Safety Document Group 3

Occupational Safety Document for Operating Plasma Cutting Machines

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 PROFESSIONS)

Discover the essential occupational safety document for operating a plasma cutter! From ensuring employee safety to accident prevention measures, this document will help you clearly understand the procedures and safety measures when using a plasma cutter in the workplace. Ensure maximum safety and efficiency with detailed and practical guidance.

PART I: CURRENT STATE OF SAFETY PRACTICES FOR WORK INVOLVING PLASMA CUTTING MACHINES

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

II. Some Occupational Accidents When Operating a Plasma Cutter

Operating a plasma cutter in a production environment requires caution and strict adherence to safety procedures. Although there have been advancements in technology and occupational safety management, unfortunate accidents can still occur. Here are some common occupational accidents when operating a plasma cutter:

- Injury from electric shock: Direct contact with the plasma current can cause safety issues. Employees not wearing adequate protective gear or not following proper safety procedures can be injured by the plasma current.

- Fire and explosion: The use of flammable liquids and gases, as well as flammable materials during the plasma cutting process, can lead to the risk of fire and explosion. If these materials are not managed and handled correctly, fires and explosions can occur, causing serious injury to employees and damage to equipment.

- Burns: The high temperature of the plasma can cause burns when employees do not wear enough protective gear or fail to follow proper safety procedures.

- Injury due to inconsistent cut quality: If the plasma cutter is not operating correctly or is not regularly maintained, it can lead to inconsistent cut quality. This not only affects product quality but also increases the risk of injury to employees due to unpredictable material handling.

- Noise hazard: The operation of a plasma cutter is often accompanied by high noise levels, which can be harmful to employees’ hearing if they do not wear adequate ear protection.

To minimize the risk of accidents when operating a plasma cutter, companies need to strictly adhere to safety procedures, ensure that employees are properly trained, and always wear full protective equipment during work. At the same time, regular maintenance and inspection of equipment are also very important to ensure safety for everyone in the work environment.

PART II: OCCUPATIONAL SAFETY AND HEALTH WHEN OPERATING A PLASMA CUTTER

I. Introduction

A. Overview of the importance of occupational safety when operating a Plasma Cutter

Occupational safety when operating a plasma cutter is not just a legal requirement but also a crucial part of a safe work culture in a production environment. Ensuring employee safety during the operation of a plasma cutter plays a decisive role in many different aspects.

First and foremost, occupational safety ensures the health and safety of employees. Working in a high-risk production environment, such as operating a plasma cutter, can present many dangers, from electric shock and fire hazards to injuries from materials or equipment. By applying proper safety measures, organizations can minimize these risks and protect the health of their employees.

Second, occupational safety also ensures the continuity of the production process. Workplace accidents not only cause health damage and personal loss but also affect the efficiency and profitability of the business. Each accident can lead to downtime, legal costs, and a decline in employee morale. At the same time, accidents can damage equipment and cause production losses. By ensuring occupational safety, businesses can maintain continuous production and enhance productivity.

Finally, implementing occupational safety is an inseparable part of an organization’s social and ethical responsibility. Providing a safe working environment is not only the right thing to do legally but also a way to show care and respect for employees. This can also help attract and retain talented employees, while improving the company’s image in the community and with business partners.

B. Important safety protocols and regulations when operating a Plasma Cutter

Adhering to safety protocols and regulations is a crucial part of ensuring employee safety when operating a plasma cutter. First and foremost is ensuring that all employees are fully trained on how to use the plasma cutter and related safety measures. This training should include identifying potential hazards, accident prevention measures, and how to respond in case of an incident.

Additionally, ensuring that all employees wear adequate protective gear is an important part of the safety process. This may include helmets, safety glasses, heat-resistant gloves, and reflective vests. Wearing proper protective gear not only protects workers from the risk of injury but also minimizes the risk of accidents.

Safety protocols also include regular inspection and maintenance of the plasma cutter. The equipment must be checked to ensure it is operating correctly and that there are no faults that could cause a hazard. Furthermore, establishing and maintaining safe work procedures, including the use of safe materials and minimizing the risk of fire, is also an important part of ensuring safety when operating a plasma cutter.

II. Components and Functions of a Plasma Cutter

A. The different components of a Plasma Cutter

A plasma cutter is a complex device, comprising many important components that play a role in the cutting and operation process. One of the main components of a plasma cutter is the Plasma Source, which generates the high-temperature plasma stream to cut through material. The plasma source is often controlled by specialized control systems to ensure cutting quality and efficiency.

Another important component is the gas system, which includes gas cylinders and a gas distribution system, supplying gas (usually argon or nitrogen) for the plasma creation process. The gas is used to create the plasma and to cool the cutting zones.

The torch head is also an indispensable part of the plasma cutter, including electrodes and other components to create the plasma arc and direct the plasma stream to the material being cut. The torch head can often be adjusted to suit different materials and thicknesses.

The control system is another important component of the plasma cutter, controlling parameters such as plasma current, cutting speed, and gas pressure to ensure optimal performance and cutting quality.

B. Structure and operating principle of a Plasma Cutter

A plasma cutter operates on the principle of plasma, a state of matter created by the ionization of gas. The basic structure of a plasma cutter includes a plasma source, a gas system, a torch head, a control system, and auxiliary systems.

The plasma source is where plasma is created by passing gas (usually argon or nitrogen) through an ionizing electrode flame, creating a high-temperature plasma stream. The gas system supplies gas for the plasma creation process and provides cooling gas for the cutting zone.

The torch head typically includes electrodes and other components to create the plasma stream and direct it to the material to be cut. The electrodes are usually made of high-temperature resistant materials such as tungsten or copper and are designed to withstand the high temperatures of the plasma.

The control system ensures that parameters such as plasma current, cutting speed, and gas pressure are controlled and adjusted correctly to ensure optimal performance and cutting quality.

C. Applications in the metal fabrication industry of a Plasma Cutter

Plasma cutters are widely used in the metal fabrication industry due to their ability to cut quickly, accurately, and flexibly. One of the main applications of a plasma cutter is cutting thick metal sheets, including carbon steel, stainless steel, and aluminum. Because plasma can reach high temperatures, a plasma cutter can efficiently cut through thick metal materials, helping to create metal products with precise sizes and shapes.

In addition, plasma cutters are also used to cut non-ductile metals like cast iron and titanium, where their precise and fast cutting capabilities are very important. Other common applications include cutting complex parts and irregular shapes, working on custom projects, and mass-producing high-quality metal components.

Plasma cutters can also be used to cut more ductile metals such as aluminum and copper. The ability to adjust the plasma current and other parameters allows the plasma cutter to adapt to different metal materials, delivering the best cutting results for each specific application.

D. Risks associated with operating a Plasma Cutter

Operating a plasma cutter can pose many risks to employees and the work environment if appropriate safety measures are not followed. One of the main risks is electric shock, where direct contact with the plasma current can cause serious health problems. This is especially true when employees do not wear adequate protective gear or do not follow proper safety procedures.

The risk of fire and explosion is also a significant issue related to operating a plasma cutter, especially when working with flammable materials. The use of flammable gases and liquids can lead to the risk of fire if proper safety procedures are not followed and if there is no effective fire prevention system.

In addition, other risks such as injury from the high temperature of the plasma, the risk of injury from uneven cuts, and noise hazards also need to be considered. Using a plasma cutter in an improper work environment can cause health and safety problems for employees, while also affecting production efficiency and quality.

III. Safety Inspection and Maintenance Before Operating a Plasma Cutter

A. Safety inspection before operating a Plasma Cutter

Before starting to operate a plasma cutter, performing safety inspection steps is very important to ensure a safe working environment for employees. One of the important steps is to check the condition of personal protective equipment such as helmets, safety glasses, heat-resistant gloves, and reflective vests. Ensure that all this equipment is thoroughly checked and in good working condition before starting work.

Next, check the gas and cooling systems of the plasma cutter to ensure they are working correctly and that there are no leaks. A gas leak can lead to a serious risk of fire and explosion, so it is very important to thoroughly check and repair these issues.

Furthermore, a technical inspection of the plasma cutter is a step that cannot be overlooked. Ensure that all parts of the machine are working correctly and there are no faults that could cause a hazard. If any problems are found, repair or replace the necessary parts before proceeding with operation.

B. Guide to periodic maintenance of a Plasma Cutter

- Inspect and clean the torch head: Regularly inspect and clean the parts of the torch head such as the electrode and plasma nozzles. The accumulation of dirt and debris can reduce cutting performance and increase the risk of failure.

- Inspect the gas and cooling systems: Ensure that the gas and cooling systems of the plasma cutter are both working correctly. Check for gas leaks or signs of insufficient gas pressure and take necessary corrective actions.

- Maintain main components: Perform maintenance on the main components of the plasma cutter such as the controller, plasma source, and mechanical parts. Ensure that these parts are regularly inspected and maintained to ensure stable operation.

- Check the control system: Inspect the control devices to ensure they are working correctly and there are no errors that could pose a risk to the operation process.

- Replace worn or damaged components: Replace worn or damaged components correctly and promptly to ensure the performance and safety of the machine.

IV. Safe Operating Procedure for a Plasma Cutter

A. Step-by-step guide on the safe operating procedure for a Plasma Cutter

- Pre-operation safety check: Before starting work, check personal protective equipment such as helmets, safety glasses, and heat-resistant gloves. Ensure that the work environment has been cleaned and there is no risk of fire or explosion.

- Inspect the machine and equipment: Next, thoroughly inspect the plasma cutter and control devices to ensure they are working correctly. Check the gas and cooling systems to ensure there are no leaks or other issues.

- Prepare the material to be cut: Prepare the material to be cut and place it on the work table in a safe and stable manner. Ensure that the material does not move during the cutting process and place it in a convenient position for operation.

- Perform the cutting procedure: Once everything is prepared and safety is ensured, begin the cutting procedure according to the manufacturer’s instructions. Ensure that the plasma cutter is adjusted correctly and that safety procedures are followed throughout the work process.

- Finish and re-check: When the job is complete, re-check the machine and the work environment to ensure everything is in a safe condition. Turn off the machine and store personal protective equipment properly.

B. Emergency response measures and incident response mechanisms when operating a Plasma Cutter

- Stop work and report the incident: In the event of an incident, immediately stop operating the plasma cutter and report the incident to management and other employees in the work area. Ensure that everyone is aware of the cause of the incident and can suggest response measures.

- Cut the power supply: If there is a risk of electric shock or electricity-related issues, cut the power supply immediately to prevent the risk of a serious accident.

- Control and extinguish fire: In case of a fire or explosion risk, use fire suppression equipment or fire extinguishers to control and extinguish the fire. Ensure that everyone is safely evacuated and no one is near the hazardous area.

- First aid and medical care: Ensure that first aid kits and medical supplies are available if needed. Use first aid skills to provide assistance to the injured and call for emergency services if necessary.

- Report and evaluate the incident: After handling the incident, ensure that all relevant information has been recorded and reported to management. Conduct an incident evaluation to understand the cause and propose preventive measures to avoid recurrence in the future.

V. Risk Assessment and Hazard Management When Operating a Plasma Cutter

A. Identifying potential risks and hazards in operating a Plasma Cutter

During the operation of a plasma cutter, identifying and assessing potential risks and hazards is very important to ensure the safety of employees and the work environment. Some common potential risks and hazards include:

- Risk of electric shock: The plasma stream can create a risk of electric shock if proper safety procedures are not followed or if there are damaged equipment or wires.

- Risk of fire and explosion: The use of flammable gases and liquids during the operation of a plasma cutter can create a risk of fire and explosion if safety measures are not followed or if there is a gas leak.

- Risk of injury: The high temperature of the plasma and metal materials can create a risk of injury if safety procedures are not followed or if work is not done carefully.

- Risk of environmental pollution: The use of gases and liquids during the operation of a plasma cutter can cause environmental pollution if they are not handled correctly or if there are leaks or spills.

- Noise hazard: The operation of a plasma cutter can generate high noise levels, posing a risk of hearing damage to employees if proper protective measures are not used.

By identifying and assessing these potential risks and hazards, we can apply appropriate preventive and safety measures to minimize the risk of accidents and protect the health of employees and the work environment.

B. Effective hazard prevention strategies when operating a Plasma Cutter

1. Regular inspection and maintenance of the Plasma Cutter for safe operation

- Inspect the electrical and electronic systems: Thoroughly inspect the electrical and electronic components on the plasma cutter such as the electrode, controller, and electrical system. Ensure that there are no damaged or shorted wires, and that all components are functioning correctly.

- Inspect the compressed air and gas systems: Check the compressed air and gas systems to ensure there are no leaks or failures. Perform pressure checks and replace faulty parts if necessary to ensure safe and effective operation.

- Inspect and maintain mechanical parts: Check the mechanical parts of the machine such as shafts, bearings, and the motion system to ensure they operate smoothly and show no signs of wear or damage. Perform maintenance and replace necessary parts to maintain the machine’s performance.

- Inspect and replace consumable parts: Perform regular checks and replace consumable parts such as electrodes, air filters, and plasma hoses when they are worn or damaged. Ensure that new components are installed correctly and comply with safety standards.

2. Comply with occupational safety regulations for the safe operation of a Plasma Cutter

- Training and instruction: All employees involved in operating a plasma cutter must be fully trained on safety measures, operating procedures, and incident handling. Regular training is also a way to update knowledge and new skills, helping to raise safety awareness for all employees.

- Use of protective equipment: All employees must adhere to wearing full personal protective equipment such as helmets, safety glasses, heat-resistant gloves, and reflective vests. The use of protective equipment helps protect employees from potential risks and accidents that may occur during work.

- Adherence to safety procedures: All employees must follow the safety procedures defined in the company’s regulations and follow the instructions of the plasma cutter manufacturer. This includes using the machine correctly, performing safety checks before operation, and handling incidents safely and effectively.

- Incident reporting: Any incident or issue related to occupational safety must be reported immediately to the management or the company’s occupational safety department. This helps ensure that preventive and corrective measures can be taken promptly to prevent recurrence in the future.

3. Identify and mark safe zones when operating a Plasma Cutter

- Identify the safe work zone: First, it is necessary to identify the main work zone for operating the plasma cutter. This is where employees frequently work and come into contact with the machine.

- Mark the boundaries: Use marking methods such as tape lines or signs to clearly define the boundaries of the safe work zone. This helps employees recognize and adhere to these boundaries to avoid accidents and unwanted collisions.

- Ensure clear space for movement: Ensure that the space for movement around the plasma cutter is wide enough for employees to move easily and safely. Avoid placing obstructing objects in this area.

- Sort and store materials: Sort and store materials to be cut clearly and safely, avoiding clutter and disorganization in the work area. This helps minimize the risk of collisions and accidents during operation.

- Instruct employees: Train employees on the safe work zone and how to move safely within this area. Ensure that everyone understands and follows the rules and safety procedures when working near the plasma cutter.

4. Use personal protective equipment when operating a Plasma Cutter

- Helmet: A helmet helps protect the head from objects falling from above or from the cutting process, especially in cases where there is a risk of impact.

- Safety glasses: Safety glasses help protect the eyes from plasma rays and sparks that may be emitted during the cutting process, reducing the risk of eye injury or burns.

- Heat-resistant gloves: Heat-resistant gloves help protect hands from the high temperature of the cut material and plasma rays, reducing the risk of burns.

- Safety shoes: Safety shoes provide stability and protection for the feet from falling materials and the risk of slipping during work.

- Reflective vest: A reflective vest helps increase the visibility of employees in the work environment, especially in low-light conditions or when working near operating machinery.

– Heat-resistant clothing: Heat-resistant clothing provides protection for the body from high temperatures and plasma rays during operation, helping to reduce the risk of burns.

5. Emergency procedure and response in case of an incident when operating a Plasma Cutter

- Stop work immediately: In case an incident is detected, immediately stop operating the plasma cutter and report the incident to management and other employees in the work area.

- Disconnect the power source: If there is a risk of electric shock or electricity-related issues, disconnect the power source immediately to prevent the risk of a serious accident.

- Control fire and gas: In case of a fire or explosion risk, use fire suppression equipment or fire extinguishers to control and extinguish the fire. Ensure there are no gas leaks.

- First aid and medical care: Provide first aid assistance to the injured and call for emergency services if necessary. Use first aid skills to provide support to those who are injured.

- Report the incident: After handling the incident, ensure that all relevant information has been recorded and reported to management. Conduct an incident evaluation to understand the cause and propose measures to prevent recurrence in the future.

6. Participate in occupational safety courses when operating a Plasma Cutter

Occupational safety and health training is not only a legal requirement but also a commitment to the safety and health of workers. It helps employees recognize and deal with risks and hazardous situations, thereby reducing accidents, injuries, or fatalities in daily work.

The risk of accidents is always present and can happen at any time in the work environment due to the possibility of human error and the unpredictability of all situations. This emphasizes the need for occupational safety training and constant vigilance.

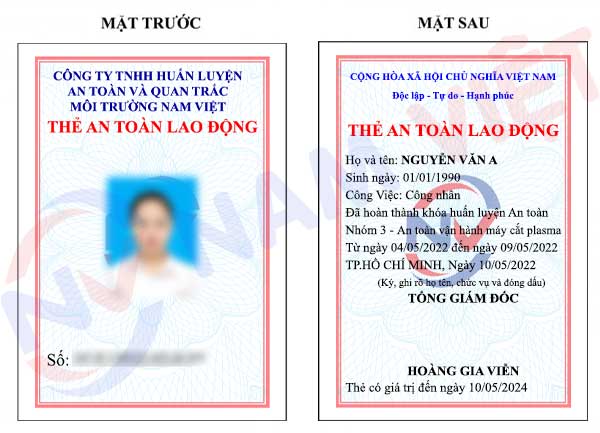

When participating in occupational safety training at Nam Viet Safety Center, workers will be thoroughly trained from theory to real-life risk scenarios. Accordingly, there will be measures to identify and prevent occupational accident risks that may occur during work. After the training course, trainees will take occupational safety tests to obtain an occupational safety certificate. From there, workers will grasp safety knowledge as well as have a valid certification for their work.

VI. Factors Affecting Occupational Safety When Operating a Plasma Cutter

A. How do weather conditions affect the operation of a Plasma Cutter?

- Temperature: High temperatures can increase the risk of fire and explosion when using gas during the plasma cutting process. Conversely, low temperatures can reduce the machine’s operating efficiency and freeze liquids in the system, causing operational problems.

- Humidity: High humidity can cause water to accumulate in the compressed air and gas systems, leading to rust and affecting the machine’s operational efficiency. This is particularly important in outdoor work environments.

- Wind and other weather conditions: Strong winds and unstable weather conditions can reduce the accuracy and uniformity of the plasma cutting process, especially for thin metal sheets.

- Sunlight: Bright sunlight can reduce visibility and increase the risk of accidents during work.

B. How does the work environment affect the operation of a Plasma Cutter?

- Workspace: A narrow and cramped workspace can reduce employees’ ability to move and create a risk of collisions and accidents. Conversely, a spacious and open area provides more favorable conditions for operating a plasma cutter.

- Cleanliness and dust environment: A plasma cutter requires a clean work environment to ensure cutting performance and machine maintenance. A work environment contaminated with dust and liquids can reduce the machine’s operating efficiency and increase the risk of failure.

- Humidity and temperature: The humidity and temperature of the work environment can affect the performance of the plasma cutter. High humidity can cause water to accumulate in the compressed air and gas systems, while low temperatures can reduce the machine’s operating efficiency.

- Lighting and illumination: The work environment needs to be sufficiently lit for employees to work safely and accurately. Insufficient light can reduce visibility and increase the risk of accidents.

C. How does the technical condition of a Plasma Cutter affect its operation?

- Cutting torch and electrode: The sharpness of the cutting torch and the condition of the electrode directly affect the quality of the cut. A dull cutting torch or a faulty electrode can lead to uneven and inaccurate cuts.

- Cooling system: The cooling system must operate effectively to control the temperature of the plasma cutter. If the cooling system is not working properly, it can lead to an increase in the machine’s temperature and cause operational problems.

- Compressed air and gas system: The compressed air system needs to be regularly maintained and inspected to ensure stable pressure and no leaks. The condition of the gas also needs to be checked to ensure quality and safety during operation.

- Controller and electronic components: The controller and other electronic components of the plasma cutter need to function correctly to control the cutting process accurately and safely.

D. How do the safety knowledge and skills of workers affect the operation of a Plasma Cutter?

- Understanding of safety procedures and regulations: Workers need to understand the safety procedures and regulations related to operating a plasma cutter. This includes how to use personal protective equipment, emergency procedures in case of an incident, and accident prevention measures.

- Machine operation skills: Skills in operating a plasma cutter are also very important. Workers need to be trained and have the necessary skills to use the machine accurately and safely.

- Vigilance: The vigilance and self-protection mindset of workers also affect safety when operating a plasma cutter. Recognizing and avoiding dangerous situations can help prevent unwanted accidents.

- Training and guidance: Regular training and guidance on occupational safety and plasma cutter operation are important to enhance the knowledge and skills of workers and minimize the risk of accidents.

VII. Occupational Safety Training on Skills for Safe Operation of a Plasma Cutter

A. Why do Plasma Cutter operators need to be trained in occupational safety?

- Protecting health and safety: Occupational safety training helps plasma cutter operators recognize and understand the potential risks and hazards in the work process. They will learn how to use personal protective equipment and apply preventive measures to protect their own health and safety and that of their colleagues.

- Reducing the risk of accidents: Occupational safety training helps minimize the risk of accidents and failures during the operation of a plasma cutter. Trained individuals will know how to identify and avoid dangerous situations, and know how to handle emergency situations effectively.

- Increasing work efficiency: People who are trained in occupational safety are often able to work more efficiently. They can operate with fewer interruptions because they recognize potential hazards and know how to avoid them.

- Compliance with legal regulations: Occupational safety training helps ensure that plasma cutter operators comply with legal regulations and industry standards. This not only helps avoid legal violations but also creates a professional and safe work environment.

B. Where to get occupational safety training for operating a Plasma Cutter?

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam today. With occupational safety training sessions held continuously at production workshops, factories, or construction sites across the country (63 provinces in Vietnam).

To ensure effective training, An Toan Nam Viet prepares carefully and meticulously down to the smallest detail. From preparing tools, equipment, teaching aids to curriculum, materials, sound, and lighting.

The occupational safety training instructors at An Toan Nam Viet are experts with many years of experience in the field. They even have research projects identifying hazards in all industries and how to prevent them.

The instructors’ lectures are drawn from practical experience and are conveyed in a lively and easy-to-visualize manner to the workers. These factors help workers feel comfortable during the learning process and absorb the teaching knowledge well. Of course, the knowledge conveyed always adheres to Decree 44/2016/ND-CP. From there, they will grasp many measures to prevent hazards and how to protect themselves. At the same time, they can also apply it most appropriately in their actual work.

VIII. The Significance of Occupational Safety in Operating a Plasma Cutter

A. The importance of maintaining occupational safety in operating a Plasma Cutter

- Protecting the health and lives of employees: Occupational safety is a top priority to ensure that employees work in a safe environment and are not at risk of injury or harm. Maintaining occupational safety in the operation of a plasma cutter helps protect the health and lives of employees.

- Reducing the risk of accidents and losses: By applying safety measures and complying with regulations, the risk of accidents and losses can be minimized. This not only helps to avoid personal harm but also helps the business reduce costs arising from workplace accidents and incidents.

- Increasing efficiency and product quality: A safe work environment helps employees concentrate more on their work without worrying about the risk of accidents. This can lead to increased work efficiency and product or service quality.

- Building employee trust and confidence: A business’s focus on occupational safety sends a message that they care about the health and safety of their employees. This can create a positive work environment, building trust and confidence between employees and the business.

B. Important safety measures to know before operating a Plasma Cutter

- Use of personal protective equipment (PPE): Ensure the full and correct use of personal protective equipment such as safety glasses, respirators, cut-resistant gloves, and body armor to protect the body from risks associated with plasma cutting.

- Inspect the work environment: Ensure that the work environment around the plasma cutter is clean, clear, and free of unnecessary objects. Remove items that could easily cause slips or trips to reduce the risk of accidents.

- Training and guidance: Before operating a plasma cutter, workers must be trained on how to use the machine, recognize hazards, and apply safety measures. They also need to be instructed on emergency procedures and how to respond in case of an incident. Complete an occupational safety training course to be issued an occupational safety card by the training center to properly complete your work profile.

- Regular machine inspection and maintenance: Ensure that the plasma cutter is regularly inspected and maintained to ensure optimal performance and reduce the risk of failure causing accidents.

- Adherence to safety regulations: Always adhere to the safety regulations set by the plasma cutter manufacturer and regulatory agencies to ensure safety and legal compliance.

PART III: Further Reference

1. Group 3 Occupational Safety Test

2. Price List for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training material for operating a Plasma Cutter

- Slide presentation for occupational safety training on operating a Plasma Cutter

- Multiple choice test on occupational safety when operating a Plasma Cutter