Occupational Safety Training in Razor Manufacturing

99,000 ₫

Note: The above price is calculated for one person, the price may fluctuate depending on the number of trainees participating in the course and depending on market movements. For more accurate pricing support, please refer to the quotation table or contact our consulting staff directly.

Occupational safety is an important issue in razor manufacturing factories and needs to be addressed promptly to ensure the health and safety of workers, and to enhance the reputation of businesses. The Occupational safety training course is one of the effective solutions to raise awareness about accident prevention for workers participating in razor manufacturing.

Table of Contents

Toggle1. Overview of Razors

a. What is a razor?

A razor is a tool commonly used for shaving facial hair for men and is made from stainless steel or other sharp materials. Razors typically have one or more blades attached to a handle and are used to remove facial hair from men.

b. Machinery used in razor production

The razor production process involves multiple steps and various machinery, including:

- Steel sheet pressing machine: Used to press steel sheets into thin pieces to make blades.

- Steel cutting machine: Used to cut steel pieces into strips to make blades.

- Blade grinding machine: Used to grind and shape the blades.

- Blade rolling machine: Used to roll the blades into a complete razor.

- Printing machine: Used to print logos and product information on packaging.

- Packaging machine: Used to pack the product after production.

These machines are often integrated with automated production lines to increase efficiency and minimize human intervention during production.

c. Razor manufacturers in Vietnam

There are many well-known razor brands worldwide, including major brands such as:

- Gillette: One of the oldest and most famous razor brands in the world. Owned by Procter & Gamble and headquartered in Boston, Massachusetts.

- Schick: A brand of the multinational company Energizer Holdings, specializing in shaving products including razors, shaving cream, and shaving gel.

- Bic: A brand known for convenient products such as pens, lighters, and razors. Owned by the Bic corporation and headquartered in Clichy, France.

- Wilkinson Sword: A razor brand of the multinational company Edgewell Personal Care, established in 1772 in the United Kingdom.

- Feather: A Japanese razor brand famous for producing the sharpest razors in the world.

In Vietnam, there are also many well-known razor brands such as 3S, VIETTIN, Gillette, Schick, Bic, Senco, and especially local Vietnamese brands like Kiên Cường and Tiến Bảo.

d. Specific jobs in a razor manufacturing factory

Group 1

- CEO, Deputy CEO, and department heads in the razor manufacturing factory.

Group 2

- Safety officers: Manage safety in the factory, design safety procedures, supervise and ensure employees follow safe work procedures.

Group 3

- Production and processing of razor components: Razor components are manufactured from various materials such as stainless steel, plastic, rubber, and other materials.

- Assembly and quality control: Razor components are assembled and checked to ensure the product operates effectively and meets safety and quality standards.

- Packing and shipping: After production and quality control, razors are packaged in various packages before being shipped to sales points or distributors.

- Maintenance and repair: Responsible for maintaining and repairing production machinery and equipment to ensure optimal operation for high-quality product manufacturing.

Group 4

- Office work, services, sales, marketing.

- Production management, quality management, human resource management, materials management, financial and accounting management.

- Product design and research: Focused on designing and researching new products or improving existing ones. Designers develop technical drawings and prototypes to test performance.

2. Overview of Occupational Safety Training for Razor Manufacturing

In this article, we focus on issues surrounding Group 3, because Group 3 is directly involved in the production process and faces the highest occupational safety risks. For reference on other groups, see here.

a. What is Group 3 occupational safety training?

- Group 3 occupational safety training consists of sessions providing awareness on how to prevent workplace accidents for employees.

- The safety training course helps employees recognize and avoid hazards, reducing the risk of workplace accidents while working.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING SERVICE

b. Training duration

Initial safety training duration

- Total training time is at least 24 hours, including examination time.

- 8 hours of theory on safety and labor hygiene policies and laws

- 8 hours of theory on basic knowledge of safety and labor hygiene

- 4 hours of theory on specialized training content

- 2 hours of practical training on specialized content

- 2 hours of theoretical testing at the end of the training course

The safety training center will divide the time into multiple sessions depending on the workers’ schedule. Typically, there will be 6 sessions over 3 days, provided the company arranges continuous training time.

Periodic safety training duration

- Before the occupational safety card expires, employees wishing to renew it must complete a periodic occupational safety training, with periodic training time being at least 50% of the initial training duration.

Explanation: Total periodic occupational safety training time is at least 12 hours, including examination time. After completing the periodic training and passing the test, employees will be reissued and extended their occupational safety card.

c. Training course content

| No. | TRAINING CONTENT | TRAINING DURATION (HOURS) | |||

| Total | Including | ||||

| Theory | Practice | Test | |||

| I | Safety and labor hygiene policies and laws system | 8 | 8 | 0 | 0 |

| 1 | Overview of the legal documents system on occupational safety and hygiene. | 6 | 6 | ||

| 2 | System of standards and technical regulations on occupational safety and hygiene. | 1 | 1 | ||

| 3 | Specific regulations of state management agencies on occupational safety and hygiene when constructing, expanding, or renovating facilities for production, use, storage, and inspection of machines, equipment, materials, and substances with strict safety and hygiene requirements. | 1 | 1 | ||

| II | Basic knowledge of occupational safety and hygiene | 8 | 8 | 0 | 0 |

| 1 | Basic knowledge of hazardous and harmful factors in the workplace. | 4 | 4 | ||

| 2 | Methods to improve working conditions. | 1 | 1 | ||

| 3 | Safety culture in production and business. | 1 | 1 | ||

| 4 | Rights and obligations of employers and employees; policies and regimes on occupational safety and hygiene for employees; functions and duties of the safety network and hygiene staff. | 1 | 1 | ||

| 5 | Occupational safety regulations, safety signs, instructions, use of safety equipment and personal protective equipment; first aid skills, prevention of occupational diseases. | 1 | 1 | ||

| III | Specialized training content | 6 | 4 | 2 | 0 |

| Comprehensive knowledge of machines, equipment, substances generating hazardous factors; analysis, evaluation, risk management of occupational safety and hygiene, safe work procedures with machines, equipment, and substances with strict safety and hygiene requirements. | 6 | 4 | 2 | ||

| IV | Final safety training assessment | 2 | 2 | 0 | 0 |

| Total | 24 | 22 | 2 | ||

See more training content of the 6 groups

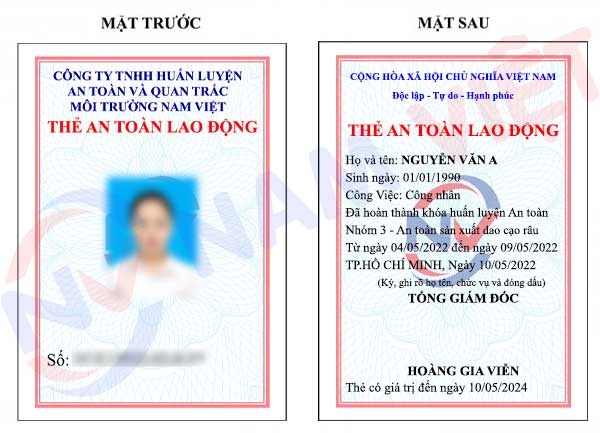

d. Occupational safety card

After completing the occupational safety training and passing the exam, employees will be issued an occupational safety card (commonly referred to as a Group 3 safety certificate).

The Group 3 safety card includes information such as: full name, date of birth, job, and specific work environment, along with training duration, official stamp, and signature confirming completion of the course.

According to the issuance regulations stated in Clause 2 of Article 24 of Decree 44/2016/ND-CP, there are two cases:

- If the employer and employee have a labor contract, the employer must sign, stamp, and endorse the safety card for Group 3 trainees after they complete the course at a certified training unit and pass the test.

- If the employee is freelance or temporary, without a labor contract, the training unit must sign, stamp, and endorse the safety card after the employee completes the course and passes the test.

3. Recognizing Hazards Affecting Workers in Razor Manufacturing

During razor manufacturing, potential hazards may include:

-

- Hot spots and sparks: In metalworking processes such as grinding, cutting, and polishing, improper use of mechanical tools can increase temperature and generate sparks, posing fire and explosion risks.

- Chemical hazards: Razor manufacturing may involve the use of chemicals such as acids, alkalis, and solvents for cleaning and surface treatment. Exposure to these chemicals can harm workers’ health, especially if not handled properly.

- Cutting and injury accidents: During razor manufacturing, workers may suffer injuries from cuts, punctures, or being impaled by mechanical tools.

- Noise and vibration: Noise and vibration from machinery during razor manufacturing can affect workers’ hearing and overall health.

- Metal dust exposure: Materials like steel can produce metal dust during cutting and processing. Long-term exposure can harm workers’ respiratory system and lungs.

- Heat and pressure hazards: Processes such as welding, casting, and pressing can generate high heat and pressure, posing dangers to workers if not managed properly.

- Back pain and other musculoskeletal issues: In addition to direct hazards of razor manufacturing, workers may experience back and shoulder pain, or other musculoskeletal problems, from prolonged improper posture.

4. Common Occupational Accidents for Workers in Razor Manufacturing

Common occupational accidents in razor manufacturing include:

- Hand and finger cuts: From using cutting or grinding machines unsafely, without regular maintenance, or without wearing adequate personal protective equipment such as gloves and protective clothing.

- Eye injuries: Bright lights from lamps or reflective materials can damage workers’ vision if protective glasses are not worn.

- Chemical poisoning: Health risks from exposure to chemicals used in cleaning or preserving razors.

5. Safety Measures When Participating in Razor Manufacturing

Safety measures for razor manufacturing include:

- Use personal protective equipment: Workers should wear safety glasses, face masks, gloves, protective jackets, clothing, and steel-toe shoes to ensure personal safety.

- Ensure hygiene and food safety: If materials come into contact with food, follow relevant food safety regulations.

- Ensure machinery and equipment safety: Safe working conditions are essential. Machines must be regularly maintained to ensure safe and efficient operation.

- Safety training for employees: Workers need training on occupational safety, proper use of safety equipment, and accident prevention measures.

- Use advanced safety technology: Sensors, alarms, and automation can be applied to reduce manufacturing hazards.

- Regular risk assessments: Frequently check and evaluate safety hazards related to razor manufacturing to implement appropriate solutions and ensure worker safety.

- Periodically conduct occupational environment monitoring in factories, collect and analyze harmful factors for workers, and adjust to reduce risks to prevent occupational diseases.

6. Benefits of Occupational Safety Training in Razor Manufacturing

An Toan Nam Viet provides the following benefits for businesses completing occupational safety training under Decree 44/2016/ND-CP on occupational safety and hygiene:

- Workers can recognize potential hazards and take preventive measures to avoid accidents.

- Businesses can establish risk prevention measures in manufacturing, operation, and maintenance processes.

- Reduce costs associated with workplace safety incidents.

- Uninterrupted manufacturing improves labor productivity and product quality.

- Compliance with occupational safety regulations minimizes legal risks.

- Enhances reputation and professionalism, strengthening brand value.

Nam Viet’s training courses provide solutions to prevent external factors from causing harm, helping individuals avoid injuries or fatalities.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

7. Customer Feedback After Completing Occupational Safety Training in Razor Manufacturing

An Toan Nam Viet has many years of experience accompanying businesses in Vietnam in general and in southern provinces in particular. This responsibility is extremely valuable to us, which is why An Toan Nam Viet’s occupational safety training is increasingly professional. The motivation for our growth comes from both positive feedback and constructive suggestions from our business partners. Below are some testimonials from clients we have served.

Hoa Dat Construction and Trading Joint Stock Company

“An Toan Nam Viet’s service has greatly simplified occupational safety and the process of completing safety documentation for our work. Their consultants are timely and enthusiastic in responding to our questions. 5 stars for An Toan Nam Viet.”

See more customer interviews after using services of An Toan Nam Viet

8. Occupational Safety Training Capability of An Toan Nam Viet

An Toan Nam Viet is a reputable and high-quality occupational safety training center in Vietnam. Our training sessions are continuously conducted at factories, workshops, or construction sites across all 63 provinces in Vietnam.

REGISTER FOR OCCUPATIONAL SAFETY TRAINING

Occupational safety training license

- An Toan Nam Viet has been inspected and certified by the Department of Occupational Safety of the Ministry of Labor – Invalids and Social Affairs, certifying our eligibility to operate occupational safety training. This reinforces our capacity to provide occupational safety training.

Materials and lectures

- Before being used in occupational safety training courses, training materials are reviewed to ensure accuracy and practical effectiveness.

- Our instructors’ teaching methods follow An Toan Nam Viet standards, researched and refined by experts in occupational safety and hygiene training to maximize learners’ comprehension.

Facilities

- Controlling classroom factors affects training efficiency and learners’ knowledge absorption.

- Our training facilities provide spacious classrooms meeting standards for area, lighting, and training equipment.

9. Nationwide Reputable Occupational Safety Training Center

At An Toan Nam Viet, we prioritize professional occupational safety training. Teaching workers to protect themselves ensures their safety while contributing to the country’s development.

We carefully prepare all details to ensure training efficiency, from tools and teaching equipment to curriculum, documents, audio, and lighting.

Our instructors are experts with years of experience. Some even have research projects identifying hazards in all industries and methods to prevent them.

Lectures are practical, lively, and easy for workers to understand, ensuring effective learning while adhering to Decree 44/2016/ND-CP.

Thus, workers learn hazard prevention methods and self-protection skills, applying them effectively in real work situations.

Our training center proudly offers professional and reliable occupational safety training with advantages:

- Competitive training fees with guaranteed quality.

- Flexible training schedule aligned with company production.

- Fast, legally compliant certification procedures.

- Experienced instructors with years of practice.

- Classrooms optimized for training efficiency and knowledge absorption.

- Lectures tailored to occupational safety at businesses.

- An Toan Nam Viet provides dedicated and professional support to clients promptly and accurately.

10. Additional Reference Materials for Occupational Safety Training in Razor Manufacturing

- Occupational safety materials for razor manufacturing

- Complete occupational safety training materials

- Occupational safety training test materials

- Occupational safety training syllabus for razor manufacturing

- Occupational safety multiple-choice test for razor manufacturing

1 review for Occupational Safety Training in Razor Manufacturing

No comments yet

namchinh.haiphong341

Dịch vụ huấn luyện an toàn lao động rất tốt nhé, giảng viên dạy rất sinh động dễ hiểu!