Safety Document Group 3

Occupational Safety Document for Permanent Magnet Manufacturing

DOWNLOAD THE OCCUPATIONAL SAFETY DOCUMENT SET (6 GROUPS, OVER 300 INDUSTRIES)

Discover the processes for ensuring occupational safety and product quality, providing useful knowledge for the modern manufacturing environment.

PART I: CURRENT STATE OF SAFETY IN THE PERMANENT MAGNET MANUFACTURING INDUSTRY

I. General Situation

The Ministry of Labour, Invalids and Social Affairs informs sectors and localities of the occupational accident situation in the first 6 months of 2024 and outlines key solutions to proactively prevent incidents and accidents in the last 6 months of 2024. According to reports from 61 out of 63 centrally governed provinces and cities, in the first 6 months of 2024, there were a total of 3,201 occupational accidents nationwide (a decrease of 227 cases, equivalent to 7.09% compared to the same period in 2023), resulting in 3,065 victims (a decrease of 197 people, equivalent to 6.04% compared to the first 6 months of 2023), including both employees under labor contracts and those working without labor contracts. Specifically:- Number of fatal occupational accidents: 320 cases, a decrease of 25 cases (7.25%) compared to the first 6 months of 2023 (including 245 cases in areas with labor relations, a decrease of 28 cases or 10.3%; and 75 cases in areas without labor contracts, an increase of 3 cases or 4.2% compared to the first 6 months of 2023);

- Number of deaths due to occupational accidents: 346 people, a decrease of 7 people or 1.98% compared to the same period in 2023 (including 268 in areas with labor relations, a decrease of 13 people or 4.63%; and 78 in areas without labor contracts, an increase of 6 people or 8.33%).

- Number of people seriously injured: 810 people, an increase of 26 people or 3.32% compared to the first 6 months of 2023 (including 710 in areas with labor relations, a decrease of 5 people or 0.7%; and 100 in areas without labor contracts, an increase of 31 people or 44.92%).

The occupational accident situation in the first 6 months of 2024 in both sectors with and without labor relations saw a decrease in the number of deaths and fatal accidents compared to the same period in 2023.

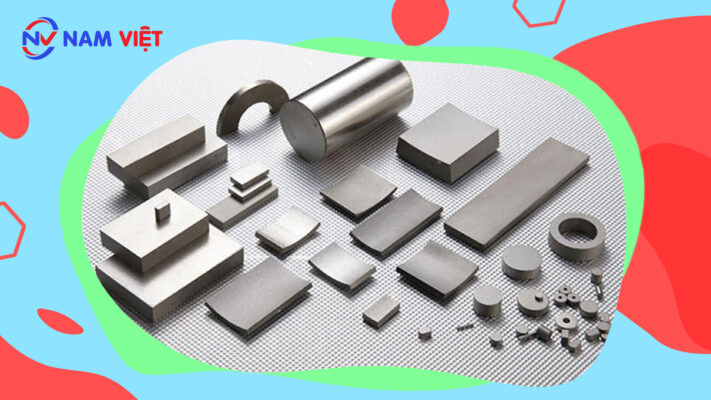

II. Some occupational accidents in permanent magnet manufacturing plants

In the permanent magnet manufacturing industry, where the production process requires high precision and the use of special materials, there have been occupational accidents that have attracted the attention of the community and authorities. These events not only highlight the risks related to occupational safety but also increase pressure on businesses in this field.

- Accidents Related to the Production Process: Some accidents have occurred in the permanent magnet production process due to technical failures or the failure of safety systems. This not only causes human losses but also disrupts the production process and affects the factory’s efficiency.

- Research on Accident Causes: Research and safety management organizations have conducted investigations after each accident to determine the specific causes. This helps to identify the factors contributing to the incidents and propose improvement measures to prevent recurrence.

- Occupational Safety Policies: The accidents have challenged the industry to update and strengthen occupational safety policies. Businesses have had to increase the intensity of employee training and enhance safety supervision to ensure that everyone complies with safety rules and regulations.

- Impact on the Market and Company Image: These accidents have had a major impact not only on the workers and their families but also on the market and the reputation of permanent magnet manufacturing companies. Businesses have had to face the challenge of restoring the trust of customers and partners.

In total, occupational accidents in permanent magnet manufacturing plants pose great challenges to this industry, while also providing opportunities to improve the occupational safety system and risk management.

PART II: OCCUPATIONAL SAFETY AND HEALTH IN PERMANENT MAGNET PRODUCTION

I. Occupational safety and health for employees operating furnaces and melting raw materials at high temperatures to form a metal alloy in preparation for permanent magnet production

1. Job characteristics of operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

The process of operating a furnace and melting raw materials at high temperatures plays a crucial role in creating the necessary metal alloy for producing permanent magnets. A notable characteristic of this job includes the diversity of input materials, mainly metals from the lanthanide group and transition metals.

The furnace is maintained at extremely high temperatures to ensure the melting process occurs effectively, creating a homogeneous liquid from different raw materials. This requires strict control over temperature and time, ensuring that every phase of the production process proceeds as planned and achieves the desired quality.

In addition, this process is also characterized by the use of purification techniques, removing impurities and ensuring the stability of the metal alloy. This poses a great challenge in terms of technology and engineering, requiring in-depth expertise and extensive knowledge of chemical processes and metallic materials.

2. Types of accidents during the process of operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

During the process of operating a furnace and melting raw materials at high temperatures to create a metal alloy for permanent magnets, various types of accidents can occur and seriously affect occupational safety and the production process. Some of the main risks include:

- Explosions and Fires: The high-temperature melting process can generate flammable gases and dust, increasing the risk of explosions and fires. Gas management and ensuring an effective exhaust system are important to minimize this risk.

- Leakage of toxic substances: High temperatures can increase the risk of toxic substances leaking from raw materials, posing a danger to the health of employees and the surrounding environment.

- Temperature Hazards: Employees may be exposed to extremely high temperatures, causing burns, explosions, or health damage. Ensuring adequate safety measures and personal protection is important.

- Machinery Failures: The machinery system operates continuously, and failures can occur, posing a challenge to occupational safety and maintenance to avoid disrupting the production process.

To minimize these accidents, it is necessary to establish strict safety measures, train employees on procedures and the use of personal protective equipment, as well as maintain periodic system checks and maintenance.

3. Causes of accidents when operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

The causes of accidents during the operation of a furnace and melting raw materials at high temperatures to create a metal alloy for permanent magnets can stem from several key factors. Firstly, a lack of uniformity in controlling temperature and time can lead to explosions or fires, especially when working with flammable metals.

Secondly, ineffective management of gas exhaust can create a hazardous environment with the accumulation of toxic gases. This increases the risk of leakage and elevates the health risks for employees and the environment.

Other causes may be related to technical failures, such as machinery or system errors, which pose a risk of disrupting the production process and endangering employees. A lack of knowledge or inadequate training on procedures and occupational safety can also contribute to the risk of accidents.

4. Measures to prevent accidents when operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

To ensure occupational safety during the process of operating a furnace and melting raw materials at high temperatures, there are several important accident prevention measures, especially through occupational safety training.

First, training employees on the process is crucial. Ensure that everyone has a clear understanding of the operating procedures, safety measures, and how to handle emergency situations. This training not only enhances employees’ knowledge but also puts them in realistic situations to reflect and experiment.

Second, ensure that employees are fully equipped and correctly use personal protective equipment (PPE). This includes helmets, masks, heat-resistant gloves, and protective clothing. Wearing the correct PPE is an important step to minimize the risk of fire and explosion and to protect the health of employees.

The exhaust system also needs to be regularly checked and maintained to ensure the air is always safe. In addition, planning for periodic checks of machinery and cooling systems is also an important measure to prevent technical failures.

5. Occupational safety regulations when operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

Occupational safety regulations are a crucial factor in protecting employees and enhancing safety during the process of operating a furnace and melting raw materials at high temperatures to create a metal alloy for permanent magnets. First, all employees must be trained in occupational safety, with a clear understanding of the procedures and safety measures. This training provides basic and detailed knowledge of potential risks, as well as how to respond to emergencies.

The regulations also include wearing the correct and full personal protective equipment (PPE), such as helmets, masks, heat-resistant gloves, and protective clothing. This establishes a wave of preventive measures to minimize the risk of fire and explosion and ensure employee safety.

The exhaust system needs to be checked periodically to ensure the air is always fresh and safe. At the same time, occupational safety regulations set rules for the use and maintenance of equipment, as well as periodic inspection and maintenance of machinery.

6. Handling emergency accident situations when operating a furnace and melting raw materials at high temperatures to form a metal alloy for permanent magnet production preparation

Handling an emergency accident situation during the operation of a furnace and melting raw materials at high temperatures requires quick thinking and proactivity from employees. In the event of an accident, the first step is to immediately report it to a manager and activate the safety alarm system.

Employees need to be familiar with the safety plan and evacuate the hazardous area quickly, using the correct personal protective equipment (PPE). At the same time, they also need to know how to use fire suppression and first aid equipment to deal with the critical situation.

While waiting for assistance, employees need to remain calm to help control the situation. Being previously trained on how to handle accidents will help them make correct and effective decisions. Effective communication with teammates and safety departments is also a key factor to ensure everyone is fully and accurately informed.

II. Occupational safety and health for employees operating the molding machine to shape permanent magnets

1. Job characteristics of operating a molding machine to shape permanent magnets

The job characteristic of operating a molding machine to shape permanent magnets is a complex process that requires professionalism and special technical knowledge. Machine operators must have a deep understanding of the operating principles of the molding machine, as well as the production process of permanent magnets.

This includes precise technical control of the machine, from feeding raw materials to the molding and cooling process. This technical adjustment requires careful skill to ensure that the final product accurately meets the necessary characteristics of a permanent magnet.

2. Types of accidents during the process of operating a molding machine to shape permanent magnets

During the operation of a molding machine to produce permanent magnets, there are many types of accidents that factories and workers need to be aware of. Some common accidents include machinery failures due to technical errors, unstable molding processes leading to defective products, and occupational safety risks.

Technical issues such as loss of machine control, sensor errors, or damaged molding equipment can lead to the production of permanent magnets that do not meet quality standards. This not only affects efficiency but also increases the risk of occupational accidents.

The molding process can also encounter difficulties when temperature, pressure, or the flow of molding material are not controlled. This can lead to a non-uniform final product and the possibility of accidents if not resolved in a timely manner.

3. Causes of accidents when operating a molding machine to shape permanent magnets

Accidents when operating a molding machine to produce permanent magnets often stem from several main causes. One of the common causes is technical failure, including molding equipment not functioning correctly or machinery failure due to breakdown. This failure can lead to a loss of control and the production of substandard products.

Another cause is the operator’s lack of knowledge and skills regarding the molding process. This may include failing to ensure the correct temperature, pressure, or flow of molding material, all of which can affect the production process and cause accidents.

Violation of safety rules is also a significant factor, when workers do not follow safety procedures or do not use personal protective equipment correctly. This increases the risk of occupational accidents and can cause serious injuries.

4. Measures to prevent accidents when operating a molding machine to shape permanent magnets

To prevent accidents when operating a molding machine to produce permanent magnets, implementing preventive measures is very important. First, training and enhancing the skills of the operator is key. This includes training on the molding process, safety equipment, and responding to technical incidents.

Improving the safety process is an effective preventive measure. This includes establishing clear safety rules and procedures, ensuring everyone works accordingly and uses full personal protective equipment.

Controlling the quality of the process is an important measure to avoid accidents. Periodic monitoring of temperature, pressure, and the flow of molding material can help prevent technical failures and ensure the final product meets the desired quality.

5. Occupational safety regulations when operating a molding machine to shape permanent magnets

Occupational safety regulations play a crucial role in protecting workers when operating a molding machine to produce permanent magnets. Specific rules should include the use of personal protective equipment such as helmets, safety glasses, and heat-resistant clothing. At the same time, workers need to be trained on how to use this equipment correctly.

The regulations should also include risk control measures such as ensuring the work environment is adequately ventilated, reducing exposure to toxic materials, and placing warning signs for workers to recognize hazardous areas.

Performing periodic checks and machine maintenance is an important part of safety regulations. This ensures that the molding machine operates stably and reduces the risk of technical failures.

6. Handling emergency accident situations when operating a molding machine to shape permanent magnets

Handling an emergency accident situation when operating a molding machine to shape permanent magnets requires quick thinking and reaction skills from employees. In case of an incident, immediately stopping the machine and notifying the safety team is important. Workers need to be trained on the use of personal protective equipment and safety measures to avoid further risks.

Performing basic first aid is also an important part of handling an emergency situation. Employees need to know how to provide first aid for any injuries and report immediately to the medical team if necessary.

Most importantly, cooperation and adherence to safety plans are key to minimizing damage and protecting the lives of workers. Organizing periodic emergency drills helps to enhance reaction skills and ensures that everyone at work knows how to respond in a dangerous situation.

III. Occupational safety and health for employees operating the machine for coating permanent magnets with a protective metal layer

1. Job characteristics of operating a machine for coating a protective metal layer on permanent magnets

The process of operating a machine to coat a protective metal layer on permanent magnets requires professionalism and precision to ensure the high quality of the final product. A notable characteristic of this job includes a deep understanding of the properties of metallic materials and the coating process. Through this, technicians need to control the temperature, pressure, and speed of the machine to ensure the uniformity of the coating layer.

It is important to perform preparatory steps before the coating process, including cleaning and preparing the surface of the permanent magnet. The coating materials must be properly prepared and strictly controlled to ensure the adhesion and durability of the coating layer.

Throughout the operation process, monitoring and adjusting the technical parameters are important to ensure that the product meets the quality requirements. A solid understanding of how permanent magnets work under different conditions is key to adjusting the coating process effectively.

2. Types of accidents during the process of operating a machine for coating a protective metal layer on permanent magnets

During the process of operating a machine to coat a protective metal layer on permanent magnets, several types of accidents can occur that affect the production process and product quality. These risks include occupational safety incidents, if employees do not follow safety rules or do not use proper protective equipment.

Temperature and pressure accidents can also occur if the operation process is not strictly controlled. A failure to maintain the correct temperature and pressure can lead to an uneven coating layer or one that does not adhere fully to the surface of the permanent magnet.

Furthermore, chemical accidents are also an important aspect to be concerned about. The leakage or improper use of coating materials can create a toxic environment or affect the quality of the magnet and reduce the performance of the product.

3. Causes of accidents when operating a machine for coating a protective metal layer on permanent magnets

The causes of accidents during the operation of a machine for coating a protective metal layer on permanent magnets can stem from many different aspects. One of the main causes is human error, including a lack of training or a lack of safety awareness. Employees who do not master the process or do not use proper protective equipment can lead to accidents.

In addition, procedural failures can also cause problems. This can include a lack of control over temperature, pressure, or the improper use of coating materials. Some technical issues such as failures in the control system or equipment can cause unwanted errors during operation.

In addition, chemical causes also play an important role. The use of unsafe coating materials or non-compliance with environmental rules can create a toxic work environment, affecting the health of employees and posing a risk of accidents.

4. Measures to prevent accidents when operating a machine for coating a protective metal layer on permanent magnets

To minimize the risk of accidents when operating a machine for coating a protective metal layer on permanent magnets, establishing and implementing preventive measures is important. Monitoring of the working environment plays a crucial role in ensuring safety and quality in the production process.

First, ensure that all employees are trained in occupational safety and have a deep understanding of the operating procedures. Use monitoring of the working environment to measure factors such as temperature, pressure, and chemicals during work, helping to monitor and control them to avoid harmful conditions.

Performing periodic checks and equipment maintenance is an important measure to prevent technical failures and ensure that machinery operates stably. Using safe coating materials and complying with environmental rules are effective ways to reduce chemical risks and protect the health of employees.

5. Occupational safety regulations when operating a machine for coating a protective metal layer on permanent magnets

Occupational safety regulations during the operation of a machine for coating a protective metal layer on permanent magnets are a key factor in ensuring a safe and efficient work environment. Employees must follow safety rules, including wearing proper protective equipment such as helmets, masks, and safety glasses.

Safety training regulations are important to ensure employees master the operating procedures and know how to respond to emergencies. Accident prevention measures must be implemented, including controlling temperature, pressure, and using safe coating materials.

Monitoring of the working environment is an important tool to assess and ensure that all factors such as temperature, pressure, and chemicals are within safe limits. Periodic inspection and maintenance of equipment are also an important part of the regulations to ensure that machinery always operates stably.

6. Handling emergency accident situations when operating a machine for coating a protective metal layer on permanent magnets

Handling an emergency accident situation when operating a machine for coating a protective metal layer on permanent magnets requires awareness and thorough preparation. Employees need to be trained on safety measures and emergency scenarios to ensure a quick and accurate response.

In the event of a temperature or pressure accident, immediately stopping the operation process and using emergency shutdown devices are the top priorities. At the same time, send an alarm signal and move employees out of the hazardous area.

In the event of a chemical accident, the use of absorbent materials or pollution control devices is necessary. At the same time, immediately notify the safety team so they can take detailed handling measures.

IV. Occupational safety and health for employees operating the packaging machine for finished permanent magnets

1. Job characteristics of operating a packaging machine for finished permanent magnets

During the operation of a packaging machine for finished permanent magnets, several important characteristics need to be noted to ensure the efficiency and quality of the product. First, the process of feeding raw materials into the machine needs to be carried out accurately to ensure a sufficient quantity of magnets and no shortages.

The packaging machine needs to be adjusted so that it can handle a variety of sizes and shapes of permanent magnets. This places high demands on the accuracy and flexibility of the machine’s control system. The packaging process needs to be digitally controlled to ensure the uniformity and safety of the final product.

In addition, the quality inspection process is also an important part of machine operation. Inspection measures should be integrated to ensure that the packaged magnets meet the quality standards. This may include checking magnetic strength, dimensional accuracy, and checking the uniformity of the magnets.

2. Types of accidents during the process of operating a packaging machine for finished permanent magnets

During the process of operating a packaging machine for finished permanent magnets, various types of accidents can occur and affect safety as well as production efficiency. One of the common risks is accidents related to the process of feeding raw materials into the machine. This incident can stem from the material getting stuck or being packaged unevenly, creating an unsafe situation for the operator.

Other accidents can arise from the machine adjustment process. If the machine is not set up correctly, it can lead to a loss of system control, posing a danger to the worker and reducing product quality. In particular, attention should be paid to the possibility of collision and abrasion during operation, which can cause machine damage and create conditions for accidents.

In addition, quality control issues can lead to accidents during the magnet packaging process. If the inspection process does not work correctly, it can lead to the packaging of products that do not meet safety and quality requirements, with serious consequences.

3. Causes of accidents when operating a packaging machine for finished permanent magnets

Accidents during the operation of a packaging machine for permanent magnets can stem from many causes. One of the main factors is the operator’s lack of attention and skill. If they are not properly trained or do not follow safety procedures, it can lead to accidents.

Another cause is related to improper maintenance and repair of the machine. If the machine is not regularly maintained or the repairs do not meet standards, it can create conditions for incidents and accidents to occur during operation.

Technical causes also contribute to the risk of accidents. If the machine is not set up correctly or the control system is not working properly, unwanted incidents can occur, posing a danger to the worker and affecting product quality.

Finally, management and supervision causes can also contribute to accidents. If safety procedures are not implemented correctly or there is no close supervision, the risk of incidents and accidents during operation will increase.

4. Measures to prevent accidents when operating a packaging machine for finished permanent magnets

To ensure safety during the operation of a packaging machine for permanent magnets, preventive measures must be strictly implemented. First, training employees is important so they have a clear understanding of safety procedures and operating skills. This helps reduce the risk of accidents due to a lack of knowledge and skill on the part of the worker.

Regular and technically correct machine maintenance is an important measure. Ensuring that the machine is always in good working condition helps reduce the risk of incidents and accidents due to machine failure.

Safety management also plays an important role. Establishing and maintaining safety rules, as well as conducting periodic risk assessments, all help to improve the level of safety in the work environment.

5. Occupational safety regulations when operating a packaging machine for finished permanent magnets

Occupational safety regulations play an important role in protecting workers when operating a packaging machine for permanent magnets. Employees must follow safety rules such as wearing proper personal protective equipment, including safety glasses and high-temperature resistant clothing.

The use of symbols and warning signs is also an important part of safety regulations. This helps workers recognize risks and provides guidance on how to avoid danger when operating the machine. In addition, educating employees about safety procedures and emergency measures is important so they can respond quickly in an emergency.

The regulations also include strict control measures such as prohibiting direct contact with the machine while it is in operation and requiring workers to be fully trained before participating in operation. This ensures that workers have sufficient knowledge and skills to minimize the risk of accidents.

6. Handling emergency accident situations when operating a packaging machine for finished permanent magnets

Handling an emergency accident situation is an important part of the safety process when operating a packaging machine for permanent magnets. In the event of an incident, the worker should immediately find a safe place and notify the manager and teammates.

Maintaining calm and performing basic first aid steps is important. This includes calling for an ambulance, providing detailed information about the situation, and performing first aid measures such as initial care and moving the injured person out of the danger zone.

PART III: Further Reference

1. Occupational Safety Test Group 3

2. Price List for Occupational Safety Training Services

3. Download Documents

- Download occupational safety training documents for permanent magnet production

- Slide presentation for occupational safety training in permanent magnet production

- Multiple choice test for occupational safety in permanent magnet production