License

- An Toàn Nam Việt has been inspected and certified by the Department of Safety of the Ministry of Labor, Invalids, and Social Affairs, confirming our capability to provide occupational safety and hygiene training.

Training Materials and Lectures

- Training materials are reviewed and approved to ensure accuracy and effectiveness before being used in courses.

- Teaching methods are standardized according to An Toàn Nam Việt’s approach, developed by occupational safety experts to maximize knowledge retention.

Facilities

- Control of classroom factors enhances teaching efficiency and knowledge absorption.

- Our training facilities provide spacious, well-lit classrooms equipped with teaching devices, meeting standard requirements.

8. Nationwide Reputable Safety Training Center

At An Toàn Nam Việt, we prioritize professional occupational safety training. We aim to equip workers with self-protection knowledge to keep them safe while working, contributing to national development.

To ensure effective training, every detail is meticulously prepared—from tools and equipment to curriculum, materials, audio, and lighting.

Our instructors are experts with many years of experience and research in hazard recognition across various industries and prevention strategies.

Lectures are practical, engaging, and easy to understand, ensuring workers learn comfortably. Training strictly follows Decree 44/2016/ND-CP.

Workers learn multiple hazard prevention measures and how to apply them effectively in real work situations.

Our training center is proud to provide professional, reliable occupational safety training with advantages including:

- Competitive training costs without compromising quality.

- Flexible training schedules aligned with company operations.

- Quick certification procedures compliant with the law.

- Experienced instructors.

- Controlled classroom factors to enhance teaching efficiency and learning outcomes.

- Customized lectures suited to business occupational safety needs.

- Dedicated and professional support for clients.

9. Additional Occupational Safety Training Materials

- Occupational Safety Training Document Set

- Occupational Safety Material for Ultrasound Machine Operation

- Occupational Safety Training Test Set

- Occupational Safety Multiple Choice Test for Ultrasound Operation

- Occupational Safety Training Slides for Ultrasound Machine Operation

1 review for Occupational Safety Training for Operating Ultrasound Machines

No comments yet

phanminhhang341

Dịch vụ tốt!!!